Treatment method for nanometer carbon material

A nano carbon material and processing method technology, applied in the field of nano materials, can solve the problems of large amount of oxidant, long reaction time, unsuitable for mass production, etc., and achieve the effect of less amount of oxidant, short reaction time and good purification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

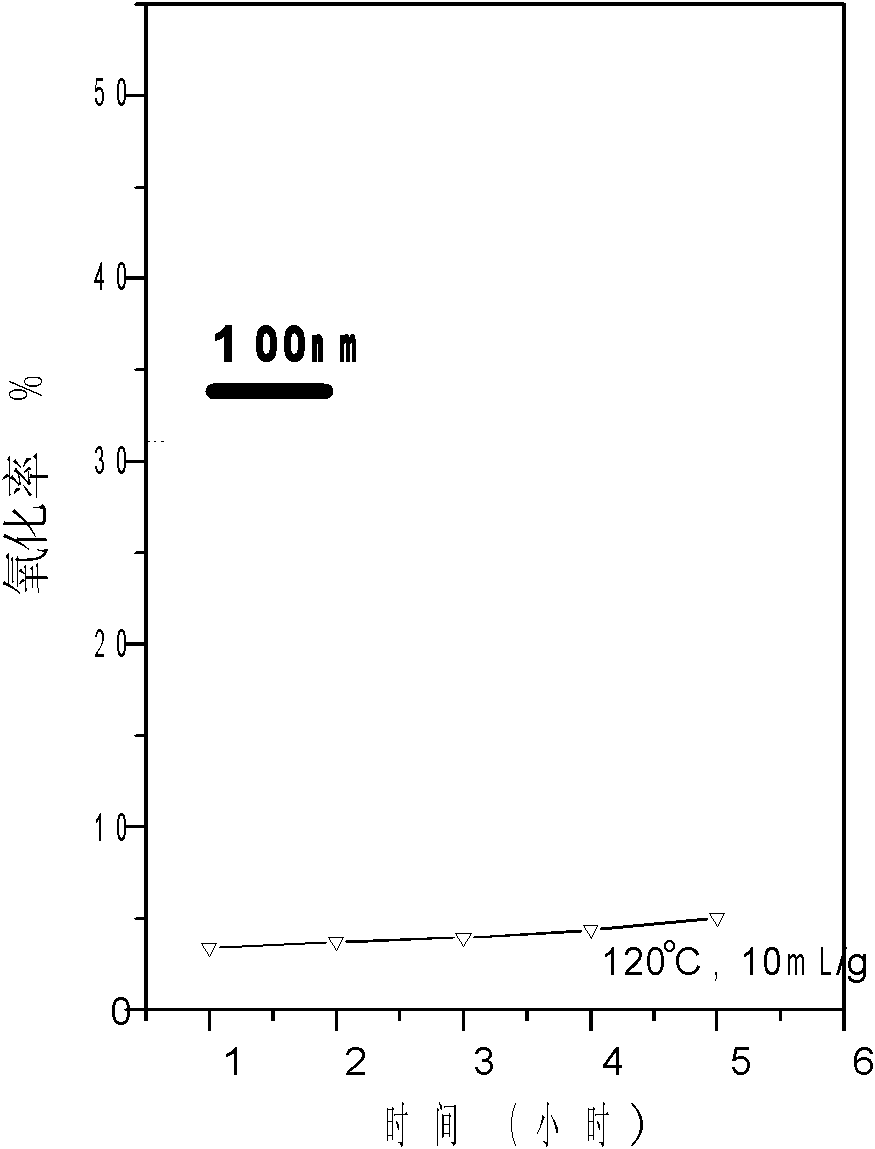

[0041] Put 1g of carbon nanotubes on the SiO of the glass liner 2 In the sand core;

[0042] In the polytetrafluoro liner of autoclave, drip 10ml mass concentration and be the nitric acid of 67%, then the glass lining tube that carbon nanotube is housed is placed in the polytetrafluoro liner of autoclave, seal;

[0043] Place the sealed autoclave in an oven, heat, and react at 120°C for 5 hours;

[0044] After the reaction was completed, cool down at room temperature, then take out the glass liner and wash it with water and ethanol, respectively.

[0045] The oxidation time curve of the carbon nanotubes treated in this embodiment is as follows: figure 1 shown.

