Production method of dioctyl terephthalate

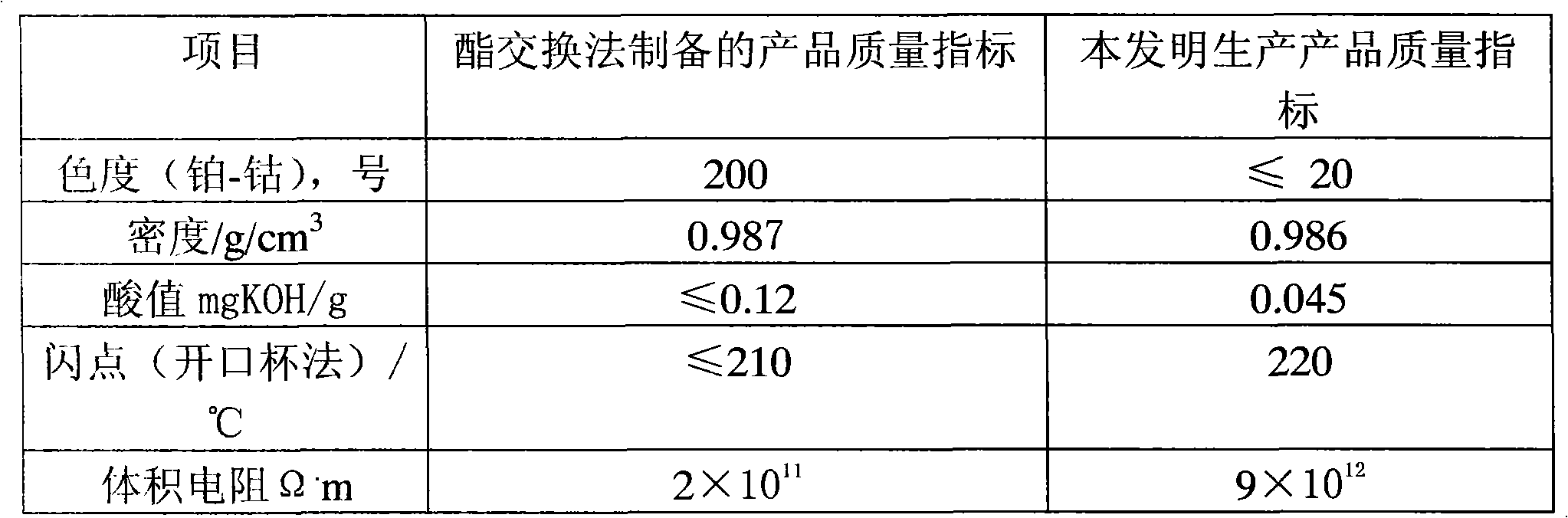

A technology of dioctyl phthalate and purified terephthalic acid, which is applied in the field of preparing dioctyl terephthalate from metal complex solid-supported catalytic synthesis of purified terephthalic acid, can solve the problems of poor product quality, pollution, Complicated technological process and other problems, to achieve the effect of high quality rate, low product pollution and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of production method of dioctyl terephthalate, comprises the steps:

[0018] 1) Put purified terephthalic acid and 2-ethylhexanol into the esterification reaction kettle in a weight ratio of 1:1, heat while stirring, and when the temperature gradually rises to 174, 198 and 205°C, add titanium Tetrabutyl acetate, stannous oxalate and hydrous aluminum oxide, the total amount added is 0.27% of the total weight of terephthalic acid and 2-ethylhexanol, the esterification temperature is controlled at 210°C, and the reaction is carried out for 8 hours. When the acid value is low At 0.3mgKOH / g, the esterification reaction ends and enters the refining process;

[0019] 2) Reduce the temperature of the material in the above step to below 100°C, transfer it to a neutralization tank, and wash it with water at 90°C to remove excess reaction alcohol. After separating the water phase, add an inorganic filter, and use it immediately Porous materials for decolorization and adsor...

Embodiment 2

[0023] A kind of production method of dioctyl terephthalate, comprises the steps:

[0024] 1) Put purified terephthalic acid and 2-ethylhexanol into the esterification reaction kettle in a weight ratio of 1:1.45, heat while stirring, and when the temperature gradually rises to 175, 195, and 200°C, add titanium Acetate tetraisopropyl ester, stannous oxide and sodium hydroxide, adding the total amount is 0.22% of the total weight of terephthalic acid and 2-ethylhexanol, the esterification temperature is controlled at 218 ° C, reacted for 7 hours, when the acid value When it is lower than 0.3mgKOH / g, the esterification reaction ends and enters the refining process;

[0025] 2) After reducing the temperature of the material treated in the previous step to below 100°C, transfer it to a neutralization tank, and wash it with water at 170°C to remove excess reaction alcohol. After separating the water phase, add an inorganic filter , used for decolorization and adsorption of porous m...

Embodiment 3

[0029] A kind of production method of dioctyl terephthalate, comprises the steps:

[0030] 1) Put purified terephthalic acid and 2-ethylhexanol into the esterification reaction kettle in a weight ratio of 1:1.09, heat while stirring, and when the temperature gradually rises to 175, 198 and 205°C, add titanium Acid tetramethyl ester, dioxyl tin oxide and sodium aluminate, adding the total amount is 0.16% of the total weight of terephthalic acid and 2-ethylhexanol, the esterification temperature is controlled at 215 ° C, and reacted for 7 hours, when the acid When the value is lower than 0.3mgKOH / g, the esterification reaction ends and enters the refining process;

[0031] 2) Reduce the temperature of the material treated in the above step to below 100°C, transfer it to a neutralization tank, and wash it with water at 175°C to remove excess reaction alcohol. After separating the water phase, add an inorganic filter, That is, the porous material used for decolorization and adsor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com