A power cable stripping device

A technology for power cables and cable bodies, applied in the field of power cable stripping devices, can solve the problems of difficult to control cutting force, low cable stripping efficiency, easy damage to conductive cores, etc., and achieves the effects of increasing stripping quality, reducing damage and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

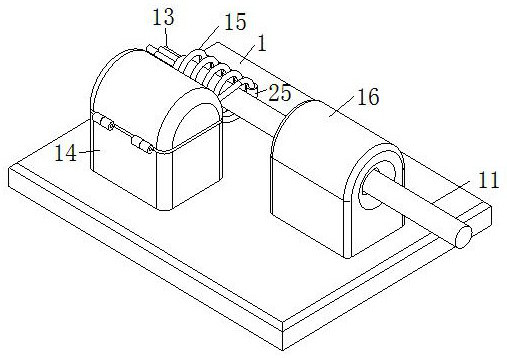

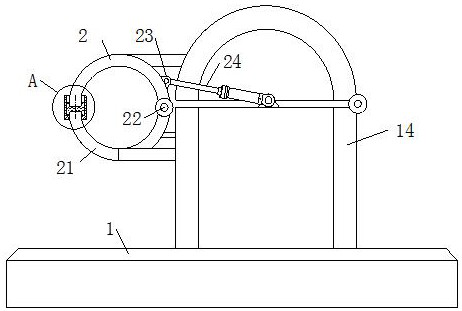

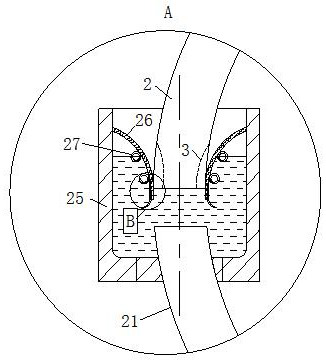

[0033] Such as Figure 1 to Figure 7 As shown, a power cable stripping device according to the present invention includes a workbench 1, a cutting unit and a heating unit; a cable body 11 runs through the middle of the cutting unit, and the cable body 11 includes an insulating layer 12 and a conductive core 13; The heating unit includes a heating table 14 and a high-frequency heating coil 15, the high-frequency heating coil 15 is connected to a power supply through a high-frequency generator, and the high-frequency heating coil 15 is coaxially arranged with the cable body 11; the cutting unit includes a cutting table 16, The driving roller 17 and the driven roller 18, the driving roller 17 and the driven roller 18 are symmetrically arranged, and the cable body 11 runs through the gap between the driving roller 17 and the driven roller 18; the driven roller 18 is rotationally connected with the cutting table 16 , the driving roller 17 is driven by a reduction motor; the middle ...

Embodiment 2

[0041] Such as Figure 8 to Figure 9 Shown, comparative example one, wherein another kind of implementation mode of the present invention is:

[0042] Described lifting unit comprises supporting column 4, and supporting column 4 is arranged on the both sides of rotating shaft 39, and supporting column 4 is provided with chute 41, and rotating shaft 39 is embedded in chute 41 and is slidably connected with chute 41, and the two ends of rotating shaft 39 are rotatably connected with Axle sleeve 42, the bottom of the axle sleeve 42 is provided with a push rod 43, and the bottom end of the push rod 43 is covered with a cylinder 44; the corresponding position of the cylinder 44 is rotatably connected with a worm gear 45, and one side of the worm gear 45 is meshed with a The worm 46 is driven to rotate by the lifting motor 47; one side of the worm wheel 45 is fixedly connected with a cam 48 at the position corresponding to the ejector rod 43; The rod 43 and the driving roller 17 ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com