Patents

Literature

84results about How to "For the purpose of purification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic complex supported activated carbon adsorbent and its preparation method and application

InactiveCN101053820AAchieve the purpose of purificationEfficient removalOther chemical processesActivated carbonSorbent

The invention relates to an organic complex supported activated carbon adsorbent, which has activated carbon as a carrier and organic complex distributed on a pore path of the activated carbon. The preparing method comprises: immerging the activated carbon treated by vacuumizing in a maceration extract; removing solvent by vacuumizing; leaching the sample using an eluate while vacuum filtrating; and washing the the sample using deionized water while vacuum filtrating. The adsorbent is applicable for purifying peroxide (H2O2) solution by a way of: adding the adsorbent into the peroxide solution, absorbing and filtering the mixture to effectively remove organic matter impurity from the peroxide solution as well as remove various metallic iron impurities such as Al, Ti, Cr, Mn, Fe, Ni, Cu, Zn, Ga, Rb, Sr, Mo, Ag, Sb, W, Au, Hg, etc., thus the aim of purification is achieved. Accordingly, the adsorbent of the invention is suitable for purifying of peroxide solution, in particular commercial grade peroxide solution having more organic matter impurity.

Owner:SOUTH CHINA UNIV OF TECH

Aqueous two-phase extraction and separation method for flavonoids, saponins and polysaccharides of astragalus

InactiveCN102697839AShort experiment cycleHigh recovery rateAntipyreticDigestive systemDipotassium hydrogen phosphateMedicinal herbs

The invention relates to an aqueous two-phase separation method for total flavonoids, saponins and polysaccharides in astragalus. The method comprises the following steps of smashing an astragalus medicinal material; adding a solvent and performing solid-liquid extraction; filtering and removing impurities to obtain crude extract of the total flavonoids and the saponins of the astragalus; taking and concentrating the crude extract of the astragalus; adding an aqueous two-phase system formed by absolute ethyl alcohol / dipotassium hydrogen phosphate, adding water to make the total amount of the system be a constant value; mixing uniformly and standing, wherein the aqueous two-phase system is divided into an upper phase and a lower phase; taking an ethanol phase which contains a large amount of total flavonoids and saponins of the astragalus out; and concentrating the ethanol phase under a reduced pressure to obtain the extract of the total flavonoids of the astragalus. The method has the beneficial effects that the extraction rate of the total flavonoids and the total saponins of the astragalus; simultaneously the total flavonoids and the total saponins can be separated from the polysaccharides of the astragalus in the crude extract; the used solvent is low in toxicity, favorable to environment friendliness and low in cost; the inactivation or the denaturation of the flavonoids and the saponins of the astragalus cannot be caused; the phase separation time is short; the interfacial tension is low; and residual organic solvent does not exist.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Glufosinate separation and purification method

ActiveCN104860988ASlow flowFast flowGroup 5/15 element organic compoundsPurification methodsCentrifugation

The invention belongs to the field of pesticide production and particularly relates to a glufosinate separation and purification method. According to the method, the separation and purification is started when a glufosinate hydrochloride reaction solution in the steps of distilling the glufosinate hydrochloride reaction solution under reduced pressure to remove dilute hydrochloric acid, adding ammonia water to adjust the pH to maximally produce ammonium chloride, distilling under reduced pressure to remove water, adding a flotation solvent for dispersion, placing the material into a chute at specific temperature and speed, performing flotation separation according to the difference in the proportion of a principal component and subsidiary salt, removing the solvent, dissolving the material in aqueous methanol to remove trace ammonium chloride, filling ammonia gas to adjust the pH value to 8, performing centrifugation and drying to obtain a final product. The glufosinate separation and purification method uses a flotation method for separating the principal component glufosinate and an intermediate of the principal component from the subsidiary salt ammonium chloride and the aqueous methanol for purification and is high in yield, good in purity, simple in process, low in cost and is suitable for industrial production.

Owner:石家庄瑞凯化工有限公司

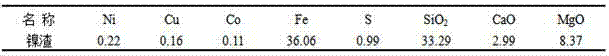

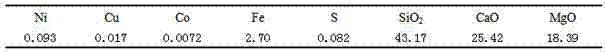

Method for recovering valuable metals from nickel-copper molten slag through selective reduction

InactiveCN102851513AAchieve restorationControl the degree of restorationProcess efficiency improvementSteelmakingMolten state

The invention belongs to the technical field of solid waste comprehensive utilization, and relates to a method for recovering valuable metals from nickel-copper molten slag through selective reduction. A process comprises the steps that: nickel-copper smelting slag is subjected to selective reduction under a high-temperature molten slag state, such that nickel, cobalt, and copper valuable metals in the slag can be completely reduced; the reduction of a small amount of iron is controlled, such that an intermediate alloy rich in nickel, cobalt, and copper is produced; most of the rest molten slag exists in a form of iron silicate; a solvent and a reducing agent are added, such that iron in the molten slag is completely reduced, and crude iron containing trace nickel, cobalt, and copper can be produced; and crude iron is adopted as an iron alloy and steelmaking raw material. The method provided by the invention has the advantages that a high-temperature nickel-copper smelting molten slag stepped selective reduction process is adopted, and nickel-copper smelting slag is utilized under a molten state, such that slag secondary heating cost is saved, valuable metal graded utilization is realized, product market application field is widened, and solid waste economical and effective utilization is realized.

Owner:JINCHUAN GROUP LIMITED

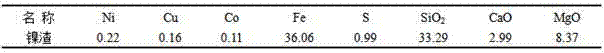

Method for desalting purification of polymer product in polyphenylene sulfide production

ActiveCN104817696AEfficient dehydration and desalinationReduce the content of inorganic saltsSolventChemical industry

The present invention relates to a method for desalting purification of the polymer product in polyphenylene sulfide production, and belongs to the technical field of chemical industry materials. A purpose of the present invention is to provide a method for efficiently removing salts, water, solvents and other impurities from the polymer product during a polyphenylene sulfide synthesis process so as to achieve solvent recovery and efficient polymer desalting. According to the present invention, the method can be applied in the post-treatment process, wherein the post-treatment process comprises: adopting anhydrous sodium sulfide and p-dichlorobene as raw materials, and carrying out a high temperature high pressure solution condensation polymerization reaction to produce a polyphenylene sulfide resin product; the method is characterized in that after completing the condensation polymerization reaction, the polyphenylene sulfide mixture in the reaction system is subjected to filtration separation, and the separated filter cake is subjected to acid washing, ultrasonic washing, water washing and drying to obtain the purified product; and with the method, the inorganic salt content in the polymer product can be significantly reduced, and the quality and the performance of the PPS product can be improved and enhanced.

Owner:CHANGZHOU UNIV

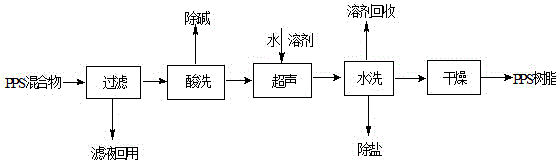

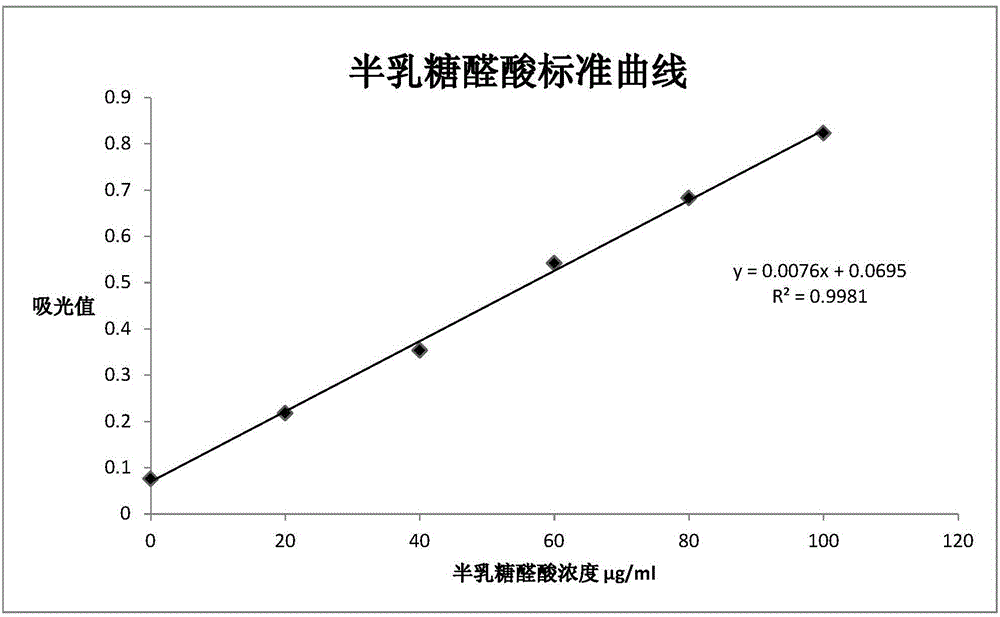

Method for extracting pectin from pepper skin slag

The invention belongs to the technical field of plant extracts and particularly relates to a method for extracting pectin from pepper skin slag. The method comprises the process flows: acid-extracting, discoloring, alcohol-precipitating, purifying and drying. The method disclosed by the invention not only can adopt inorganic acid, but also can adopt organic acid to extract, and the organic acid is used for overcoming a pollution problem of inorganic acid extraction on environment; hydrogen peroxide or active carbon is adopted to discolor, so that a problem that the pepper pectin extracting liquor is dark in color and difficult to discolor is solved; alcohol, isopropanol, methanol, acetone and ethyl acetate are used for purifying to sufficiently prepare the pectin with higher purity. According to the method disclosed by the invention, process operation conditions are easy to control, purifying method is simple, pectin yield averagely can reach 9.5%, content of galacturonic acid is not less than 65%, and the pectin belongs to high-ester pectin.

