A kind of preparation method of silica gel carrier for olefin catalyst

A technology for olefin catalysts and silica gel, which is applied in the field of preparation of silica gel carriers for olefin catalysts, and can solve problems such as cumbersome operation steps, high energy consumption, and large solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

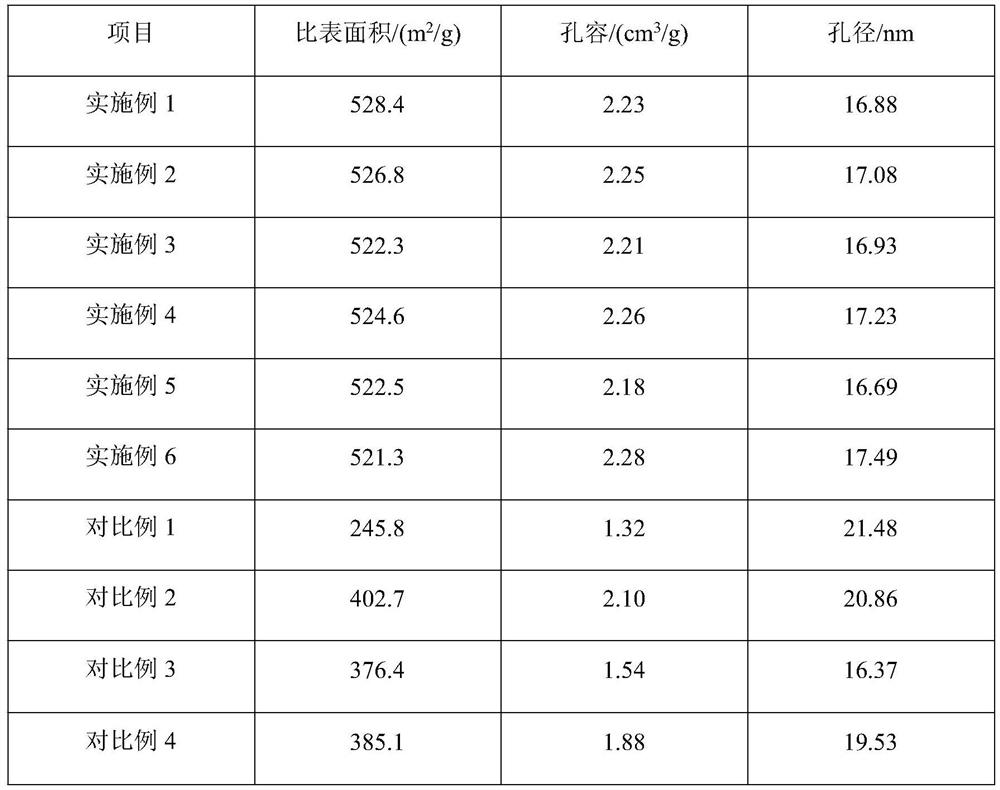

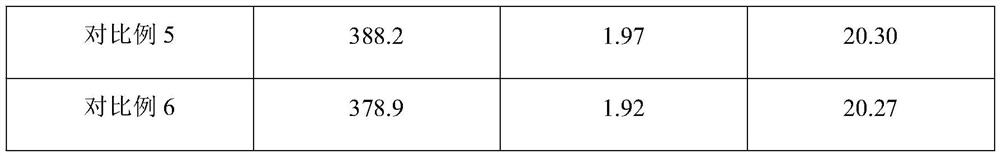

Examples

Embodiment 1

[0040] Put 60ml of dilute sulfuric acid solution with a concentration of 1.1mol / L in a closed reactor, add 3.0ml of 5.0mol / L ammonia solution at 30°C to react for 20min, and raise the temperature to 50°C under stirring. Add a 1.2mol / L sodium silicate aqueous solution at a flow rate of 3ml / min, adjust the pH of the reaction solution to 7, add distilled water to disperse the sol thoroughly, and react at a constant temperature for 0.5h. Add 12mL of ethanol aqueous solution with a mass fraction of 4% slurry hydrotalcite at a flow rate of 3ml / min (the volume ratio of ethanol to water is 1:6), and react at a constant temperature for 1.0h after the addition is complete. Add a 1.2 mol / L sodium silicate aqueous solution at a flow rate of 4 ml / min, adjust the pH of the reaction solution to 11, and react at a constant temperature for 1.0 h. Add n-butanol sulfuric acid aqueous solution with a concentration of 1.0mol / L at a flow rate of 6mL / min (the volume ratio of n-butanol to water is 1:...

Embodiment 2

[0042] The preparation process is the same as in Example 1, except that 6.0 ml of 5.0 mol / L ammonia solution is added at 30°C for 20 minutes, and the temperature is raised to 50°C. Add a potassium silicate aqueous solution with a concentration of 1.2 mol / L at a flow rate of 3 ml / min, adjust the pH value of the reaction solution to 6, add distilled water to completely disperse the sol, and react at a constant temperature for 0.5 h. Other conditions are identical with embodiment 1. The test results are shown in Table 1.

Embodiment 3

[0044] The preparation process was the same as in Example 1, except that 10 mL of ethanol aqueous solution with a mass fraction of 7% slurry-like hydrotalcite was added at a flow rate of 3 ml / min (the volume ratio of ethanol to water was 1:9), and the reaction was carried out at a constant temperature for 1.0 h after the addition. Add 1.2 mol / L sodium silicate water solution at a flow rate of 4 ml / min, adjust the pH value of the reaction solution to 12, and react at a constant temperature for 1.0 h. Other conditions are identical with embodiment 1. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com