Thermal stimulation and chemical stimulation combined process of hot-dry-rock thermal reservoir

A chemical stimulation, combined process technology, applied in drilling compositions, chemical instruments and methods, wellbore/well components, etc., can solve chemical stimulants and rock mass minerals react quickly and enhance chemical stimulants. Metal corrosion It can solve problems such as natural gas, underground wells, casing string damage, etc., to achieve good stimulation effect, slow response speed, and the effect of weakening corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

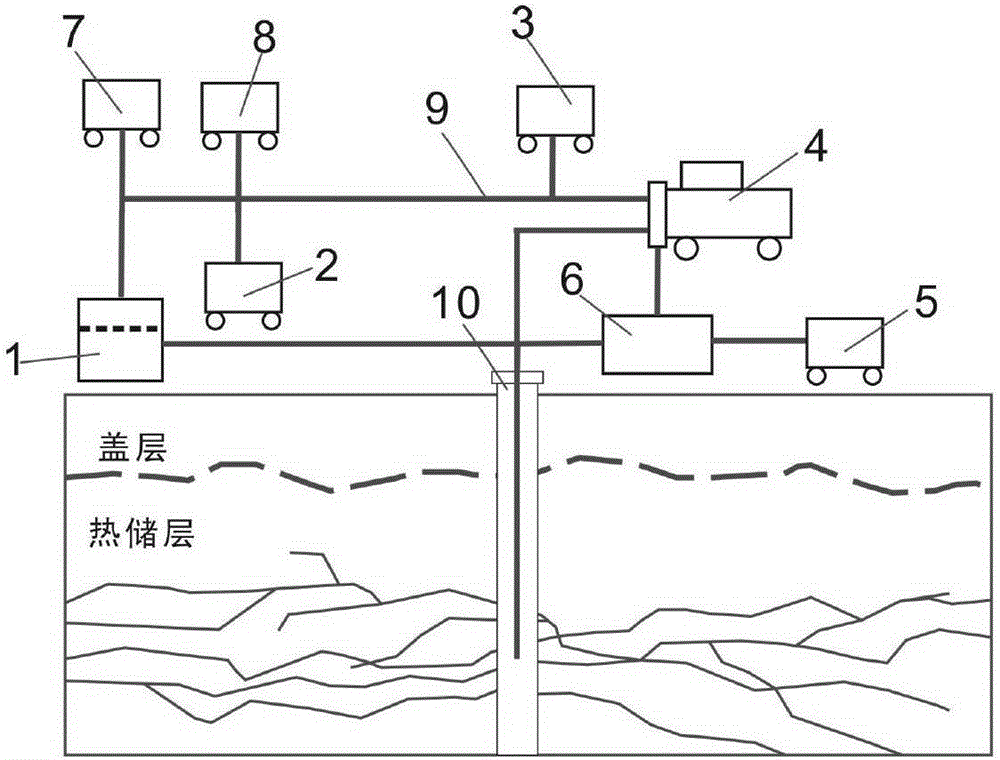

[0030] A. Inject the clean water from the reservoir 1 into the hot dry rock reservoir rock mass through the high-pressure pipeline 9 and the injection well 10. The injection pressure at the bottom of the construction pump well does not exceed the minimum principal stress of the rock mass, and the time is controlled to 2 days. The construction environment is 10°C;

[0031] B. Inject the clear water from the reservoir 1, the HCl from the HCl supply tank car 2 and the additive from the additive tank car 3 into the sand mixer 4 through the high-pressure pipeline 9 and mix them. Calculate the amount per 100 milliliters of water: 5 grams of HCl, high temperature acidification slow 1 gram of etching agent, 1 gram of iron ion stabilizer, 1.5 grams of high temperature foam stabilizer, 20 grams of acid and alkali resistant high temperature foam agent and 1 gram of clay stabilizer. The prepared acid solution is injected into the foam generator 6 through the sand mixer 4, and then the car...

Embodiment 2

[0041] A. Inject the clean water from the reservoir 1 into the hot dry rock reservoir rock mass through the high-pressure pipeline 9 and the injection well 10. The injection pressure at the bottom of the construction pump well does not exceed the minimum principal stress of the rock mass, and the time is controlled to 3 days. The construction environment is 15°C;

[0042] B. Inject the clear water from the reservoir 1, the HCl from the HCl liquid supply tanker 2 and the additive from the additive tanker 3 into the sand mixer 4 through the high-pressure pipeline 9 and mix them. Calculate the amount per 100 milliliters of water: 8 grams of HCl, high-temperature acidification slow 2 grams of etching agent, 1.5 grams of iron ion stabilizer, 1.5 grams of high temperature foam stabilizer, 20 grams of acid and alkali resistant high temperature foam agent and 1.5 grams of clay stabilizer. The prepared acid solution is injected into the foam generator 6 through the sand mixer 4, and th...

Embodiment 3

[0052] A. Inject the clean water from the reservoir 1 into the hot dry rock reservoir rock mass through the high-pressure pipeline 9 and the injection well 10. The injection pressure at the bottom of the construction pump well does not exceed the minimum principal stress of the rock mass, and the time is controlled to 3 days. The construction environment is 20°C;

[0053] B. Inject the clean water from reservoir 1, the HCl from HCl supply tank car 2 and the additive from additive tank car 3 into sand mixer 4 through high-pressure pipeline 9 and mix them. Calculate the amount per 100 milliliters of water: 12 grams of HCl, high-temperature acidification slow 3 grams of etching agent, 2 grams of iron ion stabilizer, 1.5 grams of high temperature foam stabilizer, 20 grams of acid and alkali resistant high temperature foam agent and 2 grams of clay stabilizer. The prepared acid solution is injected into the foam generator 6 through the sand mixer 4, and then the carbon dioxide is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com