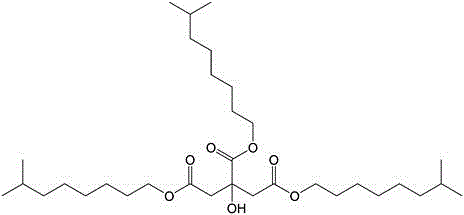

Triisononyl citrate compound and preparation method thereof

A technology of citric acid tri-compound, which is applied in the field of tri-isononyl citrate compound and its preparation, can solve the problems of poor low temperature resistance, high volatility, poor extraction resistance and the like, and achieves low wear resistance and volatility. Small, good plasticizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The preparation method of novel load heteropolyacid catalyst:

[0037] 1) Ultrafine SiO 2 Carrier pretreatment: take a certain amount of particle size is 3μm, specific surface area is 220m 2 Soak the ultrafine silicon dioxide per gram with 2mol / L dilute hydrochloric acid for 4 hours, wash it with deionized water, dry it under an infrared lamp, and bake it in a muffle furnace at 500°C for 2.5 hours;

[0038] 2) PO 4 3- -RuO 4 2- / SiO 2 Catalyst preparation: immerse the carrier treated in step 1) in 4mol / L sodium ruthenate solution, filter and dry after 6 hours, then immerse it in a phosphoric acid solution with a mass fraction of 50%, and heat it in a water bath to 50 ℃, after 4 hours, filter, dry, roast and wash with water to remove the soluble substances in the catalyst, and put it in a desiccator for later use;

[0039] Preparation of triisononyl citrate:

[0040] 1) Add 192.14g of citric acid, 504.88g of isononyl alcohol, 55.76g of cyclohexane and 0.96g of ca...

Embodiment 2

[0044] The preparation method of novel load heteropolyacid catalyst:

[0045] 1) Ultrafine SiO 2 Carrier pretreatment: take a certain amount of particle size is 4μm, specific surface area is 189m 2 Soak the ultrafine silica per gram with 2mol / L dilute hydrochloric acid for 6 hours, wash it with deionized water, dry it under an infrared lamp, and bake it in a muffle furnace at 500°C for 3.3 hours;

[0046] 2) PO 4 3- -RuO 4 2- / SiO 2 Catalyst preparation: immerse the carrier treated in step 1) in 4mol / L sodium ruthenate solution, filter and dry after 6 hours, then immerse it in a phosphoric acid solution with a mass fraction of 40%, and heat it in a water bath to 50 ℃, after 4 hours, filter, dry, roast and wash with water to remove the soluble substances in the catalyst, and put it in a desiccator for later use;

[0047] Preparation of triisononyl citrate:

[0048] 1) Add 192.14g of citric acid, 663.55g of isononyl alcohol, 81.29g of cyclohexane and 4.03g of catalyst in...

Embodiment 3

[0052] The preparation method of novel load heteropolyacid catalyst:

[0053] 1) Ultrafine SiO 2 Carrier pretreatment: take a certain amount of particle size is 5μm, specific surface area is 170m 2 Soak / g of ultrafine silica with 2mol / L dilute hydrochloric acid for 8 hours, wash it with deionized water, dry it under an infrared lamp, and bake it in a muffle furnace at 500°C for 4 hours;

[0054] 2) PO 4 3- -RuO 4 2- / SiO 2 Catalyst preparation: immerse the carrier treated in step 1) in a 4mol / L sodium ruthenate solution, filter and dry after 6 hours, then immerse it in a phosphoric acid solution with a mass fraction of 45%, and heat it in a water bath to 50 ℃, after 4 hours, filter, dry, roast and wash with water to remove the soluble substances in the catalyst, and put it in a desiccator for later use;

[0055] Preparation of triisononyl citrate:

[0056] 1) Add 192.14g of citric acid, 778.95g of isononyl alcohol, 106.82g of cyclohexane and 6.92g of catalyst into a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com