Owner:CHINA AGRI UNIV

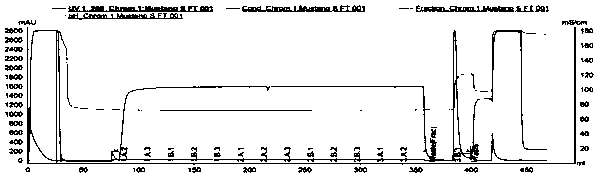

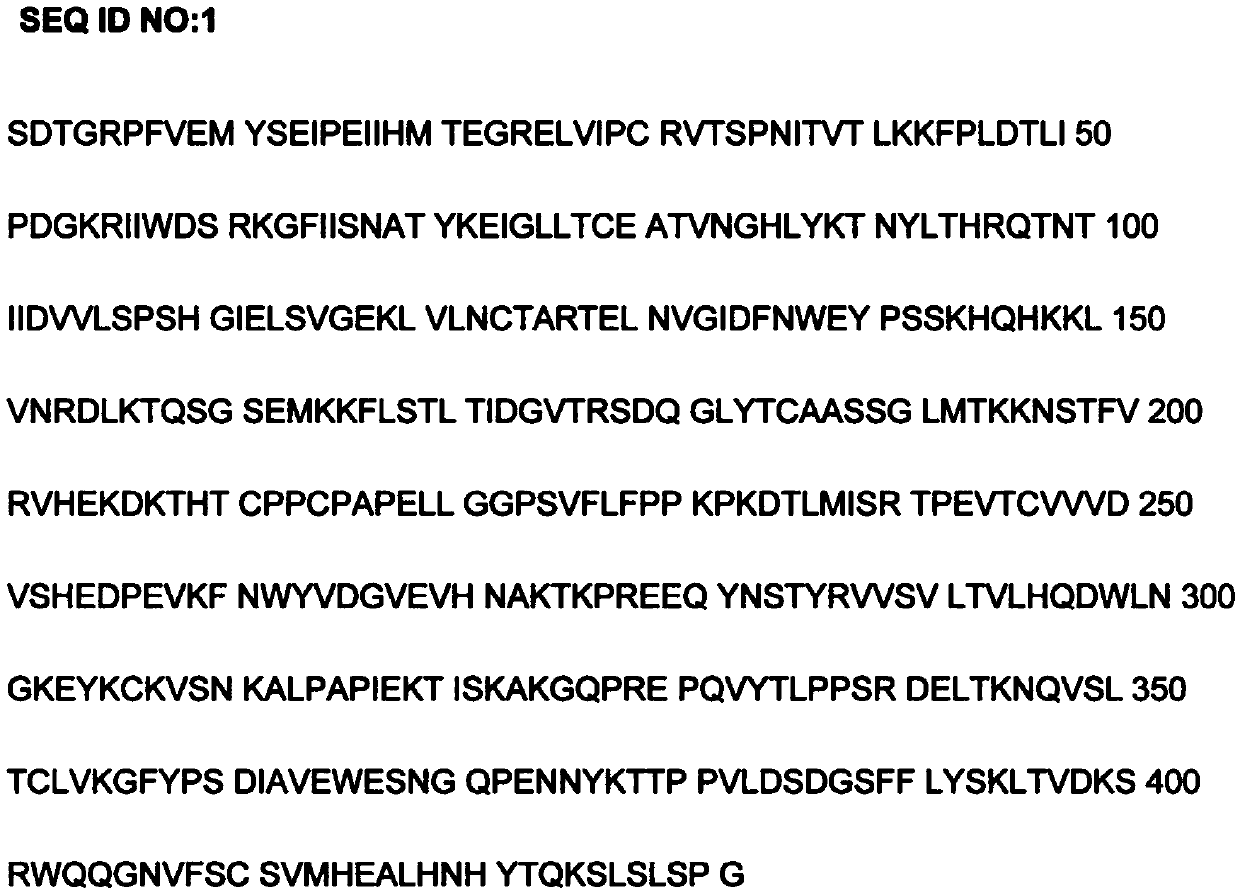

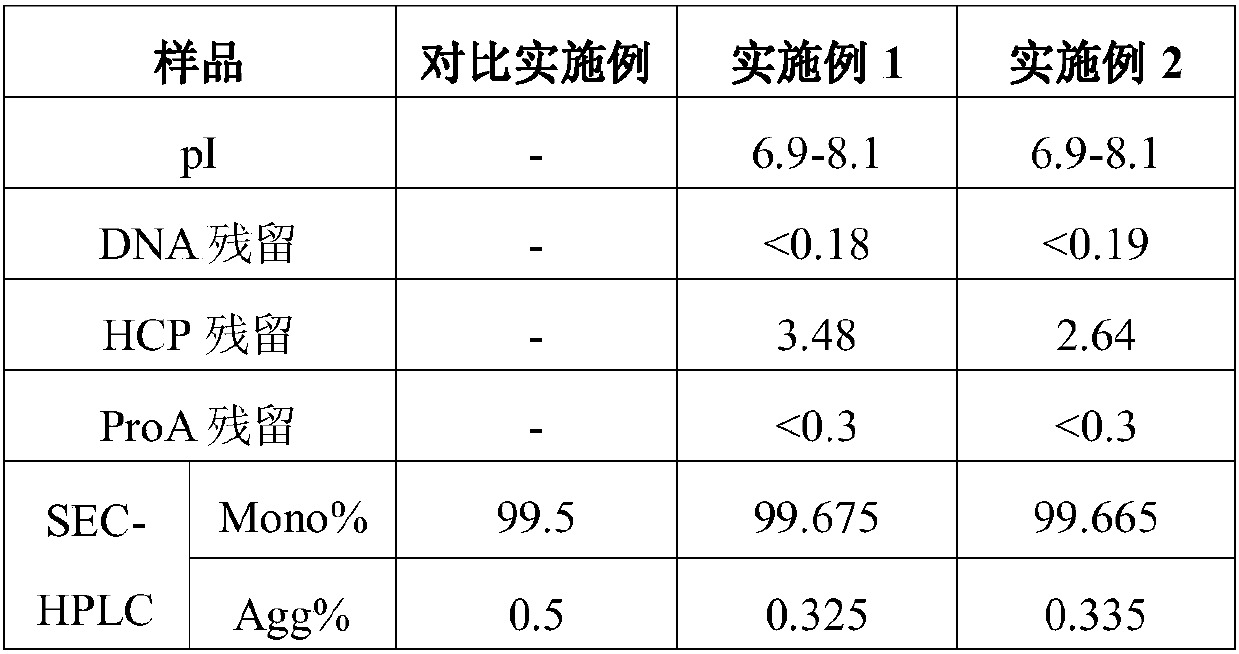

Purification method of recombinant human vascular endothelial growth factor receptor-antibody fusion protein

ActiveCN105175548AEasy to removeFor the purpose of purificationPeptide preparation methodsHybrid peptidesPurification methodsProtein target

The invention relates to production of a genetic engineering drug by a recombinant DNA technology, belongs to the biotechnical field, and particularly relates to a purification method of a recombinant human vascular endothelial growth factor receptor-antibody fusion protein, that is to say, a cell supernatant containing the recombinant human vascular endothelial growth factor receptor-antibody fusion protein is successively subjected to affinity chromatography, anion exchange chromatography, cation exchange chromatography, hydrophobic chromatography and desalination chromatography to obtain the high-quality recombinant human vascular endothelial growth factor receptor-antibody fusion protein. The purification method has the characteristics of low cost, high purity of the target protein, easily controlled technological process, easily large-scale enlarged production and the like.

Owner:QILU PHARMA CO LTD

Purification method for Tylosin

ActiveCN101565438AFor the purpose of purificationSugar derivativesSugar derivatives preparationPurification methodsPhosphoric acid

The invention relates to a purification method for tylosin. The invention describes the post treatment of the extraction liquid of tylosin when chloroform is used for extracting the tylosin from fermentation filter liquid, i.e. a purification method. The essential of the method is as follows: the extraction liquid is concentrated into a condition that chloroform is basically removed; a condensateis dissolved by acid water; butyl acetate or toluene or 4-methyl-2-pentanone is added; the pH value is adjusted to 7.5-9.5 by alkali liquid, and extraction and phase splitting are sequentially performed; and a tartaric acid aqueous solution or a phosphoric acid aqueous solution is added to an ester phase for performing back extraction, back extraction liquid is obtained and is sprayed and dried, or the pH value of the back extraction liquid is adjusted to 7.5-10.5, and the back extraction liquid is pressed and filtered or centrifugated to obtain the tylosin.

Owner:河北威远药业有限公司

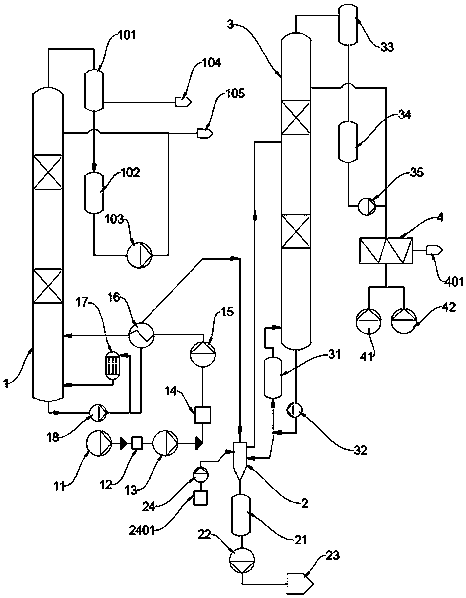

Stripping liquid regeneration device and process

PendingCN108568131AImprove primary separation efficiencyQuick removalPhotosensitive material processingFractional distillationLiquid wasteFiltration

The invention relates to a stripping liquid regeneration device and process. The device structurally comprises a dewatering rectification tower, a film evaporator and a decolorizing rectification tower arranged sequentially along the flow direction of stripping liquid in a waste stripping liquid purification process, wherein the feeding hole end of the dewatering rectification tower is provided with a waste stripping liquid smelting pool and a primary film filtration pool which are connected in sequence. By adopting the stripping liquid regeneration device and process, the overall regenerationefficiency of the stripping liquid and the final yield of the stripping liquid are increased, and the demand of recycling of the waste stripping liquid of photoresist is met.

Owner:四川久远化工技术有限公司

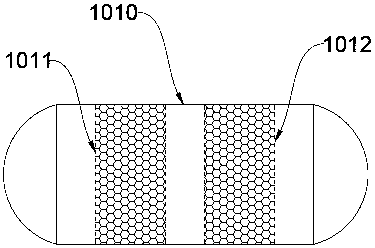

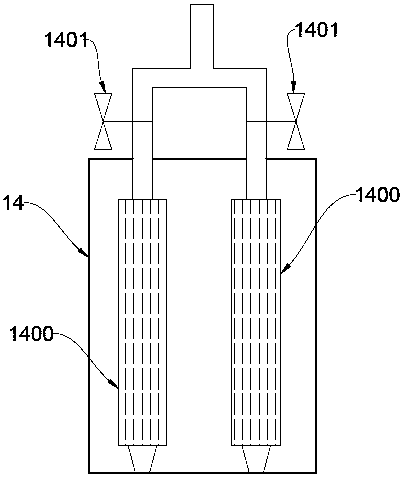

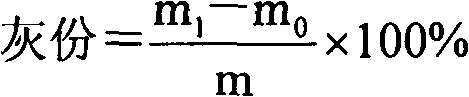

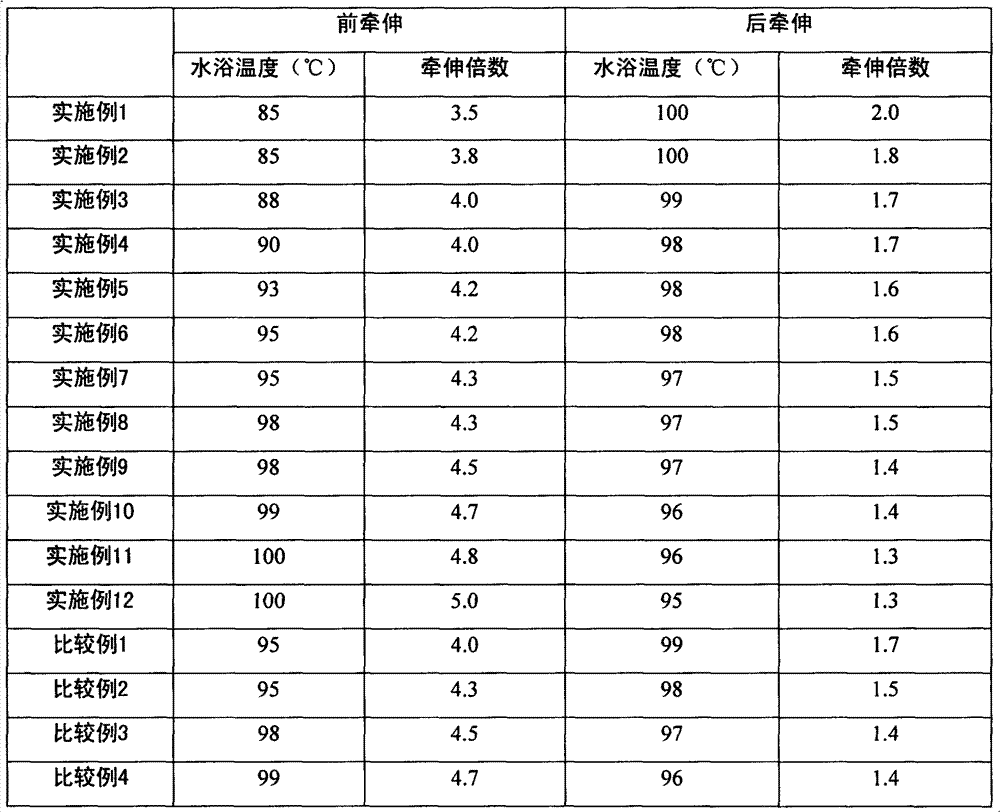

Preparation method for polyacrylonitrile-based carbon fiber protofilament

ActiveCN102953140ADrafting smoothlyHigh breaking strengthArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsSolvent

