Deodorant fibrous structure and air filter

A fiber structure and deodorizing technology, which is applied in the field of deodorizing fiber structures and air filters, can solve the problem that secondary odor cannot be completely suppressed, and achieve the effects of excellent adsorption capacity, excellent performance and excellent reaction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

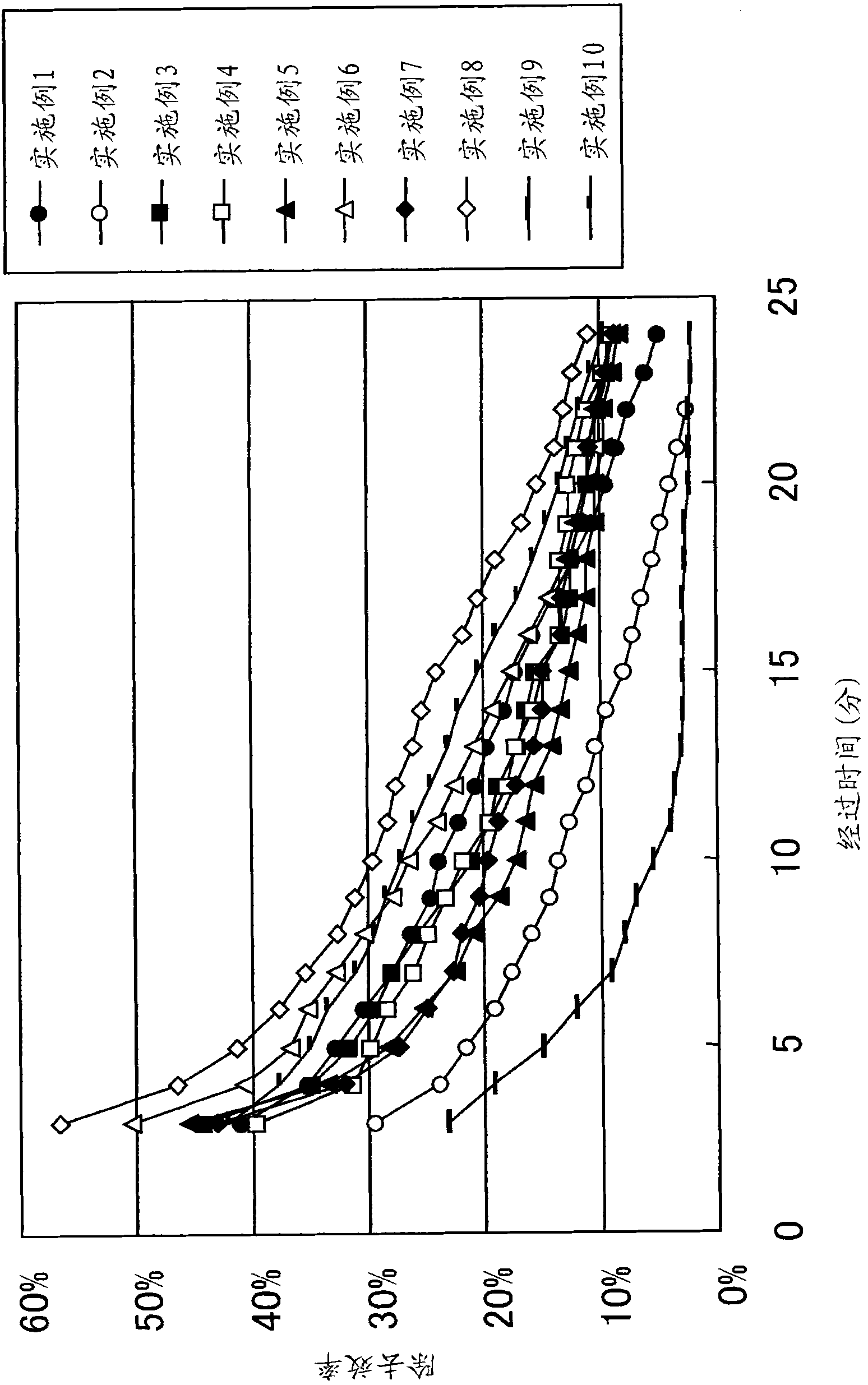

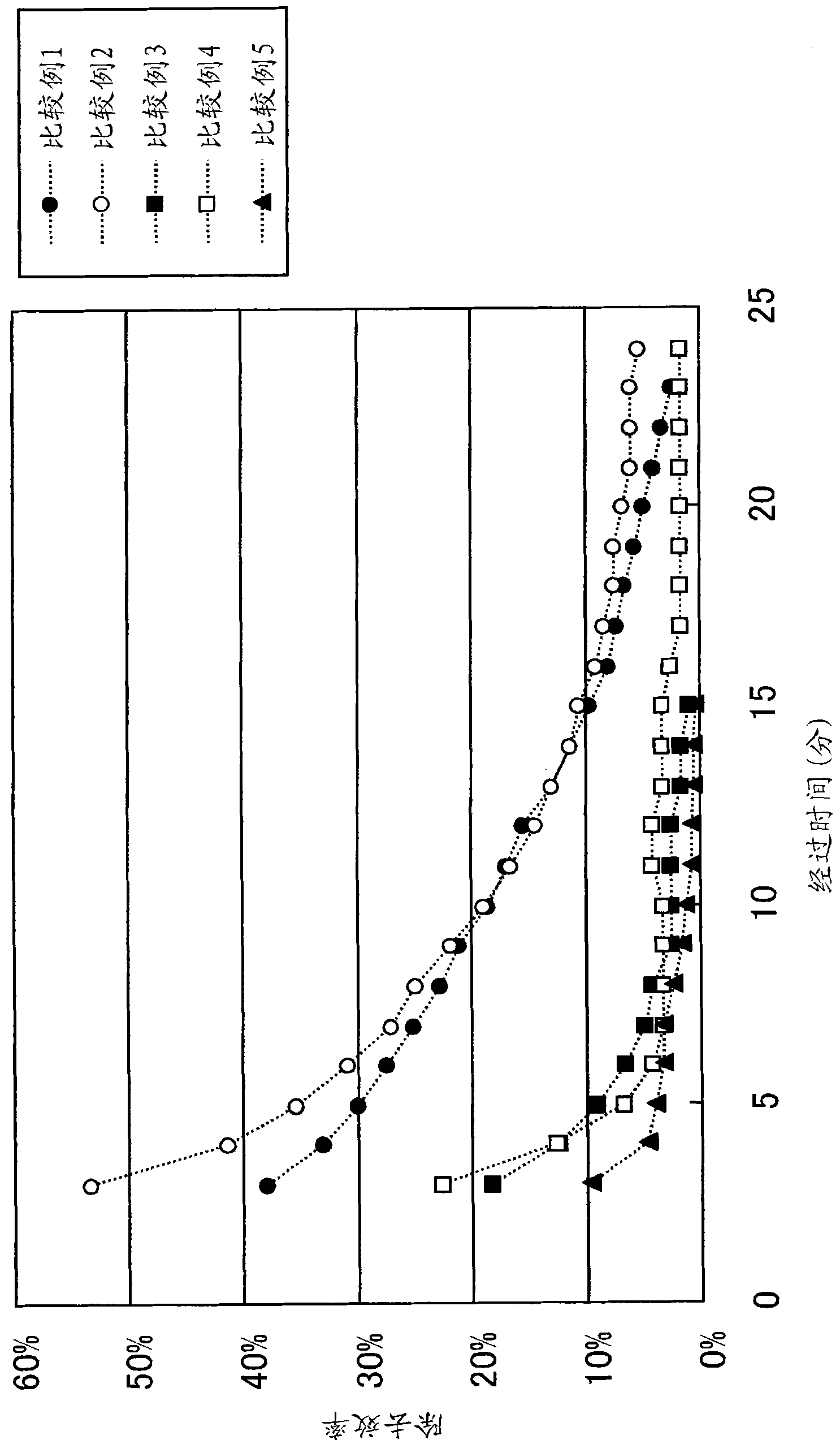

Examples

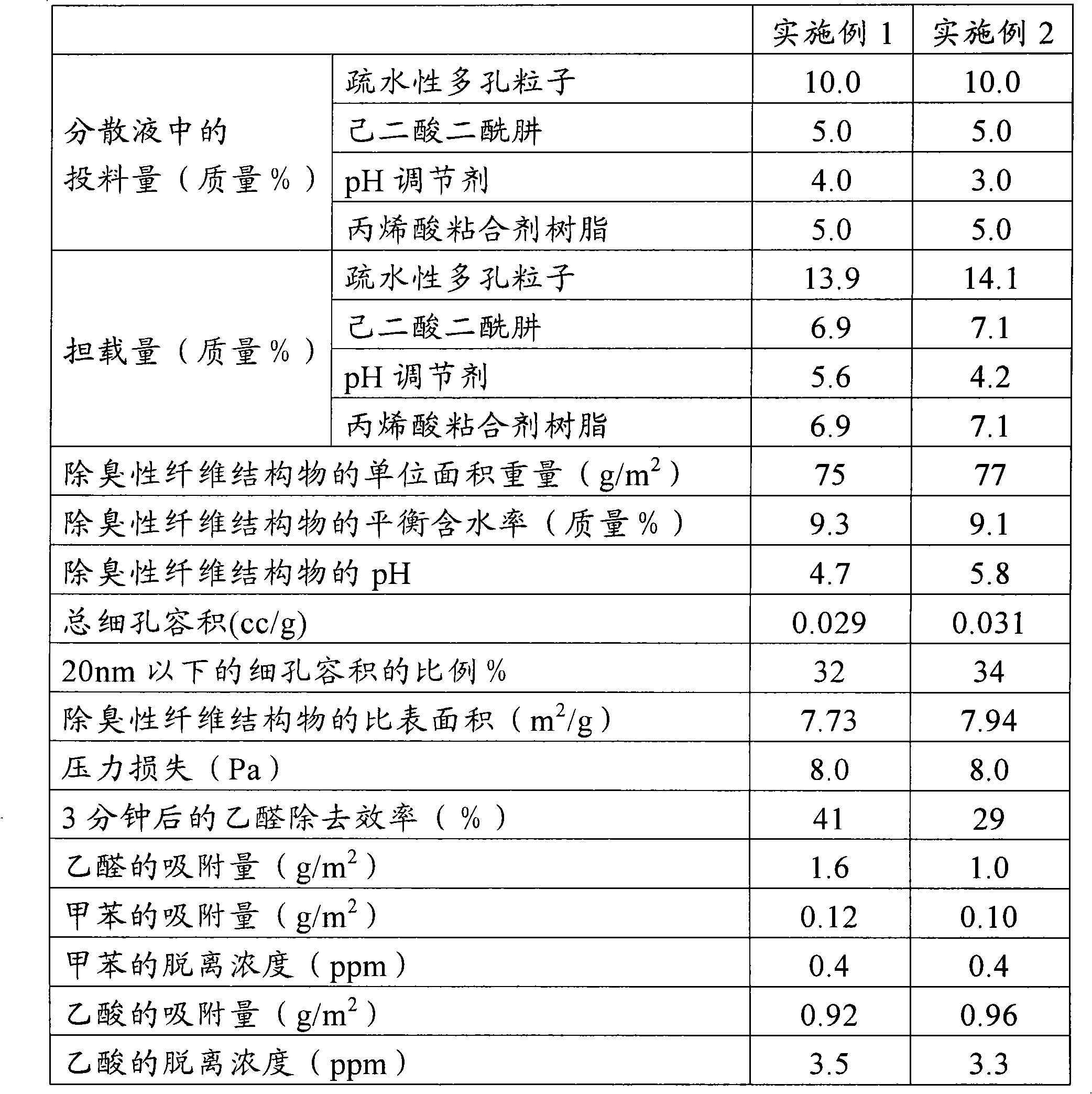

Embodiment 1

[0120] (inorganic particles)

[0121] Hydrophobic porous particles are used as the inorganic particles. The hydrophobic porous particles have an average particle diameter of 4 μm and a specific surface area of 250 m 2 Hydrophobic porous silica (Mizupearl K-400 manufactured by Mizusawa Chemical Industry Co., Ltd.) with an average pore diameter of 18 nm and an equilibrium moisture content of 5.2% per g.

[0122] (water soluble amine compound)

[0123] As the water-soluble amine compound, adipic acid dihydrazide (manufactured by Nippon Chemical Co., Ltd.) was used.

[0124] (pH adjuster)

[0125] Adipic acid is used to adjust the attachment liquid to the weakly acidic side.

