Corn husking equipment for agricultural machinery

A technology for agricultural machinery and corn, applied in the field of corn peeling equipment for agricultural machinery, can solve the problems of corn kernel damage, affecting the processing and sales of peeled corn, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

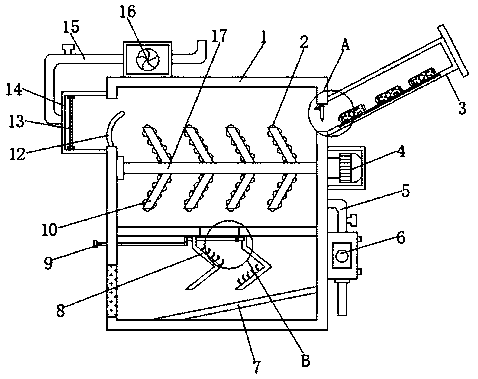

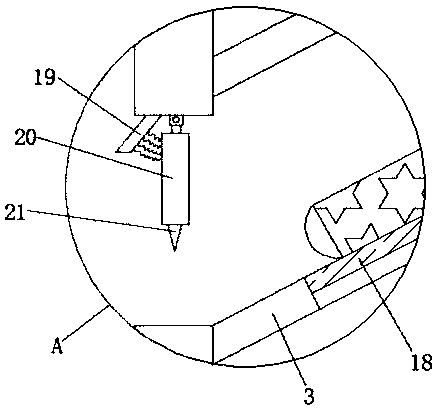

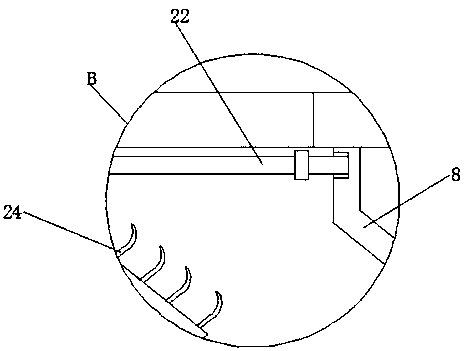

[0033] refer to Figure 1-4 , a corn peeling equipment for agricultural machinery, comprising a box body 1, a feed cylinder 3 is plugged into one side outer wall of the box body 1, and an exhaust fan 16 is connected to the top outer wall of the box body 1 by bolts, one of the exhaust fan 16 The side outer wall is plugged with a suction pipe 15, and one end of the suction pipe 15 is plugged with a collecting box 14, and the collecting box 14 is connected on the side outer wall of the casing 1 by bolts, and the top of the collecting box 14 and the The inner wall of the bottom is clamped with a filter screen 13, the outer wall of one side of the box body 1 is connected with a blower 6 by bolts, and the top outer wall of the blower 6 is inserted with an air inlet pipe 5, and the outer wall of one side of the box body 1 is connected by bolts. The inner wall of one side of the protective shell is connected with the motor 4 by bolts, the outer wall of one end of the output shaft of t...

Embodiment 2

[0037] refer to Figure 5-6 , a corn peeling equipment for agricultural machinery. Compared with Embodiment 1, the outer wall of one side of the filter screen 13 is welded with a support rod 25, and the outer wall of the support rod 25 is welded with a steel needle 26.

[0038] Working principle: When in use, people can put corn into the box body 1 through the feeding barrel 3. When the corn enters the box body 1 from the feeding barrel 3, the first blade 18 at the bottom of the feeding barrel 3 can slide down The bottom epidermis of the corn is scratched, and the second blade 21 at the bottom of the support plate 20 can scratch the upper epidermis of the corn at the final stage of entering the box 1, thereby improving the efficiency of subsequent peeling of the corn. At the same time, one side of the support plate 20 The spring connected to the outer wall can avoid the situation that the second channel may be blocked due to the different specifications of the corn. When the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com