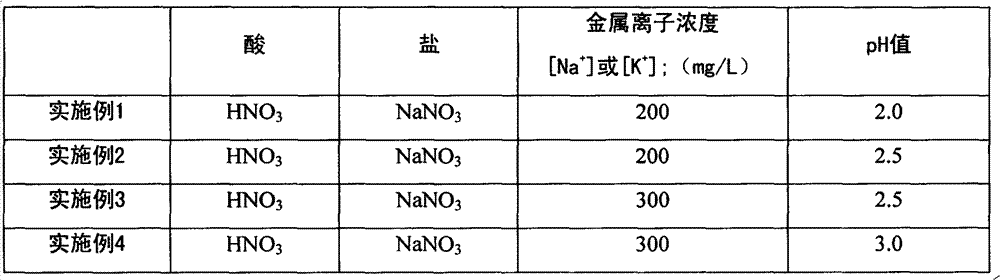

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a spinning raw material polyacrylonitrile resin is itaconic acid. The preparation method comprises the following successive steps: preparing a spinning solution from the resin by using DMSO or DMAc as a spinning solvent and carrying out spinning and solidification so as to prepare a nascent fiber; placing the nascent fiber in an aqueous solution of the spinning solvent for water bath drafting and carrying out drip washing with deionized water; dipping the nascent fiber in a buffer solution containing acid A and salt B, wherein A is sulfuric acid, hydrochloric acid or nitric acid, and B is a sodium salt or a sylvite of A, and dipping time is controlled to be 2 to 10 min; placing the nascent fiber in pure water for water bath drafting; subjecting the nascent fiber to hot bath rinsing with deionized water until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and then continuing rinsing for 5 to 15 min; and carrying out post-processing procedures like oiling and dry densification so as to obtain a product of the polyacrylonitrile-based carbon fiber protofilament. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high-silicon aluminum-silicon alloy by recycling crystalline silicon cutting waste through metallic aluminum

The invention discloses a method for preparing a high-silicon aluminum-silicon alloy by recycling crystalline silicon cutting waste through metallic aluminum. Metallic aluminum particles, the crystalline silicon cutting waste and a fluxing agent are mixed according to a certain proportion and are contained in a graphite crucible and placed in an induction furnace for high-temperature melting; after heat preservation is carried out for a period of time, the product is cooled to room temperature at certain cooling speed; and after residues on the surface of the sample are separated out of the solidified alloy sample, the high-silicon aluminum-silicon alloy can be obtained. Due to the fact that the crystalline silicon cutting waste and the metallic aluminum particles are used as the raw materials, the content of Fe, Cu, Mn, Ni and other impurities in the prepared high-silicon aluminum-silicon alloy is far lower than the aluminum-silicon alloy impurity standard requirement. The method is low in cost, efficient and environment-friendly, the problem of comprehensive recovery of current silicon waste is solved, the high-silicon aluminum-silicon alloy product can also be directly produced through silicon waste, and a new way is provided for economical utilization of silicon containing waste.

Owner:KUNMING UNIV OF SCI & TECH

Purifying method of ionic liquid

InactiveCN102441285AReduce consumptionFor the purpose of purificationEvaporationPurification methodsIonic liquid

The invention provides a purifying method of ionic liquid. The purifying method comprises a step that: the ionic liquid is purged by using inert gas, such that volatile impurities in the ionic liquid are removed. With the method, volatile substances in synthesized or recovered ionic liquid containing volatile impurities can be removed in a relatively short time, such that the purification of the ionic liquid is realized. Compared to traditional methods, with the method provided by the invention, the purification time can be shortened, the energy consumption during the purification period can be reduced, and the degradation of the ionic liquid can be avoided.

Owner:BEIJING UNIV OF CHEM TECH

Method for purifying yellow pigment in yellow ginger

InactiveCN101792612ALarge adsorption capacityFor the purpose of purificationNatural dyesPurification methodsDesorption

The invention relates to a method for purifying yellow pigment in yellow ginger, comprising the following steps of scrubbing, slicing, drying and pulverizing wet yellow ginger; adding ethanol solution for extraction through reflux at constant temperature; removing ethanol by rotation and evaporation; drying to obtain a crude product of dioscorea zingiberensis pigment; preparing the crude product of dioscorea zingiberensis pigment into dioscorea zingiberensis pigment solution; enabling the dioscorea zingiberensis pigment solution to pass through a macroporous resin column, and eluting with distilled water to remove impurities ; carrying out elution with ethanol; and concentrating and drying the obtained ethanol eluent to obtain a refined product of dioscorea zingiberensis pigment. In the invention, the macroporous resin column is utilized to specifically absorb yellow pigment in yellow ginger, and elution is carried out by using ethanol so as to achieve the purpose of purifying dioscorea zingiberensis pigment. The method has the advantages of easy adsorption and desorption, large adsorption capacity and high color value of the product with the pigment yield rate of 4.48 percent and the color value of 114.5.

Owner:SHAANXI UNIV OF SCI & TECH

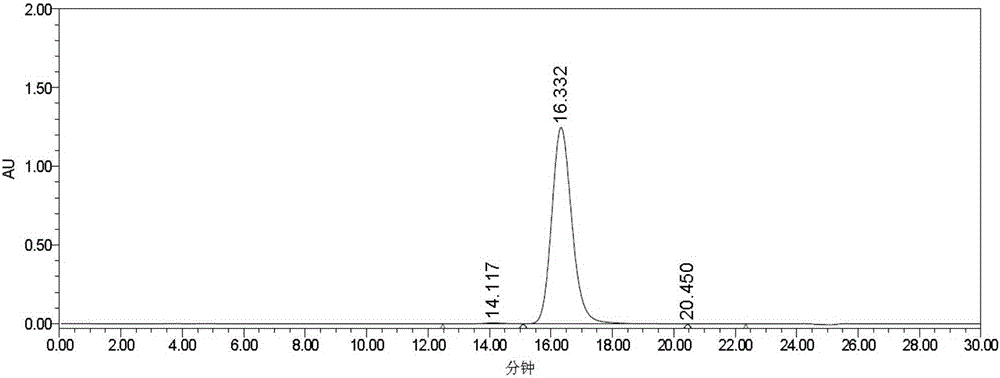

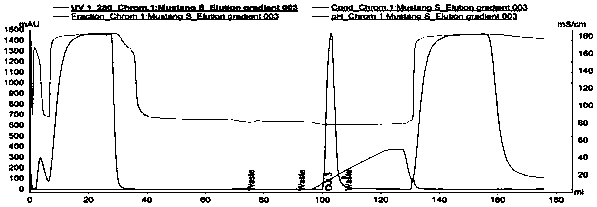

Method for purifying antibody through cation exchange chromatography

InactiveCN109336970AFor the purpose of purificationFast operating flowPeptide preparation methodsImmunoglobulinsChromatographic columnImpurity

The invention relates to the technical field of antibody purification, in particular to a method for purifying antibody through cation exchange chromatography. The method comprises the following steps: performing cation exchange chromatography treatment on an antibody solution, adjusting the pH of the antibody solution to be 5.0 to 7.0 and the conductivity to be 3 to 20mS / cm, performing sample loading, adjusting the pH of an equilibration buffer to be 5.0 to 7.0 and the conductivity to be 3 to 20mS / cm, and performing purification through a flowthrough method or an overload method. The method has the advantages that the antibody is purified through the cation exchange chromatography, and the pH and conductivity of the antibody solution and the equilibration buffer are adjusted, so that target antibody monomer cannot be or is rarely combined with a cation chromatographic column or membrane, and flows out with flowthrough liquid, and impurity components can be combined with the chromatographic column or membrane, so that the purpose of antibody purification is achieved; meanwhile, the antibody yield can reach greater than 90 percent.

Owner:HJB HANGZHOU CO LTD

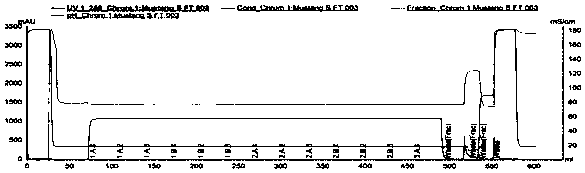

Method for purifying VEGF capture agent fusion protein

ActiveCN109929038AFor the purpose of purificationSimple purification processPeptide preparation methodsHybrid peptidesAnion-exchange chromatographyAnion Exchange Proteins

The invention relates to a method for purifying VEGF capture agent fusion protein. The method comprises the following steps: (1) affinity chromatography; (2) anion exchange chromatography; and (3) cation exchange chromatography. The purification process of the invention is simple and can effectively reduce the preparation cost, which is very beneficial for mass production.

Owner:SHANDONG BIOANTY BIOLOGICAL TECH CO LTD

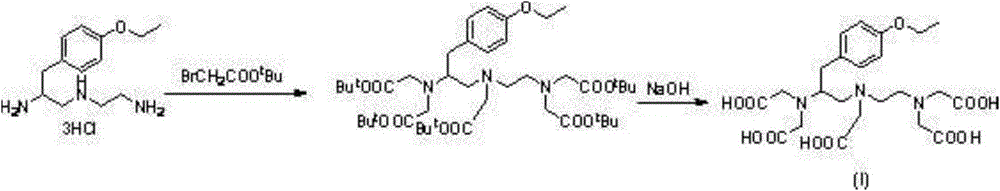

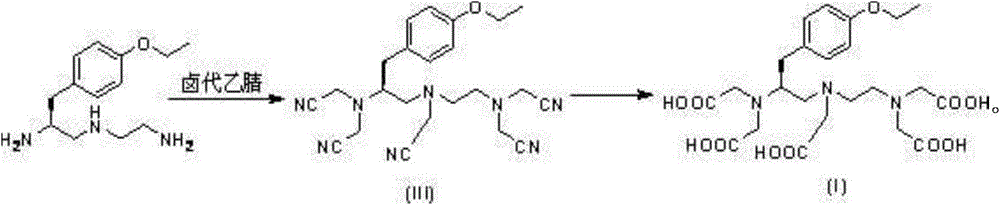

Preparation method of (4S)-3, 6, 9-triaza-3, 6, 9-tri(carboxymethyl)-4-(4-ethoxy benzyl)undecanedioic acid

ActiveCN104130146AFor the purpose of purificationSuitable for industrial productionOrganic compound preparationAmino-carboxyl compound preparationIon exchangeOrganosolv

The invention provides a preparation method of (4S)-3, 6, 9-triaza-3, 6, 9-tri(carboxymethyl)-4-(4-ethoxy benzyl)undecanedioic acid. The method includes: taking (4S)-1-(4-ethoxy benzyl)-3-azapentane-1, 5-diamine or its hydrochloride as the starting material, reacting the starting material with haloacetonitrile under the catalysis of an anhydrous carbonic acid alkali metal salt in an organic solvent to obtain 4S-3, 6, 9-triaza-3, 6, 9-tri(cyanomethyl)-4-(4-ethoxy benzyl)undecanedinitrile solid, using ethyl acetate to perform recrystallization purification on the solid, and directly conducting hydrolysis to obtain (4S)-3, 6, 9-triaza-3, 6, 9-tri(carboxymethyl)-4-(4-ethoxy benzyl)undecanedioic acid. Complicated chromatographic treatment and ion exchange column chromatography purification methods are avoided in the invention. Compared with traditional methods, the method provided by the invention lowers the production cost, is simple to operate, and is suitable for industrialized production.

