Patents

Literature

50results about How to "Invention effect is obvious" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

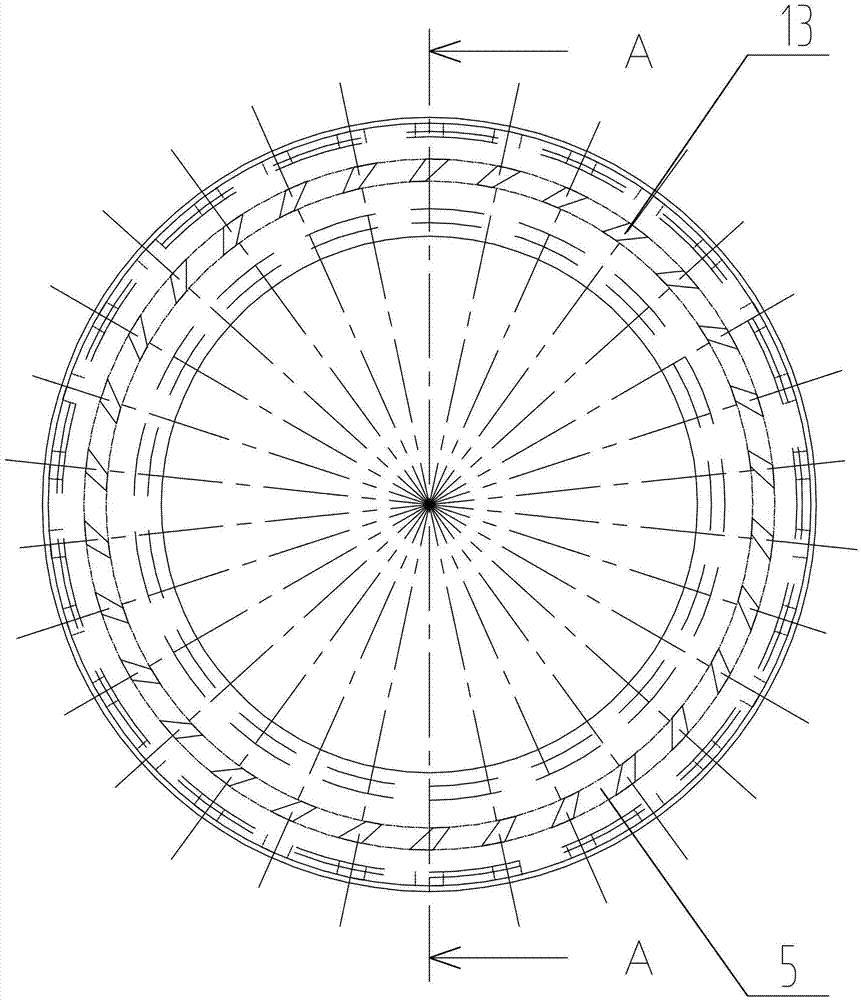

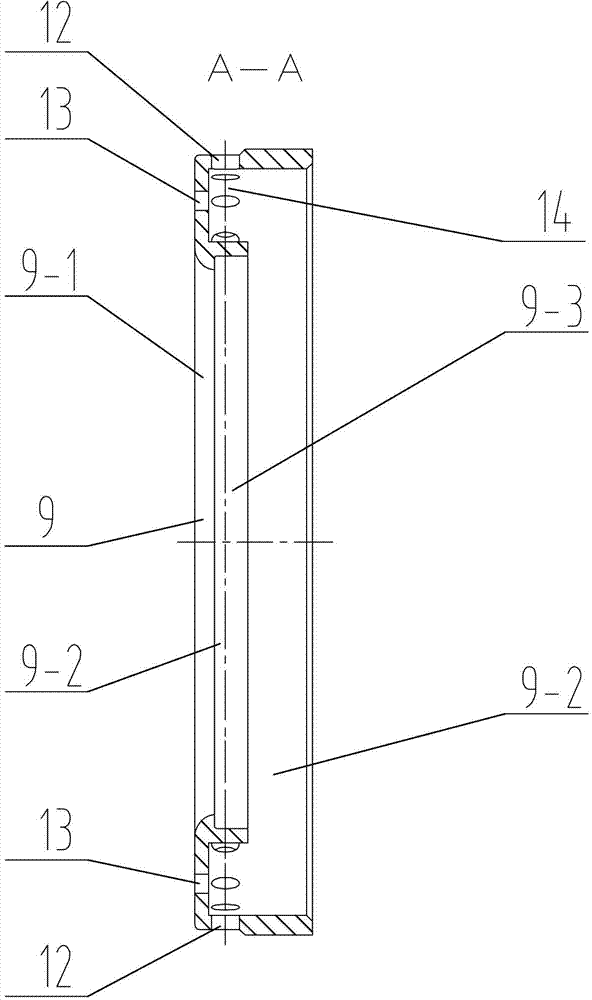

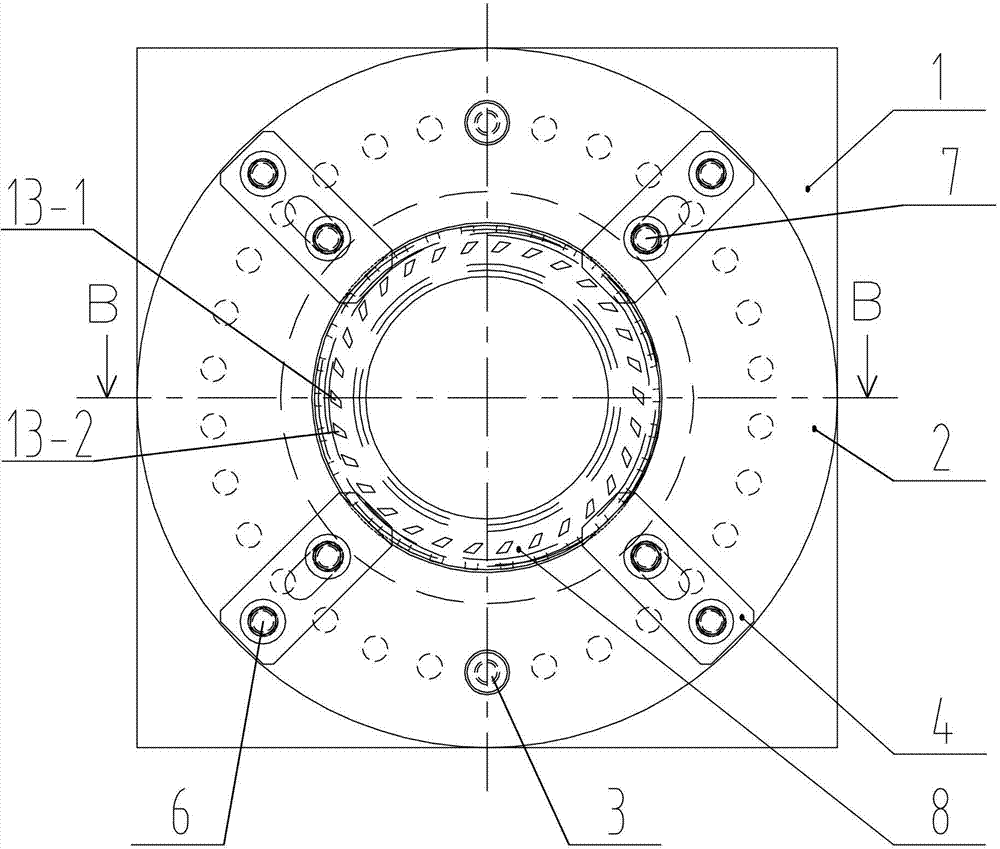

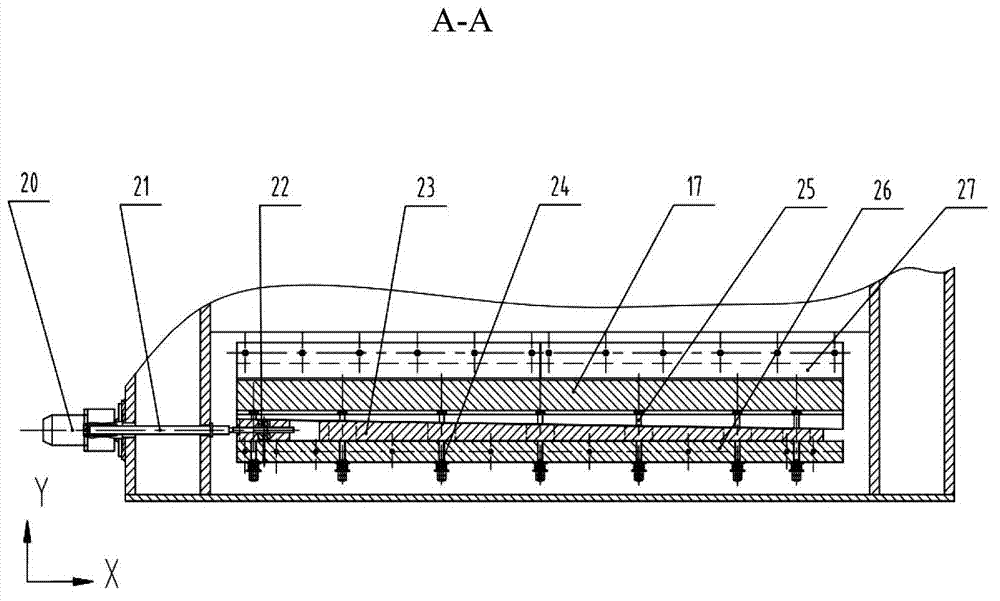

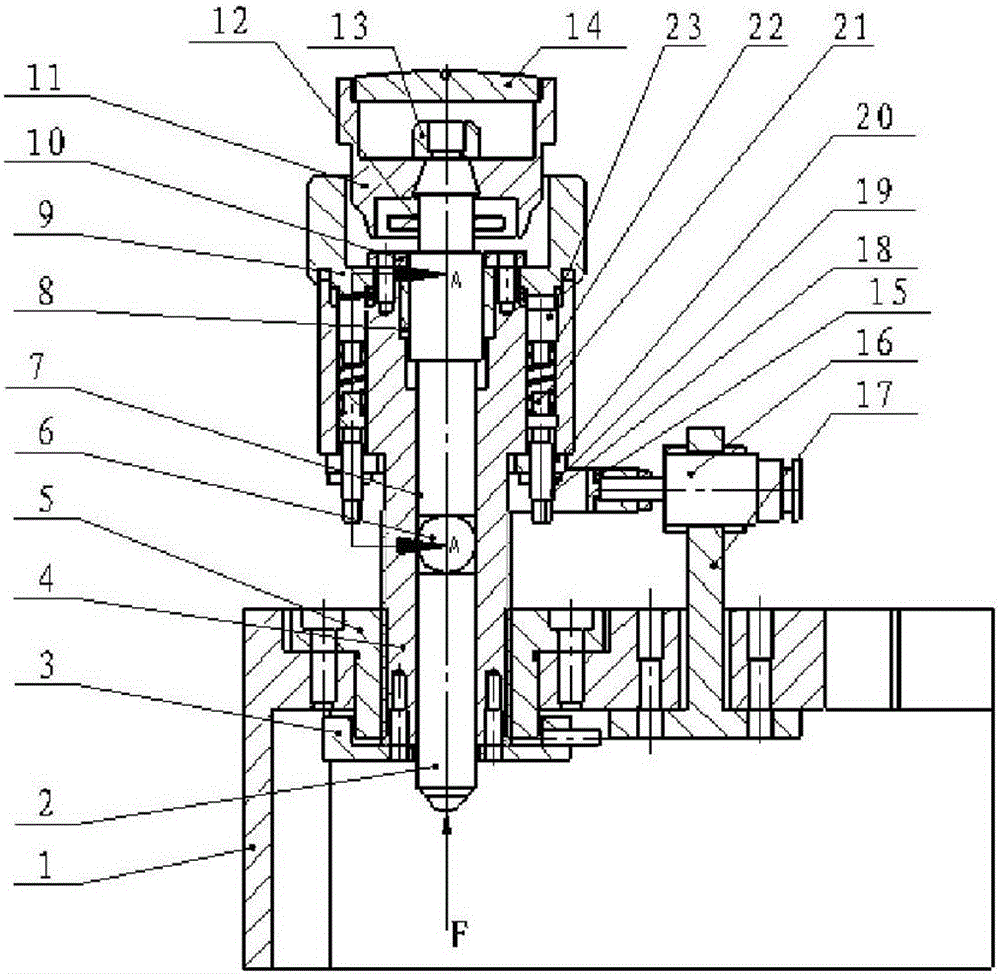

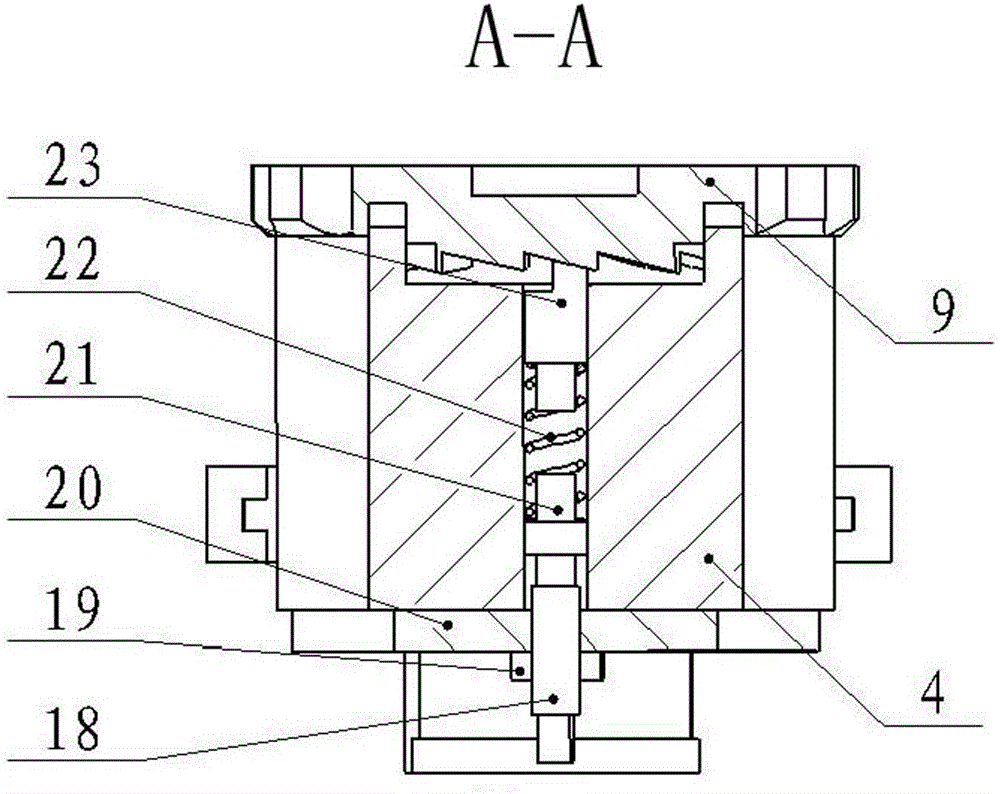

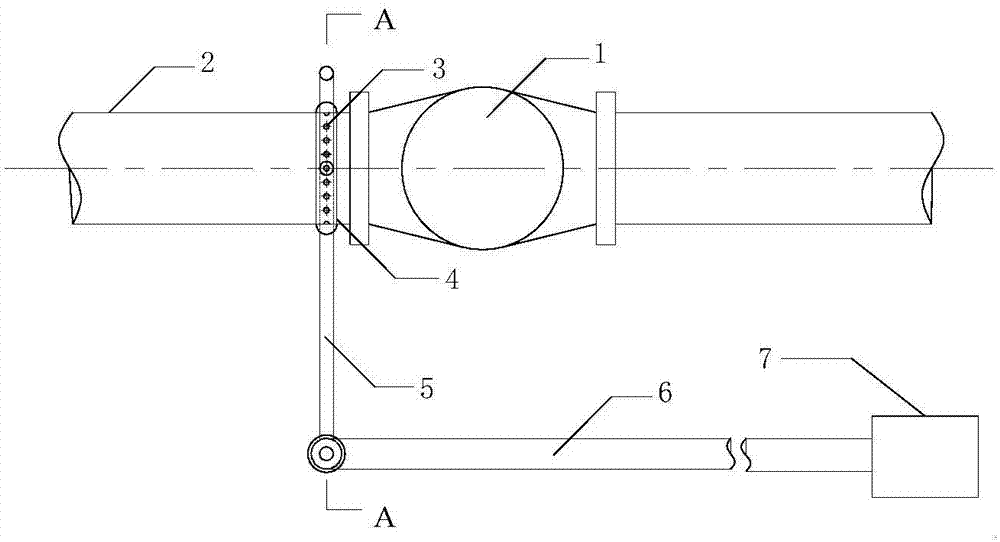

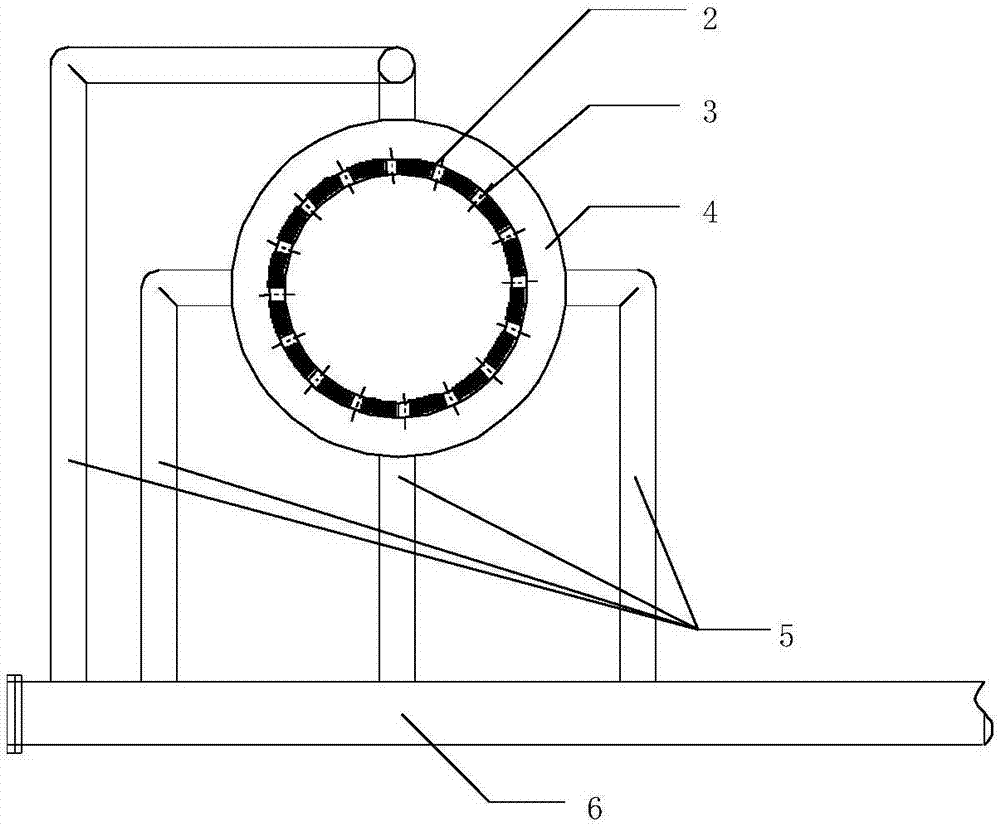

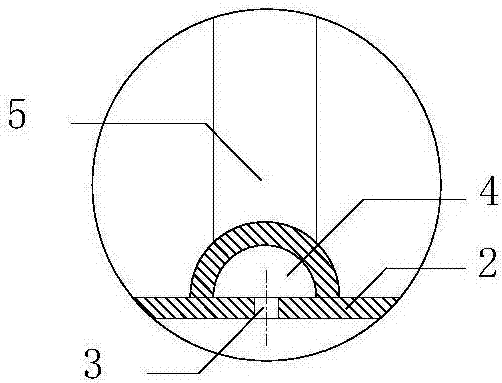

Method for realizing machining of combustion-compression ring bushes by using combustion-compression ring bush cutting clamp

ActiveCN102950479ASmall amount of deformationGuaranteed machining accuracyPositioning apparatusMetal-working holdersCombustionWork in process

The invention discloses a method for realizing the machining of combustion-compression ring bushes by using a combustion-compression ring bush cutting clamp, relating to a machining method for ring parts. The invention aims to solve the problems that because the existing combustion-compression ring bush is a thin-walled workpiece, the existing combustion-compression ring bush is easy to deform in the process of machining, so that the machining quality of the combustion-compression ring bush is affected, and meanwhile, the 30-equated positions of 30 molded holes of a combustion-compression ring bush machined by using the existing machining method are poor in accuracy. The clamp used in the invention comprises a base plate, a turntable, two positioning pins and four pressing plates. The method disclosed by the invention comprises the following steps of: 1, roughly turning an inner hole, an outer circumferential surface and two planes of a blank; 2, relieving stress of a semi-finished combustion-compression ring bush product; 3, carrying out finish turning on an inner hole, an outer circumferential surface and two planes of the semi-finished combustion-compression ring bush product; 4, drawing center position lines of radial holes and molded holes; 5, drilling 30 radial holes with a diameter of 5 mm; and 6, cutting and machining 30 molded holes. The method disclosed by the invention is used for machining combustion-compression ring bushes.

