Preparation method of bi-(2-ethylhexyl)

A technology of ethylhexyl and ethylhexylamine, which is applied in the preparation of amino compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of low product yield and complicated steps, and achieve simplified process steps and high selectivity The effect of improving and reducing investment and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

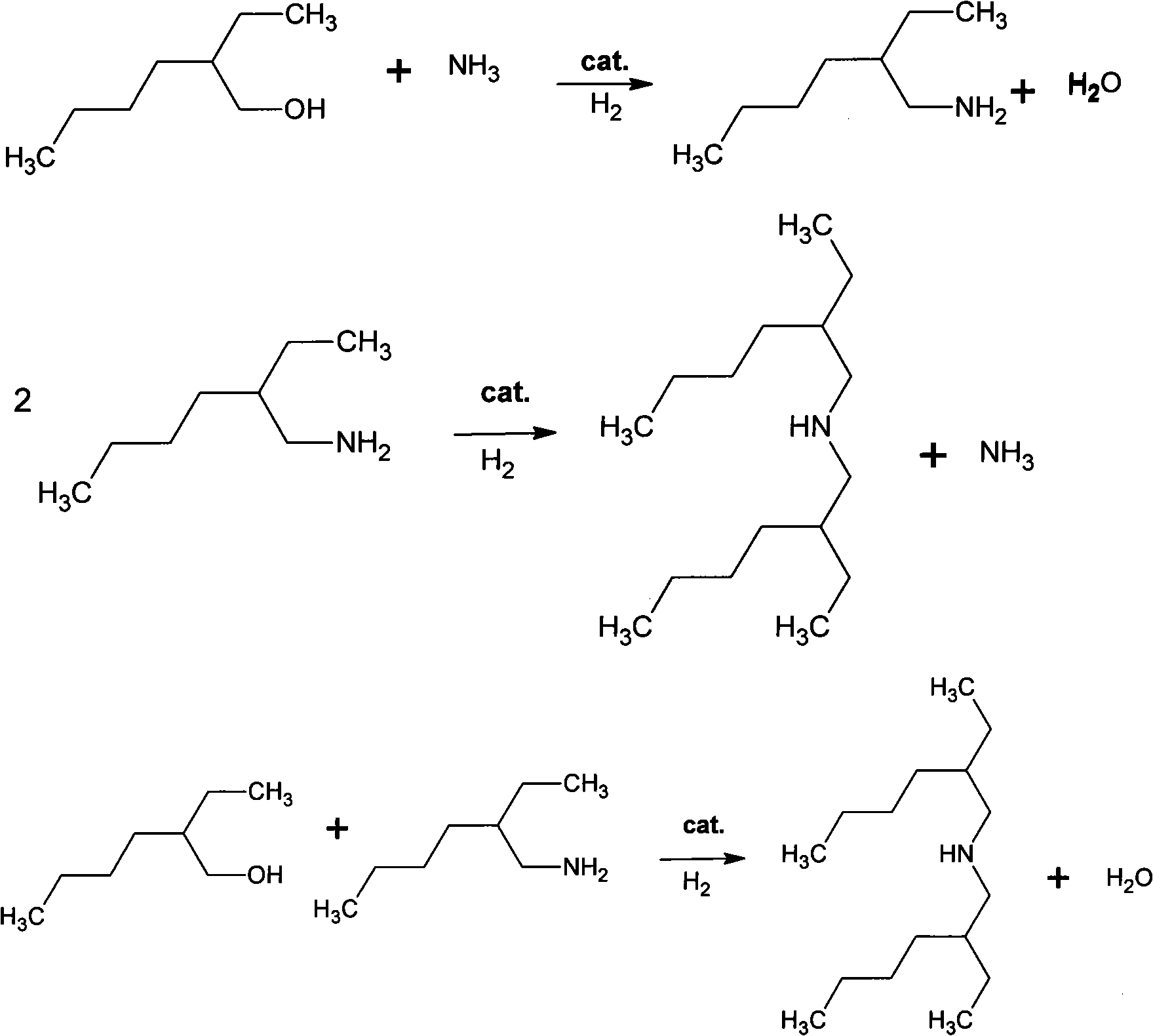

Method used

Image

Examples

Embodiment 1

[0018] Weigh 130g of 2-ethylhexanol and 10 grams of activated quaternary Raney nickel catalyst into a 1L autoclave, replace with nitrogen and hydrogen respectively, and then feed 85 grams of anhydrous liquid ammonia, then feed 0.3Mpa hydrogen, Start stirring, raise the temperature to 160-190°C and keep it for 8 hours, lower the temperature to below 100°C, release ammonia and hydrogen to 0.5Mpa, continuously feed hydrogen, keep the reaction pressure and continuously vent, heat up to 190-210°C for reaction 3 hour, cooling and venting to normal pressure, discharging, filtering the catalyst, clear liquid rectification to obtain 109g of product.

Embodiment 2

[0020] Weigh 130g of 2-ethylhexanol and 10 grams of activated binary Raney nickel catalyst into a 1L autoclave, replace with nitrogen and hydrogen respectively, then feed 85 grams of anhydrous liquid ammonia, and then feed 0.3Mpa hydrogen, Start stirring, raise the temperature to 180-210°C and keep it for 10 hours, lower the temperature to below 100°C, release ammonia and hydrogen to 0.5Mpa, continuously feed hydrogen, keep the reaction pressure and continuously vent, heat up to 200-220°C for reaction 4 hour, cooling and venting to normal pressure, discharging, filtering catalyst, clear liquid rectification to obtain product 102g.

Embodiment 3

[0022] Weigh 130g of 2-ethylhexanol and 6g of copper-nickel carrier catalyst (with clay as the carrier) into a 1L autoclave, replace with nitrogen and hydrogen respectively, then feed 85g of anhydrous liquid ammonia, and then feed 0.3MPa hydrogen , start stirring, raise the temperature to 210-240°C and keep it for 12 hours, lower the temperature to below 100°C, release ammonia and hydrogen to 0.5Mpa, continuously feed hydrogen, keep the reaction pressure and continuously vent, heat up to 220-240°C to react After 6 hours, the temperature was lowered and vented to normal pressure, the material was discharged, the catalyst was filtered, and the clear liquid was rectified to obtain 97g of the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com