Owner:安徽昊帆生物有限公司

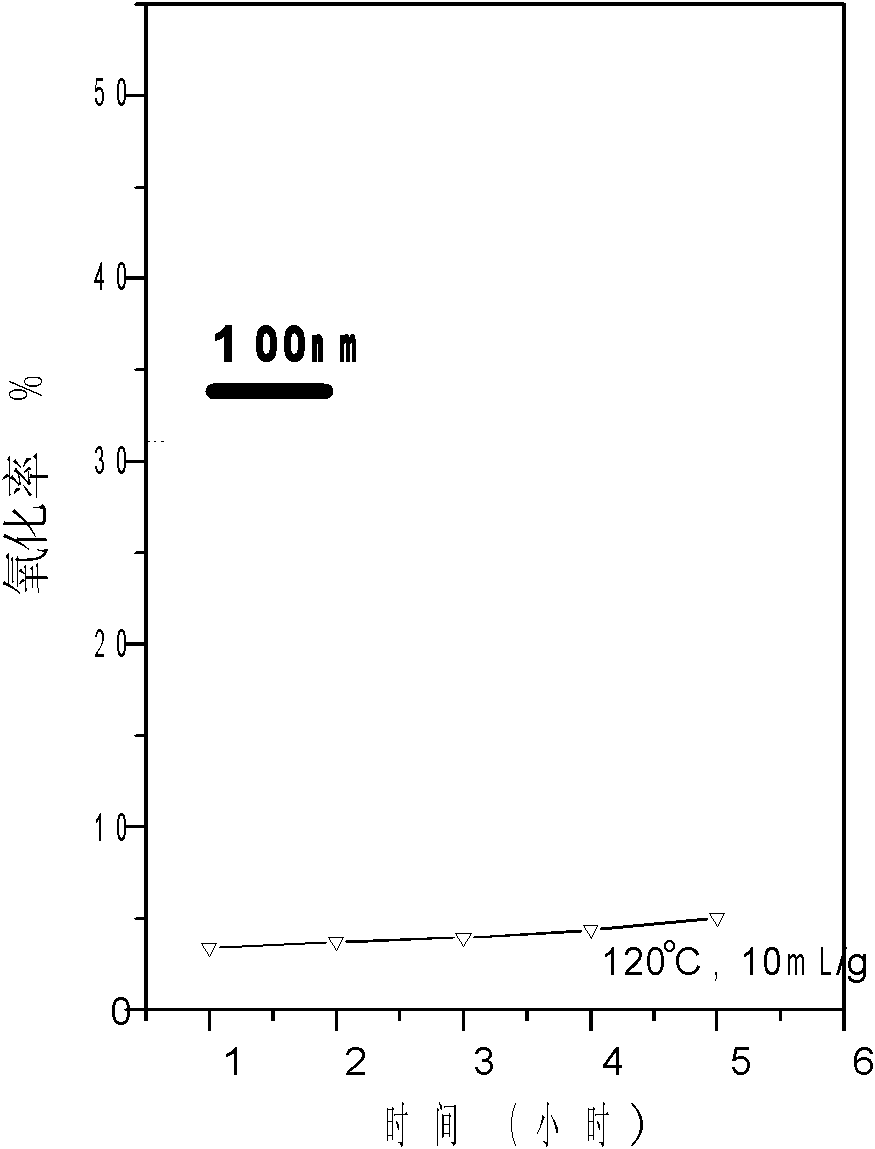

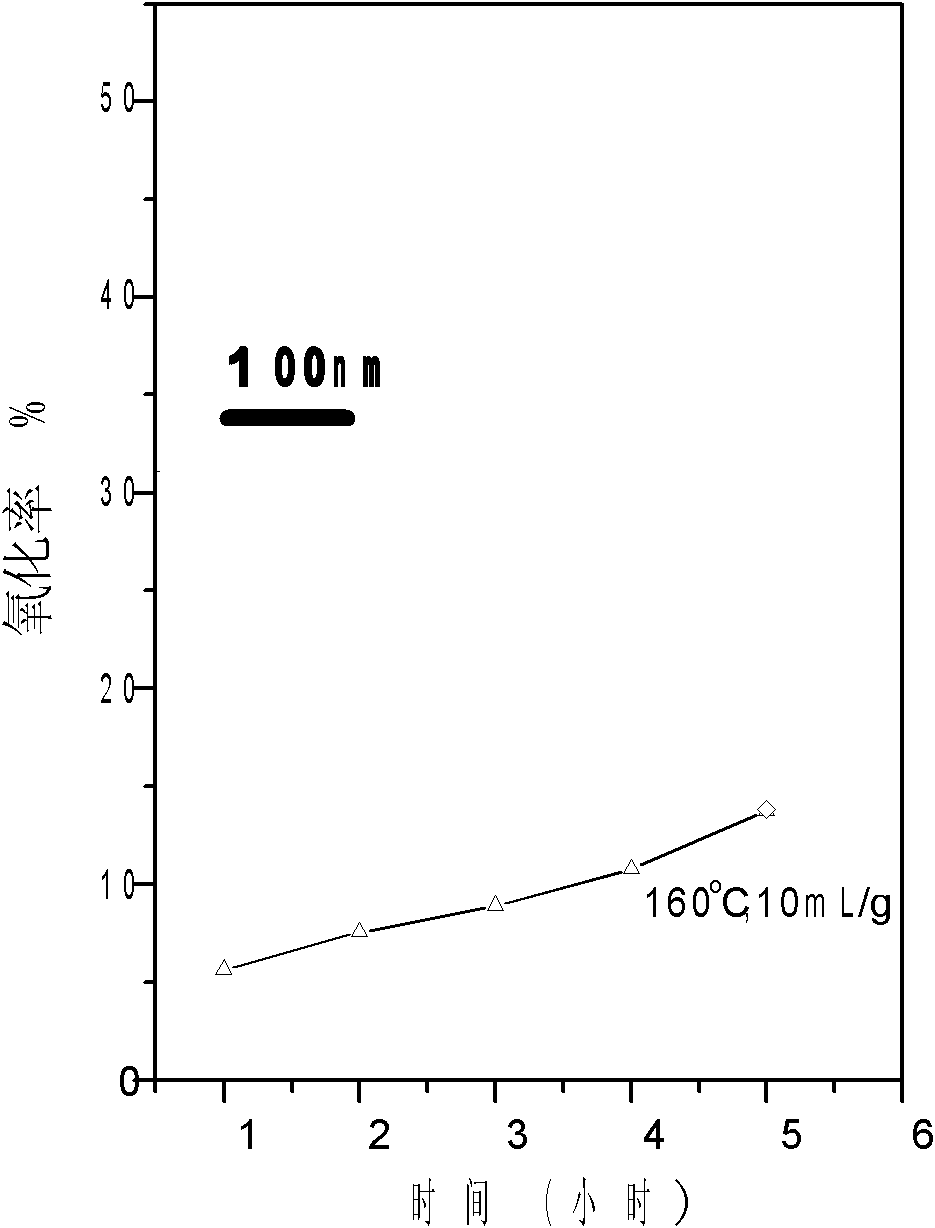

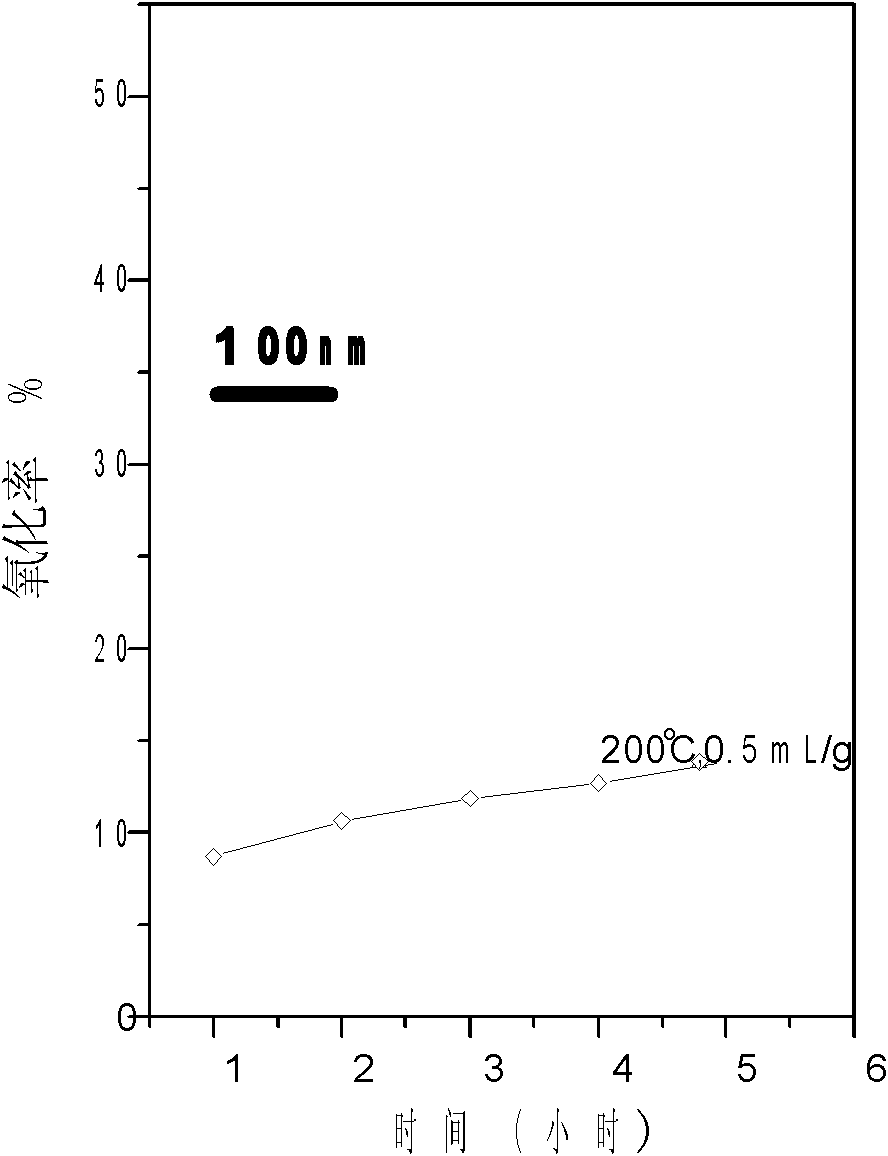

Treatment method for nanometer carbon material

The invention discloses a treatment method for a nanometer carbon material, which includes the reaction of the nanometer carbon material and gaseous oxidant in a closed container at the temperature of 120-200 DEG C, and the gaseous oxidant is hydrochloric acid and / or nitric acid. In the method, the method of the reaction of the gaseous oxidant and the nanometer carbon material is adopted; as existing in a type of gas molecules, the oxidant has higher oxidizability and can fully and rapidly react with impurities on the surface of the nanometer carbon material; and therefore, high-efficient treatment on the nanometer carbon material can be realized and the purpose of purifying the nanometer carbon material can be achieved. Compared with the prior art in which the nanometer carbon material and the oxidant react in liquid phase, the treatment method provided by the invention has the advantage as follows: the suffusion area of the gaseous oxidant adopted in the method is quite larger than that of liquid oxidant, thus being beneficial to the reaction of the nanometer carbon material and the gaseous oxidant and accelerating the purification of the nanometer carbon material. Therefore, the treatment method for the nanometer carbon material can well purify the nanometer carbon material, the usage amount of the oxidant is little, and the reaction time is short.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