Owner:HARBIN TURBINE +1

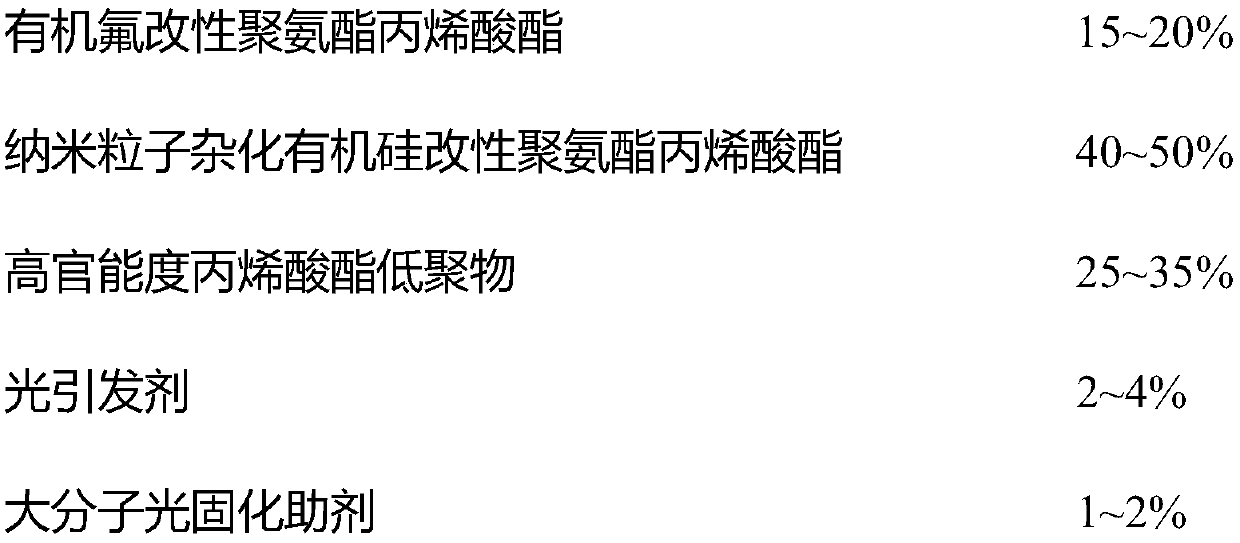

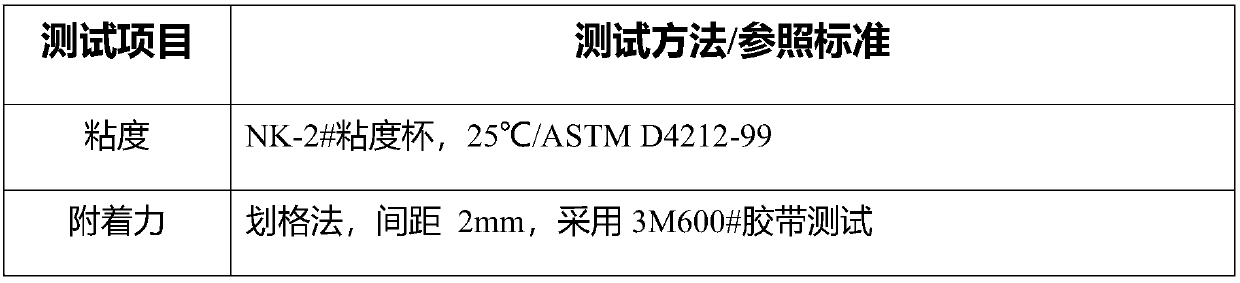

High-hardness, high-wear-resistant and anti-fingerprint ultraviolet-curable coating

ActiveCN109536001AImprove anti-fingerprint stain propertiesImprove wear resistanceFireproof paintsAntifouling/underwater paintsChemistryFingerprint

The invention discloses a high-hardness, high-wear-resistant and anti-fingerprint ultraviolet-curable coating. The coating comprises the following ingredients (by weight): organic fluorine modified urethane acrylate, nano-particle hybrid silicone modified urethane acrylate, high-functionality acrylate oligomer, a photoinitiator, a macromolecular photocuring aid, a diluent and an auxiliary agent. By using the nano-particle hybrid silicone modified urethane acrylate having high hardness and high wear resistance as the matrix resin in cooperation with the organic fluorine modified urethane acrylate having fingerprint fouling resistance and the high-functionality acrylate oligomer capable of increasing crosslinking density, and by adjusting the combination of the photoinitiator while adding the macromolecular photocuring aid in the formula, the ultraviolet-curable coating which has high hardness, high wear resistance and excellent anti-fingerprint effect and can be used for transparent plastic boards is developed. Thereby, the problem that a common coating has low hardness, poor wear resistance and poor anti-fingerprint effect is solved.

Owner:YIXING HONGTAI CHEM

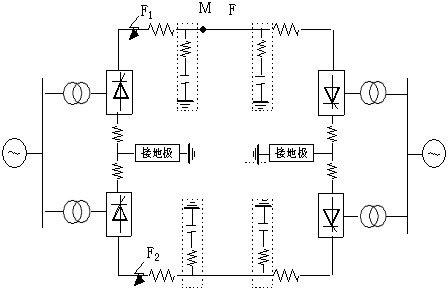

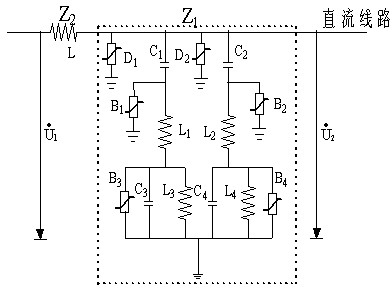

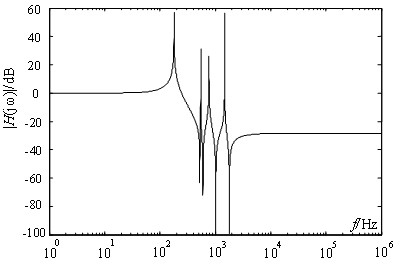

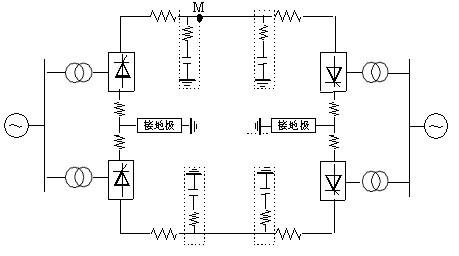

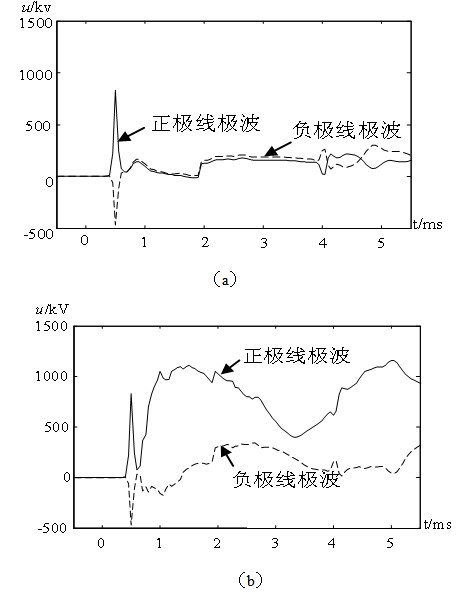

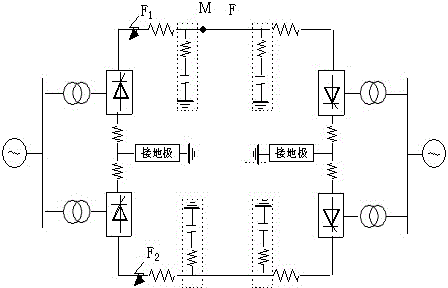

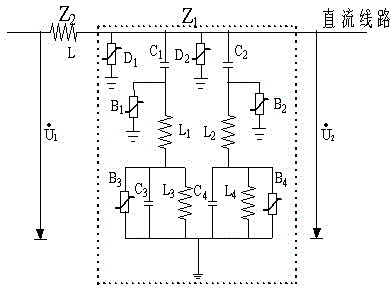

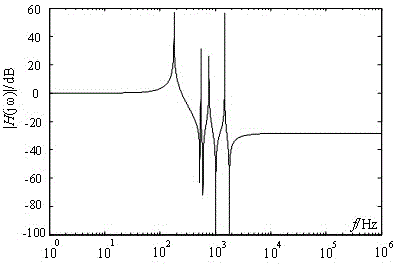

A Method of Starting Criterion for UHV DC Line Protection

ActiveCN102279309AHigh graduationEasy to judgeCurrent/voltage measurementWavelet decompositionHigh-voltage direct current

The invention discloses a criterion method for the protection startup of an extra-high voltage direct-current circuit according to a polar wave change rate. The method comprises the following steps of: when the direct-current circuit fails, determining a polar wave according to direct-current voltage and current measured at a protection installation position, wherein the sampling rate is 10 kHz and the time window is 5 ms; performing one-dimensional wavelet decomposition on the polar wave by using a db4 wavelet of a Daubechies wavelet system to obtain modulus maximums, and selecting a first modulus maximum serving as a voltage change rate startup criterion, wherein the electric quantity used by the criterion has high polar wave representation discrimination and is easy to judge; and performing one-dimensional wavelet decomposition on a fault signal by using the db4 wavelet of the Daubechies wavelet system, so that the influence of noise can be eliminated to a great extent. As proved by a large quantity of emulation results, the criterion method has a good effect.

Owner:KUNMING UNIV OF SCI & TECH

Compound essential oil for grease clearing and acne dispelling

InactiveCN101229288AImprove permeabilityImprove solubilityDermatological disorderPlant ingredientsMedicineSebum secretion

The invention relates to a compound essential oil for cleaning sebum and eliminating acnes; the invention is mainly prepared by mixing bergamot essential oil, lavender essential oil, chamomile essential oil, tea plant essential oil, cypress essential oil, geranium essential oil and raison-seed oil in a certain proportion. The invention has good effects of calming and diminishing inflammation, balancing sebum secretion as well as dissipating anxiety and frayed nerves.

Owner:BEIJING ZHONGKE YONGHE PHARMA TECH

Thermoplastic high voltage cable insulating material and preparation method thereof

