Method for extracting theaflavin from black tea

A theaflavin and black tea technology, applied in the field of plant extraction, can solve the problems of complex preparation and purification process, and achieve the effect of being suitable for large-scale production and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

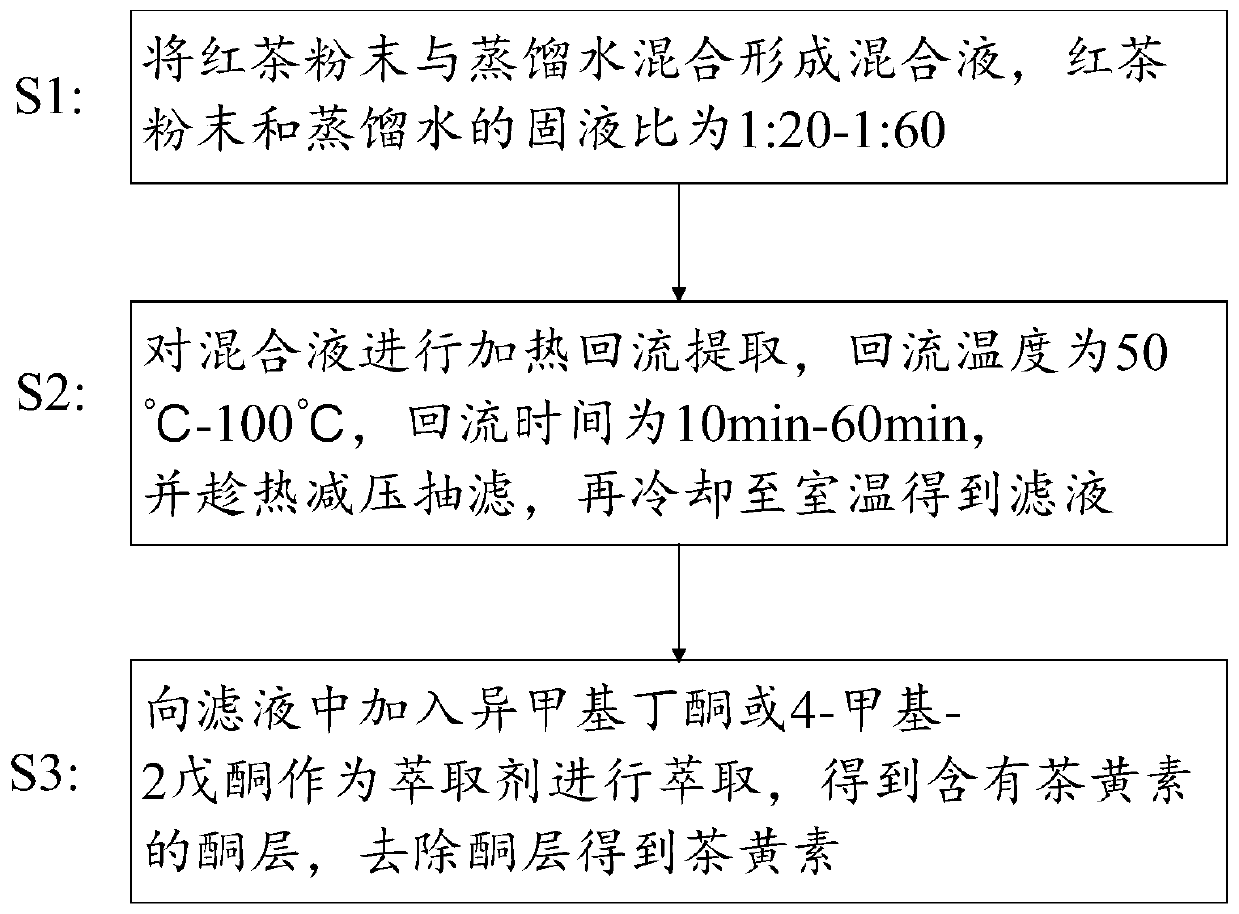

Method used

Image

Examples

Embodiment 1

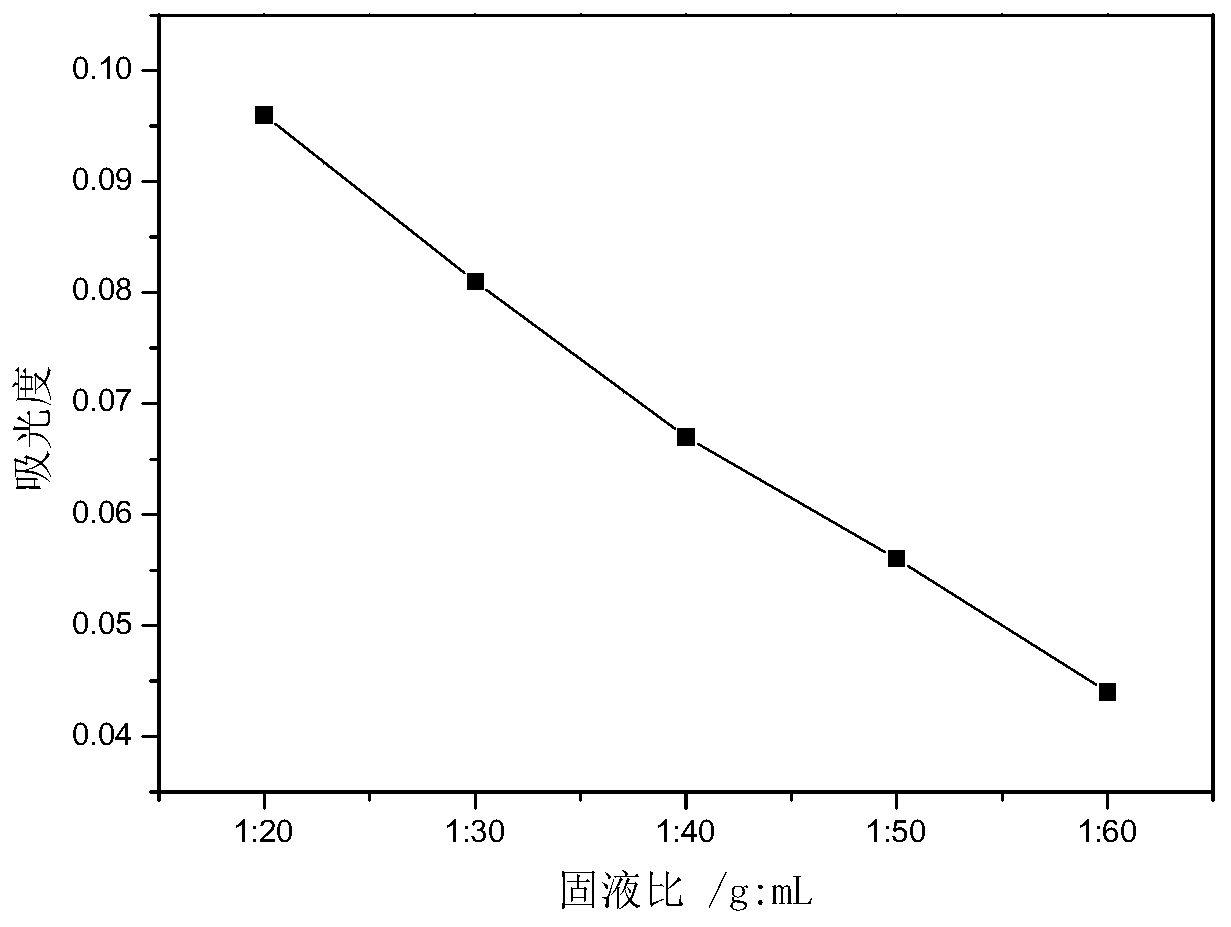

[0033] 1. Provide five different solid-liquid ratio parameters of black tea powder and distilled water, namely 1:20, 1:30, 1:40, 1:50, 1:60.

[0034] 2. Experimental procedure: Weigh 1.000g of ground black tea powder, add 20mL, 30mL, 40mL, 50mL, 60mL of distilled water respectively. Filter under reduced pressure and cool to room temperature; use a pipette to take 5 mL of the filtrate into a test tube, add 5 mL of IBMK to the test tube, shake and separate layers; use a pipette to take 2 mL of the upper ketone layer solution into a test tube, add 0.05 mol / L AlCl 3 : the mixed solution 6ml of dehydrated alcohol volume ratio 1:2, after mixing, seal with plastic wrap, place 15min to make it react completely; Take the mixed solution of IBMK and ethanol 1:2 as reference solution, use at wavelength 525nm The visible light spectrophotometer detects the absorbance, and the test results refer to Table 3 and figure 2 . From figure 2 It can be seen that the absorbance is maximum whe...

