Method for preparing few-layer graphite nanosheets through supersonic supercritical CO2-shear coupled tripping of expanded graphite

A technology of graphite nanosheets and expanded graphite, which is applied to single-layer graphene, chemical instruments and methods, graphene, etc., can solve the problems of high price, waste of resources, and large environmental impact, and achieve good peeling quality and high-efficiency peeling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

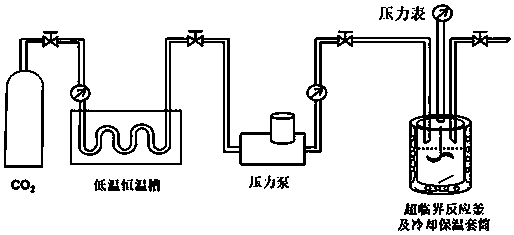

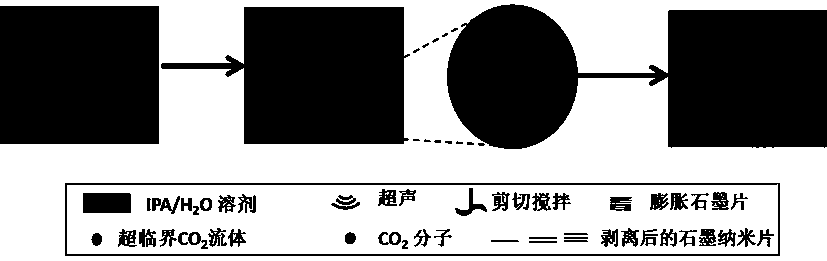

Method used

Image

Examples

Embodiment 1

[0049] Ultrasonic supercritical carbon dioxide-shear coupled exfoliation of expanded graphite to prepare a preparation method for oligolayer graphite nanosheets, the steps are as follows:

[0050] 1) Disperse 9 g of expanded graphite powder in 300 mL of isopropanol aqueous solution, and then add 0.9 g of PVP (polyvinylpyrrolidone, (C 6 h 9 NO )n) and 0.9g melamine (C 3 h 6 N 6 ) after ultrasonic dispersion for 30min to obtain expanded graphite suspension; the isopropanol and H 2 The volume ratio of O is 1:1.

[0051] 2) Under the action of high-energy ultrasound (that is, the ultrasonic power is 600W), the expanded graphite suspension is ultrasonically peeled off for 1 hour to obtain the pretreated suspension;

[0052] 3) Put the pretreated suspension in supercritical carbon dioxide and react in the shearing action, that is, pressurize to 20MPa and heat to 50°C while feeding carbon dioxide into the reactor, and set the temperature at a shear rate of 1000rpm Under the she...

Embodiment 2

[0069] Ultrasonic supercritical carbon dioxide-shear coupled exfoliation of expanded graphite to prepare a preparation method for oligolayer graphite nanosheets, the steps are as follows:

[0070] 1) Disperse 9 g of expanded graphite powder in 300 mL of ethanol aqueous solution, and then add 0.9 g of PVP (polyvinylpyrrolidone, (C 6 h 9 NO) n ) and 0.9g melamine (C 3 h 6 N 6 ) after ultrasonic dispersion for 30min to obtain expanded graphite suspension; the ethanol and H 2 The volume ratio of O is 2:8.

[0071] 2) Under the action of high-energy ultrasound (that is, the ultrasonic power is 600W), the expanded graphite suspension is ultrasonically peeled off for 1 hour to obtain the pretreated suspension;

[0072] 3) Put the pretreated suspension in supercritical carbon dioxide and react in the shearing action, that is, pressurize to 20MPa and heat to 50°C while feeding carbon dioxide into the reactor, and set the temperature at a shear rate of 1000rpm Under the shear act...

Embodiment 3

[0078] The difference from Example 1 is that the temperature in the reactor is 45°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com