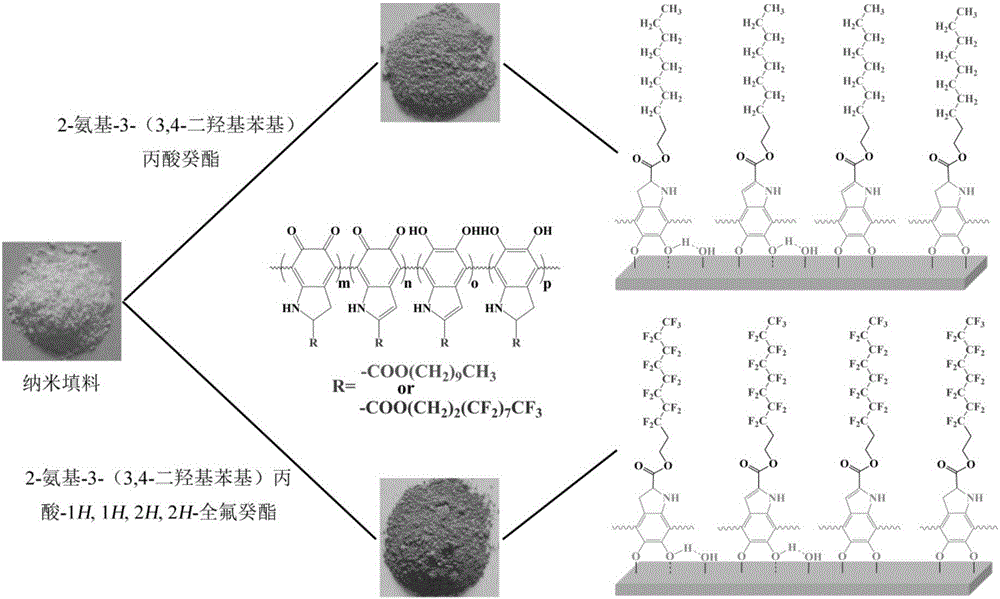

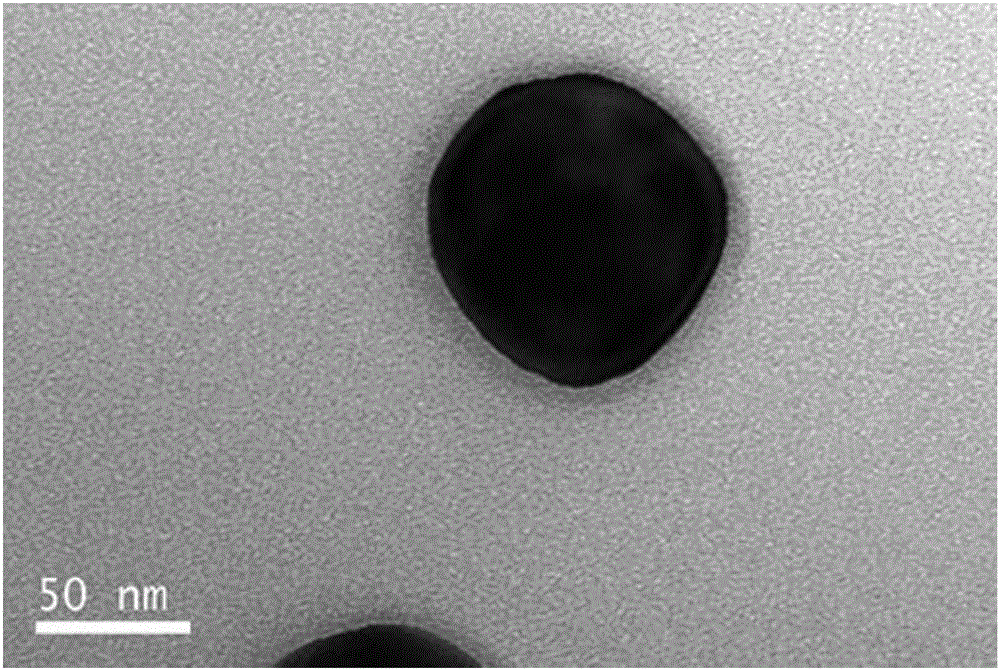

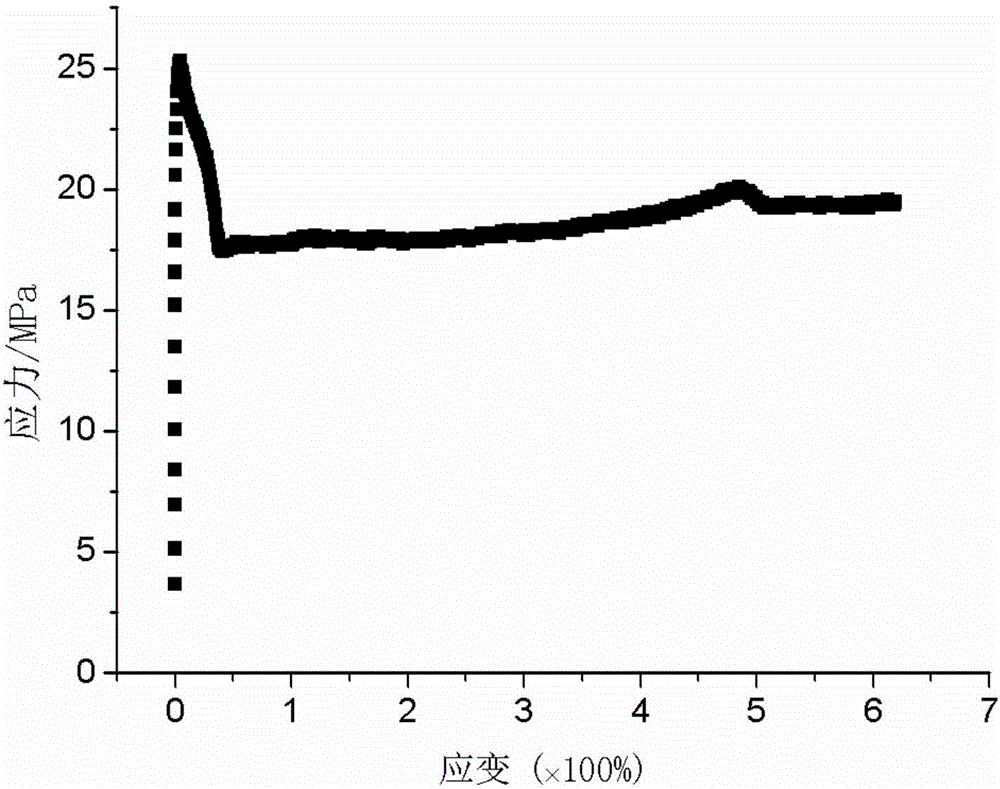

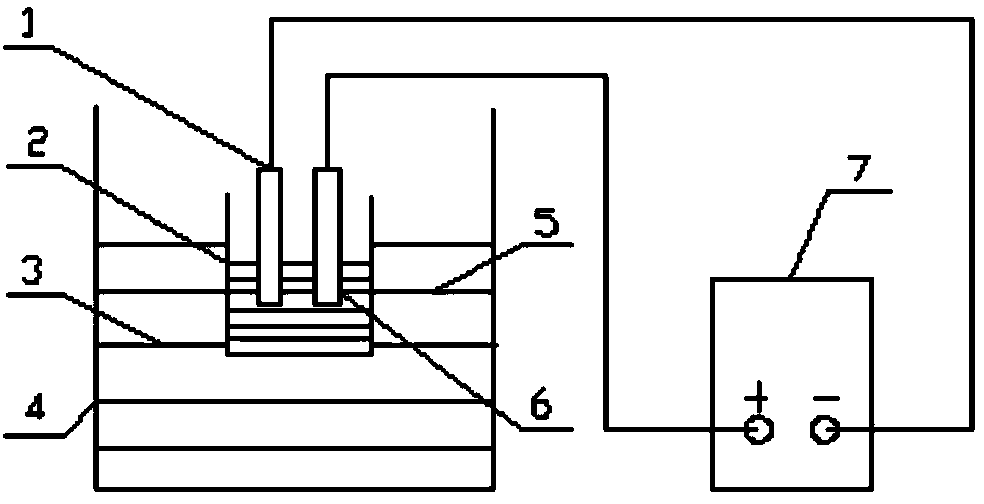

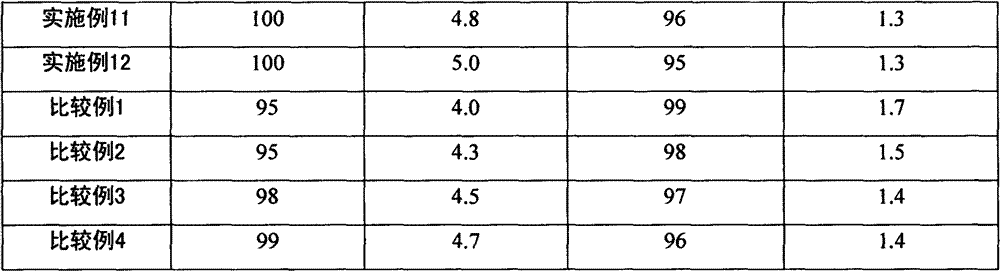

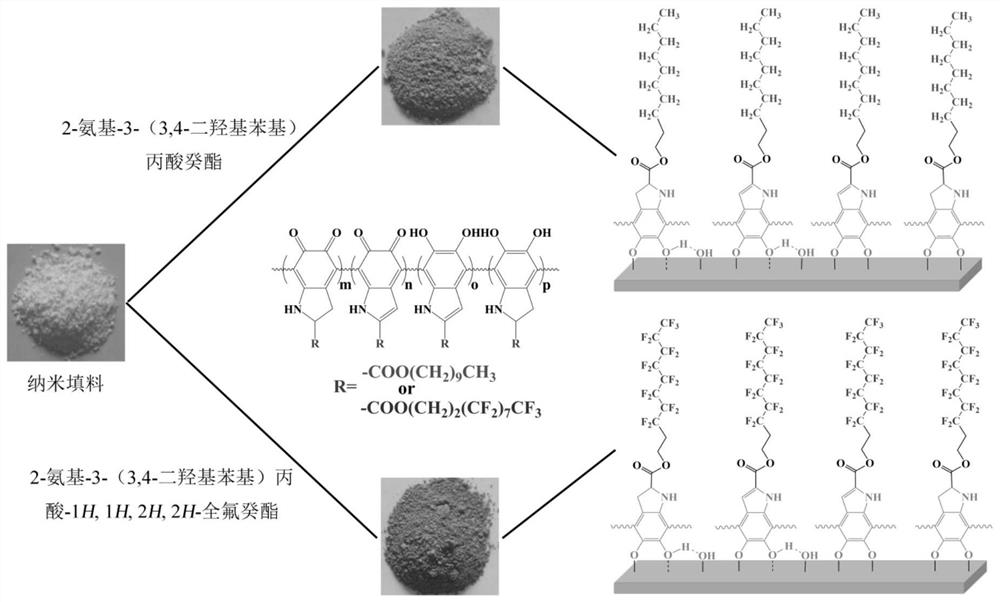

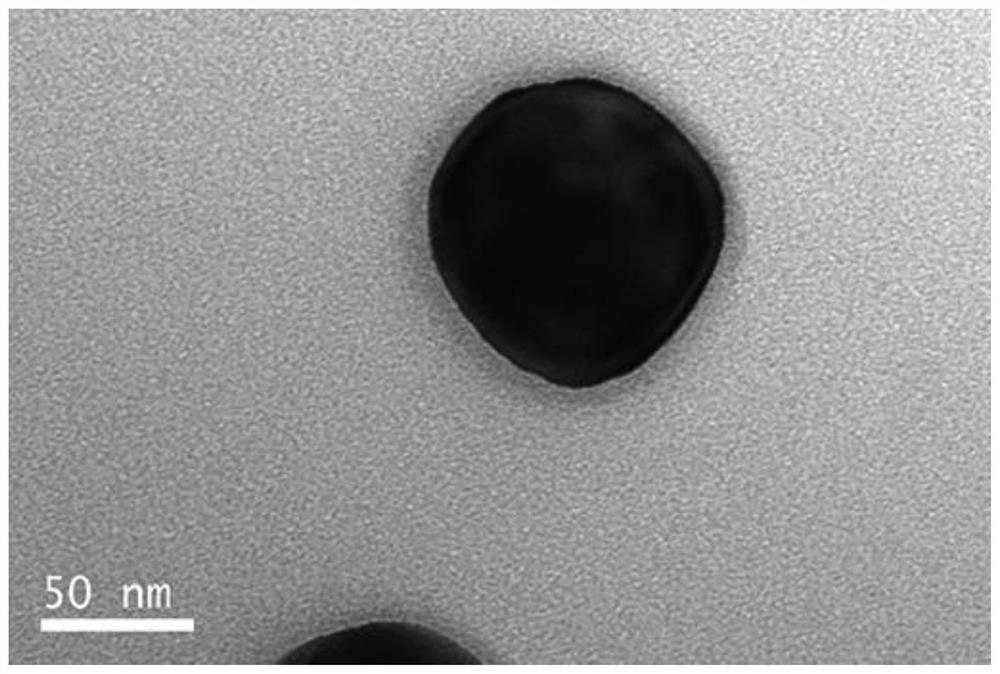

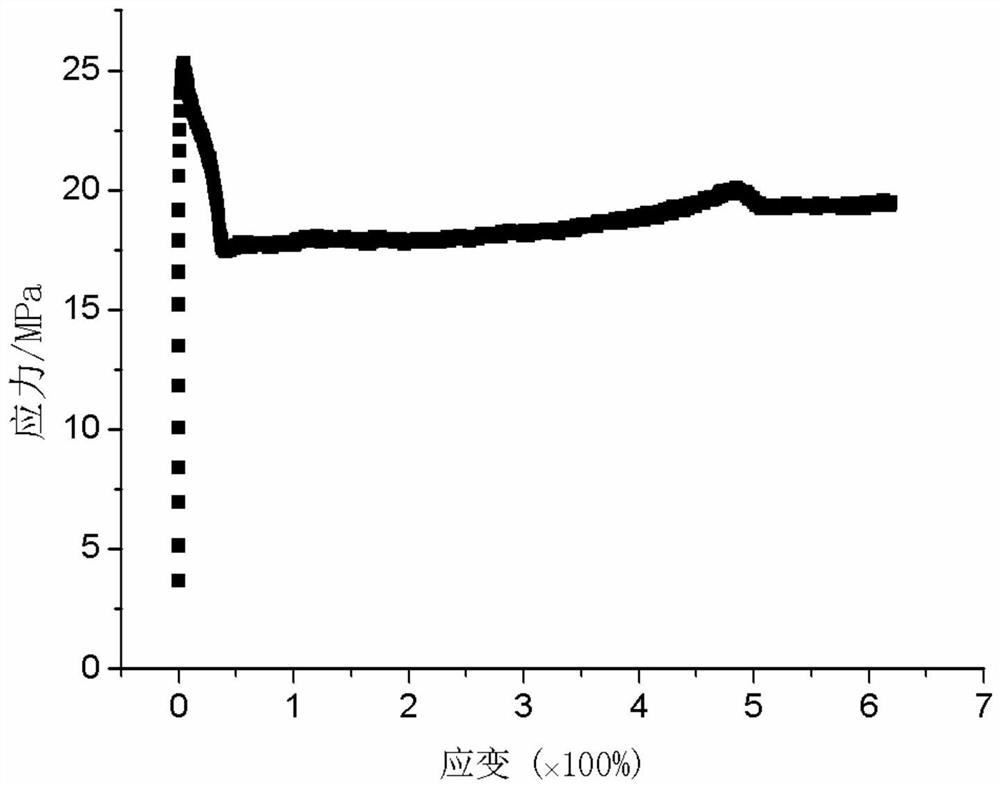

ActiveCN106543563AGood dispersionHigh breakdown strengthPlastic/resin/waxes insulatorsThermoplasticPolyolefin

The invention discloses a thermoplastic high voltage cable insulating material and a preparation method thereof. The insulating material comprises the following components in parts by weight: 100 parts of polyolefin resin, 0.1 to 6 parts of dopamine modified nano particles, and 0.1 to 0.5 part of antioxidant, wherein the dopamine has been modified, and the nano particles are inorganic. Dopamine with a long chain structure is grafted on the nano particles to modify nano particles, the dispersing property of nano particles is improved by the dopamine, at the same time, the thermal stability of the thermoplastic cable insulating material is improved, and the injection of space charges is obviously inhibited. The prepared thermoplastic high voltage cable insulating material has excellent mechanical properties, thermal properties, and insulating performance, is easy to process, and can be applied to cable insulation, especially high voltage DC cable insulation.

Owner:SHANGHAI JIAO TONG UNIV +1

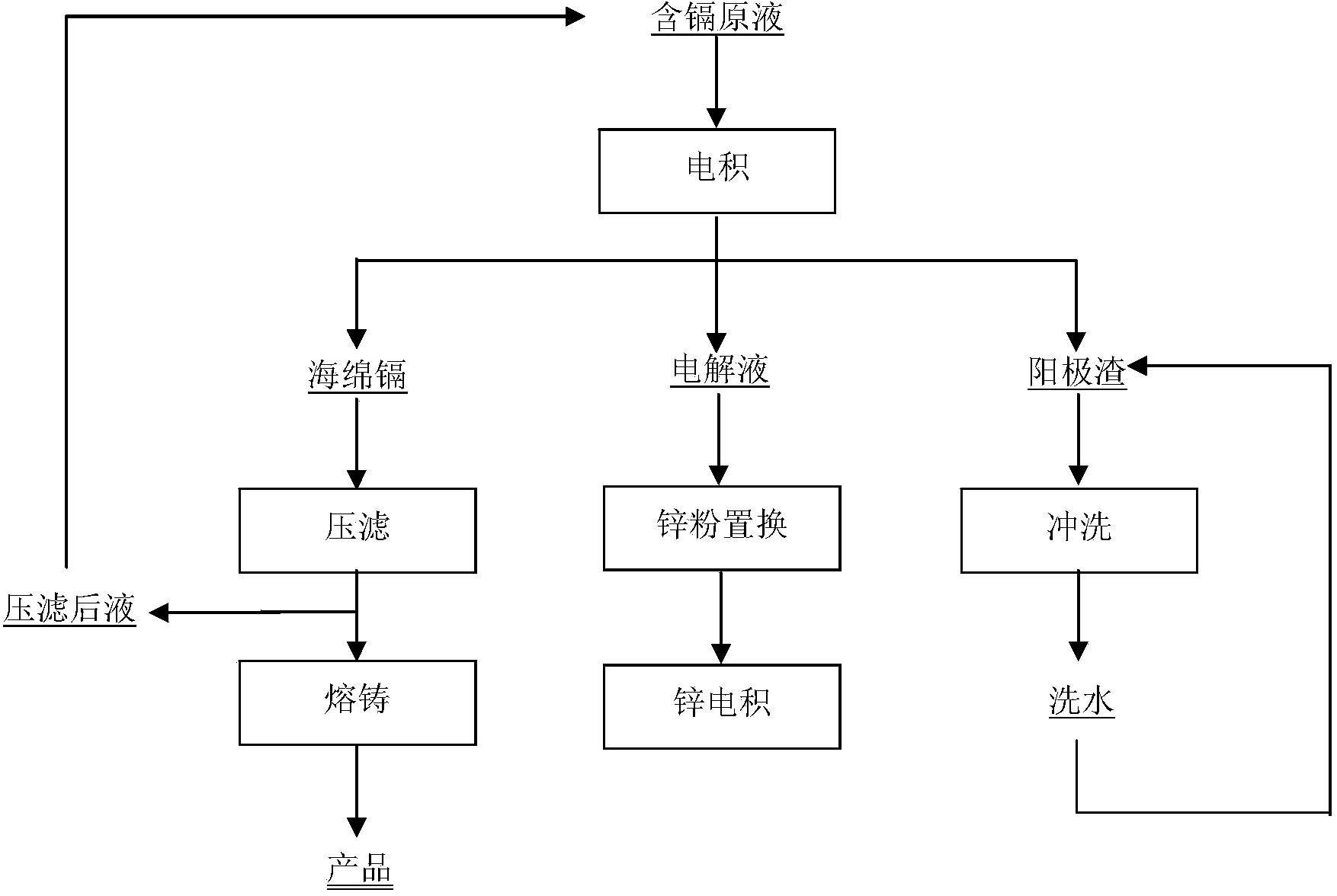

Method for manufacturing sponge cadmium under effect of micro currents

Disclosed is a method for manufacturing sponge cadmium under the effect of micro currents. The method specifically comprises the steps that a zinc plate or a zinc sheet is used as the anode, a titanium mesh or a titanium plate or an aluminum mesh or an aluminum plate or a copper mesh or a copper plate is used as the cathode, a solution containing 10-100g / L of cadmium and over 30g / L of zinc is used as a reaction stock solution, zinc plate replacement is conducted under the effect of the micro currents with the current density being 20-80A / m<2>, and the branch-shaped sponge cadmium is obtained. In the sponge cadmium manufactured through the method, the purity of cadmium is high and the impurity content is low. The zinc plate in the method is obtained in the zinc smelting electro-deposition process, the residual reacted solution can be directly returned to the zinc electro-deposition process, and raw material cyclic utilization in the whole technological process is realized. The method for manufacturing the sponge cadmium under the effect of the micro currents is simple in technological operation and equipment, reduces the cost, is tightly combined with an existing zinc smelting process, and enables industrial production to be realized easily.

Owner:CENT SOUTH UNIV

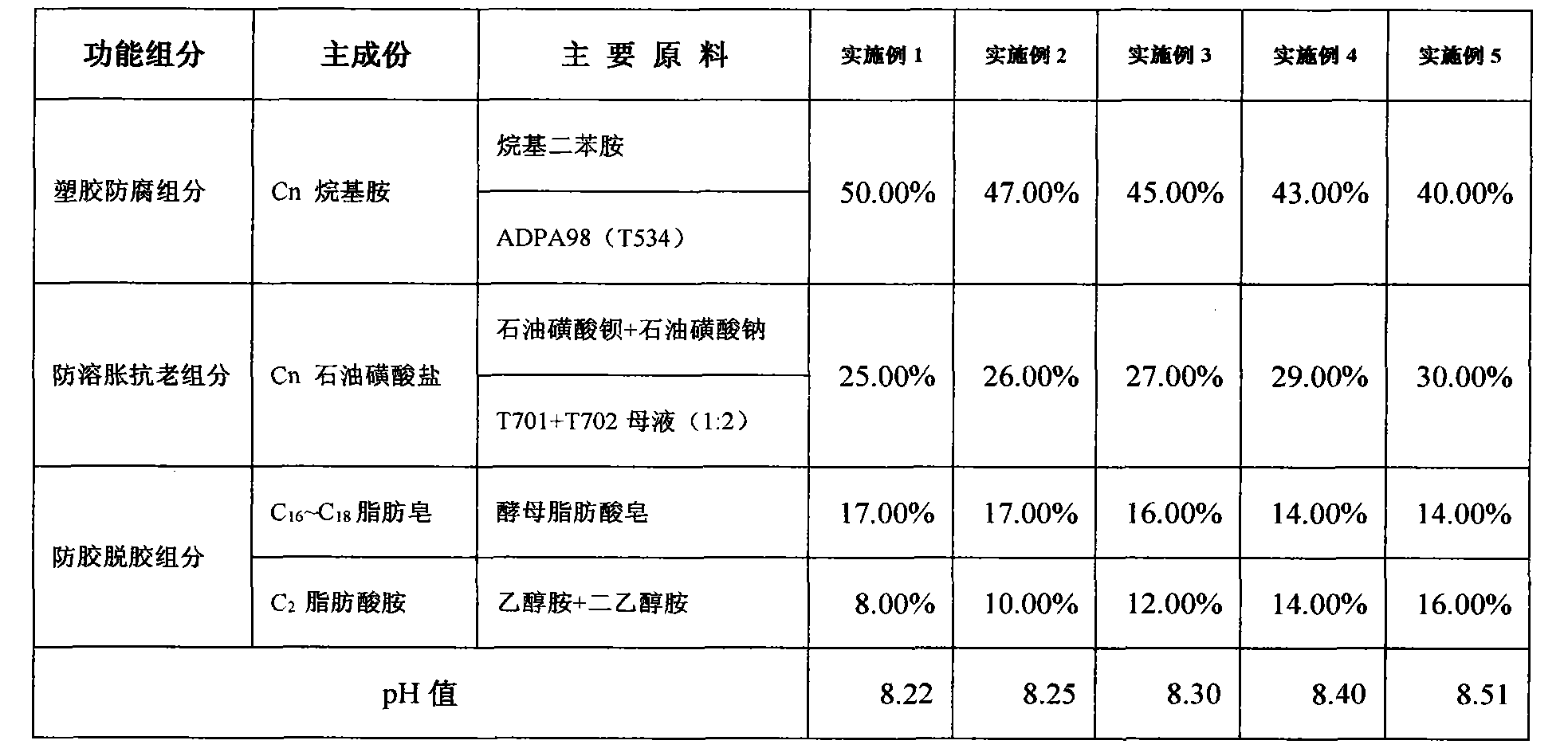

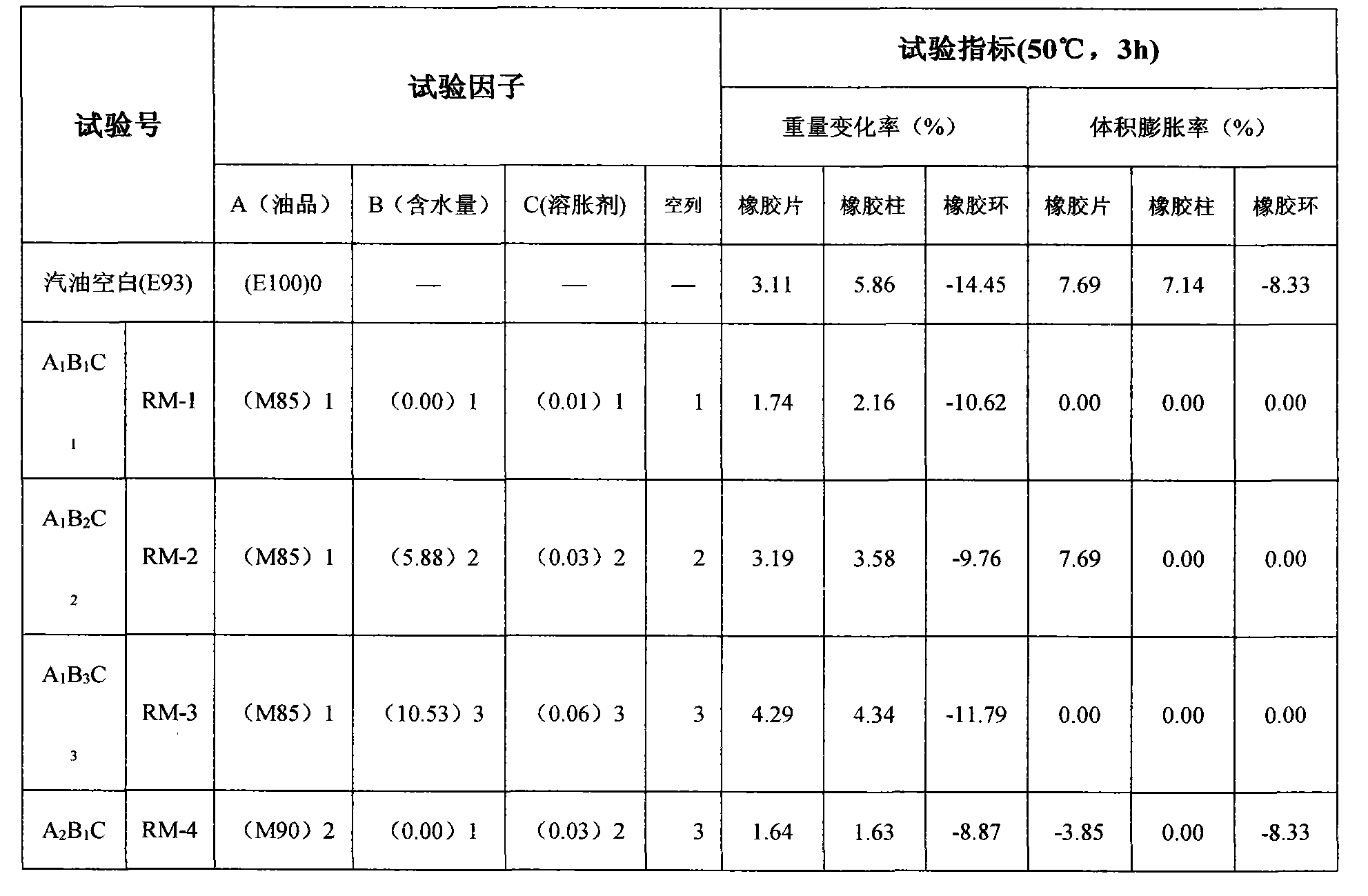

Swelling preventing and degumming agent for bio-based methanol gasoline and preparation method of swelling preventing and degumming agent

ActiveCN103320188ATurn waste into treasureTurn waste into energyLiquid carbonaceous fuelsFiberMedicine

The invention discloses a swelling preventing and degumming agent for bio-based methanol gasoline and a preparation method of the swelling preventing and degumming agent. The swelling preventing and degumming agent consists of the following ingredients in percentage by volume: 40-50% of plastic corrosion preventing ingredient, 25-30% of swelling preventing and anti-aging ingredient and 25-30% of degumming preventing ingredient; and the swelling preventing and degumming agent product is prepared through uniformly stirring the three functional ingredients at normal temperature. According to the swelling preventing and degumming agent and the preparation method of the swelling preventing and degumming agent, cleanable, environmental-friendly, reproducible and degradable petroleum yeast fatty acid soap is selected as the main raw material of a cheap additive, so that the energy is saved and the emission is reduced; and compared with the prior art, the swelling preventing and degumming agent is low in cost, non-toxic, free of pollution, low in dosage and remarkable in swelling preventing and degumming effect and cannot cause secondary pollution to the environment. According to the swelling preventing and degumming agent and the preparation method of the swelling preventing and degumming agent, the phenomenon that rubber, plastics and fiber gaskets of a fuel system are corroded, swelled, stuck, embrittled and softened due to use of methanol gasoline in the prior art is overcome; and the swelling preventing and degumming agent has the advantages that the preparation is simple, the raw materials are easily available, automotive component materials are not required to be transformed and modified, the swelling preventing and degumming effects are good, and the degumming capacity is strong.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES

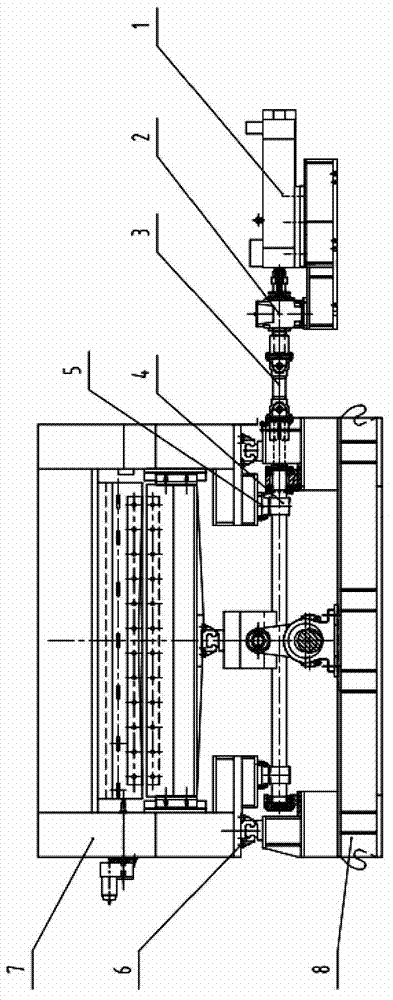

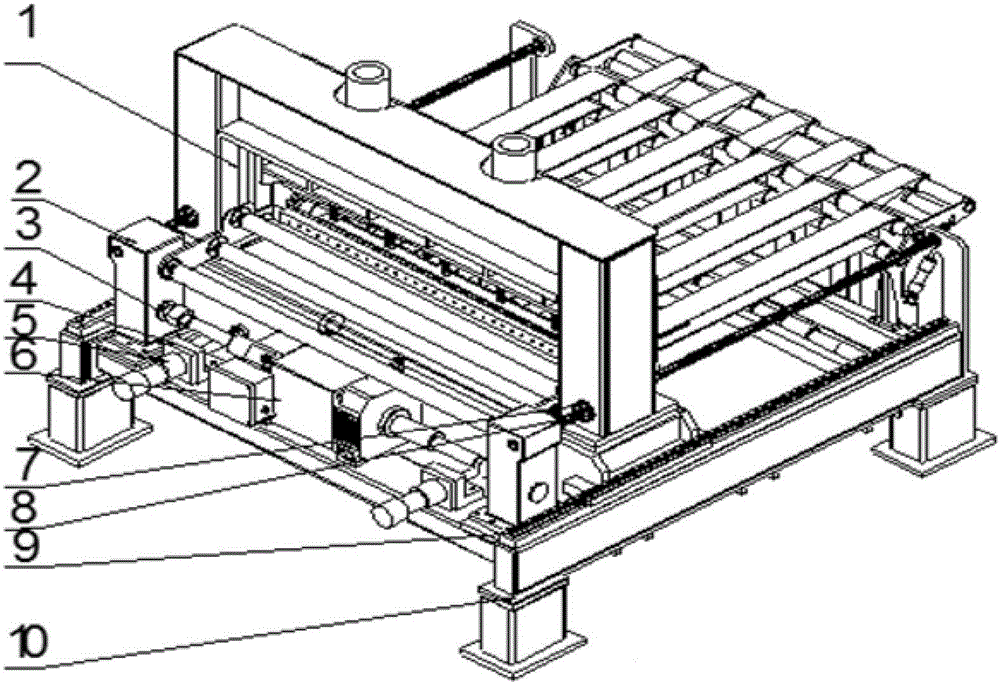

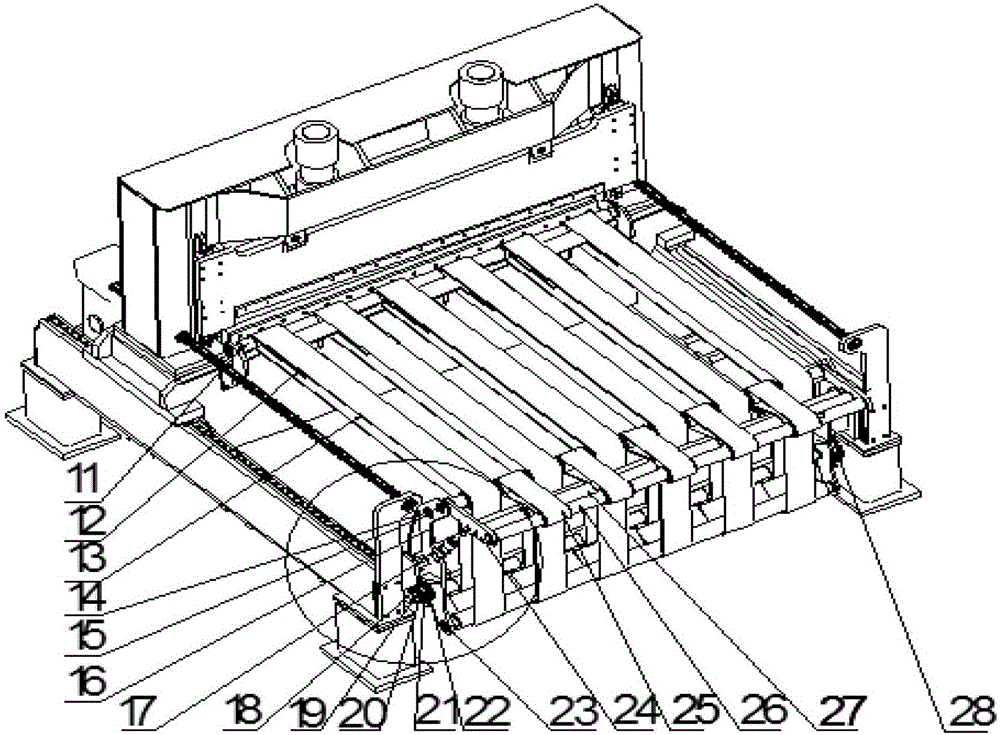

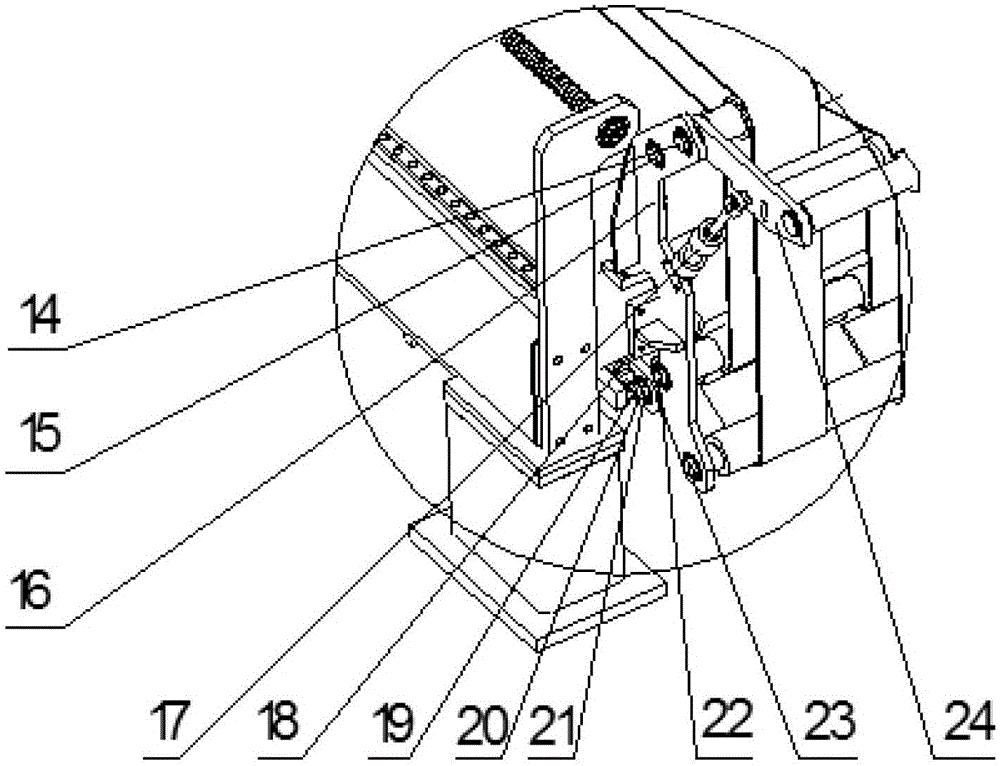

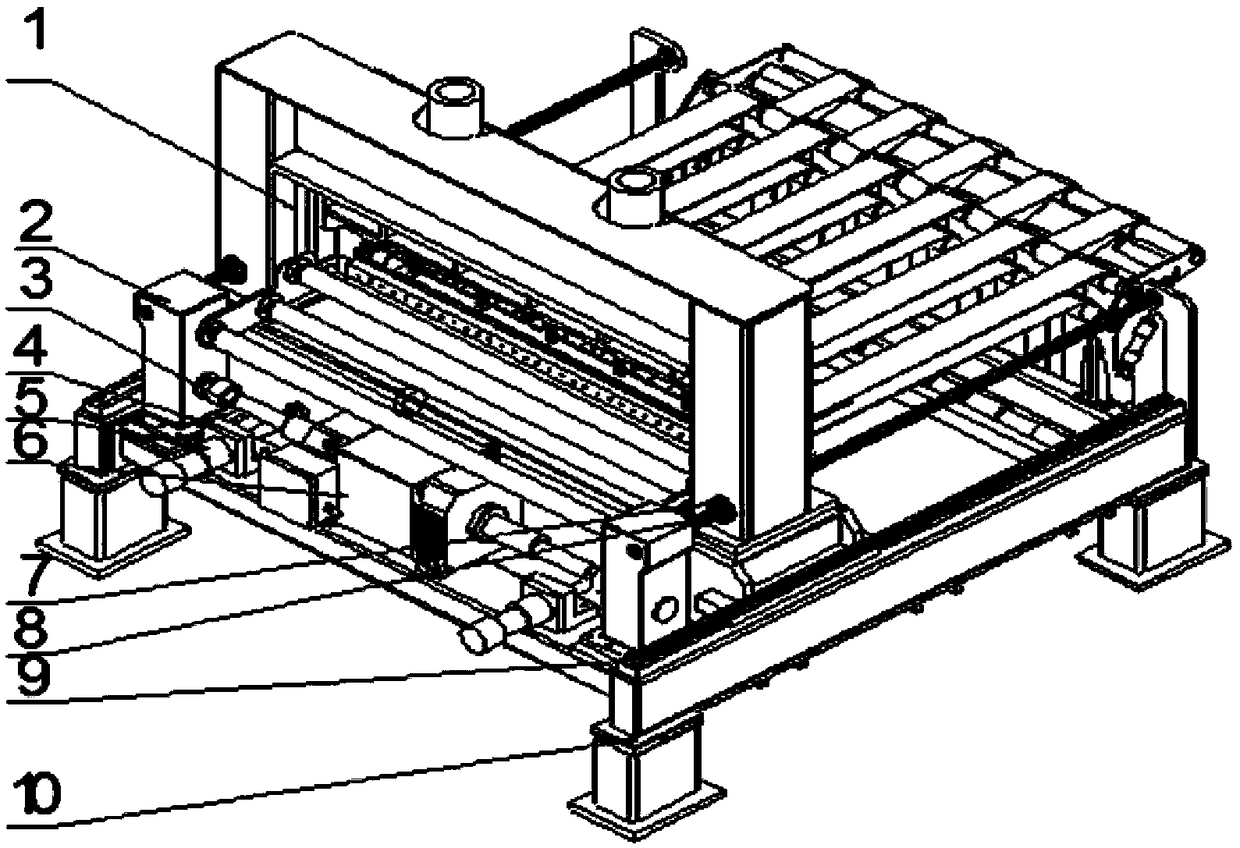

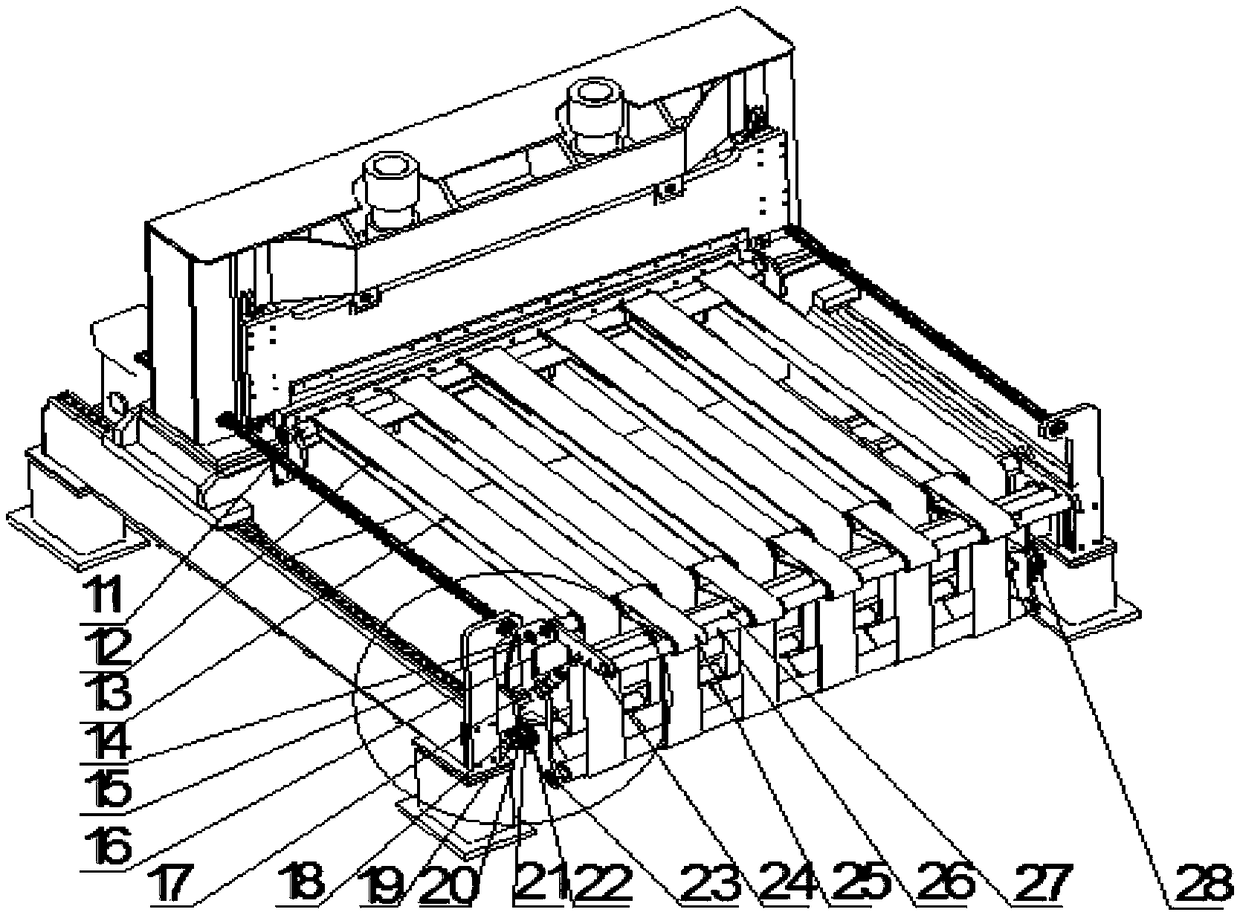

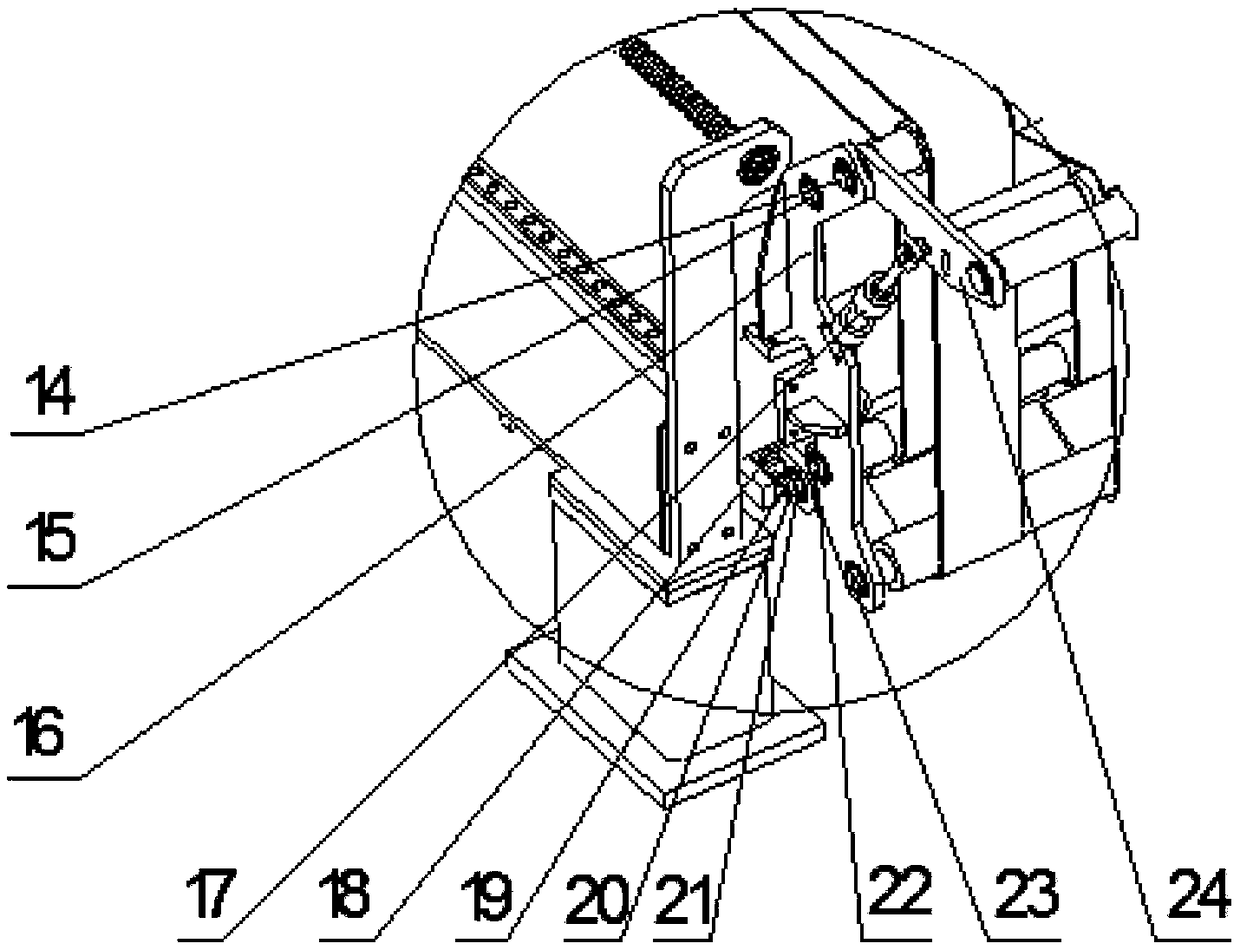

Flying shear device for finishing and shearing of thick metal strips

InactiveCN102873392AImprove speedIncrease shear frequencyStock shearing machinesShearing machine accessoriesEngineeringShear speed

The invention discloses a flying shear device for finishing and shearing of thick metal strips. The flying shear device mainly comprises a main driving device, a shearing device and a cutter clearance adjusting device. A main driving motor is connected with a shearing eccentric shaft through a speed reducer and a coupling, lower ends of two shearing links are mounted on the shearing eccentric shaft, upper ends of the two shearing links are fixedly connected with a lower shear holder, a lower cutter is fixed on the lower shear holder, an upper cutter is fixed on an upper shearing clamp, the upper shearing clamp is fixed on a base, and the cutter clearance adjusting device is used for adjusting clearance between the cutters. The flying shear device can realize high-speed continuous shearing operation. Compared with a general flying shear, the flying shear device has the advantages that the shearing speed of the flying shear device is increased by two to three times, the shearing precision is increased by two to four times, and shearing burrs and curls are eliminated thoroughly.

Owner:辽宁省机械研究院有限公司

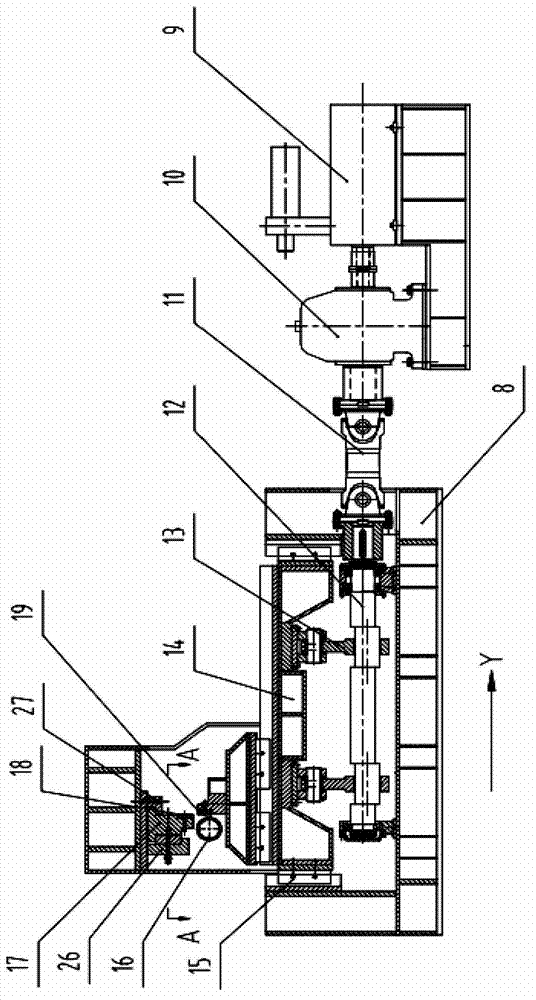

Tracking plate shearing machine for transverse plate shearing

The invention discloses a tracking plate shearing machine for transverse plate shearing and belongs to the field of metal plate shearing machinery. The tracking plate shearing machine comprises a shearing and walking device, an extensible belt device and a turnover belt device, wherein a driving system of a walking device of a shearing mechanism adopts a structure that a servo motor is matched with an accelerating air cylinder, a load is reduced during starting, starting is quick, the air cylinder absorbs inertia during returning, and positioning of a parking position is accurate. Extensible belts move with a shearing mechanism, receive sheared plates and ensure plate surface quality. The multiple extensible belts are driven simultaneously and can be independently tensioned. When a turnover belt normally works, the turnover belt is horizontal and immovable and downwards turns over during air cylinder action when a sample is needed to be taken, offline material taking is achieved, a unit is not needed to shut down, and the working efficiency is improved.

