Chinese chestnut shell peeling machine

A technology of shelling machine and chestnut ball, which is applied in the fields of shelling, food processing, pod removal, etc. It can solve the problems of sharp thorns and stinging human hands, affecting the quality of chestnuts, and low shelling efficiency, so as to achieve low cost and high shelling quality. Good, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

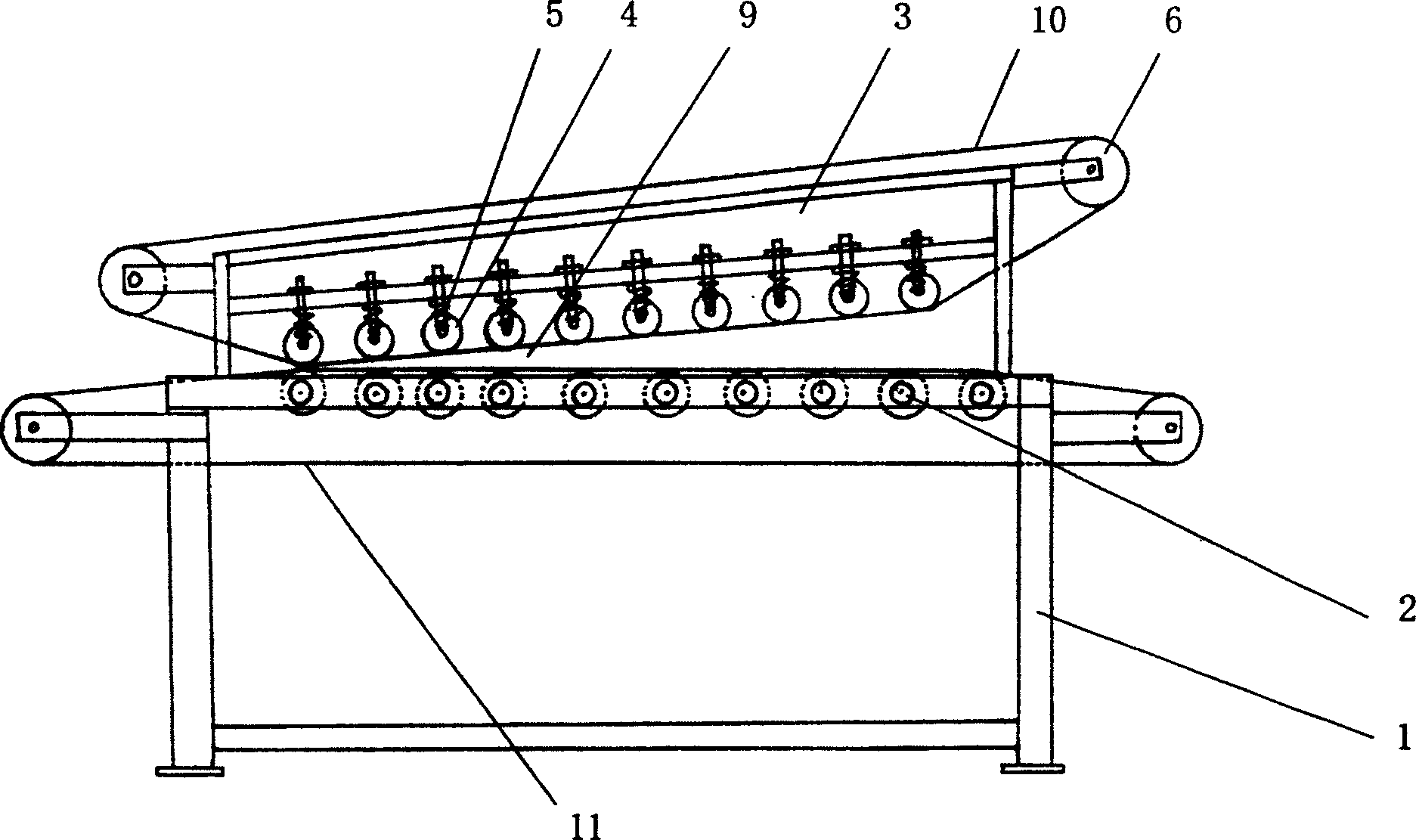

[0014] see figure 1 , a group of belt conveyors 2 are horizontally arranged on the frame 1, and a group of belt rubbing devices 3 corresponding to the scissors fork 9 formed by the belt conveyor 2 are arranged above the frame 1, and the belt rubbing device 3 is The frame 1 is driven by a driving wheel 6 and a plurality of groups of rollers 4 support a circulating belt 10. On the frame 1, the belt 11 running direction of the belt conveying device 2 is to drive into the scissors fork 9 and the belt 10 running direction of the belt kneading device 3 is to drive out of the scissors fork 9 and the belt 11 running speed of the belt conveying device 2 is greater than the belt The belt 10 running speed of kneading device 3.

