Metamifop crystallization purification method

A technology of fenpyramid and purification method, which is applied in the field of chemical raw materials, can solve the problems of high energy consumption, high cost, and large product loss, and achieve the effects of saving purification process, removing impurities, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

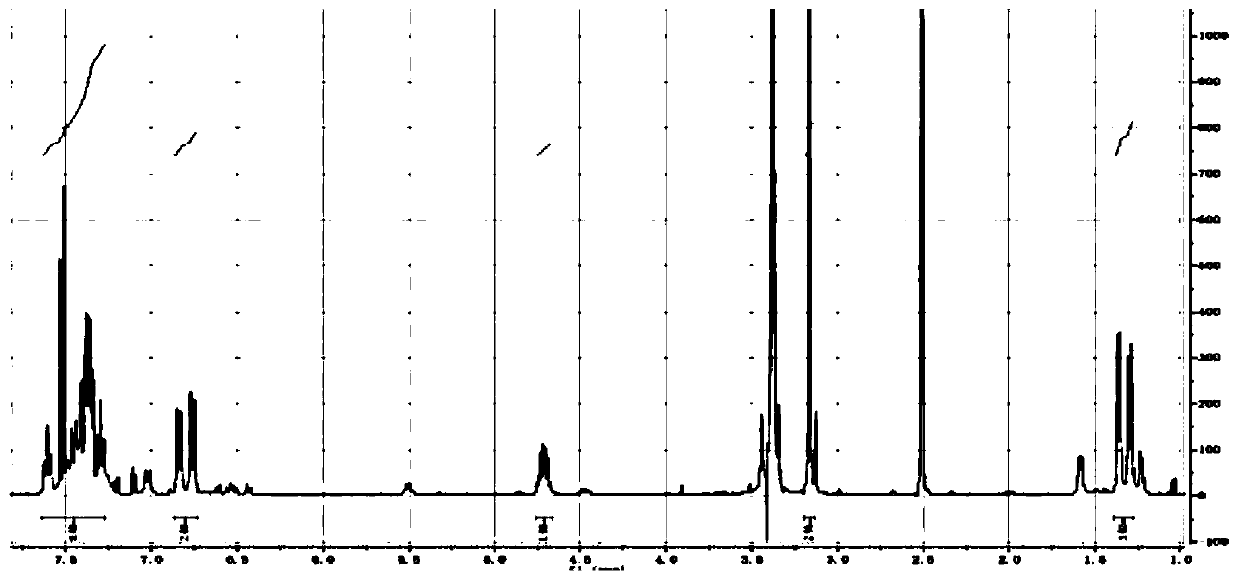

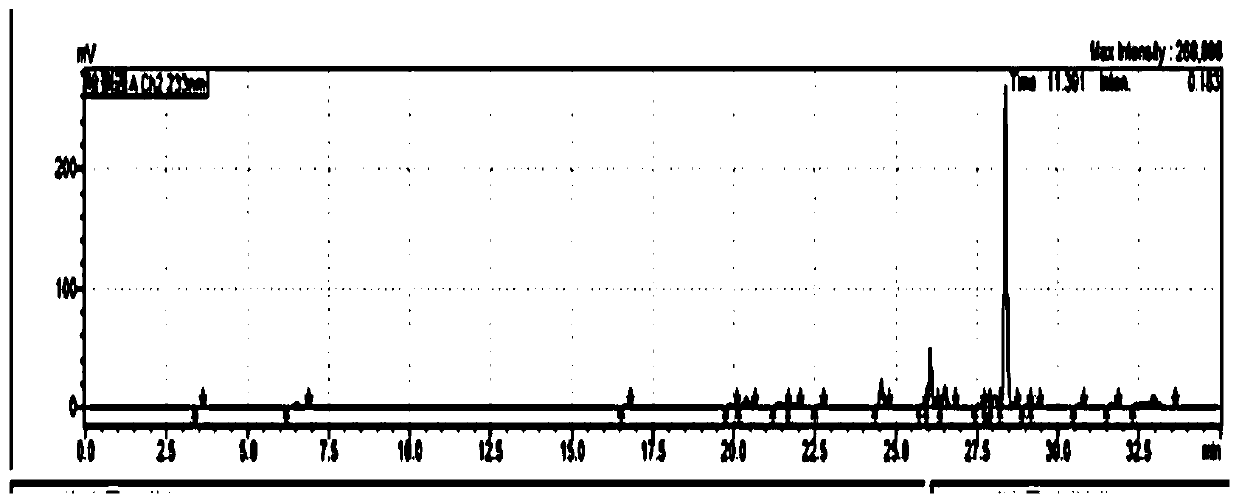

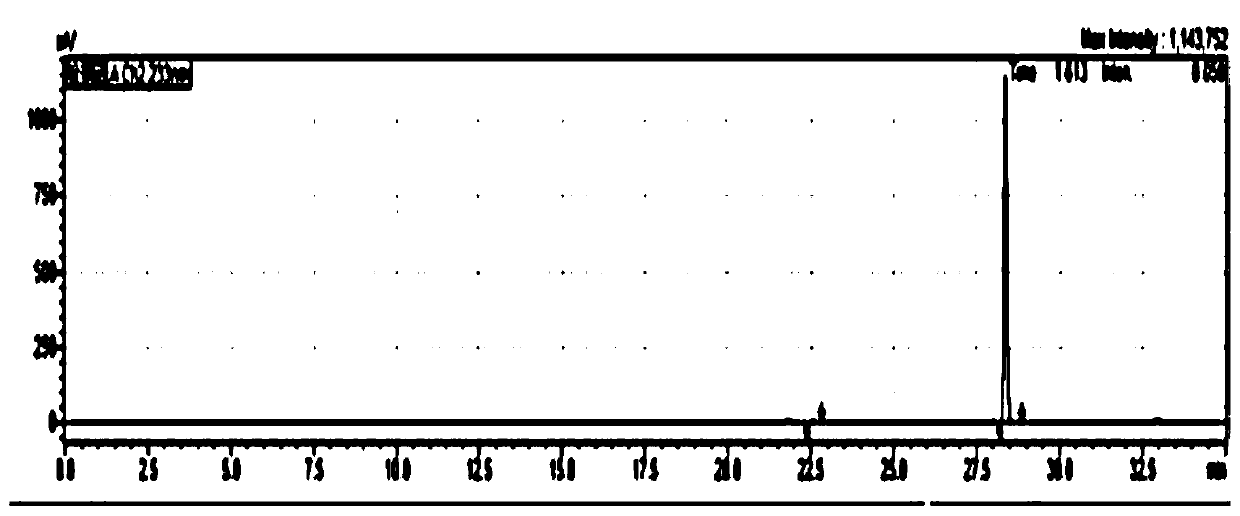

Embodiment 1

[0035] Add 120g of the crude product of fenpyramid (content 79.6%) to a 1000mL reactor, then add 360g of isopropanol, heat and stir, the temperature of the material is controlled at 80°C, stir for 1.5h to dissolve it, and after dissolving, dissolve it at 0.5°C Slowly stir at a cooling rate of / min to -5°C, keep warm for 1h, adjust the stirring speed to 45rpm, and slowly add 72g of water into the system at a uniform speed, and the adding time should be longer than 1h. g of fenpyramid seed crystals, and then stirred for 0.5h, then continued to slowly add 144g of water to the reaction kettle at a uniform speed for 3h, after the addition, stirred for 3h, filtered, and the filter cake was rinsed twice with 72g of water, and placed Dry in an oven at 50°C to obtain fenpyramid as a powdery solid. The purity is 99.57%, the content is 99.37%, and the crystallization yield is 98.67%. 1HNMR (400MHz, dmso-d6) δ7.624-7.279(m,9H),6.858–6.737(m,2H),4.752–4.674(m,1H),3.167(s,3H),1.368–1.274(m...

Embodiment 2

