A kind of method that titanium chelate catalyzes transesterification to prepare higher carbon alcohol phthalate

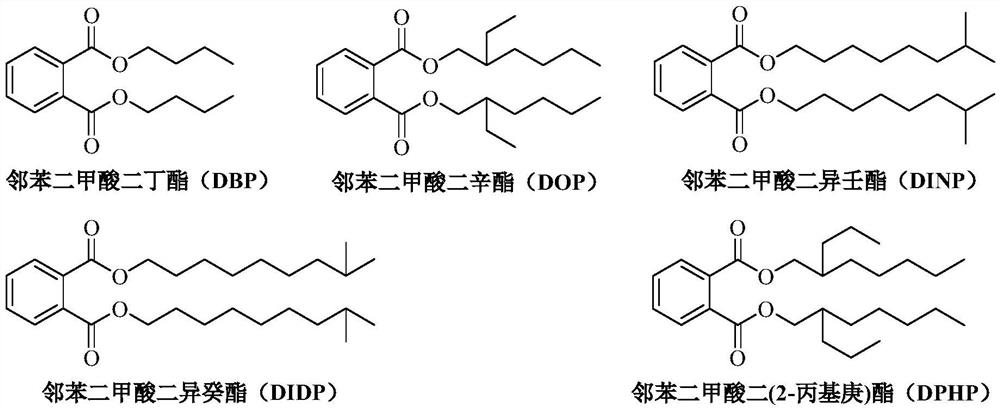

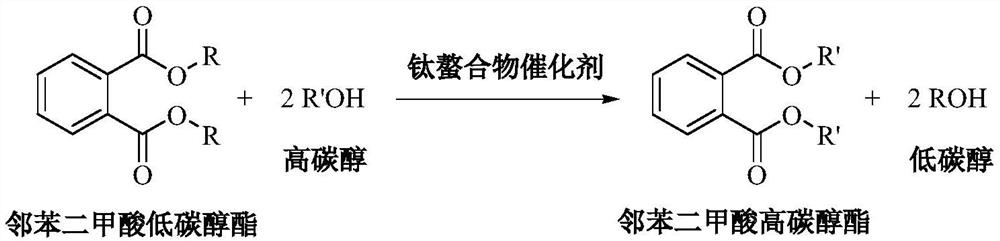

A technology of diisononyl phthalate and phthalic acid is applied in the field of titanium chelate catalyzed transesterification to prepare higher alcohol phthalate, which can solve the problem of low consumption of raw materials, many side reactions, and human body irritation. It can achieve the effect of low consumption of raw materials, few side reactions and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 19.4 grams of dimethyl phthalate (DMP, 0.1mol), 47.5 grams of 2-propylheptanol (2-PH, 0.3mol), 0.02 grams of o-phenanthroline titanium chelate (0.1% of DMP quality ) into a 100ml two-necked round-bottomed flask equipped with a water separator, the water separator was connected with a condenser, stirred evenly, and heated to 210°C for 4 hours of reaction. After the reaction, the mixture was qualitatively analyzed by gas chromatography-mass spectrometry, and passed Quantitative analysis by gas chromatography shows that the conversion rate of DMP and the selectivity of DPHP are both above 99%.

Embodiment 2~11

[0018] The specific methods of Examples 2-11 are similar to those of Example 1, and the specific reaction conditions and results are shown in Table 1. With o-phenanthroline, 2,2'-bipyridine, ethylenediamine, N,N-dimethylethylenediamine, N,N'-dimethylethylenediamine, N,N,N',N' -Tetramethylethylenediamine, 1,2-cyclohexanediamine nitrogen-nitrogen bidentate ligand titanium chelate, one or two or more are catalysts, dimethyl phthalate, phthalic acid Low-carbon alcohol esters of phthalates such as diethyl ester and dibutyl phthalate undergo transesterification with high-carbon alcohols such as 2-propylheptanol, isononanol, and isodecyl alcohol. The catalyst dosage is phthalate 0.01 to 0.1% of the mass of lower alcohol formic acid, the molar ratio of higher alcohol to lower alcohol phthalate is 2 to 4, the reaction temperature is 160 to 220°C, and the reaction time is 2 to 5 hours. Both the conversion rate of low-carbon alcohol ester and the selectivity of high-carbon alcohol ester...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com