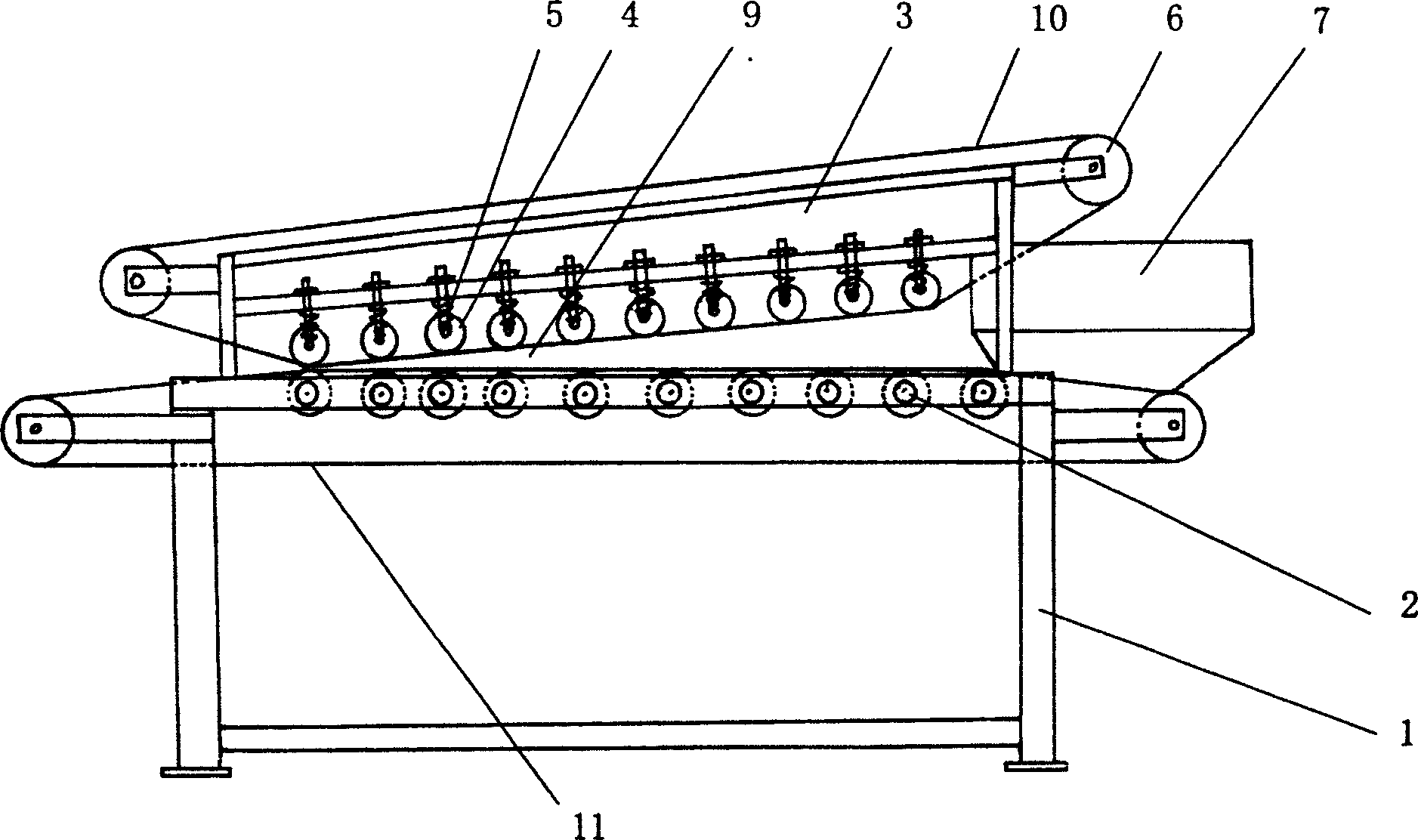

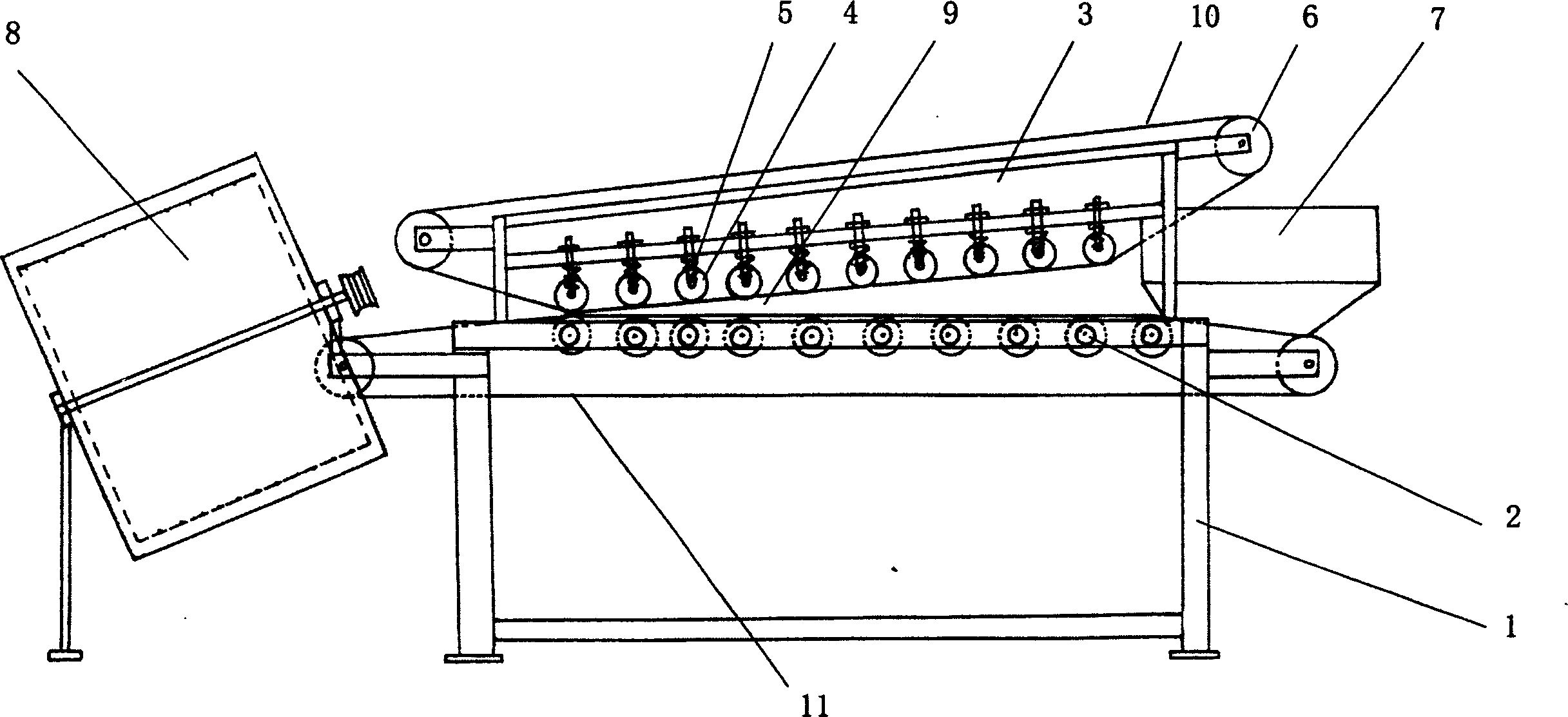

[0015] see figure 2 As an improvement of the present invention, a hopper 7 is provided at the input end of the belt convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com