Process for treating and purifying waste sodium sulfate

A technology of waste sodium sulfate and process, which is applied in filtration treatment, alkali metal sulfite/sulfate purification, water/sewage treatment and other directions, can solve the problem of insufficient purity of waste sodium sulfate treatment products, and can meet the quality requirements and purity. High, reduced energy consumption and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

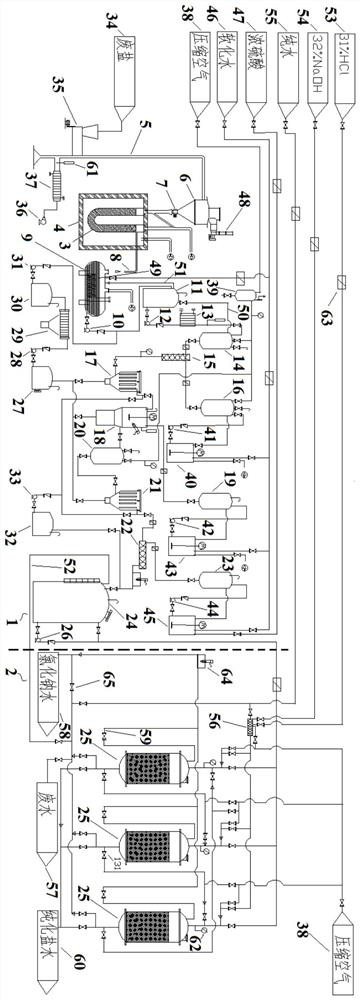

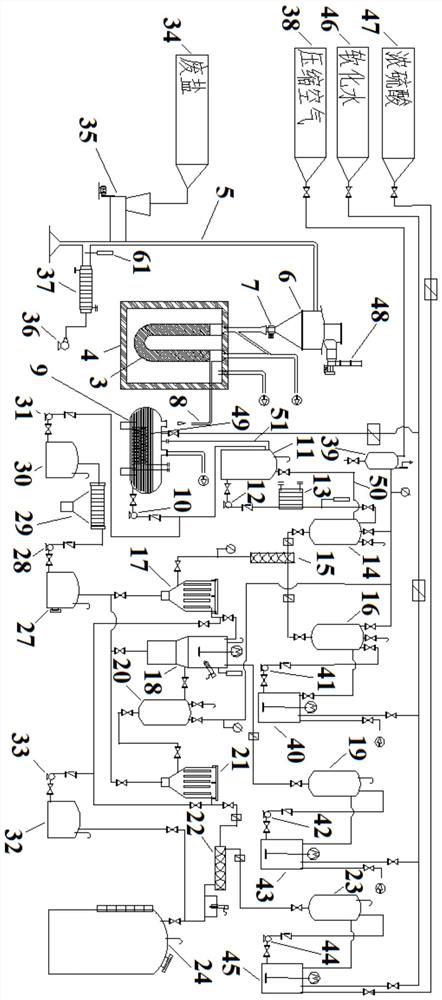

[0060] This embodiment provides a kind of waste sodium sulfate treatment and purification with a refining device, such as figure 2 As shown, it includes a U-shaped molten salt furnace 3, a molten salt furnace kiln 4 is arranged outside the U-shaped molten salt furnace 3, and the feeding end of the U-shaped molten salt furnace 3 is connected in sequence through an airflow drying conveyor 5, a high-level silo 6 and the star feeder 7 transport the waste sodium sulfate to be treated, and the discharge end of the U-shaped molten salt furnace 3 is connected with a molten salt discharge pipeline 8;

[0061] The outlet of the molten salt discharge pipeline 8 delivers molten salt to the molten salt inlet of the cooling water tank 9; the discharge port of the cooling water tank 9 is connected to the crude brine storage tank 11 through the first feeding pump 10 to deliver crude brine, The crude brine storage tank 11 is connected to the crude brine high-level tank 14 through the second f...

Embodiment 2

[0073] This embodiment provides a kind of waste sodium sulfate treatment and purification system, such as Figure 1 to Figure 3 As shown, it includes a primary refining device 1 and a secondary refining device 2;

[0074] The primary refining device 1 adopts the primary refining device for waste sodium sulfate treatment and purification provided in Example 1.

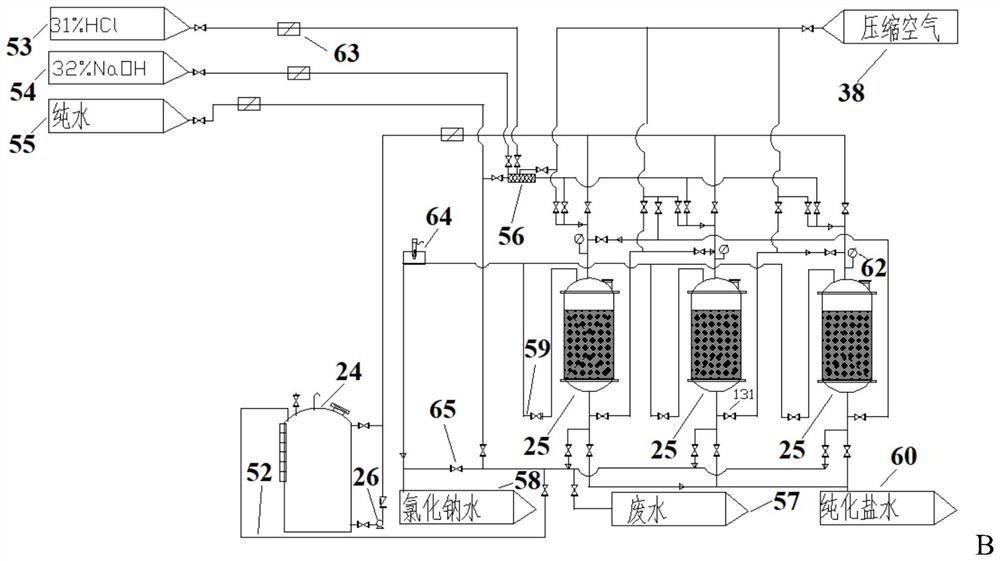

[0075] The secondary refining unit 2 includes a plurality of resin exchange towers 25 which are mutually connected and independently arranged, and the primary refined brine storage tank 24 is independently connected to the liquid inlet at the top of each resin exchange tower 25 by the third feed pump 26 , the liquid outlet at the bottom of each resin exchange tower 25 is independently connected to the purified sodium sulfate solution pipeline 60.

[0076] As a preferred solution of this embodiment, multiple resin exchange towers 25 that can be connected to each other and independently set up are set in an operation mod...

Embodiment 3

[0110]This embodiment provides a kind of waste sodium sulfate treatment and purification process, and this process includes primary refining process and secondary refining process, and this process adopts the waste sodium sulfate treatment and purification system that provides in embodiment 2, and this system includes primary refining device 1 And the secondary refining device 2, the primary refining device 1 is used to realize the primary refining process, and the secondary refining device 2 is used to realize the secondary refining process.

[0111] The primary refining process is:

[0112] Step S11, performing molten salt treatment after the waste sodium sulfate to be treated is dried by hot air;

[0113] In step S11, the temperature of hot air drying is 80-100°C;

[0114] In step S11, the temperature of molten salt treatment is 884-900°C;

[0115] Step S12, adding the molten salt treated with molten salt in step S11 into water to cool to form crude brine, adding a floccu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com