Owner:沈阳智勤机器人系统工程有限公司

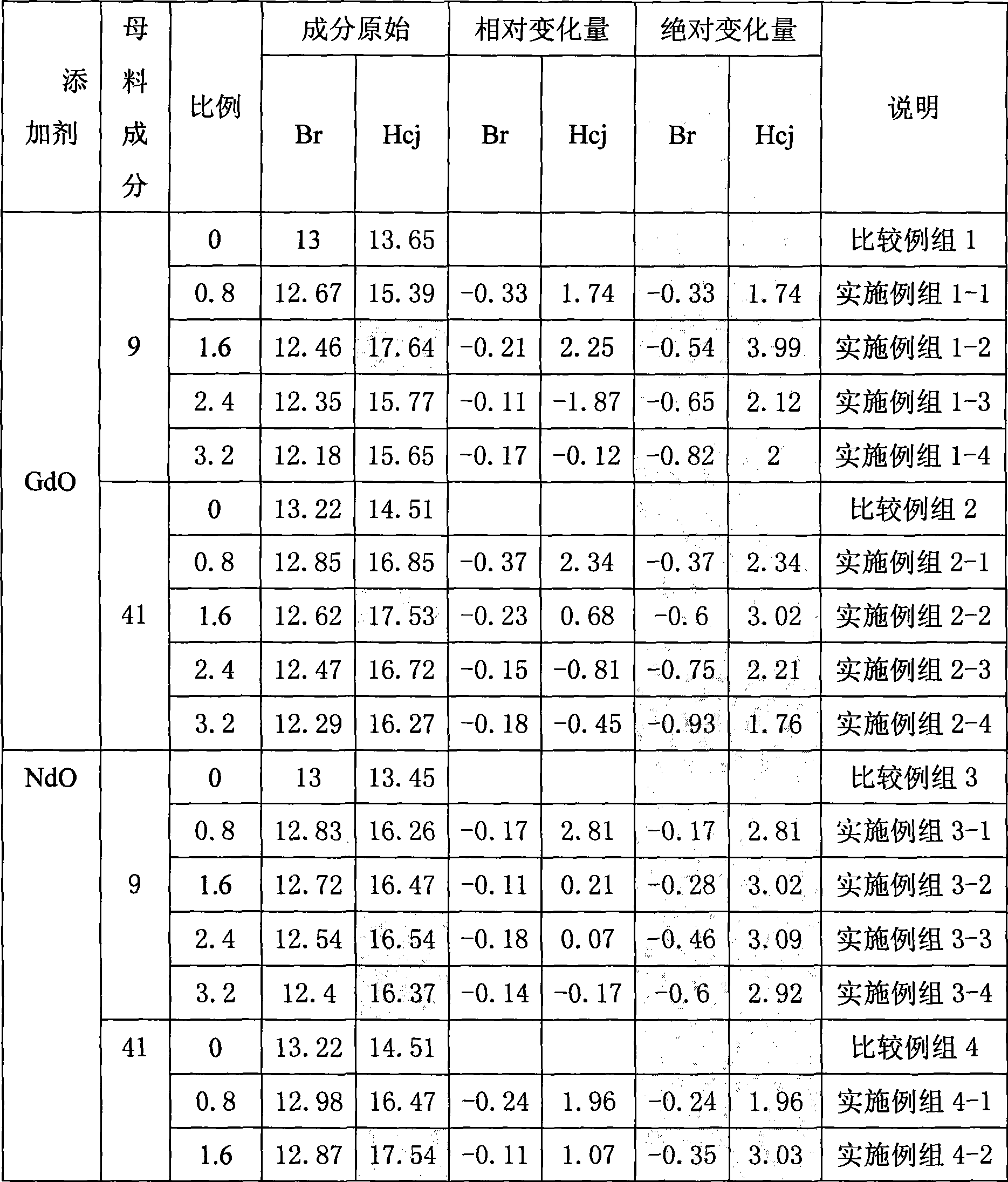

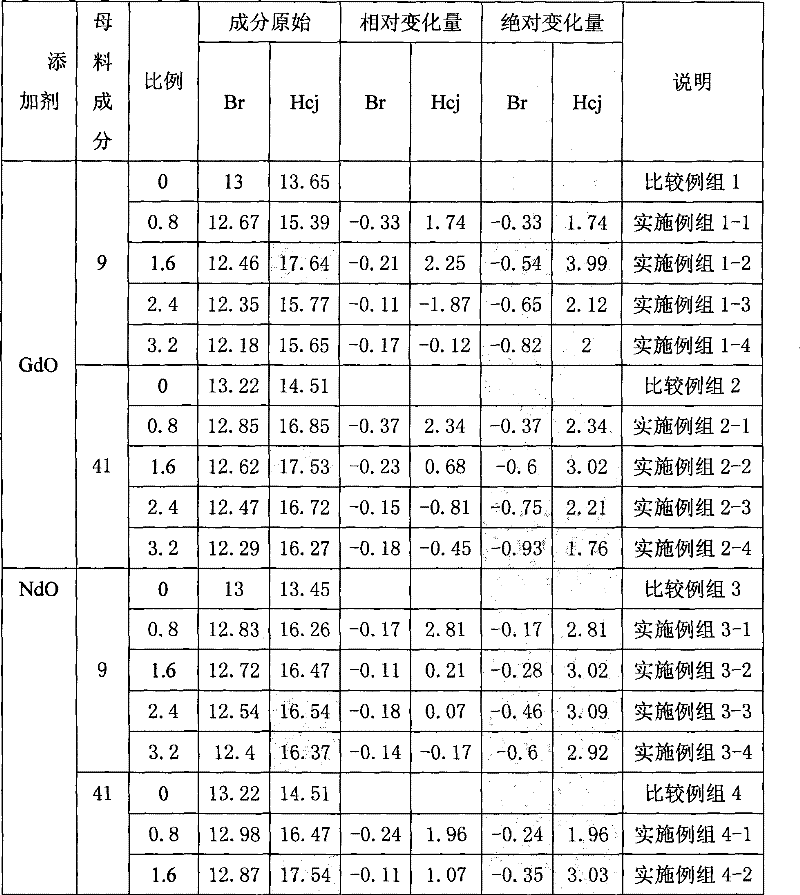

Method for improving rare earth permanent magnet coercive force

ActiveCN101499345ALow priceLow costPermanent magnetsInductances/transformers/magnets manufactureRemanenceRare earth

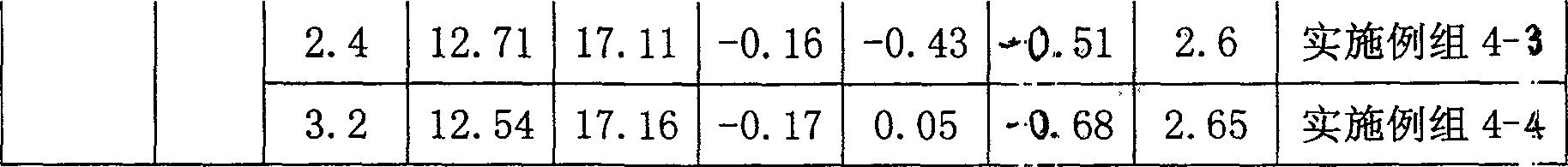

The invention discloses a method for improving coercive force of a rare-earth permanent-magnet, which is characterized in that in the process of manufacturing the rare-earth permanent-magnet, other rare-earth oxides except DyO and TbO are added into and fully mixed with prepared powdered alloy, and then the mixture is molded in an oriented way and sintered; and the added rare-earth oxides are NdO and / or GdO, and are treated by dehydration at the temperature of over 500 DEG C, and the doping proportion is 0.8-3.2% of the weight of the prepared powdered alloy. The rare-earth oxides with lower price are added into the prepared powdered alloy, and other processes are not changed, serial tests prove that when about 0.8% of rare-earth oxides are added, the coercive force is increased by 1900-3900KOe, and the remanence of the product is reduced by 200-300Gs. When the adding proportion is more than 1.6%, the remanence of the product is reduced, and the significance is significantly lowered. The method has simple technique, lower cost and remarkable effect.

Owner:SINO MAGNETICS TECH

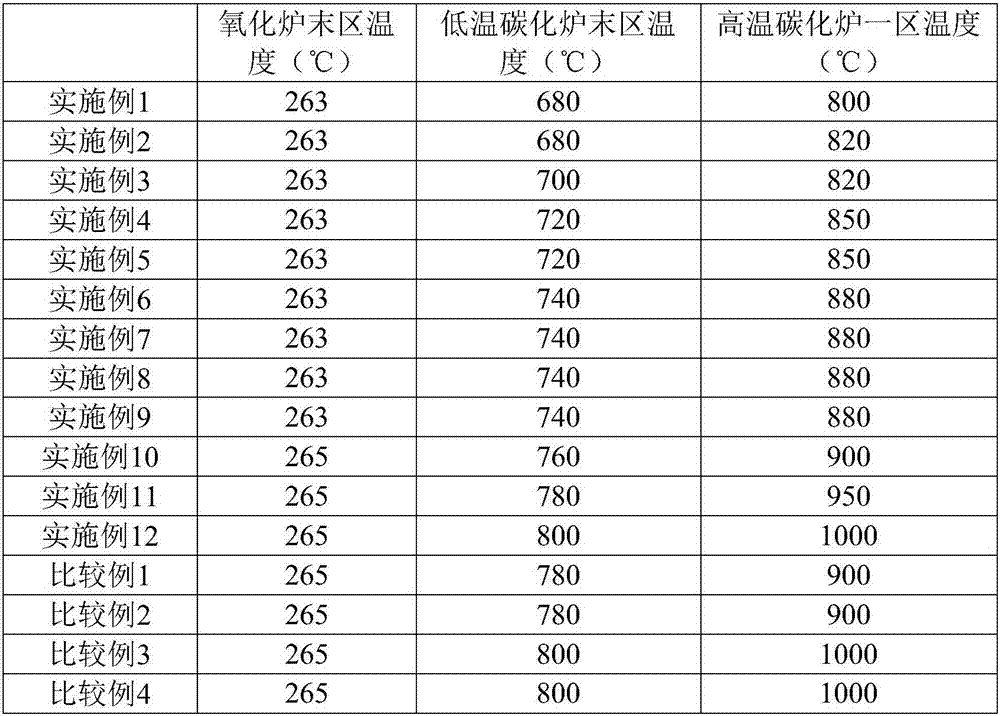

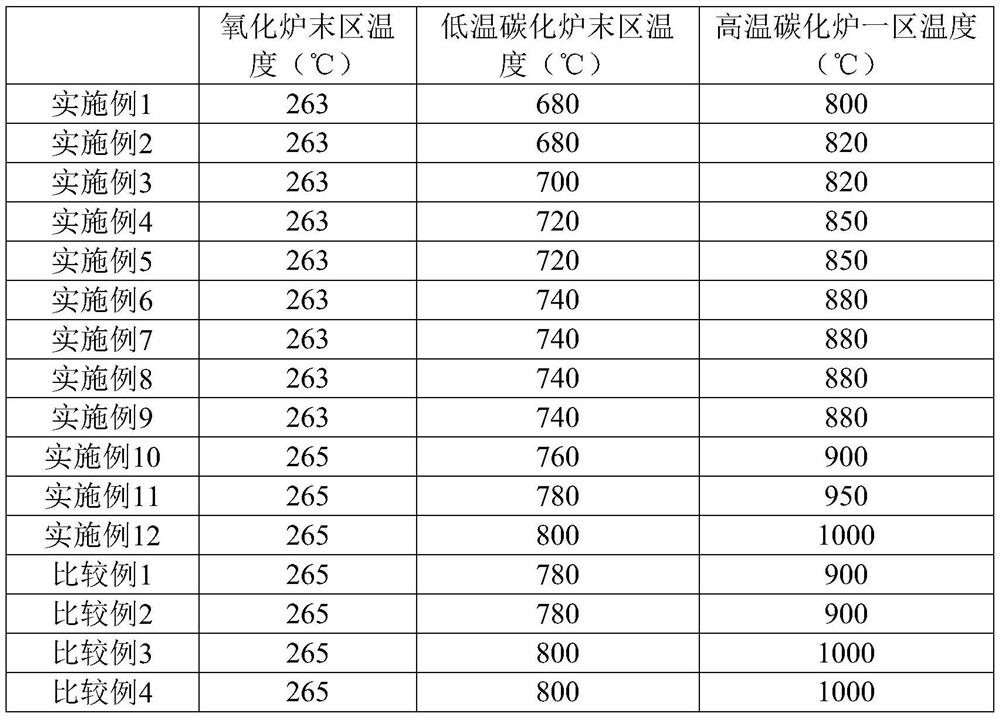

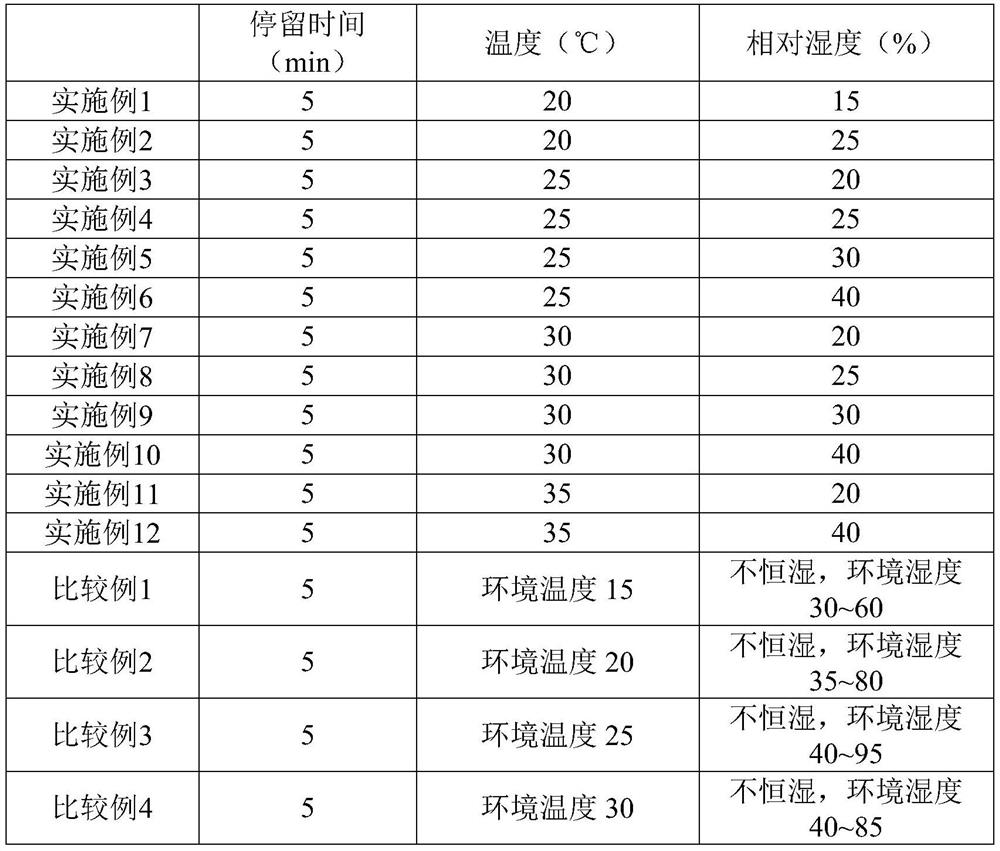

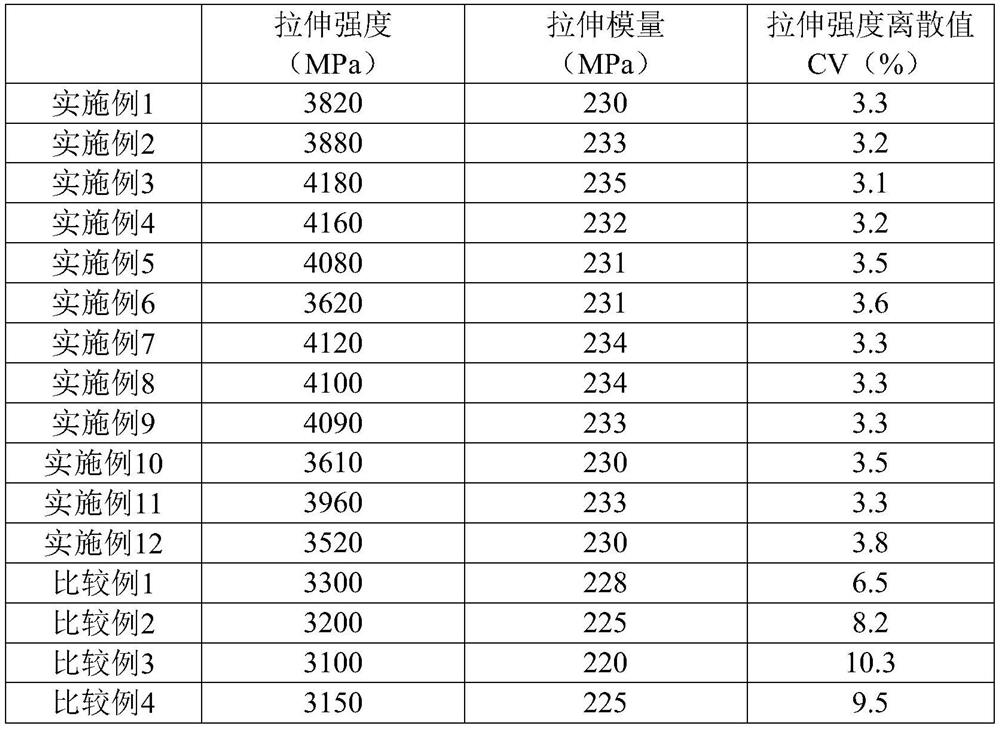

Method for improving strength of polyacrylonitrile-based carbon fibers

ActiveCN107881599ASmall temperature differenceReduce water absorptionFibre chemical featuresUniform - qualityMoisture

The invention discloses a method for improving strength of polyacrylonitrile-based carbon fibers. The method comprises the following steps: enabling polyacrylonitrile-based carbon fibers to immediately enter an environment with controlled temperature and humidity after tows are discharged out of an oxidizing furnace and a low-temperature carbonized furnace, so that a series of moisture absorptioneffects generated after the tows enters the humid environment are avoided; and enabling moisture absorbed after the tows enter the opening of the low-temperature carbonized furnace to be instantaneously gasified and bound to carbon atoms in the fibers, and releasing CO and other gases, so that defects or holes are reserved on the surfaces of the tows or inside the tows, and the strength and otherperformances of the fibers are reduced. According to the method disclosed by the invention, fluctuations brought to the strength and other performances of the carbon fibers due to changes of the temperature and humidity of the environment can be avoided, so that the prepared carbon fibers have excellent performances such as small quantity of holes, uniform quality, low discrete property, high strength and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

