Method for separation and purification of bound total bile acid in bile paste

A separation, purification, and combination technology, applied in organic chemistry, steroids, etc., can solve the problems of large amount of 95% ethanol, high risk, and long time, and achieve the effect of short purification time, simple equipment, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

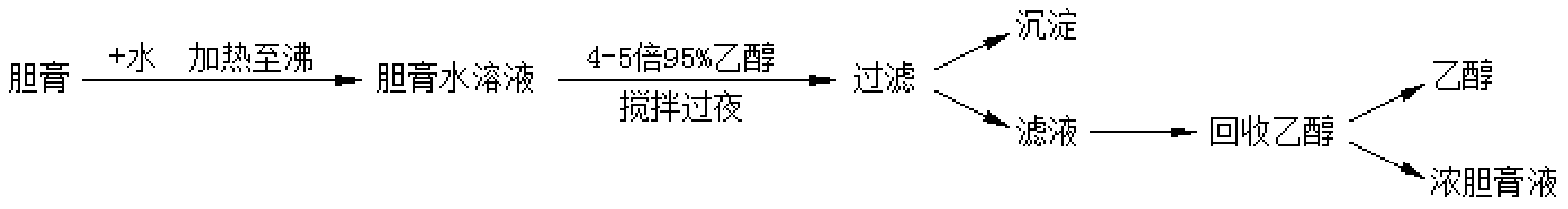

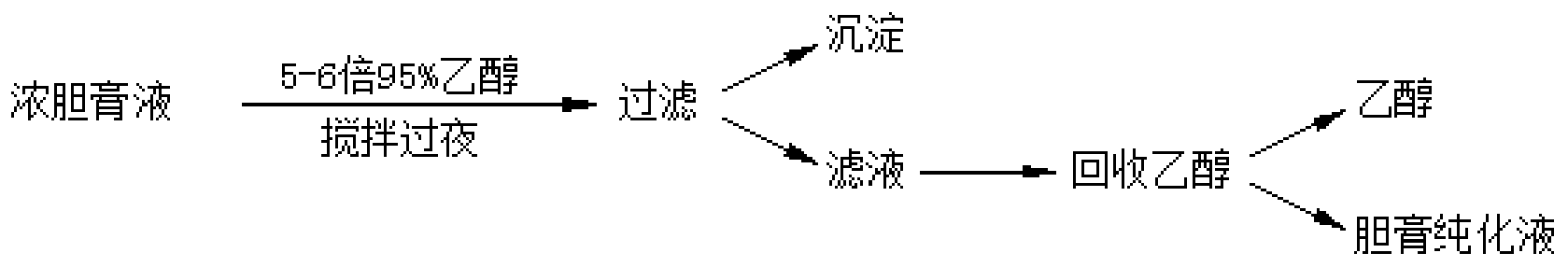

Method used

Image

Examples

Embodiment 1

[0042] A method for separating and purifying bound total cholic acid in gall paste, carried out according to the following steps:

[0043] (1) Take 1kg of pig gall paste, add 5L of tap water, heat to 95°C, stir to dissolve all the pig gall paste, obtain an aqueous solution of gall paste, and cool to 30°C;

[0044] (2) Add 4mol / L hydrochloric acid to the bile paste aqueous solution, adjust the pH to 4.2, and obtain the combined total bile acid precipitation;

[0045] (3) Wash the precipitate 4 times with tap water 4 times the weight of the precipitate and 0.05mol / L dilute hydrochloric acid, and then rinse 2 times with water for injection; the weight of combined total cholic acid after washing is 0.65kg

[0046] (4) Add 8 times the amount of water for injection and 10% dilute alkali solution to the precipitate, heat to dissolve the precipitate, the pH of the solution is 7.3, cool to room temperature, and filter with filter aid.

[0047] The filtered gall paste purified liquid c...

Embodiment 2

[0049] A method for separating and purifying bound total cholic acid in gall paste, carried out according to the following steps:

[0050] (1) Take 3kg of pig gall paste, add 12L of tap water, heat to 100°C, stir to dissolve all the paste, and obtain an aqueous solution of gall paste, cool to 25°C;

[0051] (2) Add 3mol / L hydrochloric acid to the bile paste aqueous solution, adjust the pH to 2, and obtain the combined total bile acid precipitation;

[0052] (3) Wash the precipitate 4 times with tap water 5 times the weight of the total bile acid precipitate and 0.08mol / L hydrochloric acid, and then rinse once with water for injection; the weight of the combined total cholic acid obtained is 2.28kg.

[0053] (4) Add 5 times the amount of water for injection and 15% dilute alkali solution to the precipitate, heat to dissolve the precipitate, the pH of the solution is 7.0, cool to room temperature, and filter with filter aid.

[0054] The filtered gall paste purified liquid can ...

Embodiment 3

[0056] A method for separating and purifying bound total cholic acid in gall paste, carried out according to the following steps:

[0057] (1) Take 2kg of ox gall paste, add 10L of tap water, heat to 90°C, stir to dissolve all the ox gall paste, and obtain an aqueous solution of biliary paste, cool to 20°C;

[0058] (2) Add 5 mol / L hydrochloric acid to the bile paste aqueous solution, adjust the pH to 3, and obtain the combined total bile acid precipitation;

[0059] (3) Use tap water five times the weight of the total bile acid precipitate and 0.02mol / L hydrochloric acid to wash the precipitate five times, and then rinse it twice with water for injection; the weight of the combined total bile acid obtained is 1.26kg.

[0060] (4) Add 9 times the amount of water for injection and 15% dilute alkali solution to the precipitate, the pH of the solution is 7.2, heat to dissolve the precipitate, cool to room temperature, add filter aid to filter.

[0061] The filtered gall paste pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com