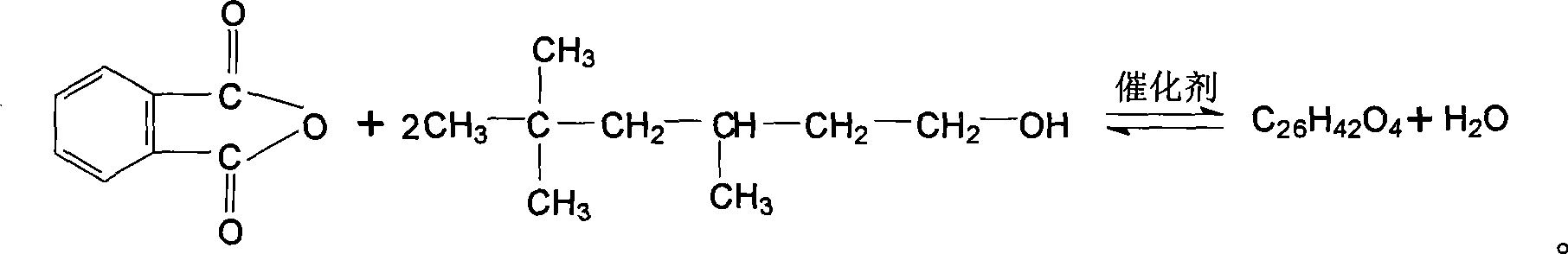

Method for producing plasticizer phthalic acid dinonyl

A technique for producing diisononyl phthalate and a production method, which is applied in the field of production of plasticizer diisononyl phthalate, can solve the problems of neutralization and water washing after post-treatment, complex wastewater treatment, etc., and achieve The production cycle is short, the product yield is high, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0020] at 30m 3 Put 3,500Kg of phthalic anhydride and 10,500Kg of isononyl alcohol into a stainless steel reaction kettle, and the feeding ratio is 1:3. While stirring, the temperature is raised (hot oil temperature is 250-270°C), and the composite catalyst tetraisopropyl titanate is added to 150-160°C. Ester and solid titanium-based compound 3.5Kg (ratio 1‰), continue to heat up to 225-230 ° C, keep warm for 2-3 hours, so that the reaction is complete. Then lower the temperature to 190-195°C, dealcoholize under reduced pressure to obtain crude DINP, and obtain DINP through traditional decolorization and filtration methods.

example 2

[0022] at 30m 3 Put 3500Kg of phthalic anhydride and 12250Kg of isononyl alcohol into a stainless steel reaction kettle, the feeding ratio is 1:3.5, heat up while stirring (hot oil temperature 250-270°C), and add the composite catalyst tetraisopropyl titanate to 160-170°C Ester and solid titanium-based compound 3.5Kg (ratio 1‰), continue to heat up to 230-235 ° C, keep warm for 2-3 hours, so that the reaction is complete. Lower the temperature to 190-195°C, dealcoholize under reduced pressure to obtain crude DINP, and obtain DINP through decolorization and filtration.

example 3

[0024] at 30m 3 Put 3500Kg of phthalic anhydride and 13300Kg of isononyl alcohol into a stainless steel reaction kettle, and the feeding ratio is 1:3.8, heat up under stirring (hot oil temperature 250-270°C), and add the composite catalyst tetraisopropyl titanate to 150-160°C Ester and solid titanium-based compound 3.5Kg (ratio 1‰), continue to heat up to 225-230 ° C, keep warm for 2-3 hours, so that the reaction is complete. Lower the temperature to 190-195°C, dealcoholize under reduced pressure to obtain crude DINP, and obtain DINP through decolorization and filtration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com