Method for preparing PVC plasticizer from by-products of production of fumaric acid and recovery alcohol

A technology for fumaric acid and alcohol recovery, which is applied in the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve problems such as large costs, and achieve the utilization of corporate waste, reduction of production costs and waste liquid treatment costs. , the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The steps of the embodiment of the present invention are as follows:

[0012] The first step: add 1 part of acid slag, 3.0 parts of reclaimed isooctyl alcohol in the reactor equipped with thermometer, distillation condensing device (jacketed), stirring device, then add 250ppm of esterification catalyst (tin oxalate compound ), heated to effluent (120-160°C) with stirring, the second step: continue to heat up to a maximum reaction temperature of 220°C, always control the temperature of the distillation head at 90-102°C during the reaction, and react until the acid value is less than 1.0 mgKOH / g; Step 4: Cool down to 195°C, dealcoholize under reduced pressure (-680mmHg) for 1 hour, stop the reaction, cool down and filter to obtain the finished product, and collect the released alcohol for recycling.

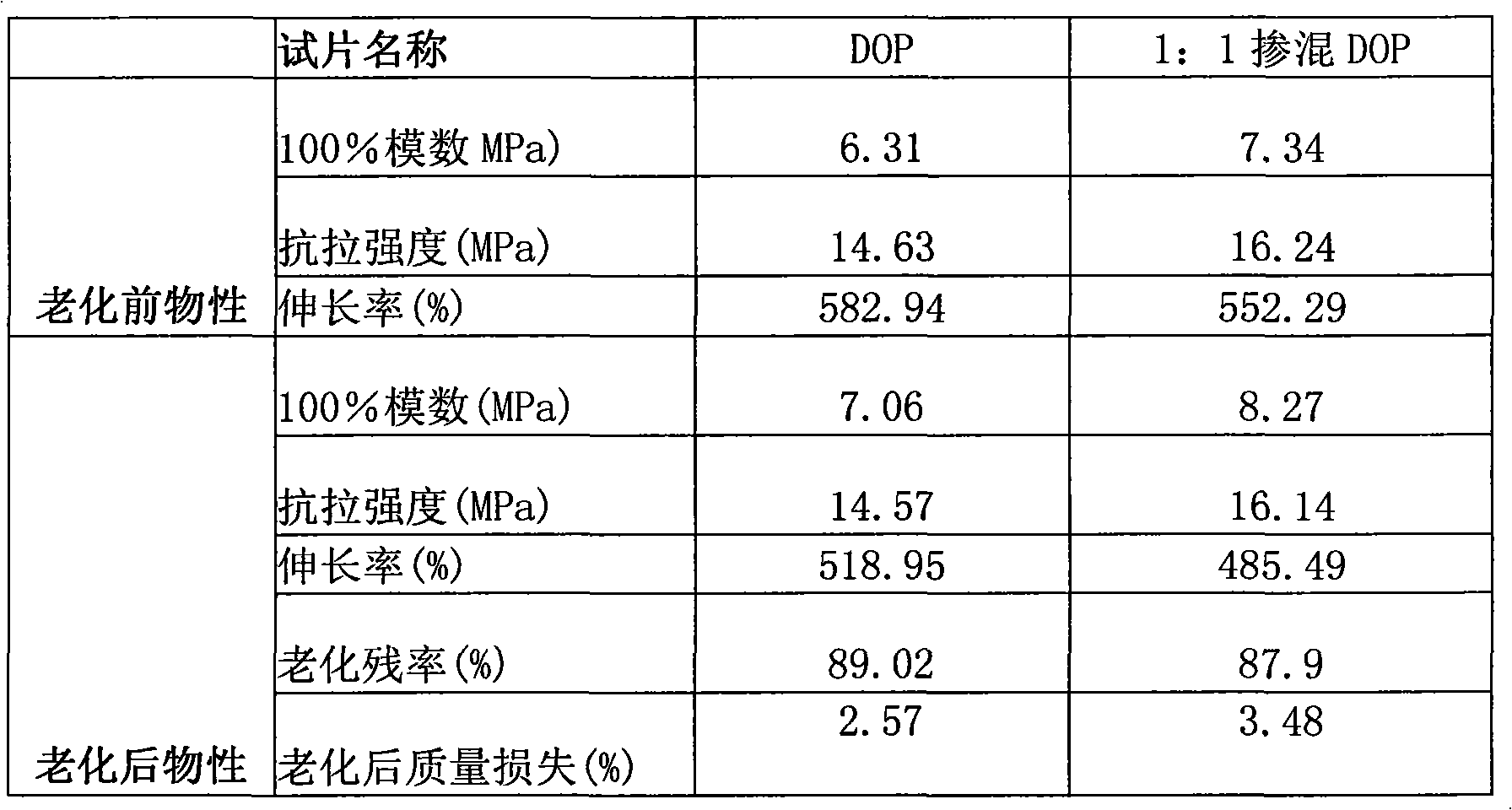

[0013] The product detection index of the embodiment of the present invention is as follows:

[0014] 1. Product chemical properties:

[0015] project

Acid va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com