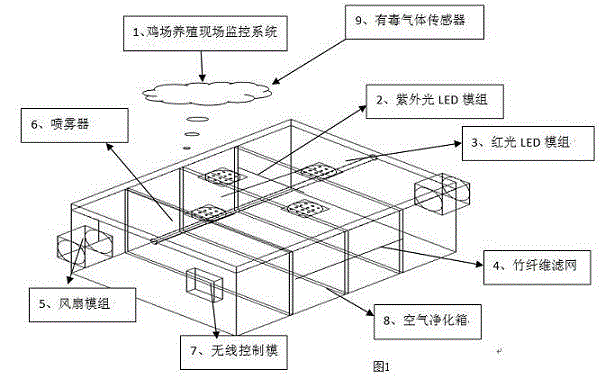

Intelligent photocatalytic air cleaner used in chicken house

InactiveCN104437076AClean air qualityPromote growthDispersed particle filtrationWireless controlResting time

The invention relates to an intelligent photocatalytic air cleaner used in a chicken house. The intelligent photocatalytic air cleaner used in the chicken house is characterized by comprising (1) breeding field monitoring system software for a chicken farm, (2) a 365nm ultraviolet LED lamp set, (3) a 670nm red-light LED lamp set, (4) a bamboo charcoal fiber dust filtrating screen, (5) an air supply and exhaust fan, (6) a sprayer, (7) a wireless control module, (8) an air cleaning tank body and (9) a poisonous gas sensor, wherein the bamboo charcoal fiber dust filtrating screen is coated with a nanometer ITO2 material which is of a core-shell structure. According to the air cleaning mechanism, air in the chicken house is absorbed into the air cleaning tank body through the air supply fan, a sun positioning system of the breeding field monitoring system software for the chicken farm determines the time, the red-light LED lamp set is turned on at the activity time of chickens and the ultraviolet LED lamp set is turned on at the rest time of the chickens to perform photocatalysis on the bamboo charcoal fiber dust filtrating screen and perform redox on poisonous gas, thereby generating negative oxygen ions and achieve the effect of cleaning air.

Owner:SUZHOU KEDA WEILONG INFORMATION TECH

Process for treating and purifying waste sodium sulfate

ActiveCN114408947AMeet quality requirementsHigh purityTreatment involving filtrationWater softeningPhosphate ionPhosphoric acid

The invention provides a process for treating and purifying waste sodium sulfate. The process comprises the following steps: step S11, drying waste sodium sulfate to be treated by hot air, and then carrying out molten salt treatment; step S12, adding the molten salt subjected to the salt melting treatment in the step S11 into water, cooling to form crude brine, adding a flocculating agent into the crude brine, and then performing primary filtration to obtain primary filtrate; step S13, adding a sodium carbonate solution into the primary filtrate obtained in the step S12, performing precipitation in a precipitation tank, and then performing secondary filtration to obtain secondary filtrate; and step S14, adding a dilute sulphuric acid solution into the secondary filtrate obtained in the step S13 for neutralization to obtain a sodium sulfate aqueous solution after primary refining. The content of cations, except sodium ions, potassium ions and chloride ions, harmful to a bipolar membrane electrodialysis membrane in the sodium sulfate aqueous solution treated by the process disclosed by the invention can be reduced to below 1ppm, the content of anions including phosphate ions, silicate ions and other insoluble inorganic matters can be reduced to below 1ppm, and organic matters in the treated saline water are not detected.

Owner:陕西聚泰新材料科技有限公司

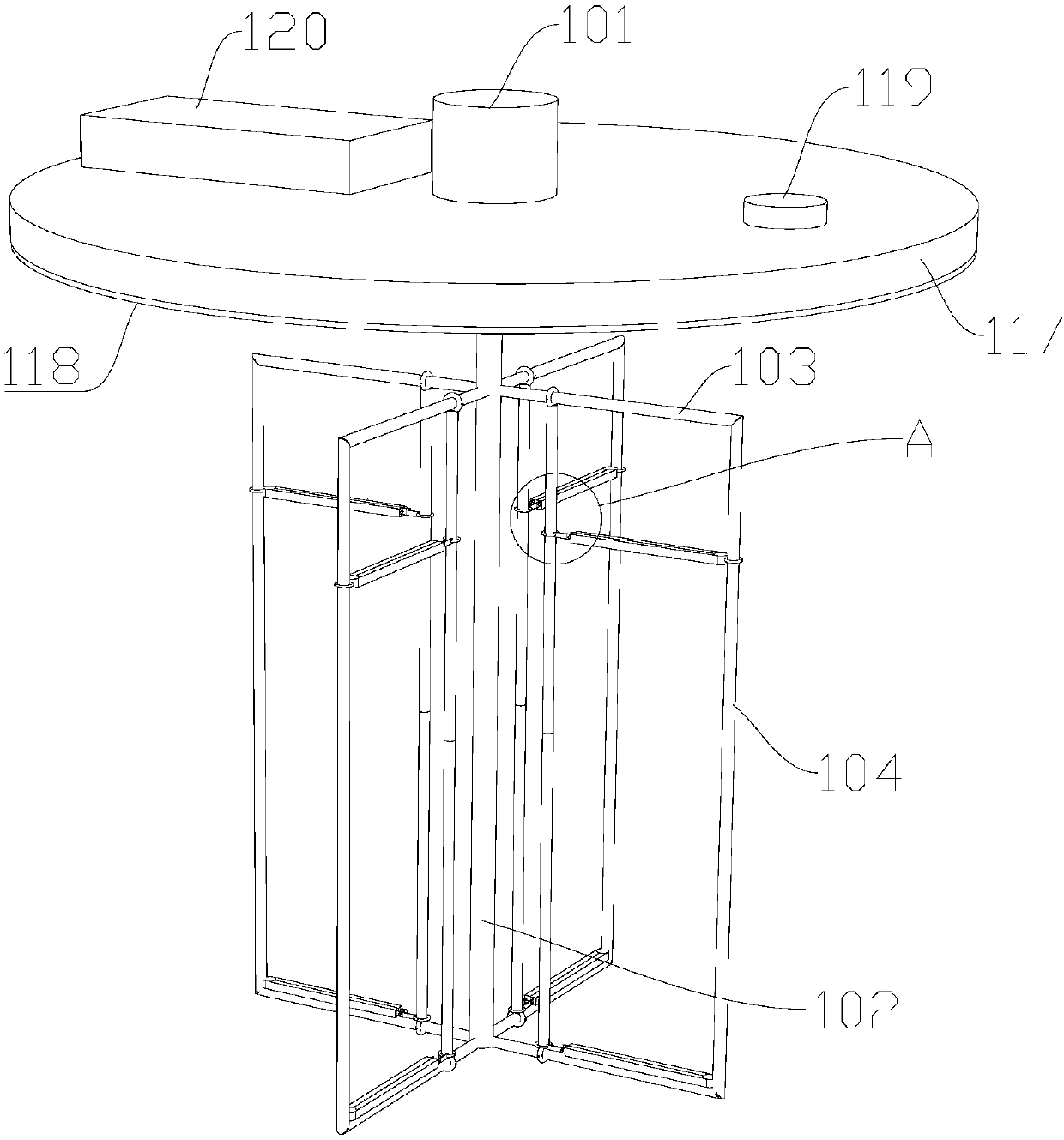

Protein dialysis device and system

PendingCN107857794AFor the purpose of purificationAvoid damagePeptide preparation methodsMagnetic stirrerProtein purification

The invention relates to the technical field of bioexperiment devices, in particular to a protein dialysis device and system. The protein dialysis device comprises a driving device and a dialysis rotating frame, the driving device is used for driving the dialysis rotating frame to rotate, the dialysis rotating frame is used for carrying a dialysis bag and comprises a wheel shaft and wheel leaves,the wheel leaves are mounted on the wheel shaft through wheel spokes which are arranged along the radial direction of the wheel shaft, and the driving device drives the wheel shaft to rotate. The protein dialysis system comprises the protein dialysis device. Sample leakage, mutual winding of multiple dialysis bags and damage to the dialysis bags when a magnetic stirrer is used can be avoided, andexudation of micromolecular protein or other impurities in the dialysis bag can be accelerated to achieve the objective of protein purification.

