Method for decolouring and purifying pectin

A technology for decolorization and impurity removal and pectin, which is applied in the field of pectin decolorization and impurity removal, can solve the problems of reduced pectin extraction rate, long cycle period, complex process, etc., and achieve the effect of facilitating industrial production, reducing production cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

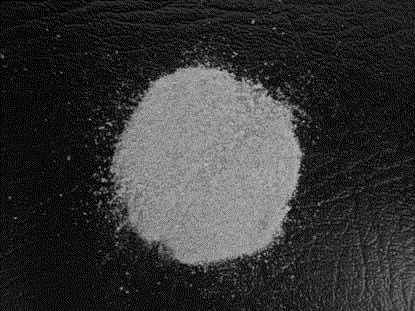

[0023] Embodiment one (see figure 2 ):

[0024] Take the concentrated and alcohol-precipitated flocculent sweet potato pectin, and obtain the flocculent pectin sample after suction filtration (ultimate vacuum degree 0.098Mpa), and add gradients of absolute ethanol, 90% alcohol, 80% alcohol washing solution, alcohol gradient washing is carried out in the order of concentration from high to low. The specific operation is as follows:

[0025] (1) Take the flocculent pectin after alcohol precipitation, add absolute ethanol to the flocculent pectin obtained after suction filtration (ultimate vacuum degree 0.098Mpa), and stir at a speed of 20r / min After 0.5h, flocculent pectin 1 was obtained by suction filtration (ultimate vacuum degree 0.098Mpa);

[0026] (2) Add flocculent pectin 1 obtained in (1), then add 90% alcohol according to the ratio of material to liquid of 1:10, stir at a speed of 20r / min for 0.5h, and then obtain floc pectin 2;

[0027] (3) Add 80% alcohol to the ...

Embodiment 2

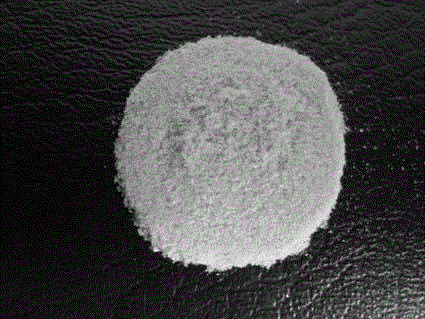

[0029] Example 2 (see image 3 ):

[0030] Take the concentrated and alcohol-precipitated flocculent sweet potato pectin, and filter the flocculent pectin sample obtained after suction filtration (ultimate vacuum degree 0.098Mpa), add a gradient of absolute ethanol, 90% alcohol, , 80% alcohol, 70% alcohol, and 60% alcohol washing solution, and carry out alcohol gradient washing in order of concentration from high to low. The specific operation is as follows:

[0031] (1) Take the flocculent pectin after alcohol precipitation, add absolute ethanol to the flocculent pectin obtained after suction filtration (ultimate vacuum degree 0.098Mpa), and stir at a speed of 20r / min After 0.5h, flocculent pectin 1 was obtained by suction filtration (ultimate vacuum degree 0.098Mpa);

[0032] (2) Add flocculent pectin 1 obtained in (1), then add 90% alcohol according to the ratio of solid to liquid of 1:20, stir at a speed of 20r / min for 0.5h, and then obtain floc pectin 2;

[0033] (3)...

Embodiment 3

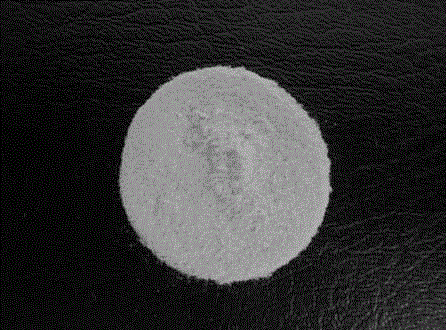

[0037] Embodiment three (see Figure 5 )

[0038] Take the concentrated and alcohol-precipitated flocculent orange peel pectin, and filter the flocculent pectin sample obtained after suction filtration (ultimate vacuum degree 0.098Mpa), add a gradient of absolute ethanol, 90% Alcohol, 80% alcohol, 70% alcohol washing solution, alcohol gradient washing in order of concentration from high to low. The specific operation is as follows:

[0039] (1) Take the flocculent pectin after alcohol precipitation, add absolute ethanol to the flocculent pectin obtained after suction filtration (ultimate vacuum degree 0.098Mpa), and stir at a speed of 20r / min After 0.5h, flocculent pectin 1 was obtained by suction filtration (ultimate vacuum degree 0.098Mpa);

[0040] (2) Add flocculent pectin 1 obtained in (1), then add 90% alcohol according to the ratio of solid to liquid of 1:15, stir at a speed of 20r / min for 0.5h, and then obtain floc pectin 2;

[0041] (3) Add 80% alcohol to the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com