Embodiment 2

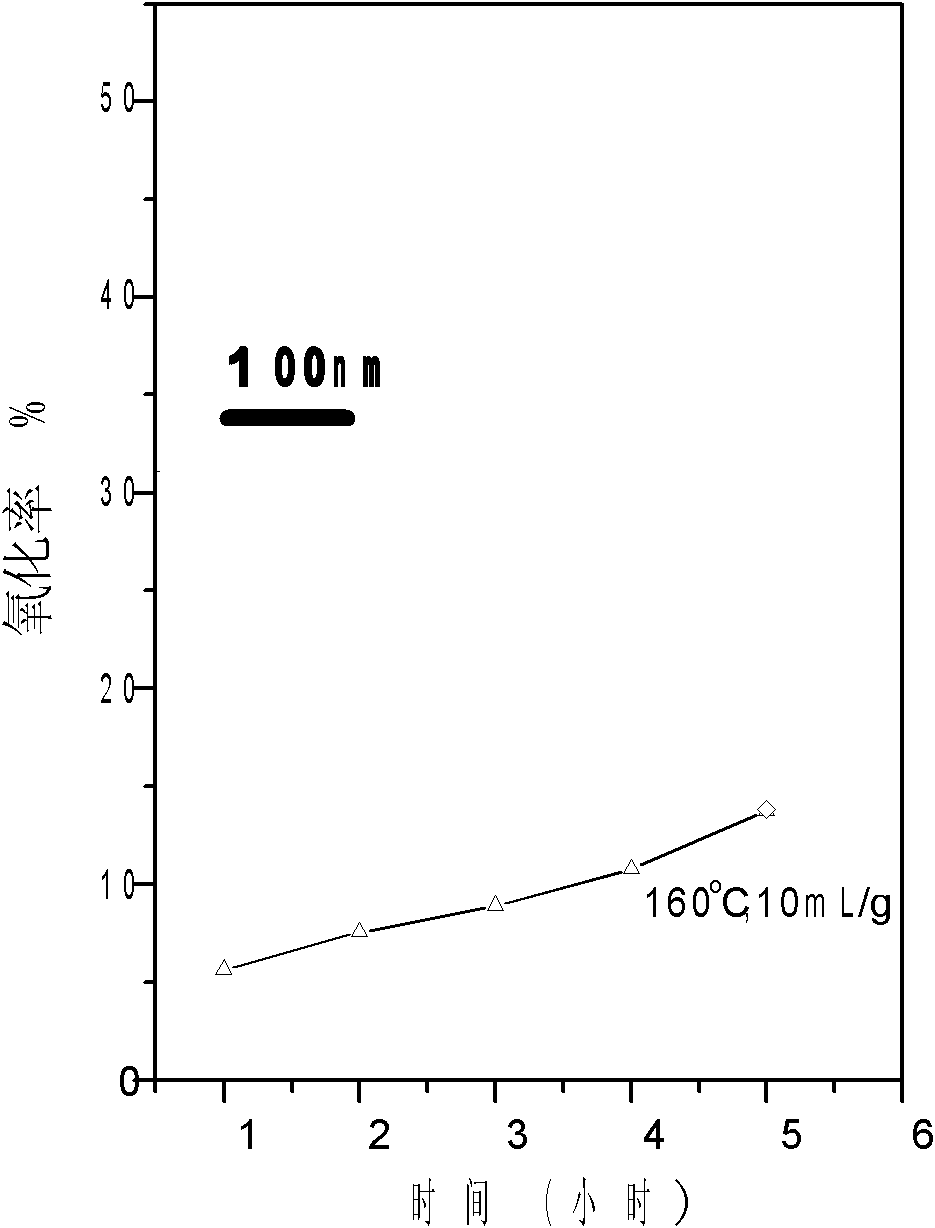

[0047] Put 1g of carbon nanotubes on the SiO of the glass liner 2 In the sand core;

[0048] In the polytetrafluoro liner of autoclave, drip 10ml mass concentration and be the nitric acid of 67%, then the glass lining tube that carbon nanotube is housed is placed in the polytetrafluoro liner of autoclave, seal;

[0049] Place the sealed autoclave in an oven, heat, and react at 160°C for 5 hours;

[0050] After the reaction was completed, cool down at room temperature, then take out the glass liner and wash it with water and ethanol, respectively.