Embodiment 2

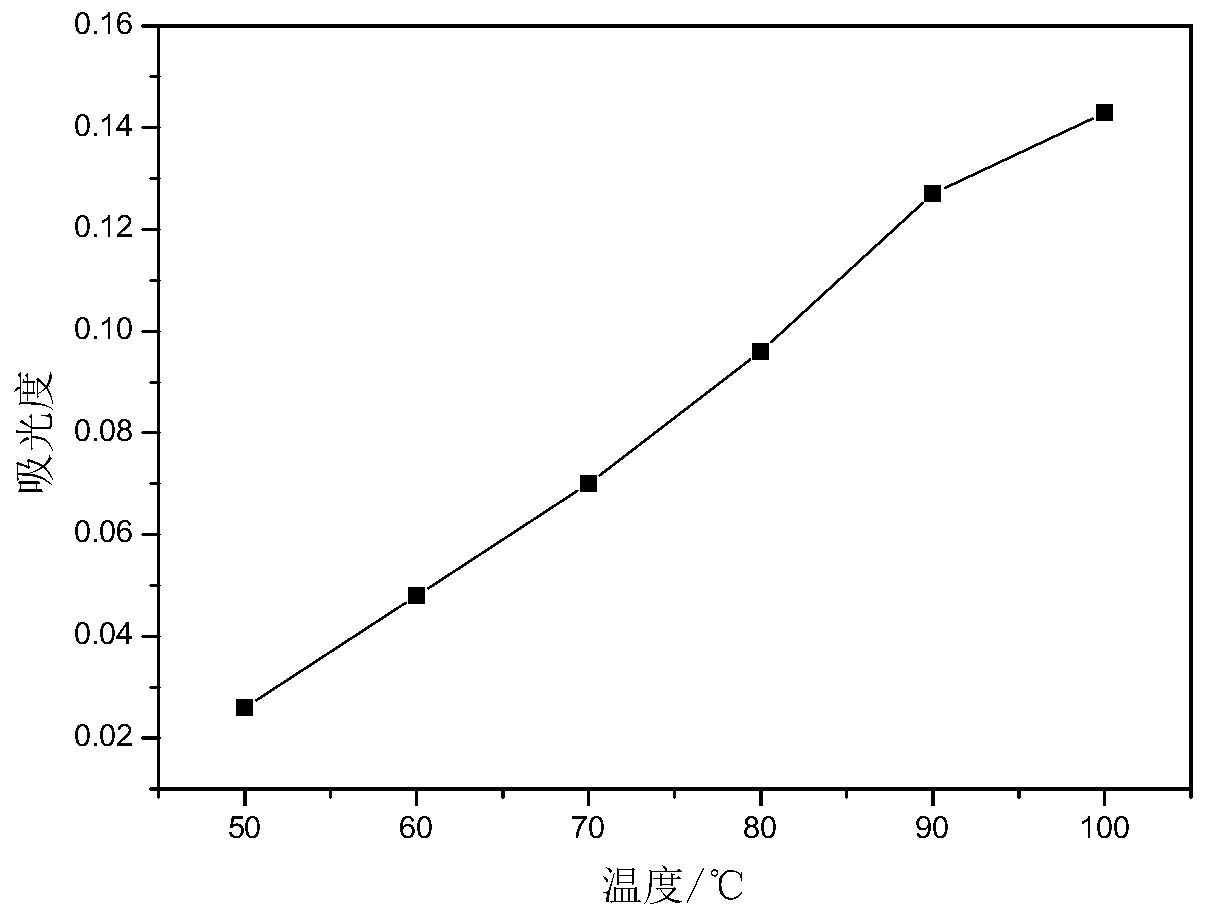

[0038] 1. Provide six different reflow temperature parameters, namely 50°C, 60°C, 70°C, 80°C, 90°C, 100°C.

[0039] 2. Experimental procedure: Weigh 1.000g of black tea powder, add 20mL of distilled water for extraction, extract at 50°C, 60°C, 70°C, 80°C, 90°C, and 100°C for 20 minutes, vacuum filter while hot, and cool to room temperature; take 5mL of the filtrate in a test tube, add 5mL of IBMK for extraction; take 2mL of the extracted ketone layer solution in a test tube, add 0.05mol / L AlCl 3: the mixed solution 6ml of dehydrated alcohol volume ratio 1:2, make it react 15min, take the mixed solution of IBMK and ethanol 1:2 as reference solution, detect its absorbance with visible light spectrophotometer at wavelength 525nm place, test result sees Table 4 and image 3 . From image 3 It can be seen that the absorbance is maximum when the reflux temperature is 100°C.

[0040] The impact of table 4 reflux temperature on theaflavin extraction

[0041]

Embodiment 3

[0043] 1. Provide six different reflux time parameters, namely 10min, 20min, 30min, 40min, 50min, 60min.

[0044] 2. Experimental process: Weigh 1.000g of black tea powder, add 20mL of distilled water for extraction, extract at 80°C for 10min, 20min, 30min, 40min, 50min, and 60min, filter under reduced pressure while hot, and cool to room temperature; take 5mL of filtrate In the test tube, add IBMK 5mL for extraction; take 2mL of the extracted ketone layer solution in the test tube, add 0.05mol / L AlCl 3 : the mixed solution 6ml of dehydrated alcohol volume ratio 1:2, make it react 15min; With the mixed solution of IBMK and ethanol 1:2 as reference solution, detect its absorbance with visible light spectrophotometer at wavelength 525nm place, test result sees Table 5 and Figure 4 . From Figure 4 It can be seen that the absorbance is maximum when the reflux time is 30 minutes.

[0045] The impact of table 5 reflux time on theaflavin extraction

[0046]

[0047] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com