Owner:天康生物制药有限公司

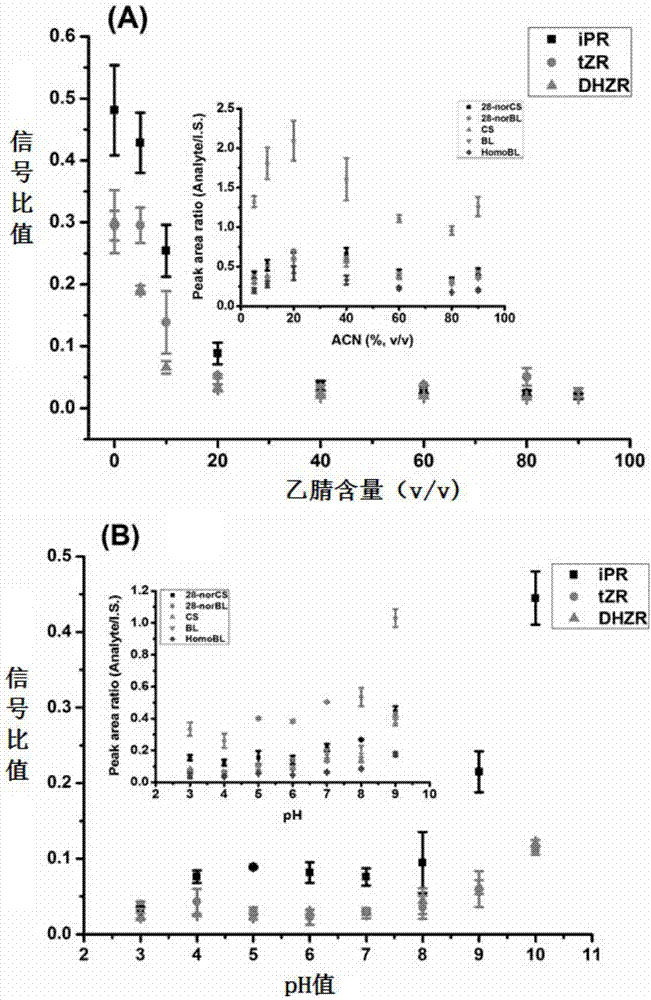

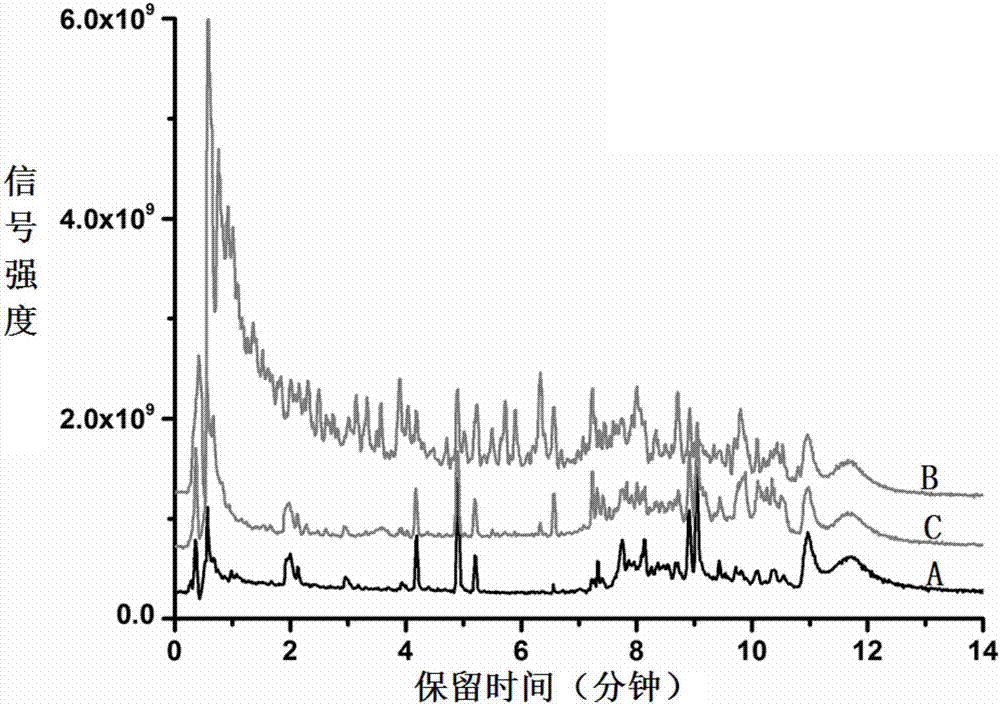

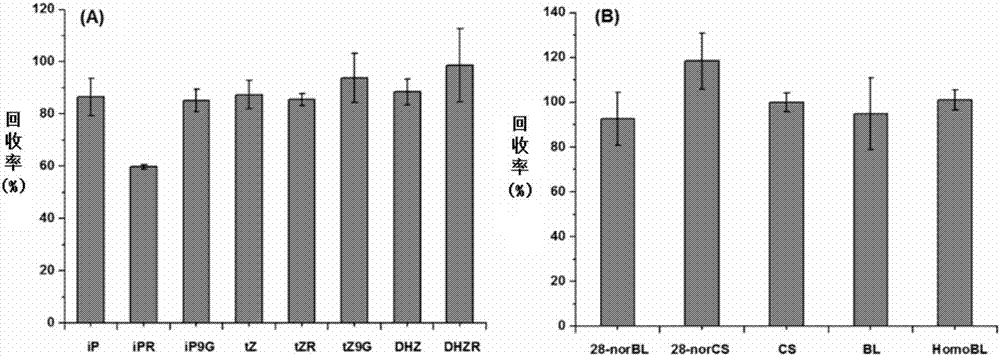

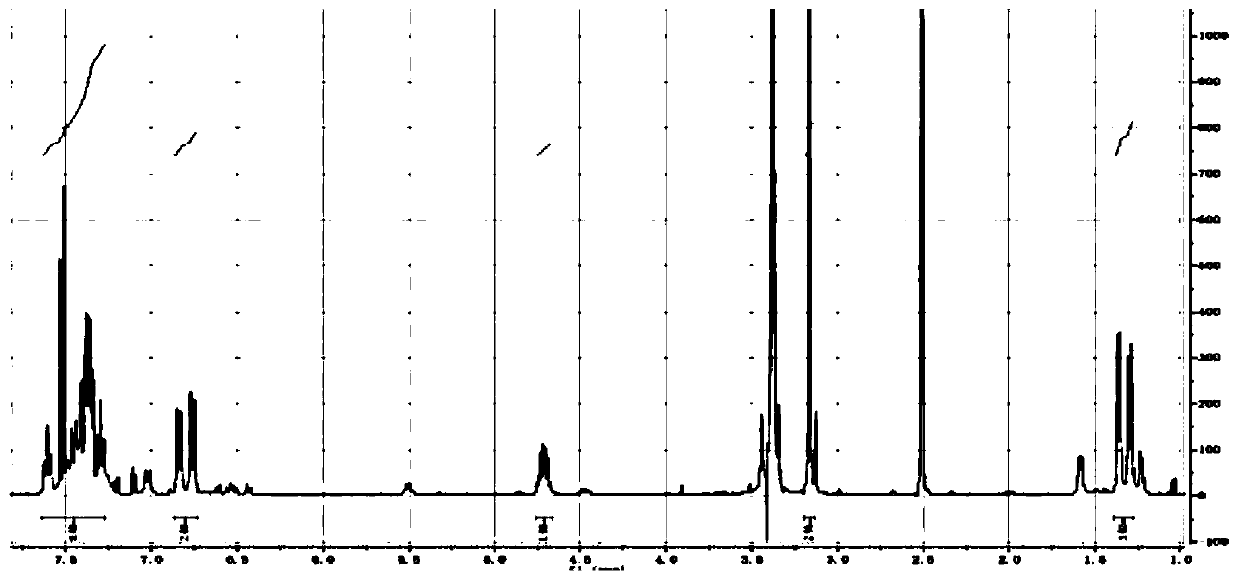

Pre-treatment method and quantitative detection method of three endogenous phytohormones with different chemical properties in plant sample

InactiveCN107543746AImprove accuracyAchieving selective re-enrichmentComponent separationPreparing sample for investigationPlant hormoneIsotope

The invention provides a pre-treatment method and quantitative detection method of three endogenous phytohormones with different chemical properties in a plant sample. The method comprises 1) quantitatively adding isotope internal standards of various endogenous plant hormones into a plant sample and then extracting the sample solution by a solvent, 2) removing impurities in the sample solution through a TiO2 material and a boron affiliative material to obtain a test solution of multiple endogenous phytohormones in the plant sample, and 3) acquiring response data of the test solution of multiple endogenous phytohormones in the plant sample through an analytical instrument and simultaneously and quantitatively detecting multiple endogenous phytohormones in the plant sample through an internal standard method. The method can realize enrichment and purification of three low-content endogenous phytohormones with different chemical properties in a small amount of plant tissue, realize simultaneous quantitative determination and has high accuracy.

Owner:武汉绿剑可瑞信科技有限公司

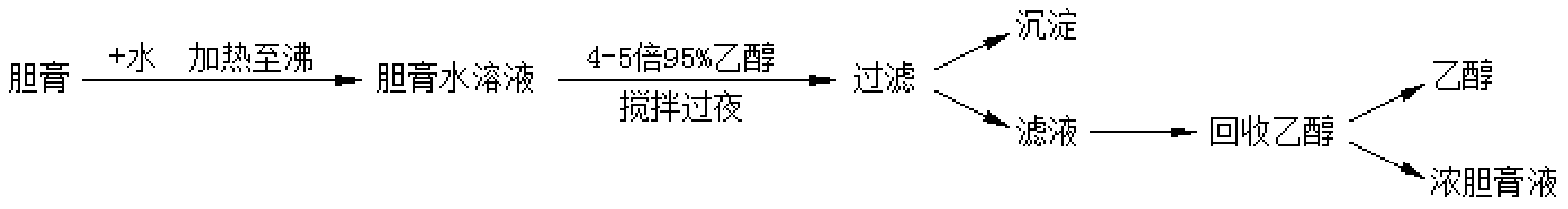

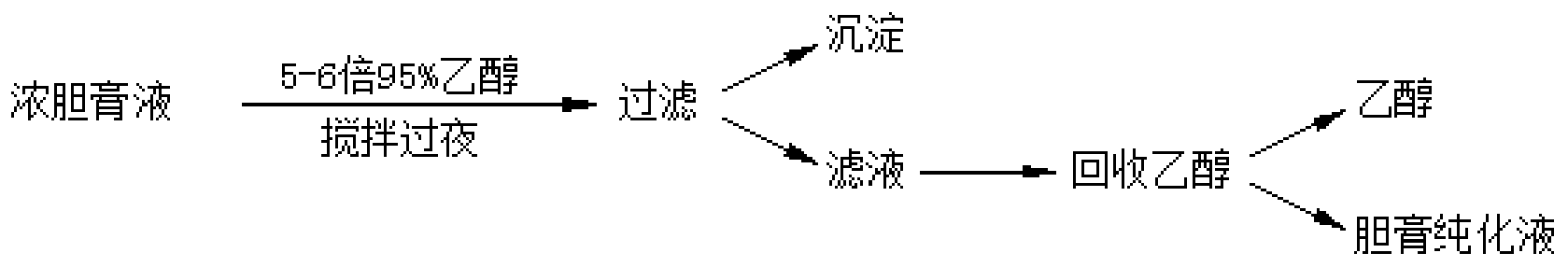

Method for separation and purification of bound total bile acid in bile paste

InactiveCN103214538AGood heat-clearing and fever-reducing effectFor the purpose of purificationSteroidsCholic acidWater soluble

The invention discloses a method for separation and purification of bound total bile in a bile paste. The method is characterized by comprising the following steps of: (1) preparing a bile paste water solution from a raw material bile paste, and cooling; (2) preparing a bound total bile acid precipitate: adding 3-5mol / L diluted acid to the cooled bile paste water solution to regulate pH to 2-5, thus obtaining the bound total bile acid precipitate; and (3) washing the bound total bile acid precipitate, and discarding a washing liquid to obtain high-purity bound total bile acid. The method, on the basis of the researched property of the bound total bile acid which is insoluble in water in an acid environment, achieves the purpose of purification by removing water-soluble impurities through a water washing process, and has the advantages of being low in cost, short in duration, simple in process, high in purity, high in safety and the like, thus being convenient for industrial mass production.

Owner:GUANGXI BDX ANIMAL DRUGS

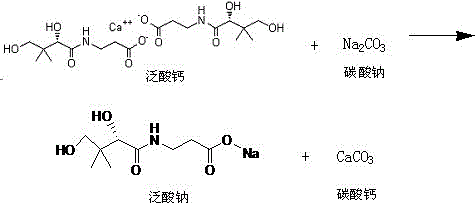

A kind of industrialized preparation method of high-purity sodium pantothenate

ActiveCN104592053BOptimize production process stepsSave man hoursOrganic compound preparationCarboxylic acid amide separation/purificationSolubilityDistillation

The invention discloses an industrial preparation method of high-purity sodium pantothenate. The method comprises the following steps: adding calcium pantothenate into purified water and dissolving to obtain calcium pantothenate solutions; adding sodium carbonate solutions into sodium pantothenate solutions, performing reaction, filtering and collecting filter liquid; adding active carbon into the filter liquid to be filtered and then filtered by a film; concentrating the liquid filtered by the film and adding ethanol; adding concentrated liquid into which ethanol is added into acetone; growing grains and drying to obtain sodium pantothenate. According to the industrial preparation method, high-temperature drying by distillation and multi-time repeated concentration are not needed, so that the working hours are shortened, and the side reaction is reduced; a special crystallizing condition is not needed, so that the problems that ethanol crystals are difficult to dissolve, easy in oil outflow and difficult to separate out are solved; because the process is simple, the working hours can be shortened by 1-2 times, and the production cost can be reduced by more than 50 percent. The used solvent is low in cost, the defects of high solubility of sodium pantothenate in ethanol and low yield are overcome, and the quality and the yield of the product are guaranteed; moreover, the purity of the product reaches 99.8 percent, and the yield is increased to 90 percent; therefore, the method is more suitable for industrial production.