[0051] The oxidation time curve of the carbon nanotubes treated in this embodiment is as follows: figure 2 shown.

Embodiment 3

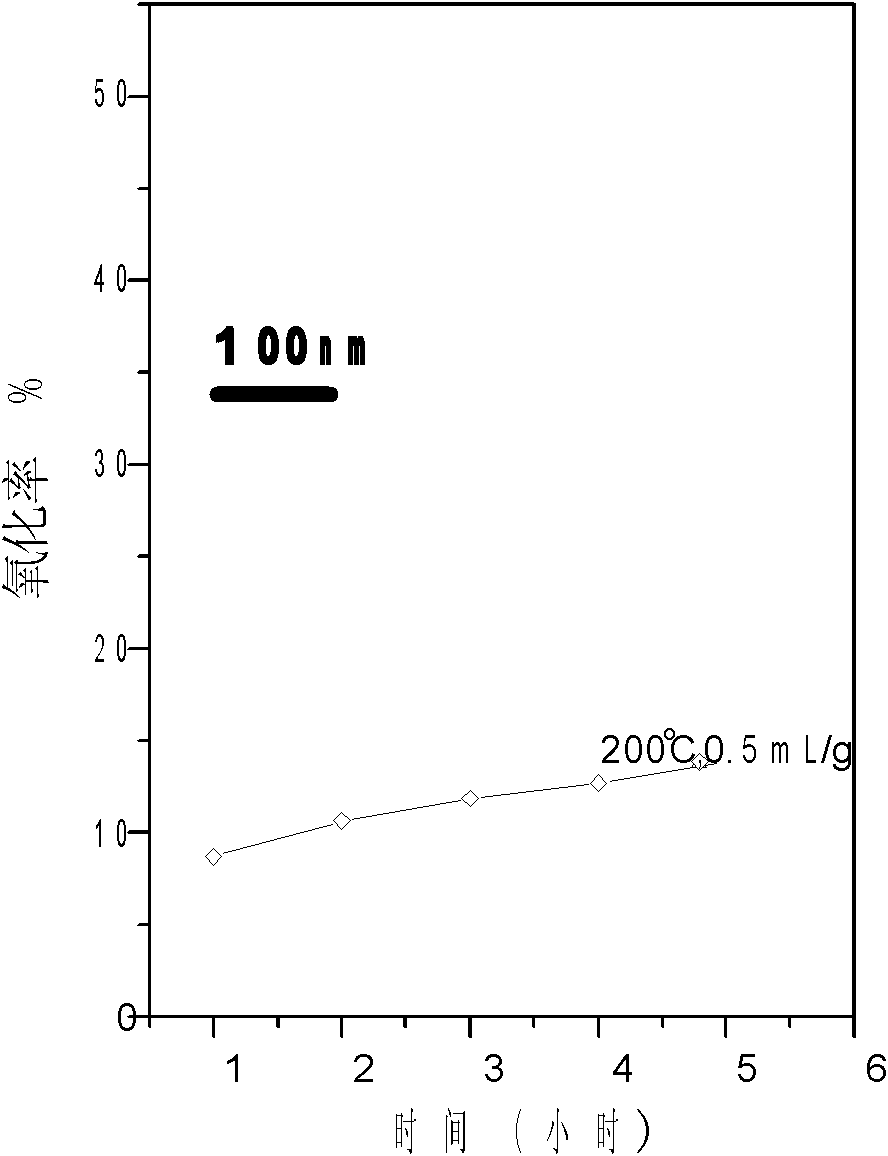

[0053] Put 1g of carbon nanotubes on the SiO of the glass liner 2 In the sand core;

[0054] In the polytetrafluoro liner of autoclave, drop 0.5ml nitric acid, then the glass lining tube that carbon nanotube is housed is placed in the polytetrafluoro liner of autoclave, seal;

[0055] Place the sealed autoclave in an oven, heat, and react at 200°C for 5 hours;

[0056] After the reaction was completed, cool down at room temperature, then take out the glass liner and wash it with water and ethanol, respectively.

[0057] The oxidation time curve of the carbon nanotubes treated in this embodiment is as follows: image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com