Graphene lubricating oil and preparation method thereof

A technology of lubricating oil and graphene, which is applied in the field of graphene lubricating oil and its preparation, can solve the problems of insufficient antirust, high temperature resistance and antibacterial performance, and achieve improved antirust and high temperature resistance, improved antirust performance, and improved The effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

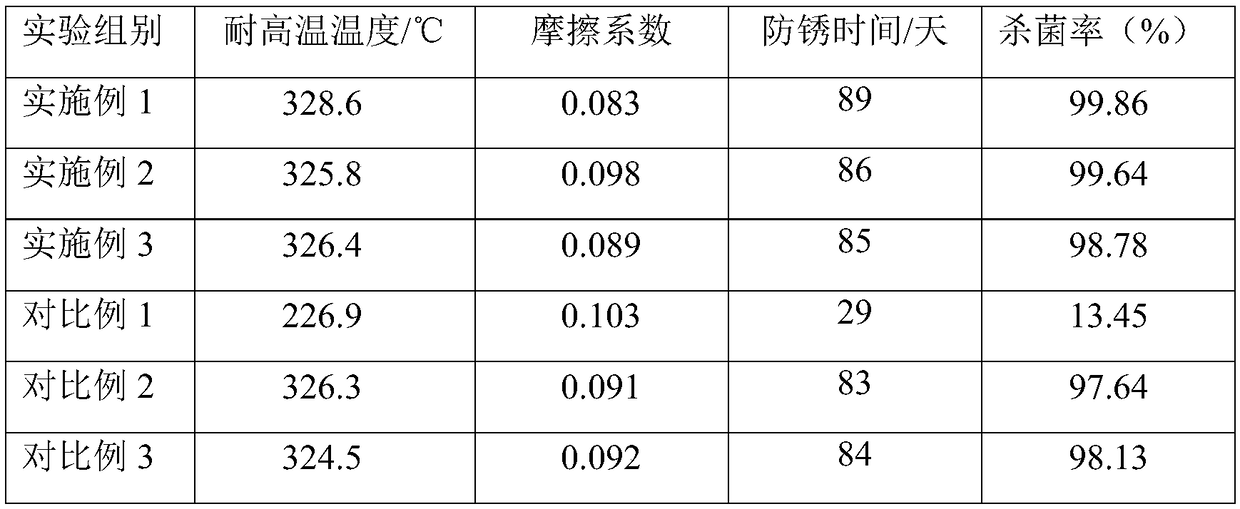

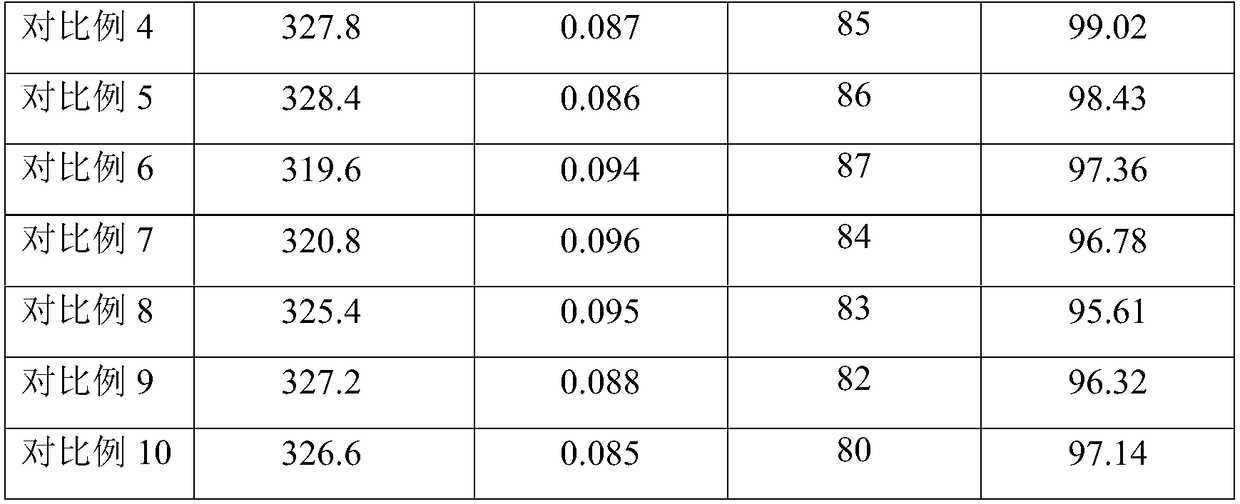

Embodiment 1

[0021] A kind of graphene lubricating oil, is made up of the raw material of following parts by weight: 23.6 parts of machine oils, 18.9 parts of rice bran oils, 5.6 parts of dipolyethylene glycol di-naphthenates, 7.4 parts of cyclohexane, 4.9 parts of triethanolamines, silane 3.7 parts of joint agent KH-570, 7.4 parts of octylphenol, 8.9 parts of 4-hydroxy-4-methyl-2-pentanone, 5.4 parts of styrenated phenol, 9.6 parts of peppermint oil, 2.8 parts of alkenyl succinate , 7.4 parts of castor oil polyoxyethylene ether, 7.4 parts of benzotriazole, 6.8 parts of cinnamyl alcohol, 2.6 parts of secondary octanol, 7.4 parts of glycerin polyoxyethylene ether laurate, 10.3 parts of methylisothiazolinone, urine 6.5 parts of pyrimidine, 4.2 parts of carbon black, 7.8 parts of wax powder, 4.2 parts of corundum powder, 10.3 parts of nano titanium dioxide, 6.9 parts of stearic acid, 7.4 parts of pentaerythritol, 2.8 parts of naphthenic acid, 4.4 parts of ammonium bicarbonate, 6.7 parts of zin...

Embodiment 2