[0041] Add 120g of the crude product of fenpyramid (content 79.6%) to a 1000mL reaction kettle, then add 460g of ethanol, heat and stir, control the temperature of the material at 50-70°C, stir for 1.5h to dissolve it, after dissolving, heat it at 0.5°C Slowly stir at a cooling rate of / min to -3°C, keep warm for 1h, adjust the stirring speed to 45rpm, and slowly add 72g of water into the system at a uniform speed, and the adding time should be longer than 1h. g of fenpyramid seed crystals, and then stirred for 0.5h, then continued to slowly add 144g of water to the reaction kettle at a uniform speed for 3h, after the addition, stirred for 3h, filtered, and the filter cake was rinsed twice with 72g of water, and placed Dry in an oven at 45°C to obtain fenpyramid as a powdery solid. The purity is 99.13%, the content is 99.26%, and the crystallization yield is 95.37%.

Embodiment 3

[0043]Add 120g of fenpyramid crude product (content 79.6%) to a 1000mL reaction kettle, then add 360g of methanol, heat and stir, control the temperature of the material at 50-60°C, stir for 1.5h to dissolve it, after dissolving, heat it at 0.5°C Slowly stir and cool down to -5°C at a cooling rate of / min, keep warm for 1h, adjust the stirring speed to 45rpm, and slowly add 72g of water into the system at a uniform speed. The adding time should be longer than 1h. g of fenpyramid seed crystals, and then stirred for 0.5h, then continued to slowly add 144g of water to the reaction kettle at a constant speed for 3h, after the addition, stirred for 3h, filtered, and the filter cake was rinsed twice with 72g of water, and placed Dry in an oven at 55°C to obtain fenpyramid as a powdery solid. The purity is 99.42%, the content is 99.35%, and the crystallization yield is 97.34%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com