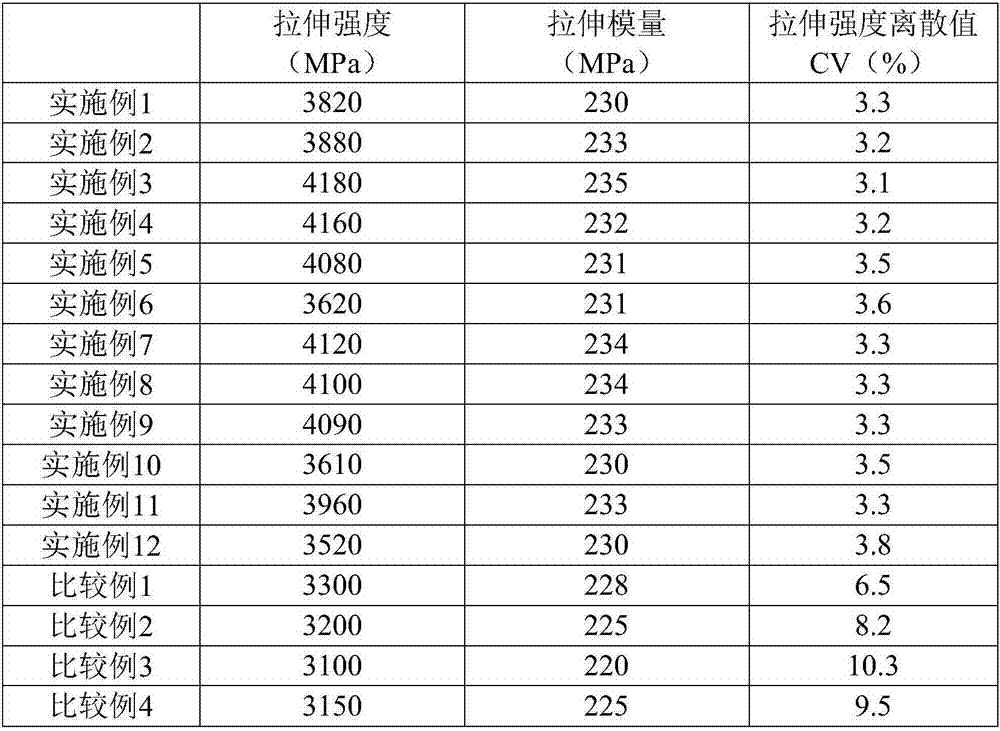

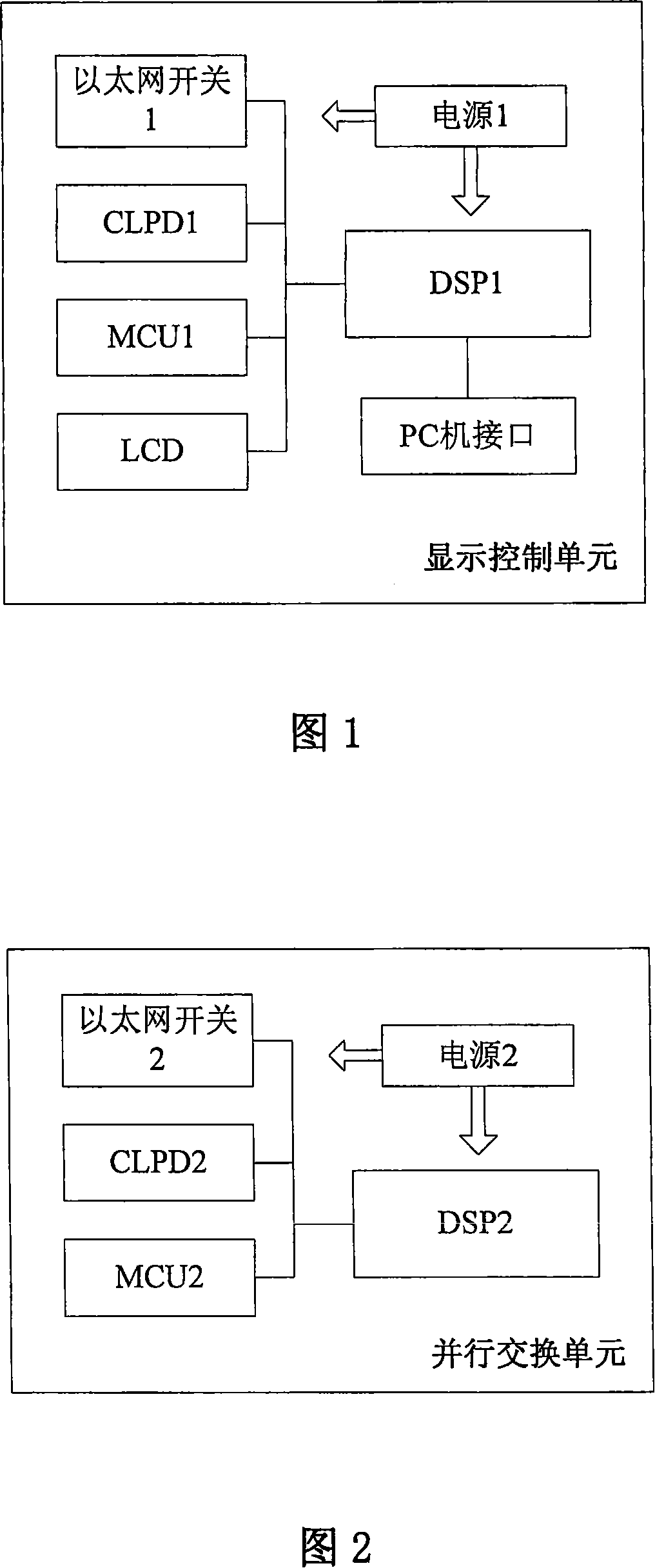

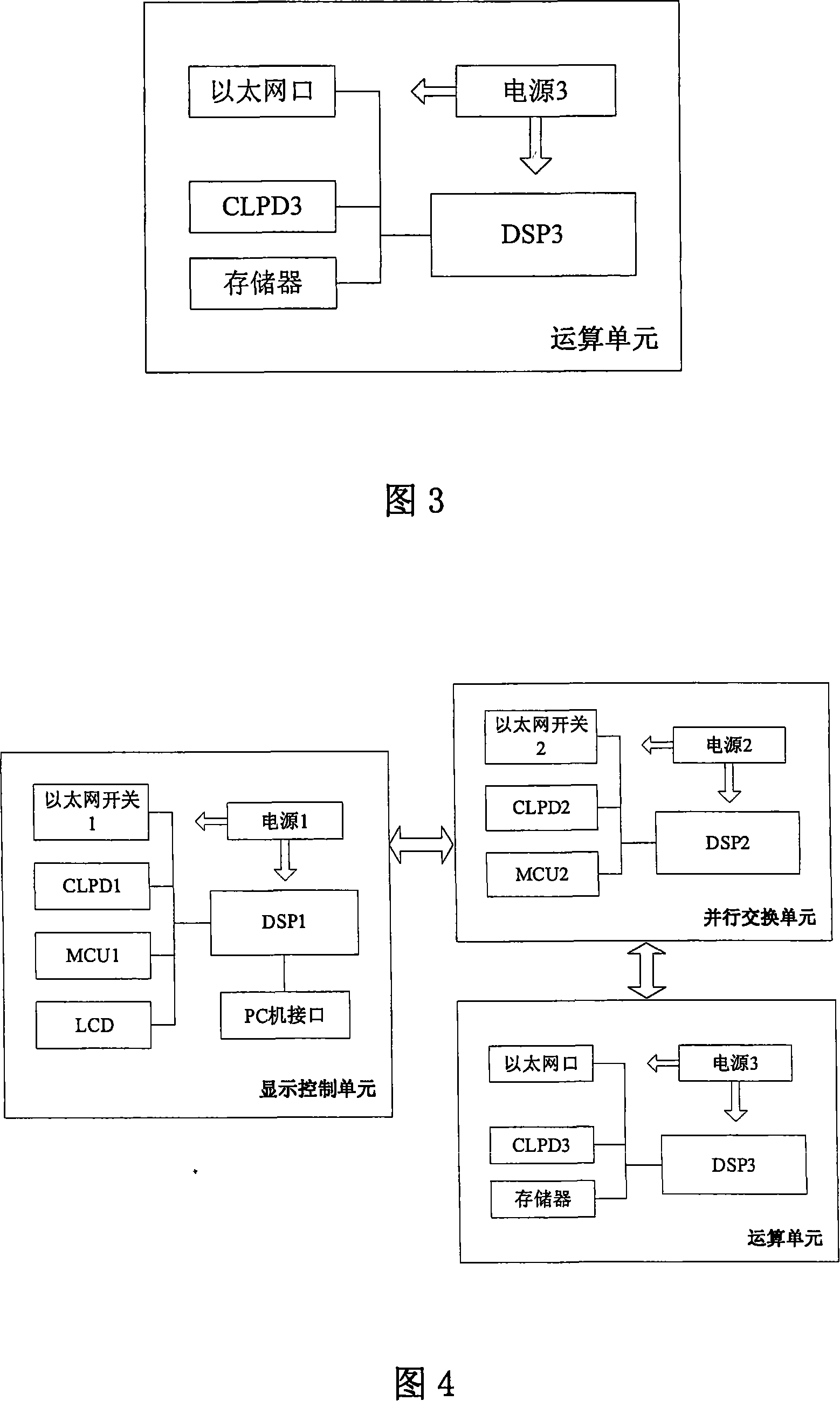

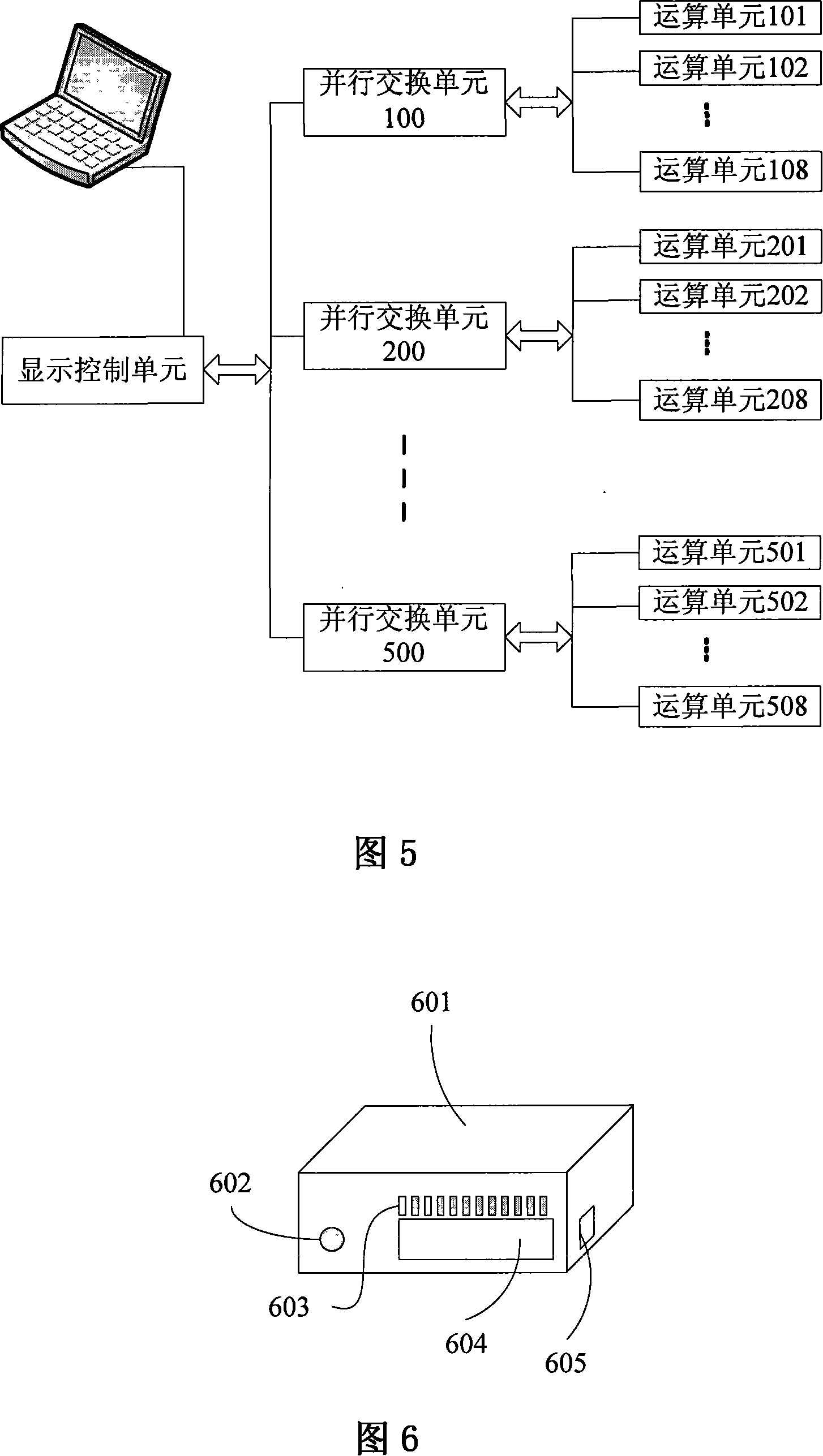

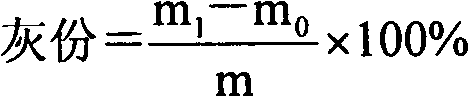

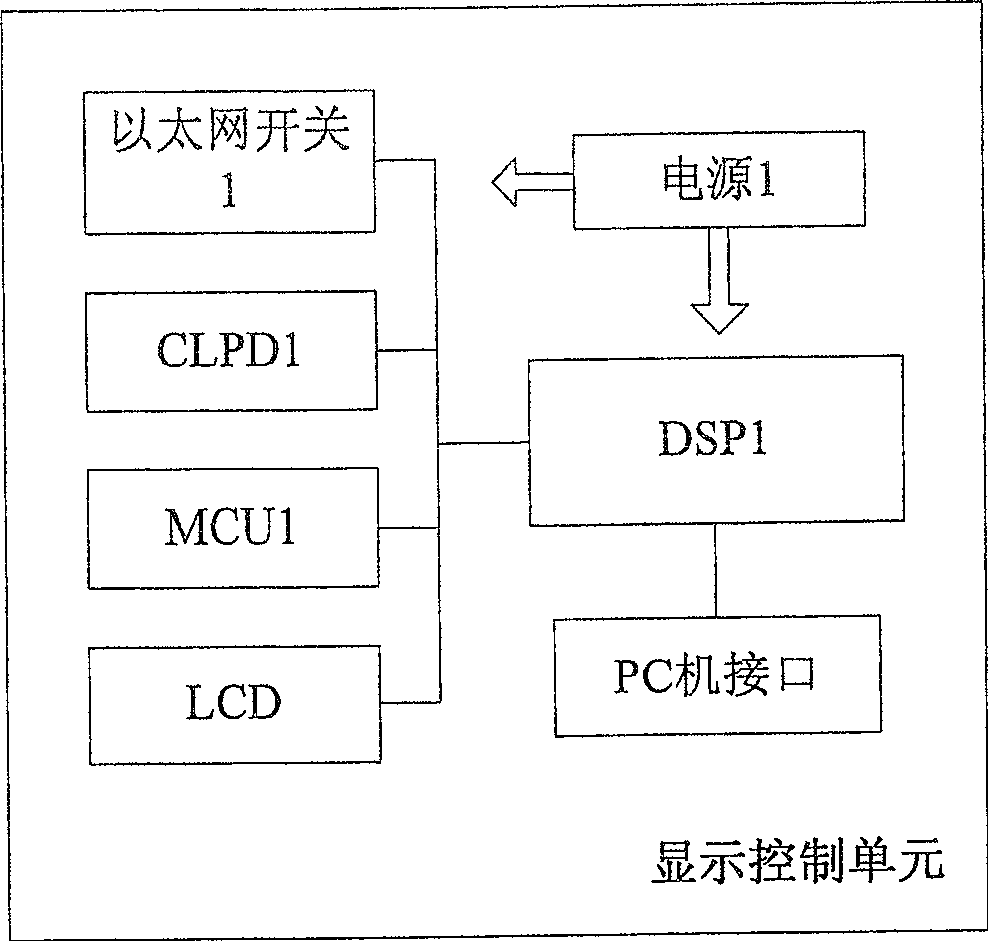

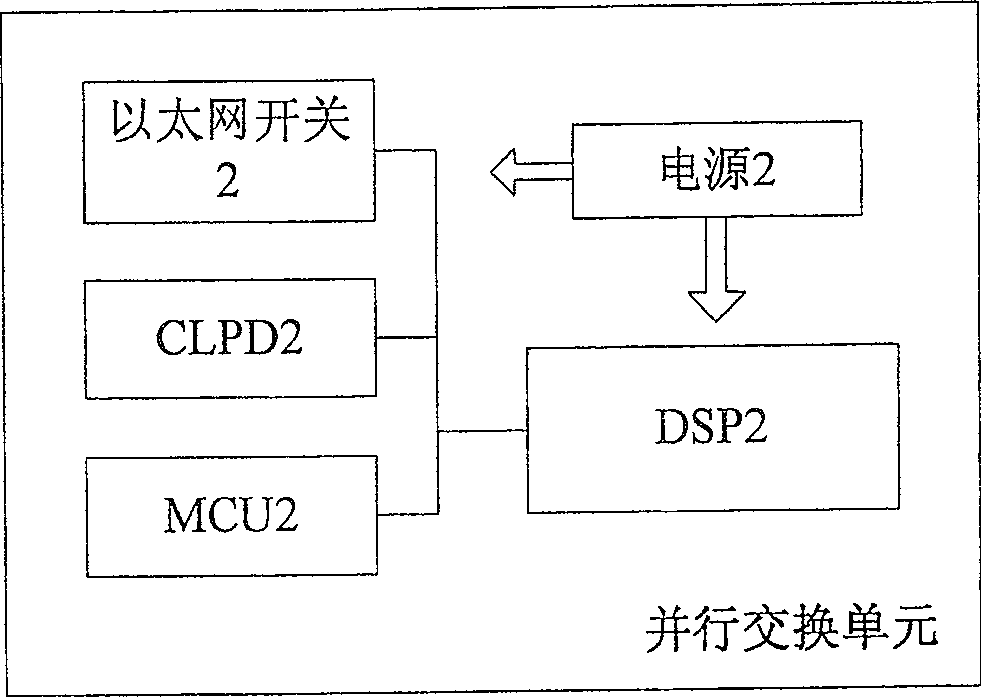

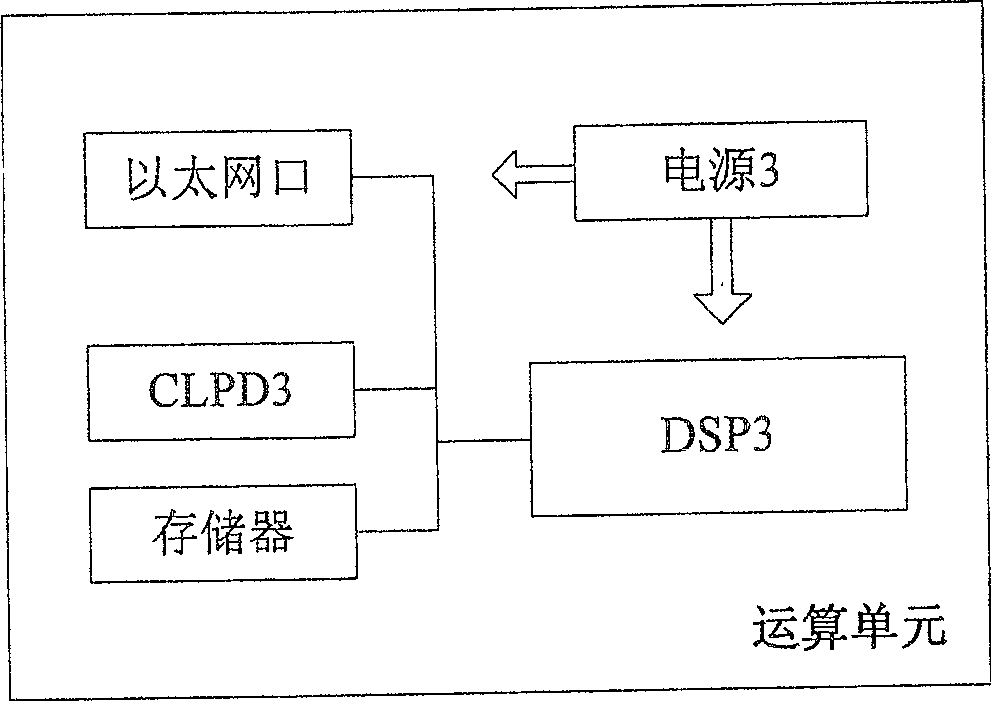

Paralleling calculating machinery based on DSP and system

ActiveCN101140559ASmall footprintReduce power consumptionDigital computer detailsStore-and-forward switching systemsCommunication interfaceControl logic

The invention provides a parallel calculation device and system based on DSP; the device comprises: A display control unit that is composed of the first DSP and the first microprocessor connected with the first DSP, the first programmable control logic element, a display monitor and at least two communication interfaces; a parallel exchange unit that is composed of the second DSP and the second microprocessor connected with the second DSP, the second programmable control logic element and at least three communication interfaces; an arithmetic unit that is composed of the third DSP and the third programmable control logic element connected with the third DSP, storages and communication interfaces; moreover, one communication interface of the parallel exchange unit is connected with one communication interface on the display control unit; the other two communication interfaces on the parallel exchange unit are respectively connected with the communication interfaces on the two the arithmetic units. The invention aims at resolving the problems of high cost, large occupied area and high power consumption in parallel calculation devices.

