Self-propelled peeling machine for jute and hibiscus cannabinus

A self-propelled, peeling machine technology, applied in mechanical processing, textiles and papermaking, fiber mechanical separation, etc., can solve the problems of affecting the retting effect, poor peeling effect, and affecting production efficiency, so as to increase the income of hemp farmers , promote industrial scale development, and improve mobile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

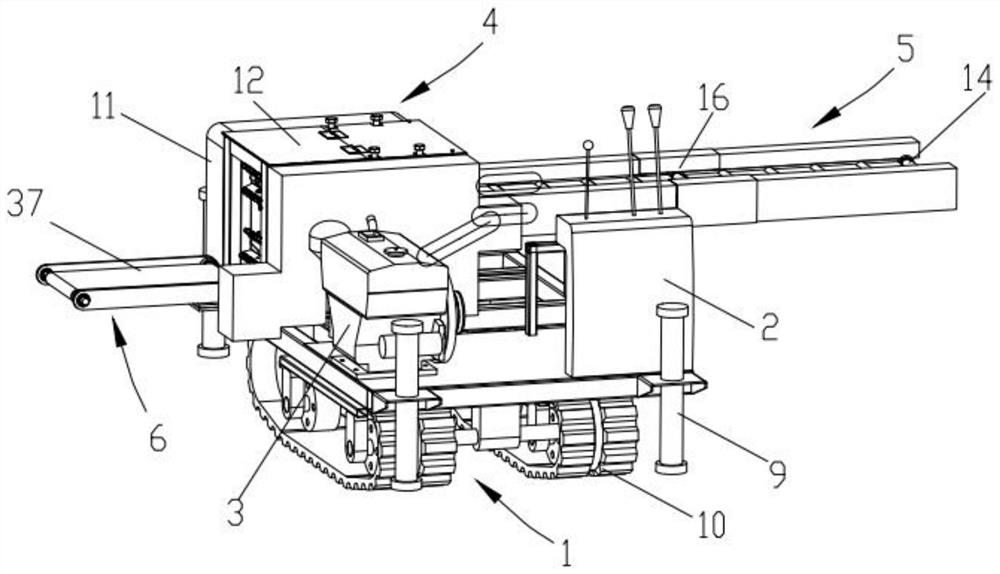

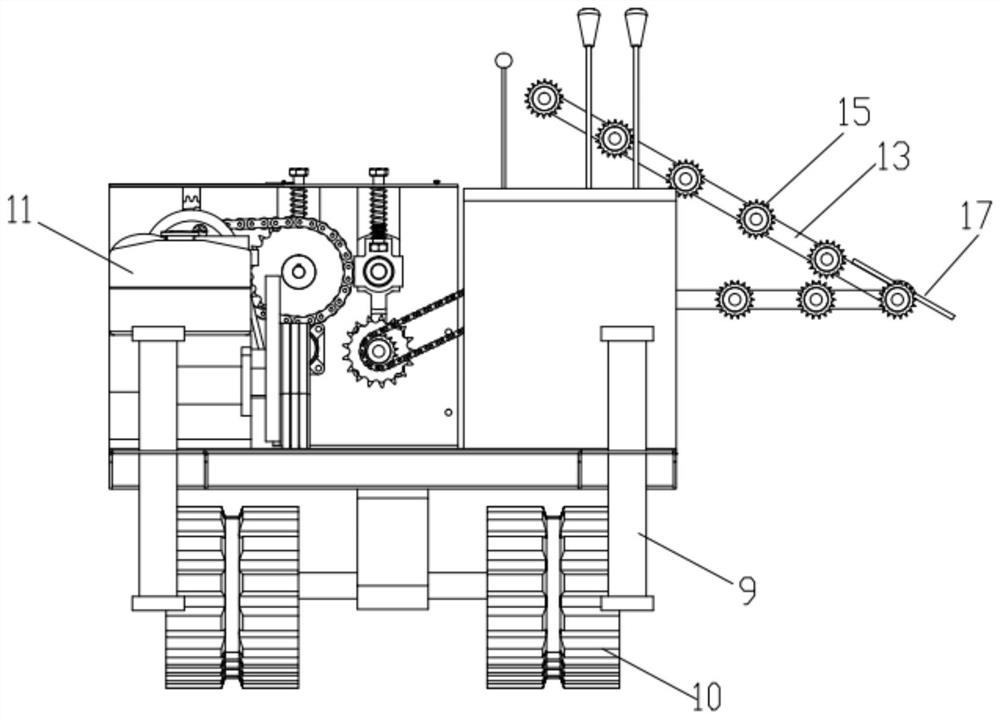

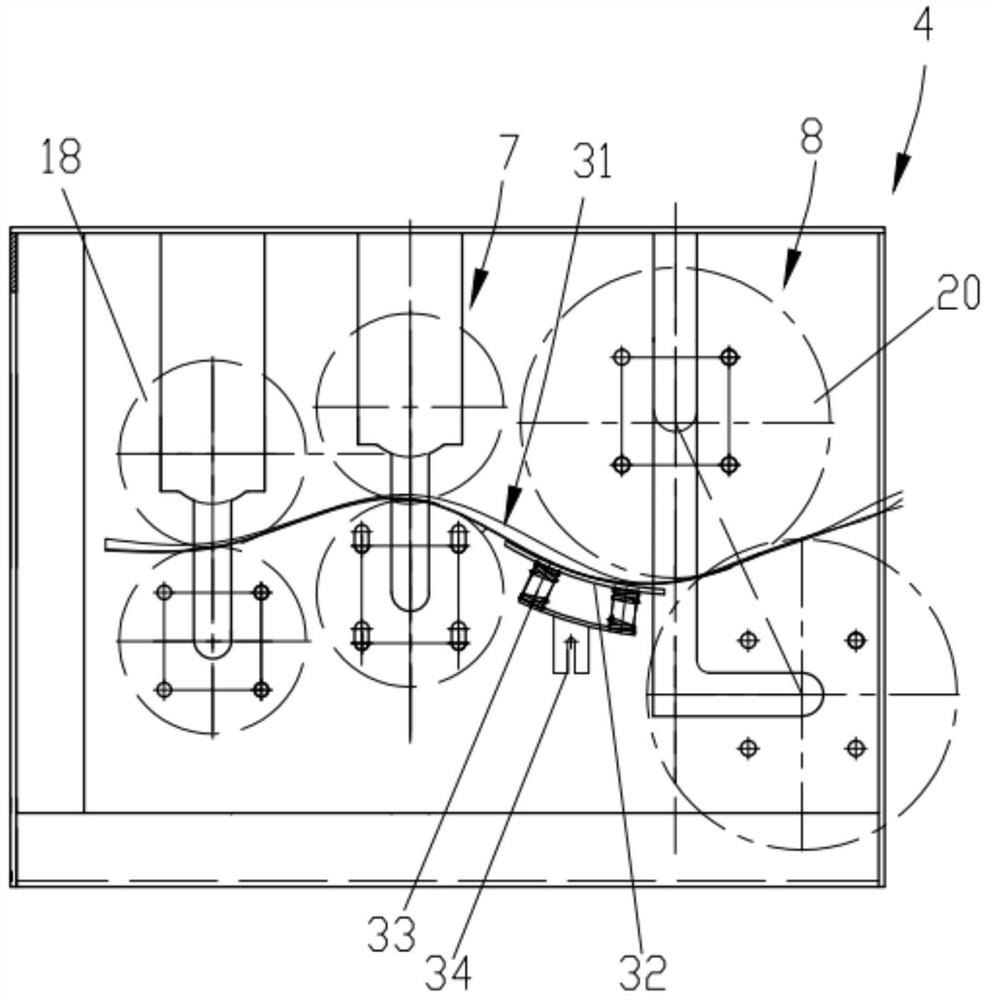

[0035] like Figure 1-11 As shown, the present invention discloses a self-propelled peeling machine for jute and kenaf, comprising a crawler chassis 1 and an operating room 2 installed on the crawler chassis 1, an engine 3, a peeling device 4, and a conveying device 5 and output device 6, crawler belts 10 are arranged on both sides of the crawler chassis 1, and the operating room 2 is the control center of the peeling machine, which is provided with an operating lever, a driver's seat and various instruments, the engine 3 adopts diesel power, and the peeling device 4 It includes a rolling mechanism 7 and a bone removal mechanism 8, the input end of the rolling mechanism 7 is connected to the delivery device 5, the output end is connected to the inpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com