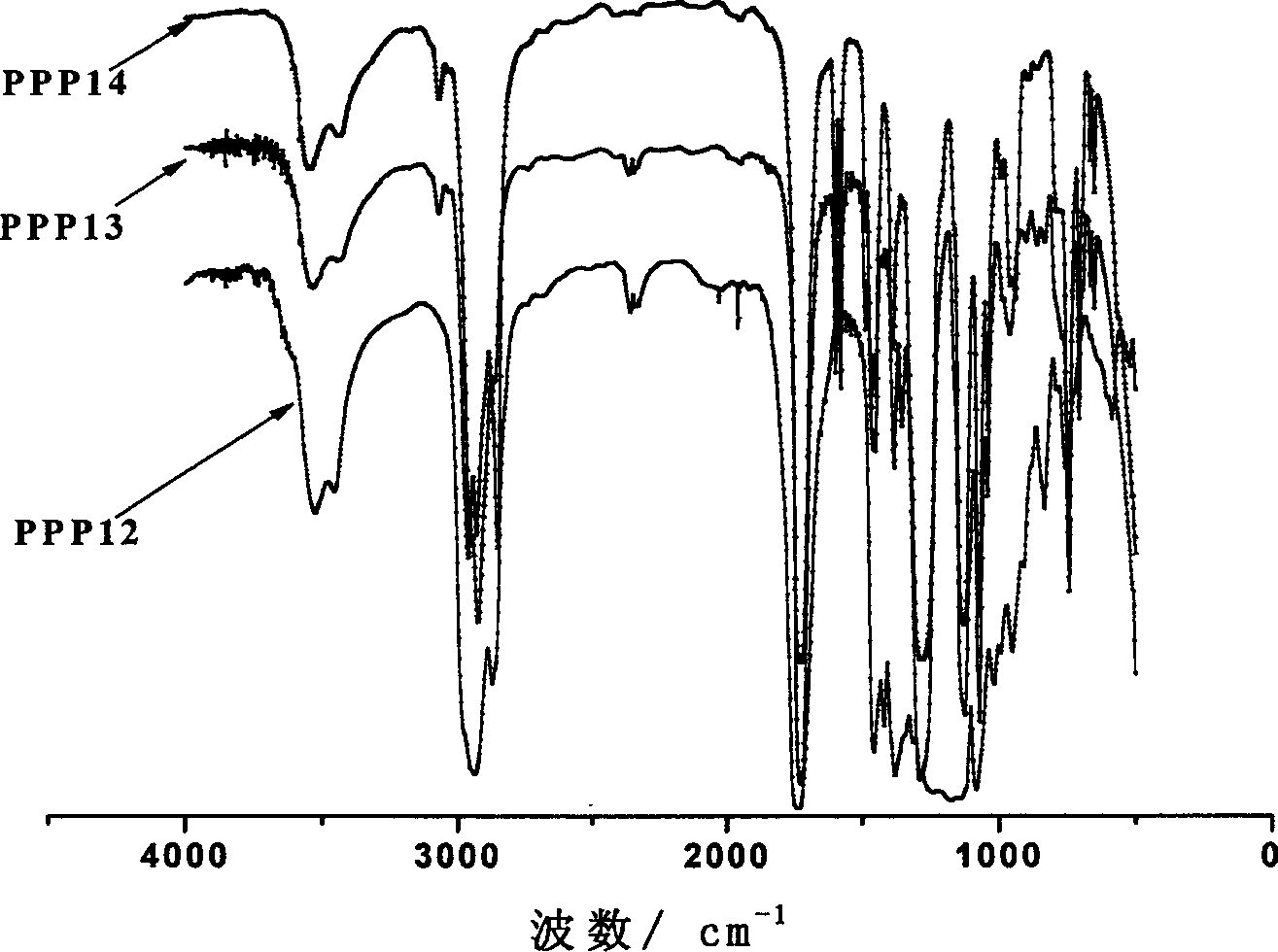

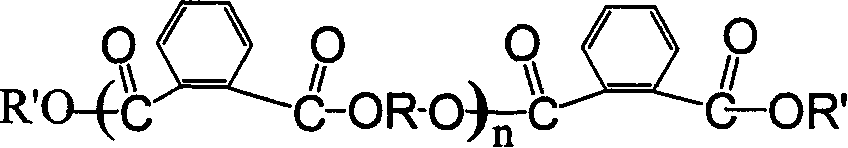

O-phthalic acid polyester plasticizer and its preparation method

A technology of phthalic acid and polyester plasticizers, applied in the field of polyester plasticizers, can solve problems such as carcinogenicity and controversy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