Owner:SUZHOU LAND HIGH TECH SYST SCI & TECHCO

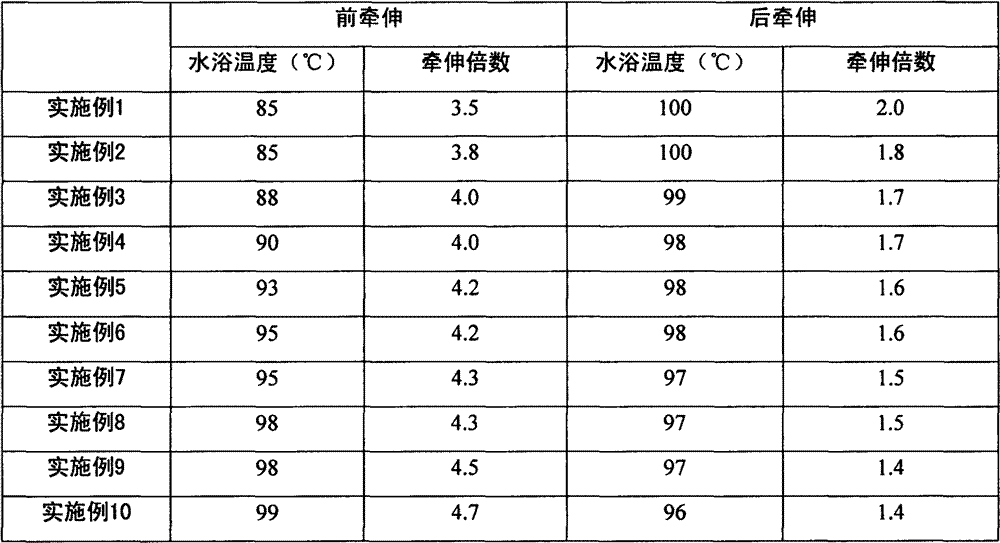

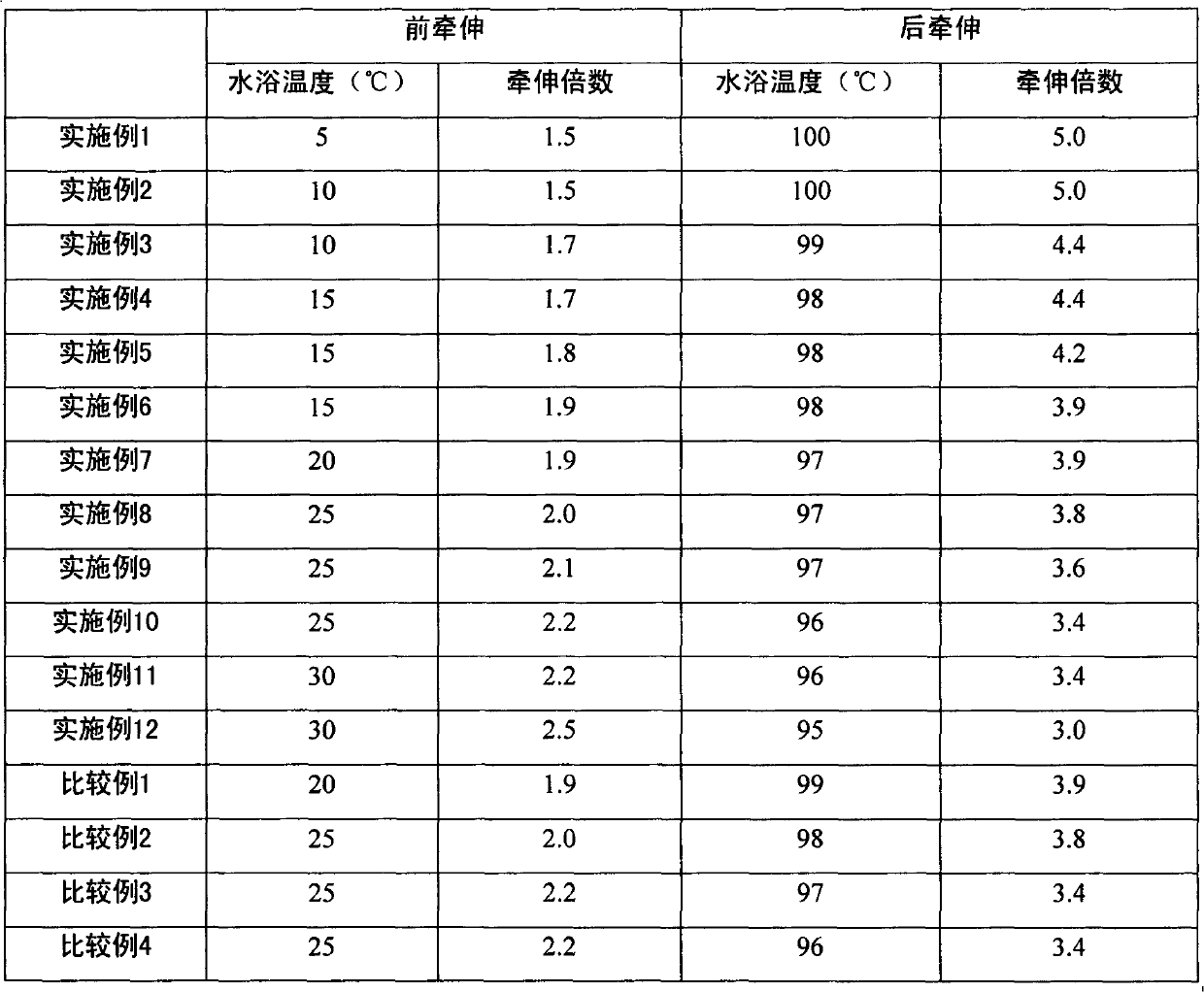

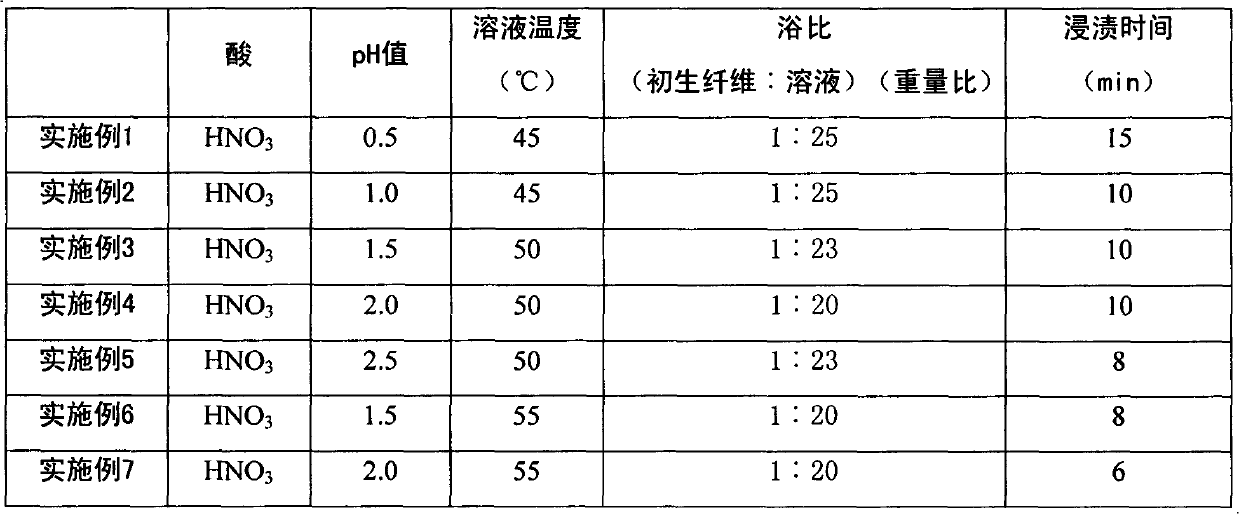

Preparation method for polyacrylonitrile-based carbon fiber protofilament

InactiveCN102953144ADrafting smoothlyHigh breaking strengthArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsBreaking strength

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a spinning raw material, i.e., polyacrylonitrile resin, is itaconic acid; a spinning solution is prepared from the resin by using DMSO or DMAc, and spinning and solidification are carried out so as to prepare a nascent fiber. The nascent fiber successively undergoes the following procedures: drip washing with deionized water; dipping in an acidic aqueous solution for 2 to 10 min; dipping in a sodium hydroxide or potassium hydroxide aqueous solution for 1 to 5 min; water bath drafting in pure water; dipping in the acidic aqueous solution for 2 to 8 min; and rinsing with deionized water until rinsing liquid is neutral. A carbon fiber protofilament is prepared by subjecting the nascent fiber to post-processing procedures like oiling and dry densification. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected, so the defects of the prior art are compensated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Thermoplastic high-voltage cable insulation material and preparation method thereof

ActiveCN106543563BGood dispersionHigh breakdown strengthPlastic/resin/waxes insulatorsThermoplasticPolymer science

Owner:SHANGHAI JIAOTONG UNIV +1

Blast furnace copper cooling plate water leakage inspection method and online cutting and blocking method

The invention discloses a blast furnace copper cooling plate water leakage inspection method and an online cutting and blocking method. Firstly, the water leakage direction is determined according to the temperature tendency of a furnace body thermocouple and the single-direction flow meter fluctuation tendency of a cooling system, ignition is conducted according to the exhausting and breathing situation, and water leakage string copper cooling plates are determined; and finally, a specific water leakage copper cooling plate is determined in the water leakage string copper cooling plates. According to the blast furnace copper cooling plate water leakage inspection method and the online cutting and blocking method, through the water feeding and retreating valve water closing examination, whether the copper cooling plate is damaged or not is judged, if no breathing phenomenon exists in a valve, it is shown that cooling equipment is in good condition, and if breathing of an exhaust valve happens, it is shown that the cooling equipment is damaged, confirmation is achieved through assistance of ignition of outer coal gas, a specific string and a specific block are sought, industrial water circulates through changing for serious damage, and the water leakage amount is controlled. The specific cooling plate is sought firstly, then judgment of an inner cavity and an outer cavity is conducted, and through the outer metal hose connecting manner change, online dismounting and cutting and blocking are conducted. By means of the blast furnace copper cooling plate water leakage inspection method and the online cutting and blocking method, an inner channel and an outer channel of the damaged copper cooling plate can be rapidly sought and cut away, a large amount of cooling water is prevented from leaking into a furnace, and the service life of the blast furnace is prolonged.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

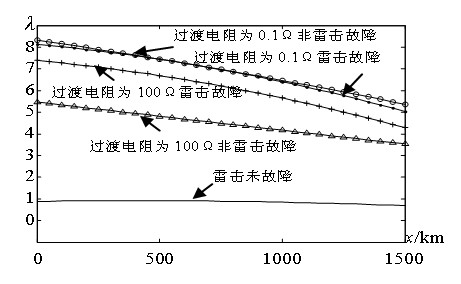

Method for recognizing lightning interference by utilizing average sampling value of short-window inner polar wave

The invention relates to a method for recognizing lightning interference by utilizing an average sampling value of a short-window inner polar wave, comprising the steps of: after a protection element starts, solving polar wave voltage according to polar line voltage and polar line current which are obtained through measurement at a relay installed place and according to formulas; directly utilizing the sampling values of the polar wave voltage and the steady-state polar line voltage in a short window; solving a ratio of the polar wave voltage to the polar line voltage which runs in a steady state; and recognizing the lightning interference by utilizing the size of the ratio, wherein the sampling frequency is 10kHz, the time widow is 5ms, the sampling is not influenced by a control system,and the time-delay protection is in a ms level. By utilizing the method, the lightning interference in a full-length range of a line can be accurately recognized. The method has good robustness, verystrong performance of tolerating a transition resistance and stronger practicality and is not influenced by the interference. Proved by vast simulation results, the method provided by the invention has good effect.

Owner:KUNMING UNIV OF SCI & TECH

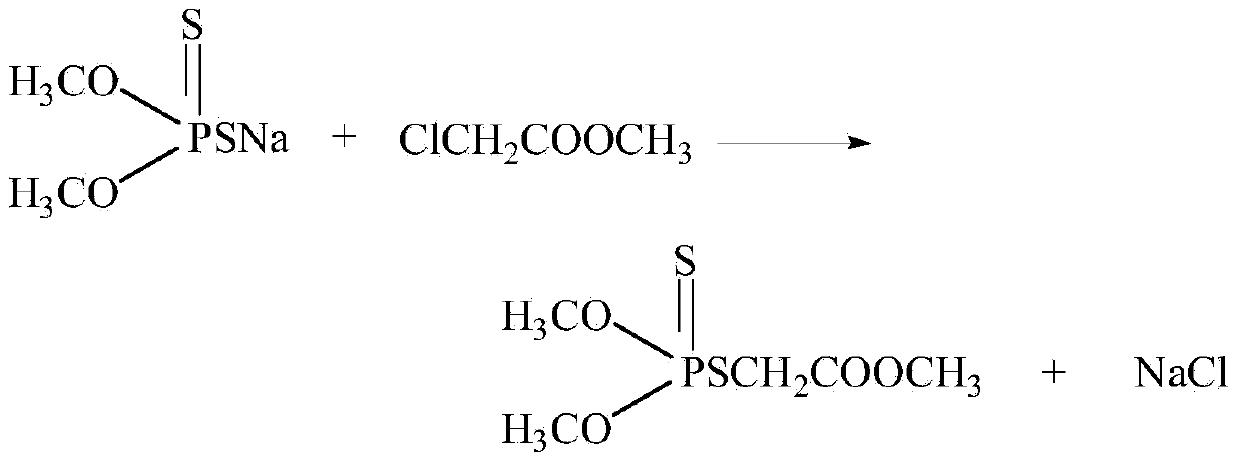

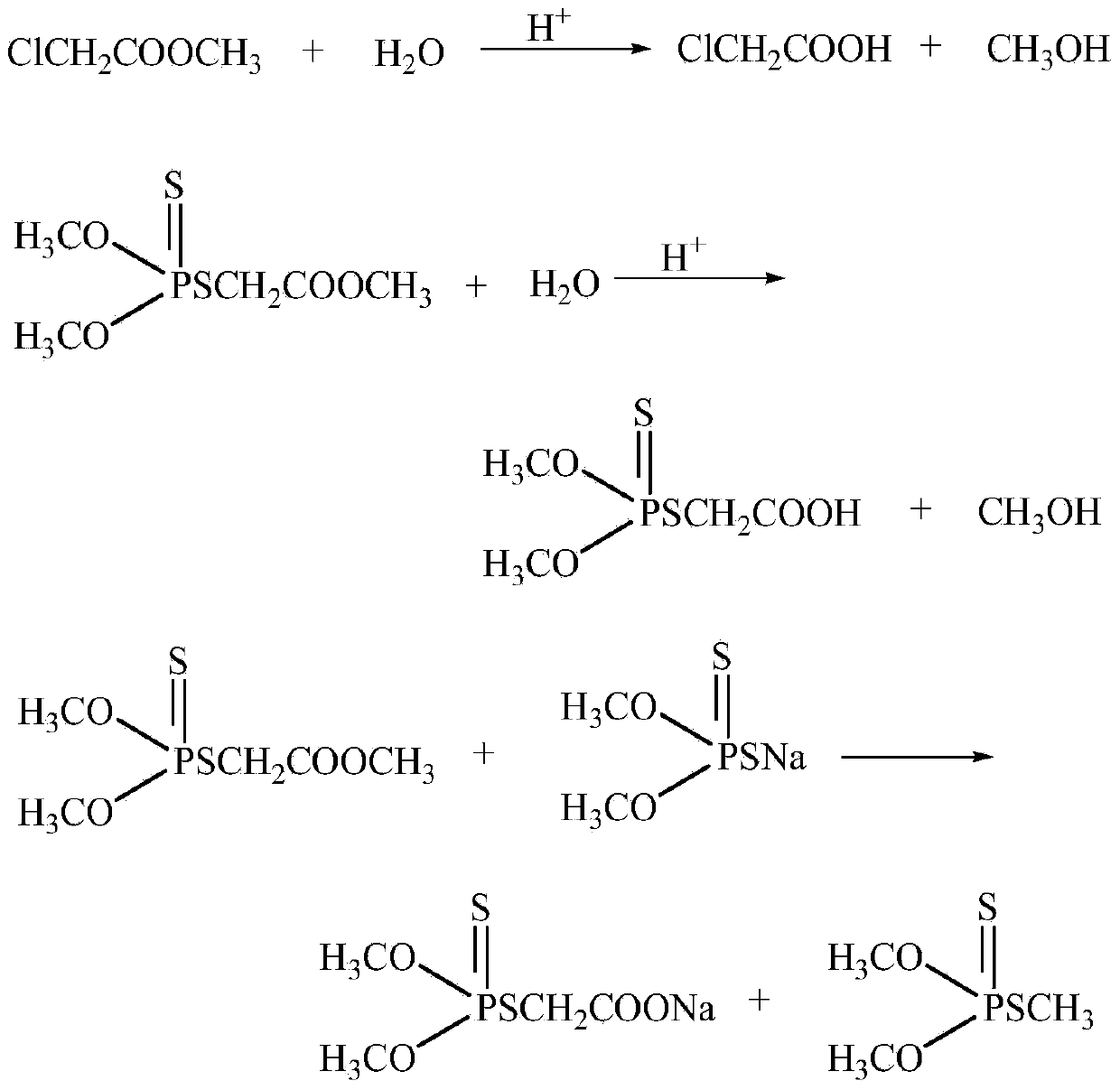

Synthetic method for thiophosphate

InactiveCN104193781AHigh yieldEmission reductionGroup 5/15 element organic compoundsDistillationThiophosphate

The invention discloses a synthetic method for thiophosphate. The synthetic method comprises the following steps: after taking thiophosphate aqueous liquor and methyl chloroacetate as raw materials to carry out primary reaction on thiophosphate and methyl chloroacetate, separating to obtain an oil phase and a water phase, carrying out continuous cyclic synthesis by virtue of the following two-step reaction: a first step, namely adding methyl chloroacetate into a water phase, reacting, and after reacting, separating to obtain oil phase of thiophosphate-containing methyl chloroacetate and water phase capable of being subjected to posttreatment and exhausted, and a second step, namely adding thiophosphate aqueous liquor into the oil phase of thiophosphate-containing methyl chloroacetate to react, and after the reacting, separating to obtain the oil phase containing thiophosphate and excessive methyl chloroacetate and the water phase, wherein methyl chloroacetate is separated from the oil phase containing thiophosphate and excessive methyl chloroacetate by virtue of distillation to obtain the thiophosphate, and circulating the water phase to the first step. The synthetic method is high in yield, short in synthesis time and low in cost, capable of effectively utilizing various raw materials and products and lowering the content of the thiophosphate in wastewater, and environmentally friendly.