[0126] (base fiber structure)

[0127] 16.5% by mass of vinylon with a single fiber fineness of 1.5dtex, 22% by mass of vinylon with a single fiber fineness of 7.1dtex, 16.5% by mass of polyethylene terephthalate with a single fiber fineness of 2.0dtex, phosphorus-containing flame-retardant Agent acr...

Embodiment 2

[0132] (inorganic particles)

[0133] The same hydrophobic porous silica as that used in Example 1 was used.

[0134] (water soluble amine compound)

[0135] The same adipate dihydrazide as that used in Example 1 was used.

[0136] (pH adjuster)

[0137] In order to adjust the adhesion liquid to the weakly acidic side, melamine phosphate is used.

[0138] (base fiber structure)

[0139] The same substance as that used in Example 1 was used.

[0140] (deodorant fiber structure)

[0141] After impregnating the above-mentioned base material fibrous structure in the aqueous solution in which the above-mentioned hydrophobic porous silica, the above-mentioned adipic hydrazide, the above-mentioned pH adjuster, and the acrylic binder resin are uniformly dispersed according to the feeding amount described in Table 1, use The rolls were twisted and dried at 100° C. for 20 minutes to obtain a deodorant fiber structure.

[0142] Table 1 shows the evaluation results of the obtained ...

Embodiment 3

[0146] (inorganic particles)

[0147] Non-porous ultrafine particles are used as the inorganic particles. The ultrafine particles have an average particle size of 0.008μm and a specific surface area of 98.21m 2 / g of alumina (AEROXIDE Alu-C manufactured by Aerosil Corporation of Japan), and the equilibrium moisture content is 4%.

[0148] (water soluble amine compound)

[0149] The same adipate dihydrazide as that used in Example 1 was used.

[0150] (pH adjuster)

[0151] Adipic acid is used to adjust the attachment liquid to the weakly acidic side.

[0152] (base fiber structure)

[0153] The same substance as that used in Example 1 was used.

[0154] (deodorant fiber structure)

[0155] The above-mentioned base fiber structure is impregnated in the aqueous solution obtained by uniformly dispersing the above-mentioned alumina, the above-mentioned adipic hydrazide, the above-mentioned pH regulator, and the acrylic binder resin according to the dosages described in Tabl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com