2-inch chip photoresist peeling basket

A photoresist and flower basket technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as pollution, scratches, and unclean peeling, improve liquid flow space, ensure production efficiency, and improve ultrasonic waves. The effect of the peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

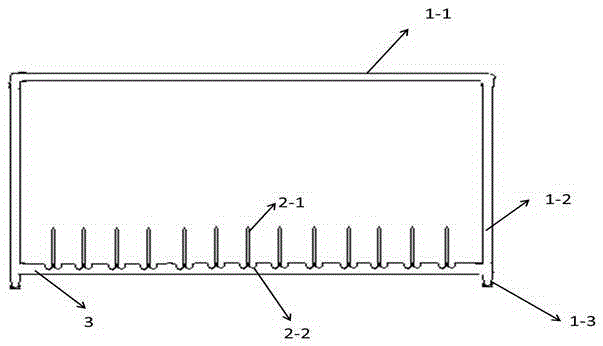

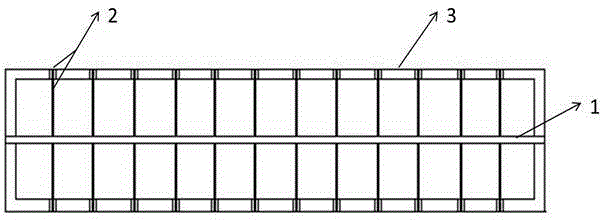

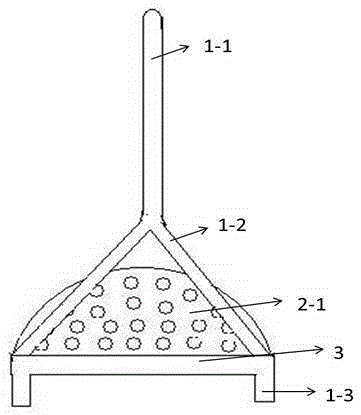

[0024] Such as figure 1 , figure 2 and image 3 As shown, the 2-inch photoresist stripping flower basket of the present invention includes a flower basket body 3 , a slot unit 2 and a bracket unit 1 . The materials of each part are preferably corrosion-resistant materials such as quartz, glass, and polytetrafluoroethylene.

[0025] The flower basket body 3 is a cuboid with a width of 3 cm and a length of 20 cm, and is made of a material with a diameter of 0.8 cm. Such as figure 1 As shown, the flower basket body 3 is evenly arranged with several ( figure 1 There are 13) card slot units 2, and the distance between adjacent card slot units 2 is 1.5cm. The bottom of the flower basket body 1 is provided with support columns 1-3. There are 4 supporting columns 1-3, which are arranged on the bottom surface of the intersection of the four sides of the flower basket body 1, and are used to support the whole flower basket. The support columns 1-3 are cylinders with a height of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com