[0028] A graphene lubricating oil is composed of the following raw materials in parts by weight: 15 parts of machine oil, 30 parts of rice bran oil, 4 parts of dimerized ethylene glycol naphthenate, 8 parts of cyclohexane, 3 parts of triethanolamine, silane Joint agent KH-5705 parts, 6 parts of octylphenol, 9 parts of 4-hydroxy-4-methyl-2-pentanone, 4 parts of styrenated phenol, 12 parts of peppermint oil, 1 part of alkenyl succinate , 9 parts of castor oil polyoxyethylene ether, 5 parts of benzotriazole, 8 parts of cinnamyl alcohol, 1 part of secondary octanol, 8 parts of glycerin polyoxyethylene ether laurate, 8 parts of methylisothiazolinone, urine 8 parts of pyrimidine, 4 parts of carbon black, 9 parts of wax powder, 1 part of corundum powder, 13 parts of nano titanium dioxide, 4 parts of stearic acid, 9 parts of pentaerythritol, 1 part of naphthenic acid, 5 parts of ammonium bicarbonate, 4 parts of zinc oxide , 5 parts of nano-graphene, 2 parts of aluminum nitride, and 10...

Embodiment 3

[0035] A kind of graphene lubricating oil, is made up of the raw material of following parts by weight: 25 parts of machine oils, 20 parts of rice bran oils, 6 parts of dipolyethylene glycol di-naphthenates, 4 parts of cyclohexane, 9 parts of triethanolamines, silane diethylene glycol 2 parts of joint agent KH-5702, 8 parts of octylphenol, 6 parts of 4-hydroxy-4-methyl-2-pentanone, 6 parts of styrenated phenol, 8 parts of peppermint oil, 4 parts of alkenyl succinate , 6 parts of castor oil polyoxyethylene ether, 8 parts of benzotriazole, 6 parts of cinnamyl alcohol, 4 parts of secondary octanol, 6 parts of glycerin polyoxyethylene ether laurate, 12 parts of methylisothiazolinone, urine 5 parts of pyrimidine, 6 parts of carbon black, 6 parts of wax powder, 5 parts of corundum powder, 9 parts of nano titanium dioxide, 8 parts of stearic acid, 5 parts of pentaerythritol, 4 parts of naphthenic acid, 3 parts of ammonium bicarbonate, 8 parts of zinc oxide , 3 parts of nanographene, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com