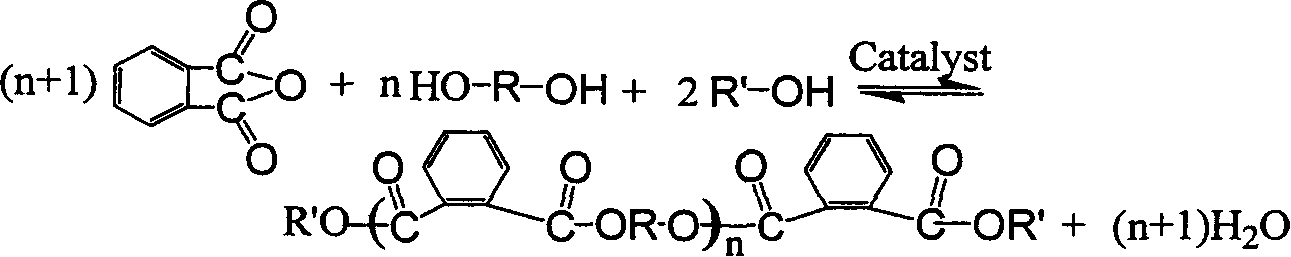

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 The preparation of poly-1,2-propylene glycol phthalate

[0037] Put phthalic anhydride, 1,2-propanediol, 2-ethylhexanol and catalyst tetra-n-butyl titanate into the reaction kettle, wherein the molar ratio of 1,2-propanediol to phthalic anhydride is 1.10:1 , the molar ratio of 2-ethylhexanol to phthalic anhydride is 0.6: 1, and the consumption of tetra-n-butyl titanate is 3‰ of the total mass of the reaction material in terms of mass, and the reaction is stirred under nitrogen and normal pressure, slowly Raise the temperature to 190°C until the acid value is lower than 15mgKOH / g, cool to 80°C, depressurize to a residual pressure of 0.04MPa under nitrogen bubbling, gradually raise the temperature to 220°C and react until the acid value is lower than 2mgKOH / g, cool the reactor The medium liquid is poly-1,2-propylene glycol phthalate.

Embodiment 2

[0038] Embodiment 2 The preparation of poly-1,3-butylene phthalate

[0039]Put phthalic anhydride, 1,3-butanediol, 2-ethylhexanol and catalyst tetra-n-butyl titanate into the reaction kettle, wherein the molar ratio of 1,3-butanediol to phthalic anhydride 1.12:1, the molar ratio of 2-ethylhexanol to phthalic anhydride is 0.55:1, and the consumption of tetra-n-butyl titanate is 3.5‰ of the total mass of the reaction material by mass, under the normal pressure of nitrogen Stir the reaction, gradually raise the temperature to 195°C until the acid value is lower than 15mgKOH / g, cool to 80°C, depressurize to a residual pressure of 0.04MPa under nitrogen bubbling, gradually raise the temperature to 220°C and react until the acid value is lower than 2mgKOH / g, After cooling, the liquid in the reactor is poly-1,3-butylene phthalate.

Embodiment 3

[0040] Embodiment 3 The preparation of poly-1,4-butylene phthalate

[0041] Put phthalic anhydride, 1,4-butanediol, 2-ethylhexanol and catalyst tetra-n-butyl titanate into the reaction kettle, wherein the molar ratio of 1,4-butanediol to phthalic anhydride For 1.15: 1, the mol ratio of 2-ethylhexanol and phthalic anhydride is 0.5: 1, and the consumption of tetra-n-butyl titanate is expressed as the total mass of the reaction mass by mass

[0042] 4‰, stirring and reacting under nitrogen gas under normal pressure, slowly raising the temperature to 200°C until the acid value is lower than 15mgKOH / g, cooling to 80°C, reducing pressure to a residual pressure of 0.04MPa under nitrogen bubbling, gradually raising the temperature to 220°C and reacting to The acid value is lower than 2mgKOH / g, and the liquid in the reactor after cooling is poly-1,4-butylene phthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com