Purification method of high-purity organic solvent 4-methyl-2-pentanone

A technology of organic solvent and purification method, which is applied in the field of purification of high-purity organic solvent 4-methyl-2-pentanone, and can solve problems such as not reaching the high-purity organic solvent 4-methyl-2-pentanone index , to achieve the effect of saving manpower, reducing energy consumption and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of purification method of high-purity organic solvent 4-methyl-2-pentanone, the steps are as follows:

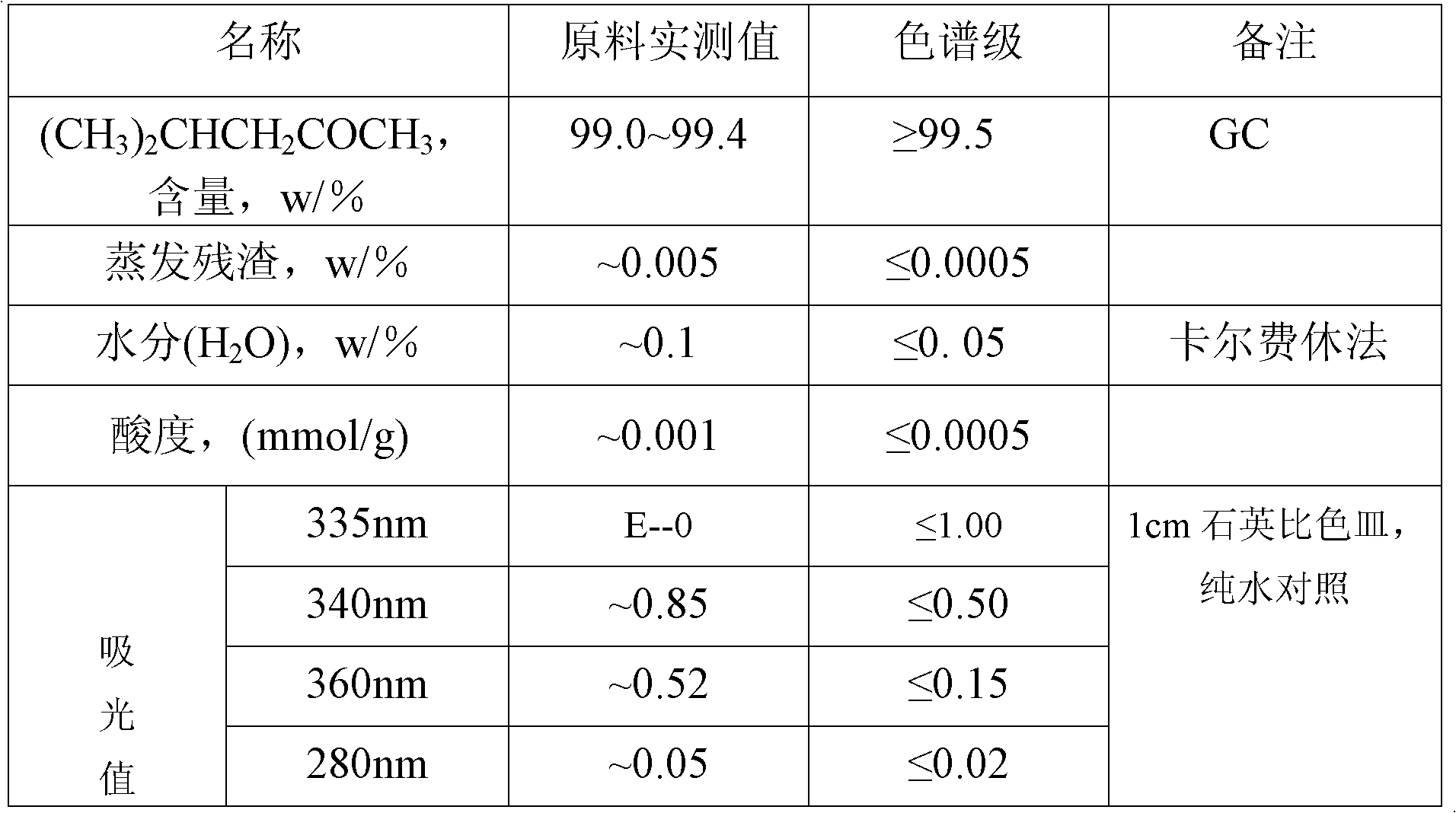

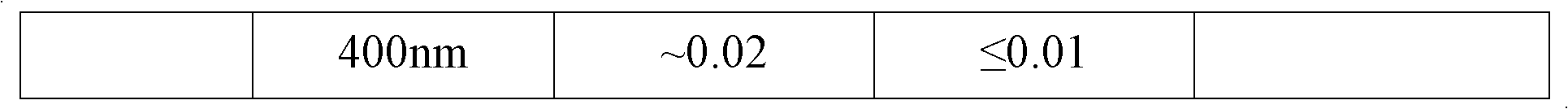

[0018] (1) Lift the raw material 4-methyl-2-pentanone (content is about 99%) to the top of the adsorption column, wherein the adsorption column is 1.2M high and 3.0cm in diameter, and the amount of acidic alumina adsorbent in it is 1 / 2 of the column height 4 / 5, the raw material is adsorbed at a rate of 30mL / min; in the column, 4-methyl-2-pentanone is in full contact with the adsorbent acidic alumina, so that a small amount of alcohol and acidic impurities are adsorbed, and the adsorption liquid is detected Quality, after the adsorption effluent is qualified, that is, the indicators of the effluent are close to the technical index requirements of the chromatographic level (see Table 1 for specific technical index requirements), enter the next step, and remove the pre-adsorption fraction with high impurities.

[0019] (2) Put the 4-methyl-2-pentanone flowing out ...

Embodiment 2

[0022] A kind of purification method of high-purity organic solvent 4-methyl-2-pentanone, the steps are as follows:

[0023] (1) Lift the raw material 4-methyl-2-pentanone (content is about 99%) above the adsorption column, the adsorption column is 1.2M high, 3.0cm in diameter, and the amount of acidic alumina inside is 4 / 5 of the column height , the 4-methyl-2-pentanone raw material is adsorbed at a speed of 80mL / min, and the next step is performed after the adsorption liquid is qualified; and the fraction with high impurities before adsorption is removed;

[0024] (2) Put the effluent from the above-mentioned adsorption column into a drying column with a column height of 1.2M and a diameter of 3.0cm, and fill it with baked and dried anhydrous calcium sulfate, and measure the water content of 4-methyl-2-pentanone after drying , the water content is controlled at ≤0.05%, and the next step is to proceed after the water content is qualified; when the water content is greater tha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com