Preparation method for polyacrylonitrile-based carbon fiber protofilament

A technology of polyacrylonitrile-based carbon fiber and polyacrylonitrile resin is applied in the field of preparing polyacrylonitrile-based carbon fiber precursor by solution spinning process, which can solve the problems of purification of precursor and deterioration of mechanical properties, and achieves good purification effect. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

[0034] Carry out the preparation of carbon fiber precursor according to the following steps:

[0035] 1) The polyacrylonitrile resin is prepared into a spinning solution by using DMSO as a solvent, and the content of the polyacrylonitrile resin in the spinning solution is 18-25 wt%. Using 30-50wt% DMSO aqueous solution as a coagulation bath to prepare nascent fibers through spinning and coagulation forming by a solution spinning process;

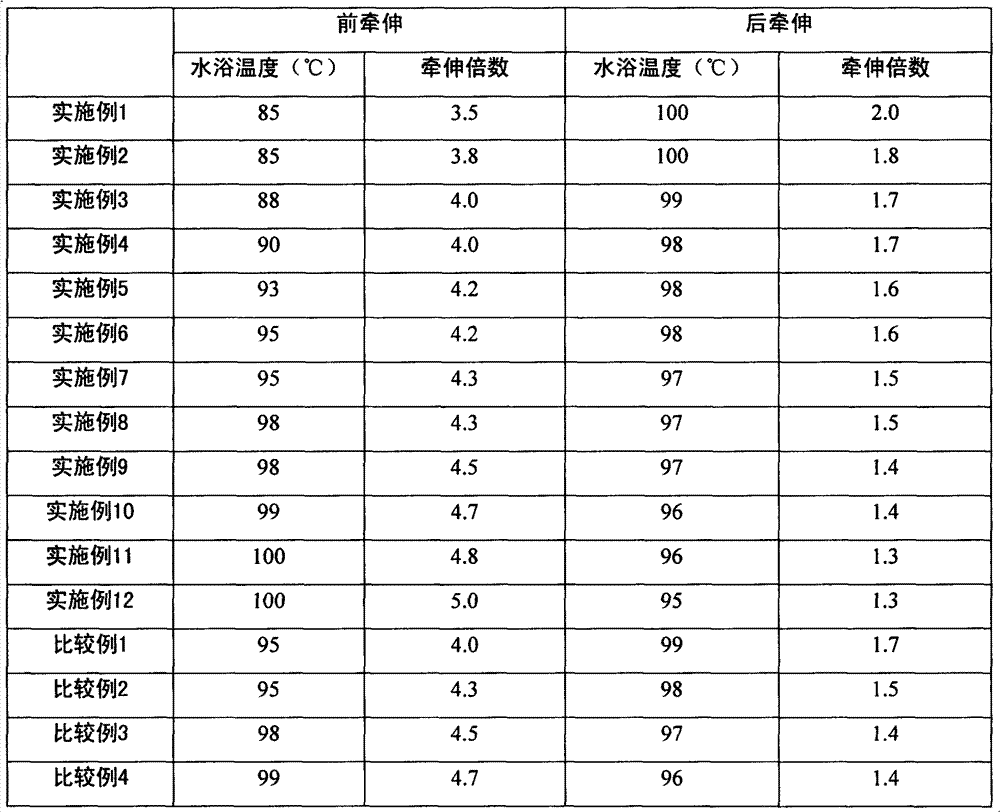

[0036] 2) The as-spun fiber is drawn in a water bath in 20-30 wt% DMSO aqueous solution, and the water bath temperature and the draw ratio of each embodiment are shown in Table 1, and this step is defined as pre-drawing in the table;

[0037] 3) The as-spun fibers are rinsed with deionized water, the water temperature is controlled at 45-60°C, and the rinse time is controlled at 2-20 minutes;

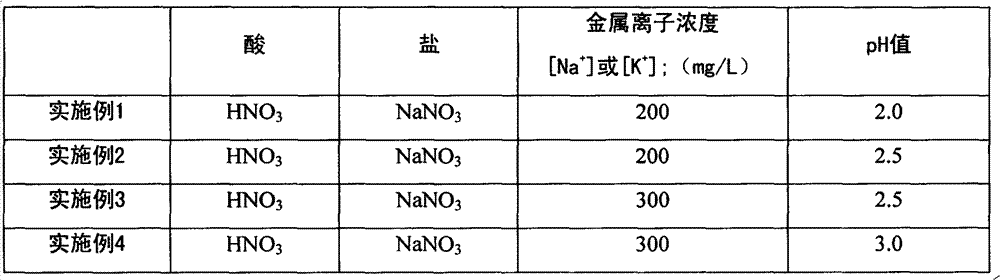

[0038] 4) The as-spun fiber is immersed in a buffer solution containing acid A and salt B. The control data of the buffer solution composition and p...

Embodiment 11~12

[0043] Carry out the preparation of carbon fiber precursor according to the following steps:

[0044] 1) The polyacrylonitrile resin is formulated into a spinning solution by using DMAc as a solvent, and the content of the polyacrylonitrile resin in the spinning solution is 18-25 wt%. Using 30-50wt% DMAc aqueous solution as a coagulation bath to prepare nascent fibers through spinning and coagulation forming by a solution spinning process;

[0045] 2) to 7) are the same as in Examples 1 to 10.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com