Owner:HEBEI YIPIN PHARMA

Preparation process of granules for protecting liver and promoting bile flow

InactiveCN103446249AHigh content of ingredientsImprove bioavailabilityDigestive systemGranular deliveryHydrocholereticsEngineering

The invention mainly relates to a preparation process of granules for protecting liver and promoting bile flow. The preparation process comprises the following steps of: 1, distilling raw sytingamicrophylla through water vapor; drying; circularly performing sealing and soaking and ultrasonic-assisted extraction twice; performing alcohol precipitation to the obtained sytingamicrophylla extracting solution at low temperature; carrying out pressure-reduced concentration to obtain a sytingamicrophylla extractive concrete to stand by service for later use; and 2, adding starch and dextrin to the sytingamicrophylla extractive concrete obtained in step 1 based on the weight ratio of (1-1.2): (1.5-2.0): (0.5-1.0); preparing a soft material; granulating; and straightening to accomplish the preparation of the granules. The preparation process provided by the invention is mild; the bioavailability is high; the granules for protecting liver and promoting bile flow, prepared by the process, are high in content of pharmaceutical ingredients, show have remarkable, stable and long-term effect, and have no toxic and side effects.

Owner:HENAN UNIV OF SCI & TECH

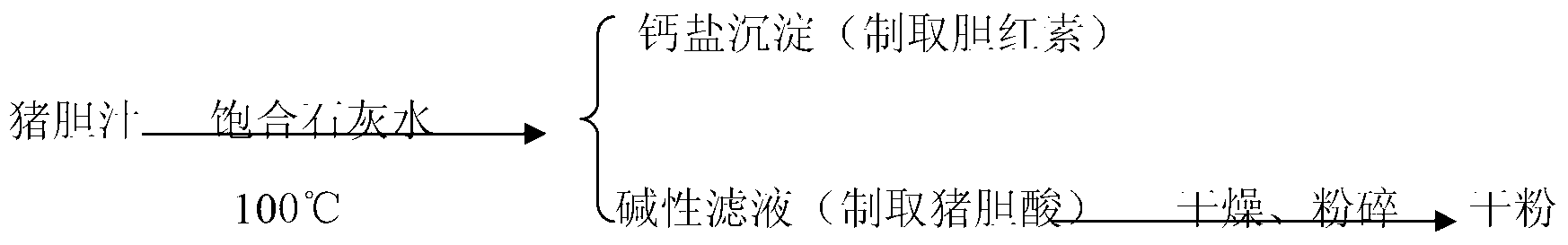

Method for extracting bile acid from bilirubin leftovers

The invention relates to a method for extracting bile acid from bilirubin leftovers. The method comprises the following steps of: adding alkali into leftovers of bile from which bilirubin is completely extracted serving as a raw material for saponifying; adding hydrogen peroxide for decolorizing; and adding an acid for separating and washing. In the invention, the aim of purifying is fulfilled by dissolving impurities such as proteins and fats in bile cream into an alkaline liquor in a high-temperature saponifying way, further removing impurities in a chemical decolorizing way and dissolving and washing out water-soluble impurities in a pH value adjusting way. The method for producing bile acid disclosed by the invention has the advantages of easiness for operating, freeness from toxic and harmful organic solvent, realization of large-scale industrial production, high product purity (bile acid is more than 98 percent), and total yield of over 40 percent.

Owner:娄倩倩 +1

Aqueous two-phase extraction and separation method for flavonoids, saponins and polysaccharides of astragalus

InactiveCN102697839BRapid phase separationHigh recovery rateAntipyreticAnalgesicsDipotassium hydrogen phosphateMedicinal herbs

The invention relates to an aqueous two-phase separation method for total flavonoids, saponins and polysaccharides in astragalus. The method comprises the following steps of smashing an astragalus medicinal material; adding a solvent and performing solid-liquid extraction; filtering and removing impurities to obtain crude extract of the total flavonoids and the saponins of the astragalus; taking and concentrating the crude extract of the astragalus; adding an aqueous two-phase system formed by absolute ethyl alcohol / dipotassium hydrogen phosphate, adding water to make the total amount of the system be a constant value; mixing uniformly and standing, wherein the aqueous two-phase system is divided into an upper phase and a lower phase; taking an ethanol phase which contains a large amount of total flavonoids and saponins of the astragalus out; and concentrating the ethanol phase under a reduced pressure to obtain the extract of the total flavonoids of the astragalus. The method has the beneficial effects that the extraction rate of the total flavonoids and the total saponins of the astragalus; simultaneously the total flavonoids and the total saponins can be separated from the polysaccharides of the astragalus in the crude extract; the used solvent is low in toxicity, favorable to environment friendliness and low in cost; the inactivation or the denaturation of the flavonoids and the saponins of the astragalus cannot be caused; the phase separation time is short; the interfacial tension is low; and residual organic solvent does not exist.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

