Method for preparing 2-ethylhexyl chloroformate

A technology of ethylhexyl and chloroformic acid, which is applied in the preparation of 2-ethylhexyl chloroformate and the field of preparation of 2-ethylhexyl chloroformate, can solve the problem of unfavorable 2-ethylhexyl chloroformate Ester synthesis, storage, transportation, dangerous operation, difficult control and operation of liquid phosgene, etc., to achieve the effect of low toxicity, convenient weighing and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Solid phosgene (77g), sodium carbonate (55g), and catalyst N,N-dimethylformamide (10g) were mixed uniformly, and stirred in toluene (750mL) at 0°C for 30 minutes. Then, 750 mL of 2-ethylhexanol / toluene solution with a concentration of 0.69 mol / L was slowly dropped into the mixture for 30 minutes. After the reaction system was stirred at 0° C. for 8 hours, sodium carbonate was separated by suction filtration, and then the solvent was separated by distillation under reduced pressure to obtain 89 g of a colorless oily liquid, namely 2-ethylhexyl chloroformate, with a yield of 93.2%. The purity of 2-ethylhexyl chloroformate obtained by titration analysis was 98%.

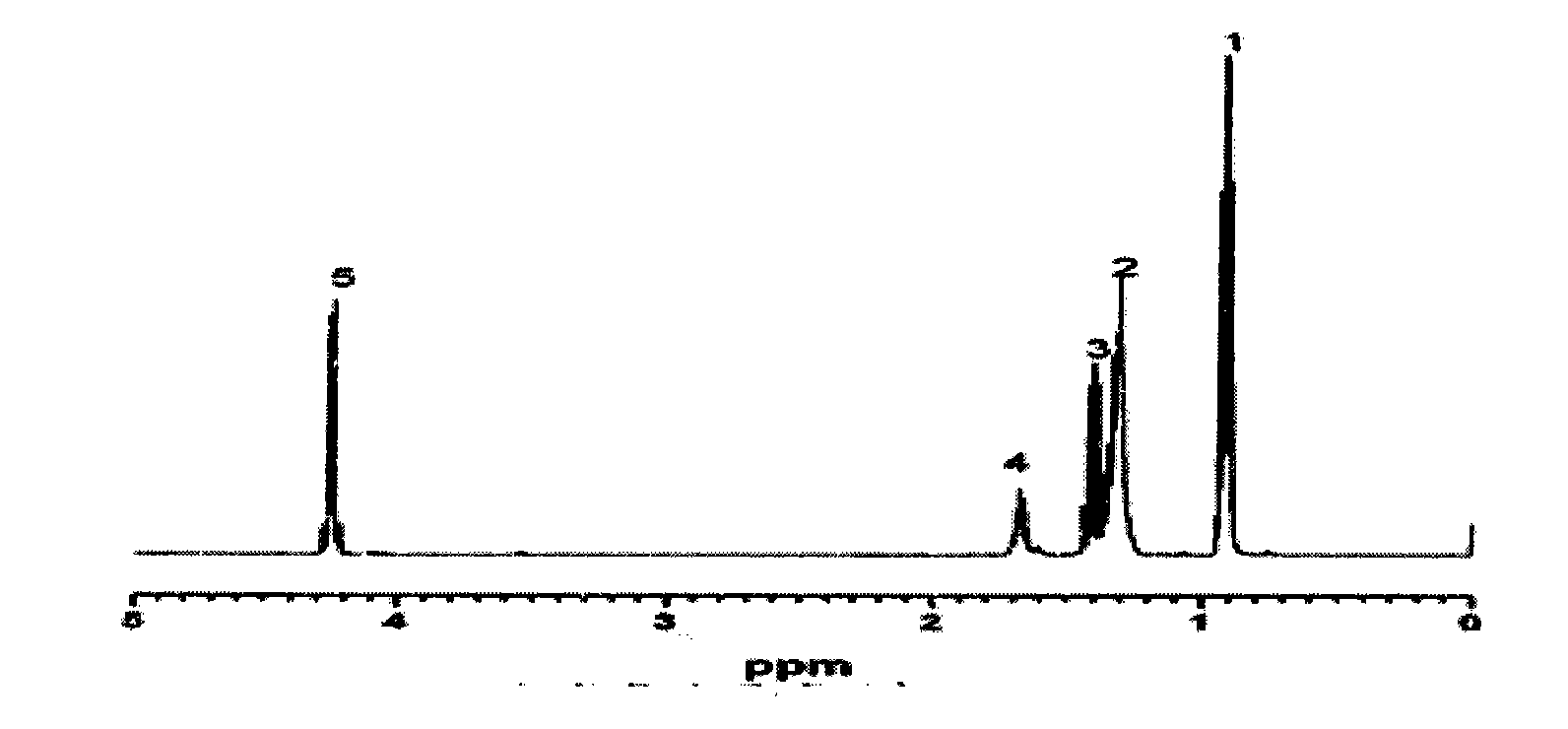

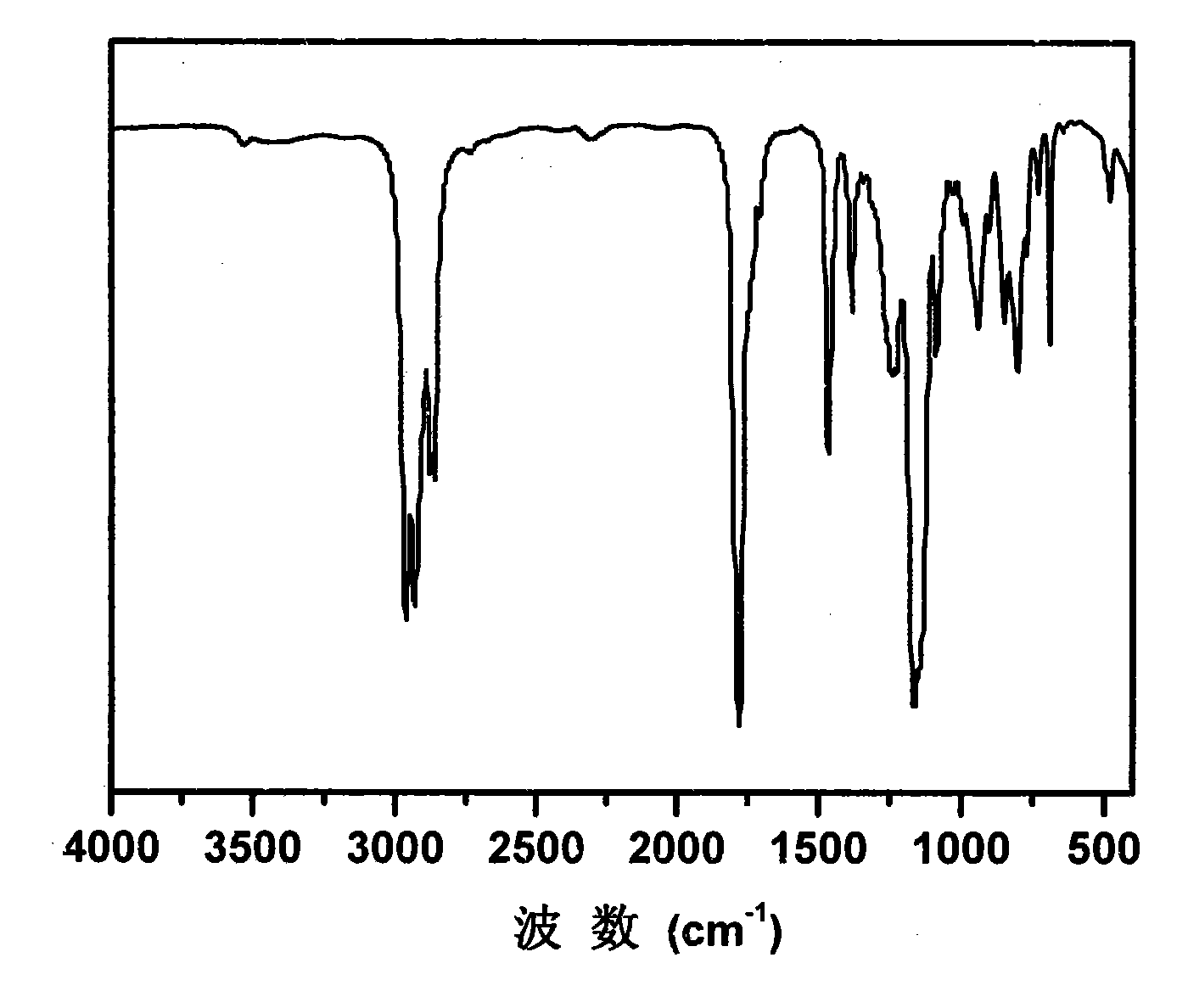

[0020] The proton nuclear magnetic spectrum of product 2-ethylhexyl chloroformate is as figure 1 , the chemical shift of the chemical environment of the hydrogen on 2-ethylhexyl chloroformate is located at δ0.93[6H, CH 3 (1)], 1.33 [6H, CH 2 (2)], 1.41 [2H, CH 2 (3)], 1.65[1H, CH(4)], 4.2[2H, CH 2 (5)]. The...

Embodiment 2

[0022] Solid phosgene (77g), anhydrous sodium bicarbonate (44g), and catalyst triethylamine (13.1g) were mixed uniformly, and stirred in dichloromethane (750mL) at 0°C for 30 minutes. Then, 750 mL of 2-ethylhexanol / dichloromethane solution with a concentration of 0.69 mol / L was slowly dropped into the mixture for 30 minutes. After the reaction system was stirred at 0°C for 8 hours, sodium bicarbonate was separated by suction filtration, and then the solvent was separated by distillation under reduced pressure to obtain 87 g of a colorless oily liquid, namely 2-ethylhexyl chloroformate, with a yield of 91.1%. , the purity obtained by titration analysis of 2-ethylhexyl chloroformate is 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com