Epoxy priming paint

An epoxy primer and raw material technology, applied in the field of coatings, can solve the problems of poor adhesion, high cost, and poor anti-corrosion salt spray performance, and achieve the effects of strong adhesion, low cost, and good anti-corrosion salt spray performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

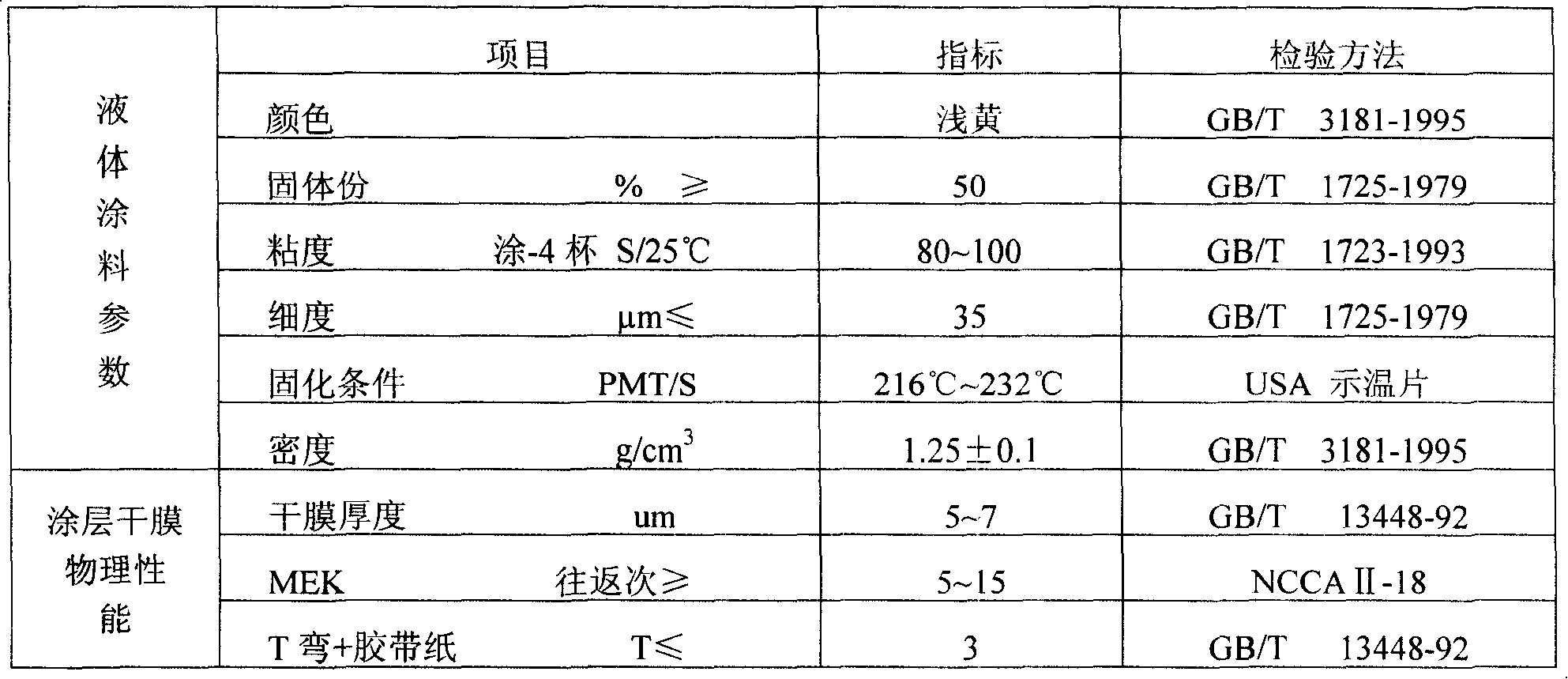

Image

Examples

Embodiment Construction

[0013] The present invention will be described in further detail below in conjunction with the examples, but the protection scope of the present invention is not limited by the examples.

[0014] Epoxy primer, which is composed of the following raw materials: additive 0.3kg, linear polyester resin 50kg, aluminum tripolyphosphate 6kg, zinc phosphate 7kg, titanium dioxide 8kg, barium sulfate 8kg, zinc chrome yellow 3kg, strontium chrome yellow 2.7kg, white carbon black 0.3kg, solvent 10kg, amino resin 4kg, leveling defoamer 1kg, catalyst 0.4kg.

[0015] The preparation process of the present invention is as follows:

[0016] Take the linear polyester resin and additives according to the stated weight, start stirring, and then add other raw materials according to the stated weight. When adding, put them in the order of light first and then heavy, stir and mix, stop stirring after dispersing evenly, and transfer to the next step Grinding is carried out in the process, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com