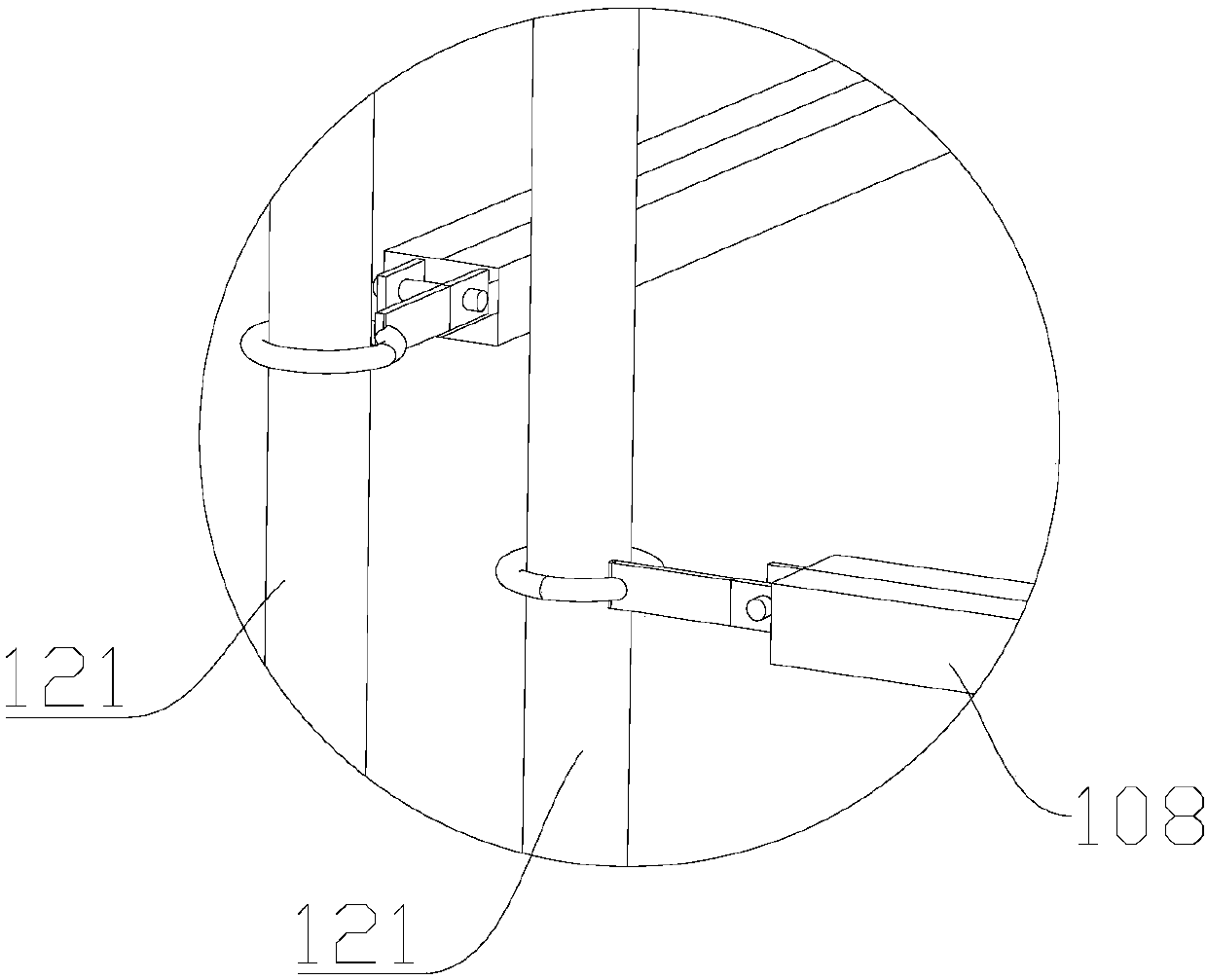

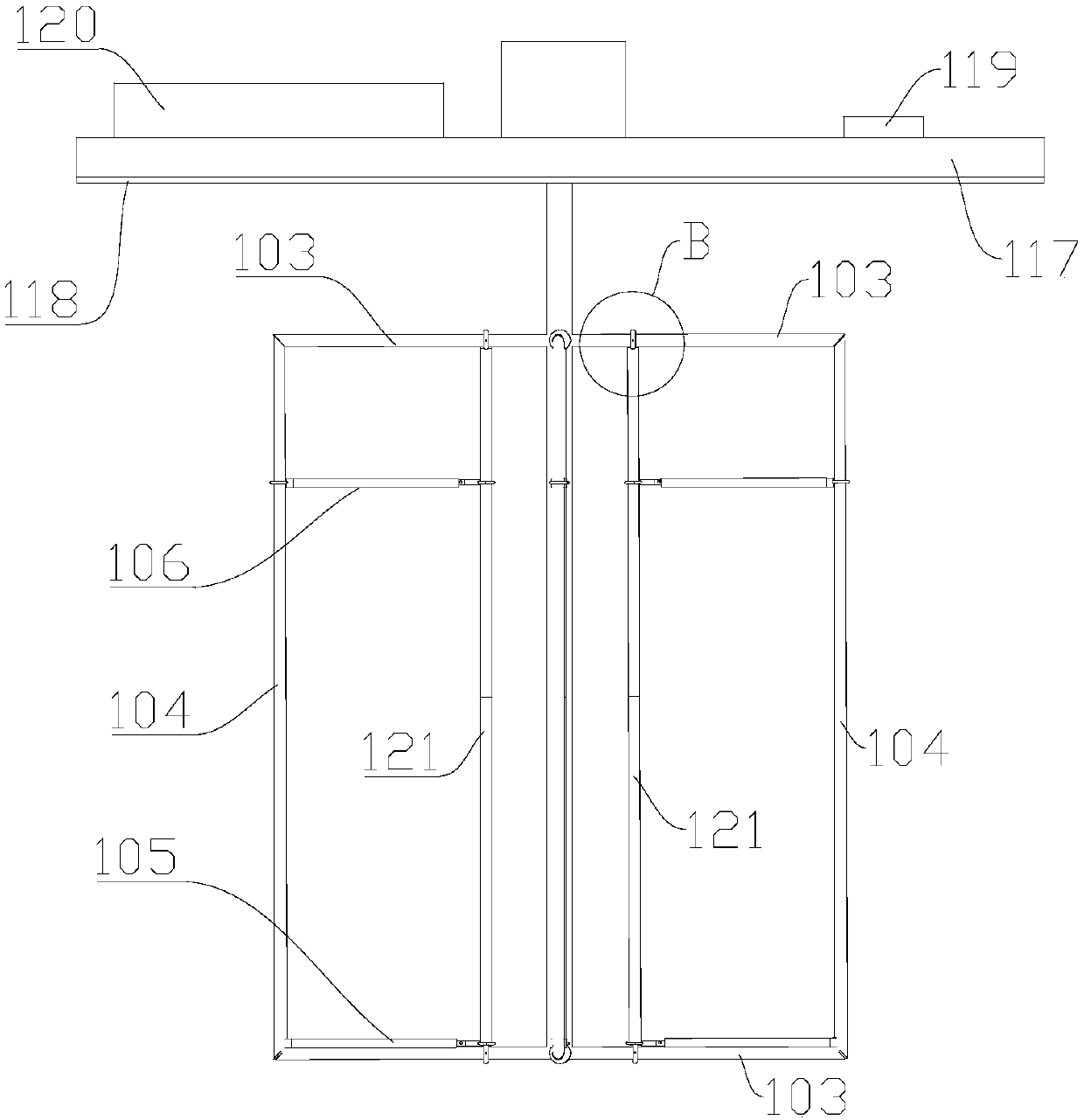

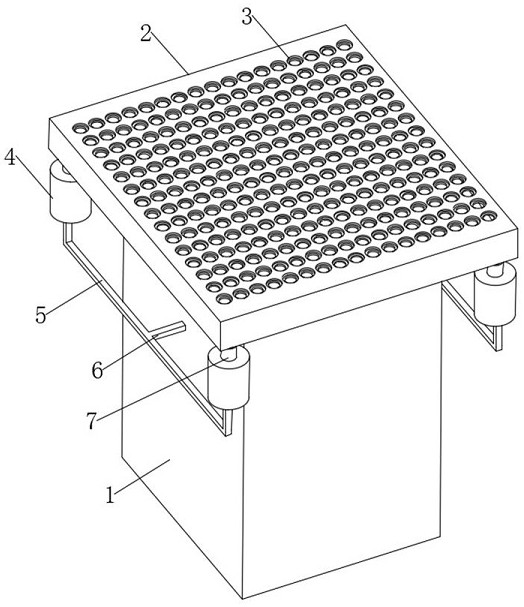

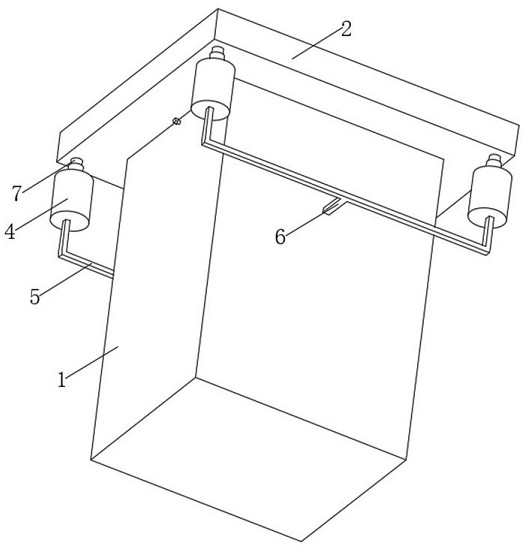

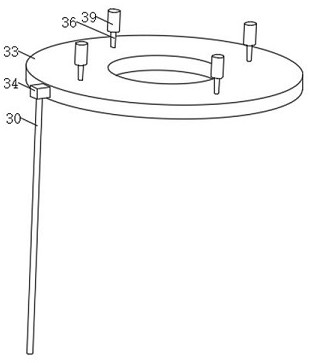

Spot welding device and method for buzzer production based on positioning and clamping

ActiveCN113560704BSolve the phenomenon of inconvenient fixationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesRubber ringSpot welding

The invention discloses a spot welding device and method for buzzer production based on positioning and clamping, and relates to the field of spot welding devices for buzzer production based on positioning and clamping, including a spot welding box, and spot welding is arranged above the spot welding box In order to solve the inconvenient fixing phenomenon in the production and processing of the buzzer, first of all, multiple sets of electronic buzzers are spaced into multiple sets of fixing holes on the spot welding table. When the electronic buzzer is located on the spot welding The rubber ring is elastically deformed by pressing the inclined surfaces in multiple sets of fixing holes on the table. The cross-section of the rubber ring forms an L-shaped clamping state covering the outer ring of the electronic buzzer, and the magnetic suction ring is adsorbed and fixed on the electronic buzzer. The bottom forms an adsorption-type positioning state, so that the electronic buzzer is stably clamped and fixed, and the adsorption-type clamping is fixed, and the structure is stable. At the same time, the adsorption-type clamping and fixing can cover and clamp the elastically deformable rubber ring The exterior of the electronic buzzer further increases the stability of the electronic buzzer.

Owner:常州市福佑电子有限公司

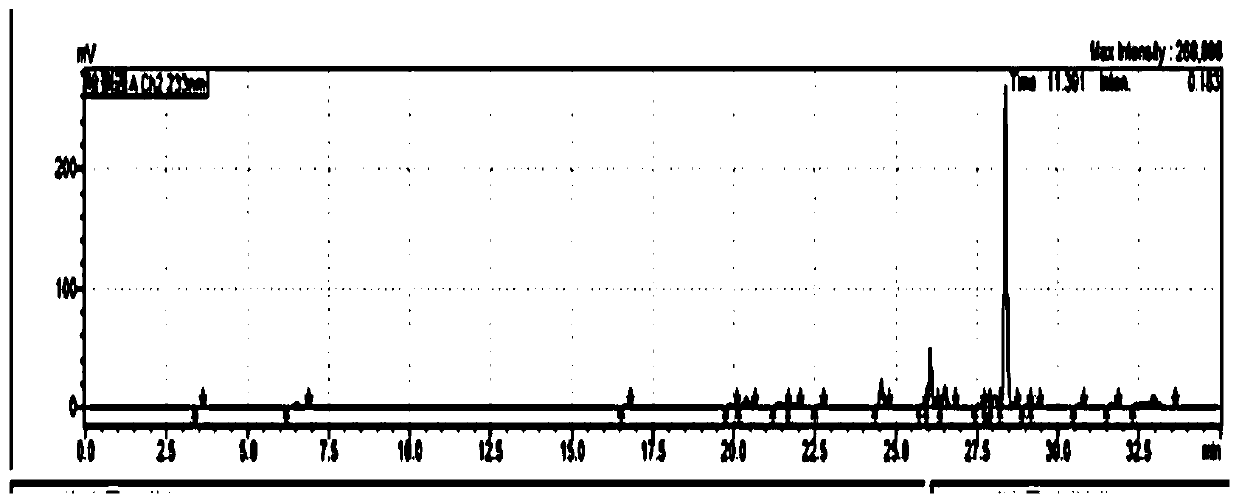

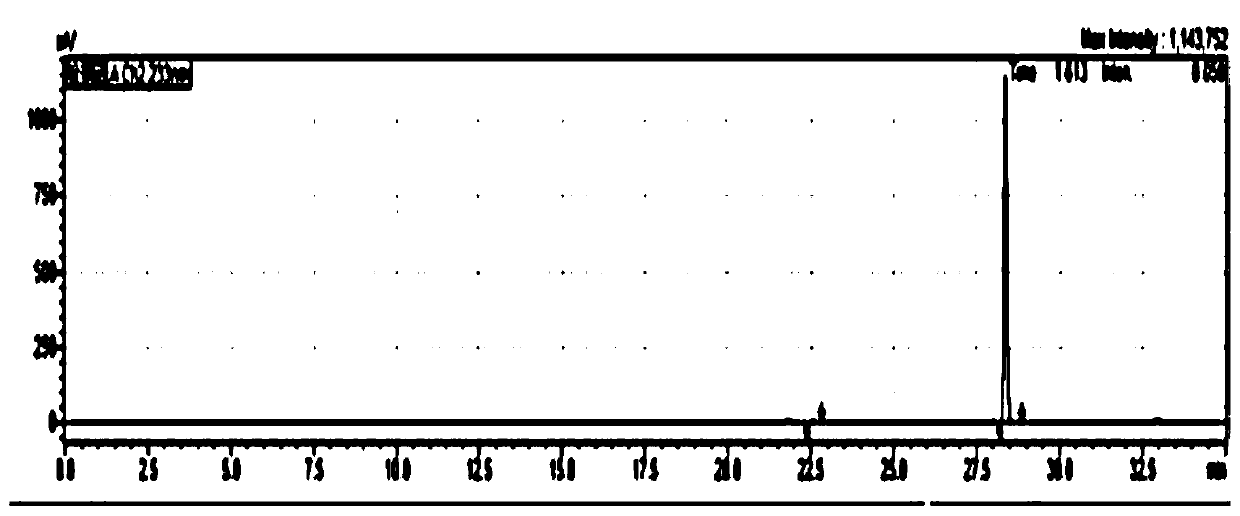

Metamifop crystallization purification method

InactiveCN109824619ARemove impuritiesSave on purification processOrganic chemistrySeed crystalChemistry

The invention discloses a metamifop crystallization purification method which includes the steps: (1) dissolving metamifop crude products in solvents A, increasing temperature to reach 40-90 DEG C andstirring solution for 0.5-2 hours; (2) slowly reducing the system temperature to range from -10 DEG C to 10 DEG C and keeping the temperature for 0-1 hour; (3) adjusting stirring speed to be higher than 30rpm and slowly adding solvents B; (4) adding 0.5%-5% of metamifop seed crystals; (5) continuing slowly adding the solvents B and stirring the solution for 1-5 hours; (6) performing suction filtration, flushing filter cakes by an appropriate quantity of solvents B, drying the filter cakes after flushing, and controlling the temperature of a drying oven to range from 30 DEG C to 60 DEG C to obtain high-content metamifop crystals after drying. The content of the metamifop crystals can reach 99% or more, the method is less in loss, low in cost and suitable for industrial production, and solvent recovery is facilitated.

Owner:ANHUI THERAPY PHARMA CO LTD

Starfish polysaccharide mask and preparing method thereof

InactiveCN106420535AInhibit oxidative hemolysisHigh yieldCosmetic preparationsToilet preparationsAlcoholFreeze-drying

The invention discloses a starfish polysaccharide mask and a preparing method thereof, and aims to solve the problem that an existing mask is uncomfortable for the skin and causes harm to the skin. The preparing method includes the steps that a starfish raw material is selected, pulped, ungreased with an acetone solution and freeze-dried into powder after ungreasing, a NaOH solution is used for extracting crude polysaccharide, ethanol precipitation is carried out after vacuum concentration, and extracts are washed with absolute ethyl alcohol and freeze-dried to obtain light yellow starfish polysaccharide; semen coicis, Chinese honeylocust fruit, ginseng and radix angelicae are selected, and a conventional boiling soaking extracting method is used for preparing traditional Chinese medicine extract liquor; the prepared starfish polysaccharide and the traditional Chinese medicine extract liquor are mixed and homogenized to prepare a mask solution; mask tissue is soaked in the mask solution and packaged in vacuum to prepare the starfish polysaccharide mask. The preparing method is reasonable in process and easy to operate, and large-scale production is easy to realize. The starfish polysaccharide mask prepared through the method is good in moisture preserving effect and whitening effect, non-irritant to the skin, natural, safe and convenient to use.

Owner:SHANDONG HOMEY AQUATIC DEV

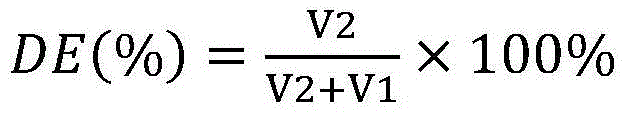

Method for decolouring and purifying pectin

The invention relates to a method for decolouring and purifying pectin. In a pectin production process, alcohol solutions in different concentrations (range of concentration of absolute ethyl alcohol is 100-60%) are used for carrying out alcohol gradient washing on flocculent pectin after alcohol precipitation, so that pigments and impurities which are wrapped and adsorbed in the flocculent pectin are dissolved and desorbed in the alcohol solutions with different surface tensions, purity and whiteness of the pectin after gradient washing can be respectively improved by more than 10.1% and 7.06%, and the aim of purifying the pectin is achieved.

Owner:SHAANXI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com