Method for desalting purification of polymer product in polyphenylene sulfide production

A polyphenylene sulfide and polymer technology, which is applied in the field of demineralization and purification of polymer products, can solve the problems of poor product quality stability, complicated procedures and high production costs, and achieves the promotion of mutual movement, efficient dehydration and desalination, and reduction of inorganic salts. The effect of the content of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

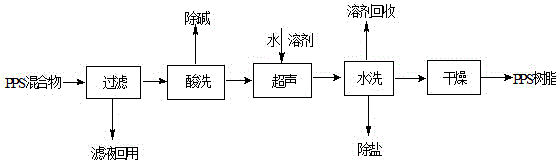

Method used

Image

Examples

Embodiment 1

[0025] Weigh 6g of PPS mixture, filter it while it is hot at 100°C, wash the filter cake once with hydrochloric acid, then add 60g of mixed solvent of N-methylpyrrolidone and water, at a temperature of 60°C, power 280W, ultrasonic frequency 25kHz Ultrasonic cleaning was performed in an ultrasonic cleaner for 1 hour, the solvent was flashed, the filtrate was washed once with deionized water, and dried to obtain a high-purity polyphenylene sulfide product. The solvent recovery rate during the above treatment was 90%, and the salt content of the purified polymer was determined to be 0.07%.

Embodiment 2

[0027] Weigh 6g of the PPS mixture, filter it while it is hot at 105°C, wash the filter cake twice with hydrochloric acid, then add 72g of a mixed solvent of N-methylpyrrolidone, N,N-dimethylacetamide and water. 80 ℃, power 280W, ultrasonic frequency 25kHz ultrasonic cleaning time 2h in the ultrasonic cleaner, flash solvent, the filtrate was washed twice with deionized water, and dried to obtain high-purity polyphenylene sulfide products. The solvent recovery rate in the above treatment process was 93%, and the salt content of the purified polymer was determined to be 0.06%.

Embodiment 3

[0029] Weigh 6g of PPS mixture, filter it while it is hot at 110°C, wash the filter cake with hydrochloric acid three times, then add 90g of mixed solvent of N-methylpyrrolidone, acetone and water, at a temperature of 90°C, power 280W, ultrasonic frequency Ultrasonic cleaning was performed in an ultrasonic cleaner at 25 kHz for 3 hours, the solvent was flashed, the filtrate was washed with deionized water three times, and dried to obtain a high-purity polyphenylene sulfide product. The solvent recovery rate in the above treatment process was 95%, and the salt content of the purified polymer was determined to be 0.03%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com