Owner:XIANGTAN UNIV

Manufacturing method for polyacrylonitrile-based carbon fiber protofilament

ActiveCN102953142ADrafting smoothlyHigh breaking strengthArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentWater bathsBreaking strength

The invention provides a preparation method for a polyacrylonitrile-based carbon fiber protofilament. The third monomer of a spinning raw material polyacrylonitrile resin is itaconic acid. The preparation method comprises the following successive steps: preparing a spinning solution from the resin by using an aqueous solution of NaSCN and carrying out spinning and solidification so as to prepare a nascent fiber; placing the nascent fiber in the aqueous solution of NaSCN for water bath drafting and carrying out drip washing with deionized water; dipping the nascent fiber in an acidic aqueous solution; dipping the nascent fiber in a sodium hydroxide or potassium hydroxide aqueous solution; placing the nascent fiber in pure water for water bath drafting; subjecting the nascent fiber to hot bath rinsing until rinsing liquid is neutral and sodium or potassium ions cannot be measured, and then continuing rinsing for 5 to 15 min; and carrying out post-processing procedures like oiling and dry densification on the nascent fiber so as to obtain a product of the polyacrylonitrile-based carbon fiber protofilament. According to the invention, purification of the protofilament is realized through rinsing, and breaking strength of fibers is not affected, so the defects of the prior art are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

Manual lithography machine aligns the workbench z-direction coarse micro-motion mechanism

ActiveCN103048896BChange forceAchieve levelingGearingPhotomechanical exposure apparatusLocking mechanismContact type

Owner:三河建华高科有限责任公司

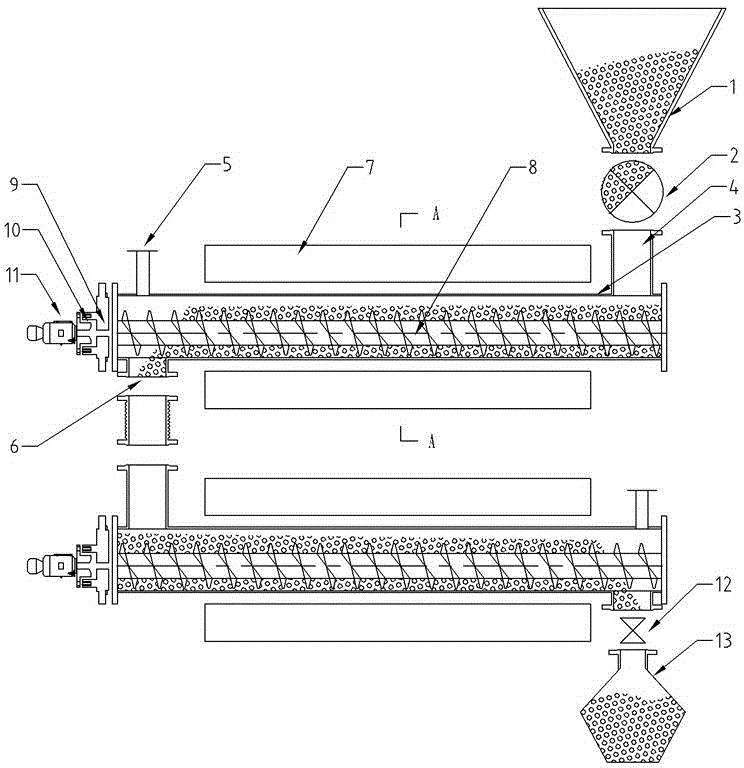

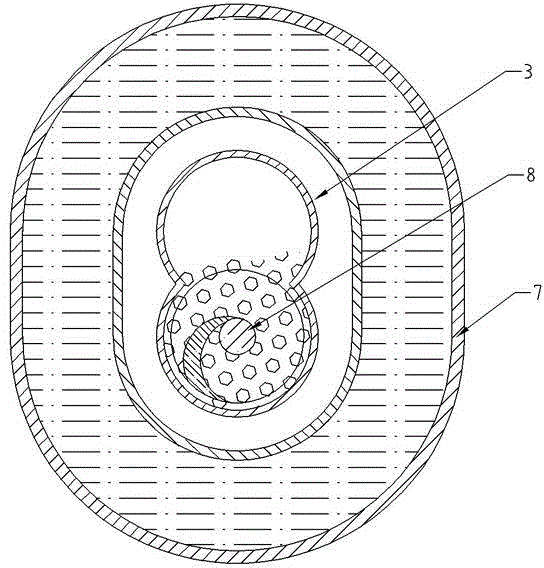

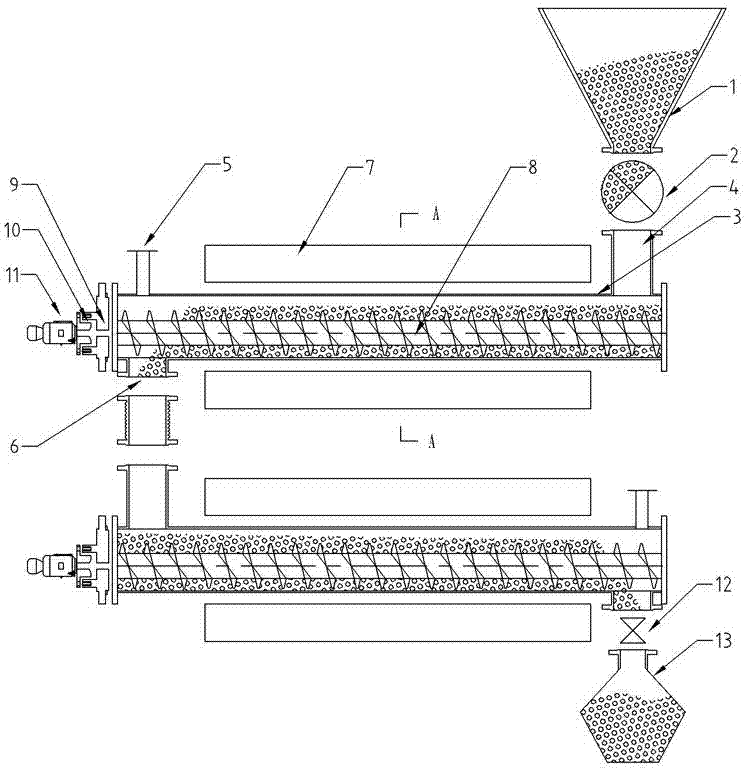

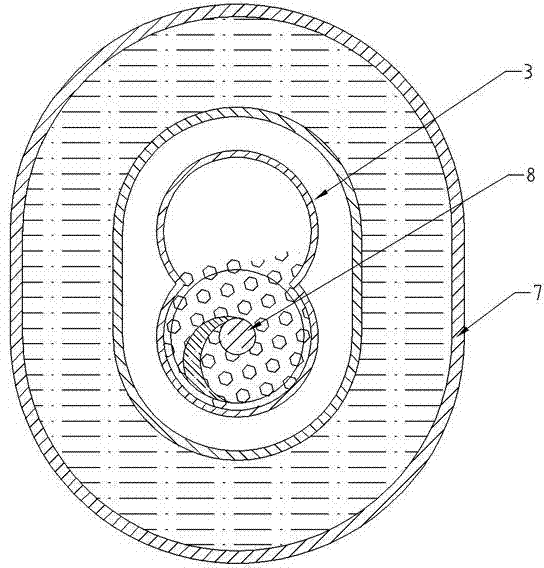

Continuous rapid drying device for grains

InactiveCN104137884AReasonable structureIngenious designSeed preservation by dryingTemperature controlPropeller

The invention relates to a continuous rapid drying device for grains and belongs to the technical field of drying. The continuous rapid drying device structurally comprises a feed system, a heating section and a discharge system, all of which are orderly connected with each other; the feed system comprises a cone-shaped feed bin and a feeder; the heating section is composed of two or more than two sections of horizontal pipes which are arranged up and down from high to low and connected in series with each other; all the sections of horizontal pipes are basically the same in structure, each section of horizontal pipe is an elongated cylinder of which the two ends are sealed with seal covers, and the part between a feeding hole and a discharge hole of the elongated cylinder is horizontally arranged in the hollow part of an elongated interlayer heat source box; a copper screw rod which is as long as a lower circular-arc-shaped groove is built in the elongated cylinder; the discharge system is composed of a receiving valve and a receiving container. The continuous rapid drying device for grains is used for drying the grain raw materials in such a manner of directly heating by use of a modified screw propeller; the continuous rapid drying device is reasonable in structure, ingenious in design, and also capable of realizing accurate temperature control and thus suitable for drying various grain raw materials relatively high in moisture content.

Owner:湖南味百信粮油有限公司

Criterion method for protection startup of extra-high voltage direct-current circuit

ActiveCN102279309BHigh graduationEasy to judgeCurrent/voltage measurementWavelet decompositionHigh-voltage direct current

Owner:KUNMING UNIV OF SCI & TECH

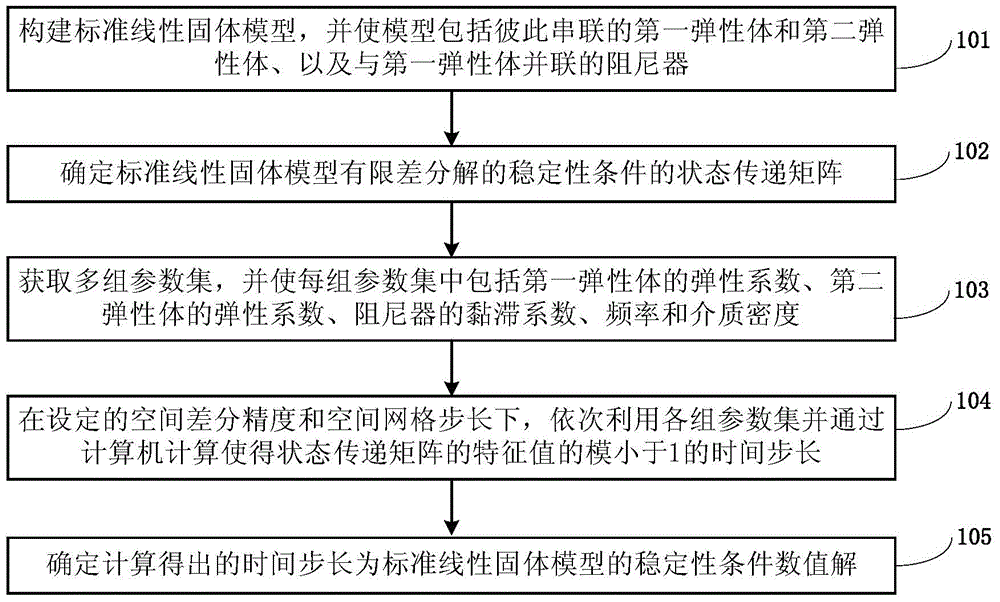

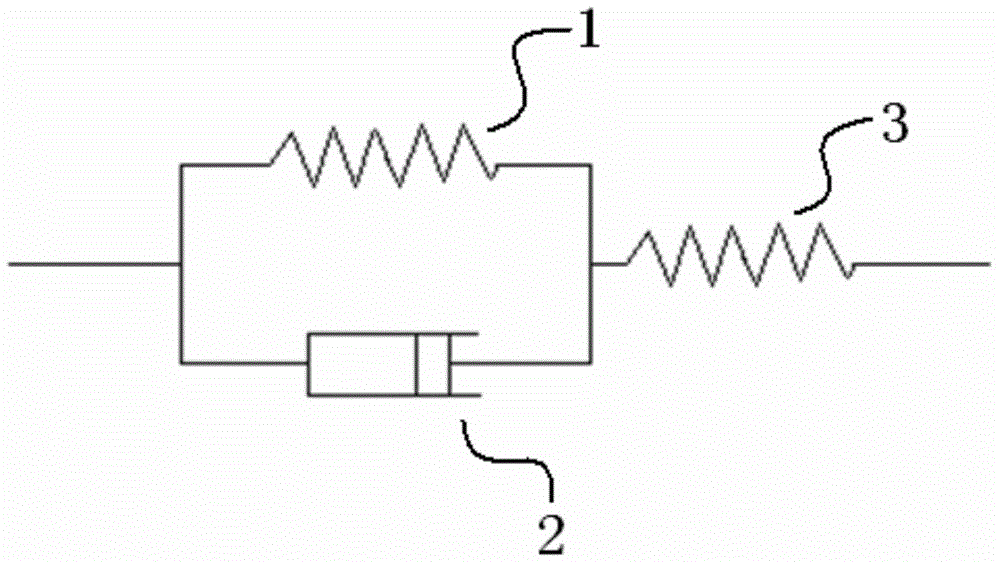

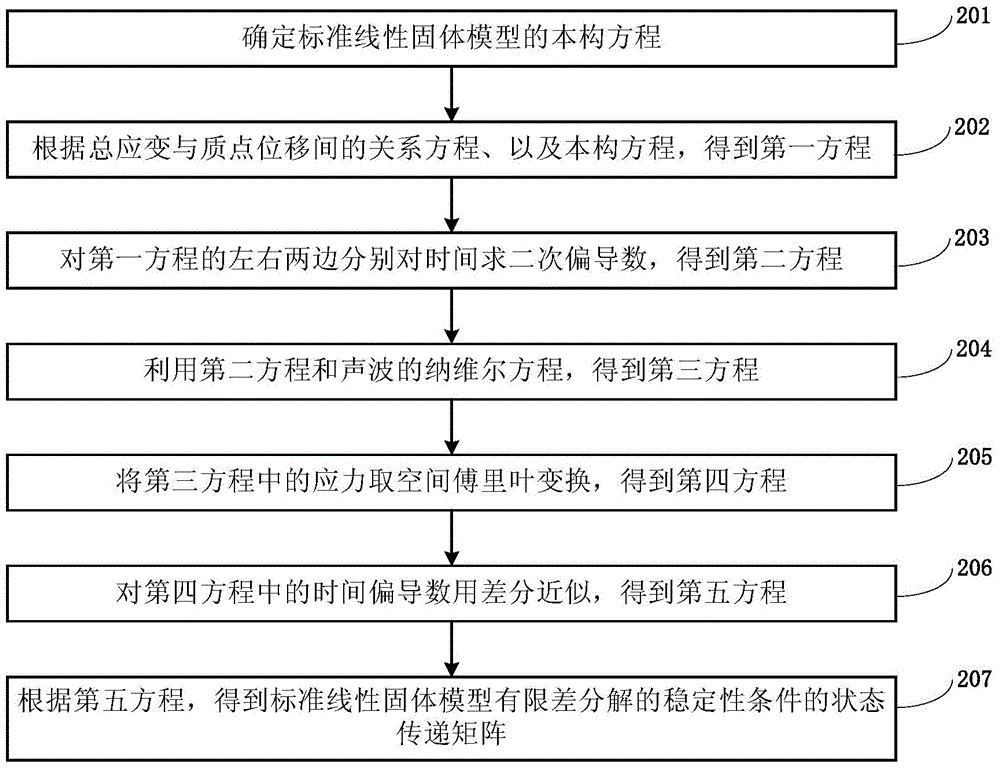

Stability condition numerical solution calculating method and system for standard linear solid model

ActiveCN105447211ASimulated Efficiency GuaranteeGuaranteed efficiencySpecial data processing applicationsElastomerStandard linear solid model

The present invention discloses a stability condition numerical solution calculating method and system for a standard linear solid model. The method comprises: constructing the standard linear solid model; determining a state transfer matrix of stability conditions of model finite difference solution; acquiring a plurality of groups of parameter sets, and enabling each group of parameter sets to comprise an elastic coefficient of a first elastomer, an elastic coefficient of a second elastomer, a viscosity coefficient of a damper, a frequency and a medium density; under set spacial differential accuracy and spacial mesh step, sequentially utilizing each group of parameter sets and carrying out calculation by a computer to enable a module of a feature value of the state transfer matrix to be smaller than a time step of 1; and determining the time step as a numerical solution. According to the stability condition numerical solution calculating method and system disclosed by the present invention, the time step which is more aligned with standard linear solid model numerical simulation of an actual viscoelastic medium can be quantitatively determined; after the time step is determined, numerical simulation based on the standard linear solid viscoelastic medium can be guaranteed to be successfully completed; the efficiency is ensured; the cost is saved; and finally, geological problems in an actual seismic exploration are solved by applying a simulated result.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paralleling calculating machinery and system based on DSP

ActiveCN100465941CSmall footprintReduce power consumptionDigital computer detailsStore-and-forward switching systemsCommunication interfaceControl logic

Owner:SUZHOU LAND HIGH TECH SYST SCI & TECHCO

Ventilating method capable of effectively inhibiting pipeline valve cavitation erosion

The invention relates to a method for inhibiting pipeline valve cavitation erosion, and belongs to the field of cavitation prevention of hydraulic engineering. In order to solve the cavitation and cavitation erosion problem of a water conveying valve in a hydraulic type boat lifter, the invention discloses a ventilating method capable of effectively inhibiting pipeline valve cavitation erosion. The ventilating method comprises the following steps of: designing a basic ventilating body form; obtaining ventilating amount needed for reducing cavitation through a decompression model test; arranging an air vent in an upstream water tube section of the valve according to the test results; and verifying main frequency loss generated by cavitation through a hydrophone. The method has the advantages that: firstly, ring-shaped ventilating measures are adopted, and aerification range is wide; secondly, aerification is performed before the valve, and aerification water flow passes through a valve runner and is sufficiently mixed, so that air bubbles are dispersed to be smaller, aerification amount is uniform, the air bubbles can be packaged better, and energy of air bubble collapse is absorbed.

Owner:NANJING HYDRAULIC RES INST +2

A continuous and rapid drying device for grain

InactiveCN104137884BHigh degree of automationInnovativeSeed preservation by dryingTemperature controlPropeller

The invention relates to a continuous rapid drying device for grains and belongs to the technical field of drying. The continuous rapid drying device structurally comprises a feed system, a heating section and a discharge system, all of which are orderly connected with each other; the feed system comprises a cone-shaped feed bin and a feeder; the heating section is composed of two or more than two sections of horizontal pipes which are arranged up and down from high to low and connected in series with each other; all the sections of horizontal pipes are basically the same in structure, each section of horizontal pipe is an elongated cylinder of which the two ends are sealed with seal covers, and the part between a feeding hole and a discharge hole of the elongated cylinder is horizontally arranged in the hollow part of an elongated interlayer heat source box; a copper screw rod which is as long as a lower circular-arc-shaped groove is built in the elongated cylinder; the discharge system is composed of a receiving valve and a receiving container. The continuous rapid drying device for grains is used for drying the grain raw materials in such a manner of directly heating by use of a modified screw propeller; the continuous rapid drying device is reasonable in structure, ingenious in design, and also capable of realizing accurate temperature control and thus suitable for drying various grain raw materials relatively high in moisture content.

Owner:湖南味百信粮油有限公司

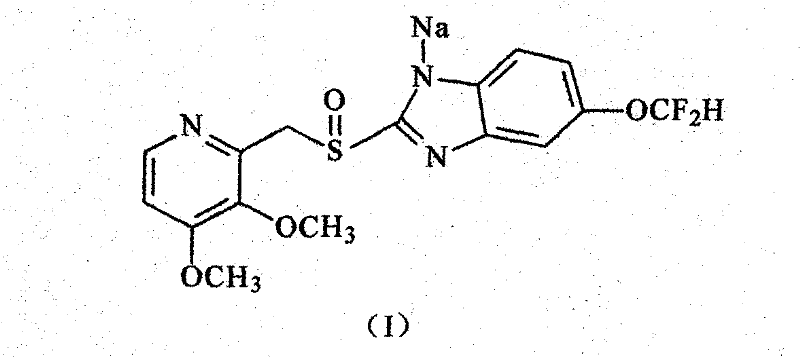

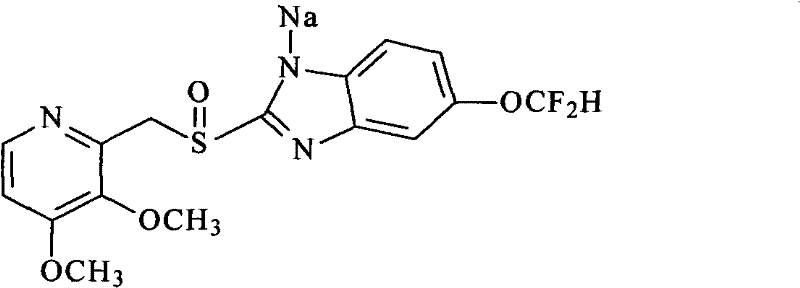

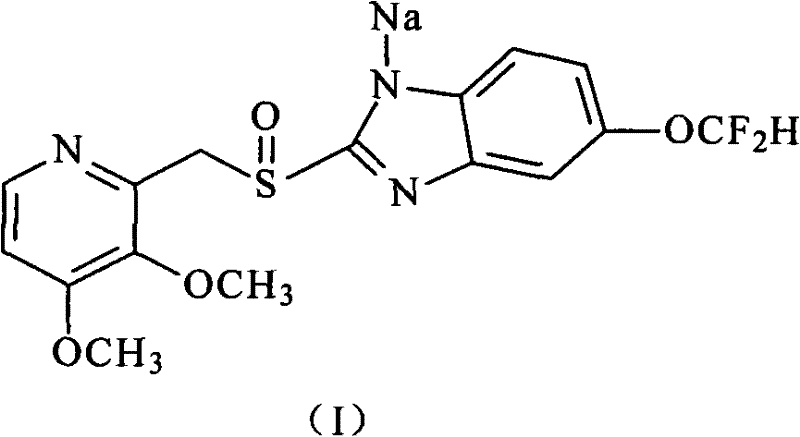

Compound of pantoprazole sodium and a preparation method thereof

InactiveCN101514198BImprove stabilityImprove clinical efficacyOrganic chemistryDigestive systemPantoprazole SodiumPantoprazole

The invention relates to a compound of pantoprazole sodium and a preparation method thereof, belonging to the technical field of medicines. By the inventive method, the refined product of pantoprazole with high yield above 90% and high purity above 99.8% is obtained, thus improving the stability and clinical application effect of the pantoprazole sodium preparation. The method of the method is simple, easy to operate, and suitable for large industrial production.

Owner:HAINAN LINGKANG PHARMA CO LTD

A tracking shearing machine for transverse shearing of plates

ActiveCN106424902BMove quicklyEasy to control speedStock shearing machinesEngineeringMechanical engineering

The invention discloses a tracking plate shearing machine for transverse plate shearing and belongs to the field of metal plate shearing machinery. The tracking plate shearing machine comprises a shearing and walking device, an extensible belt device and a turnover belt device, wherein a driving system of a walking device of a shearing mechanism adopts a structure that a servo motor is matched with an accelerating air cylinder, a load is reduced during starting, starting is quick, the air cylinder absorbs inertia during returning, and positioning of a parking position is accurate. Extensible belts move with a shearing mechanism, receive sheared plates and ensure plate surface quality. The multiple extensible belts are driven simultaneously and can be independently tensioned. When a turnover belt normally works, the turnover belt is horizontal and immovable and downwards turns over during air cylinder action when a sample is needed to be taken, offline material taking is achieved, a unit is not needed to shut down, and the working efficiency is improved.

Owner:沈阳智勤机器人系统工程有限公司

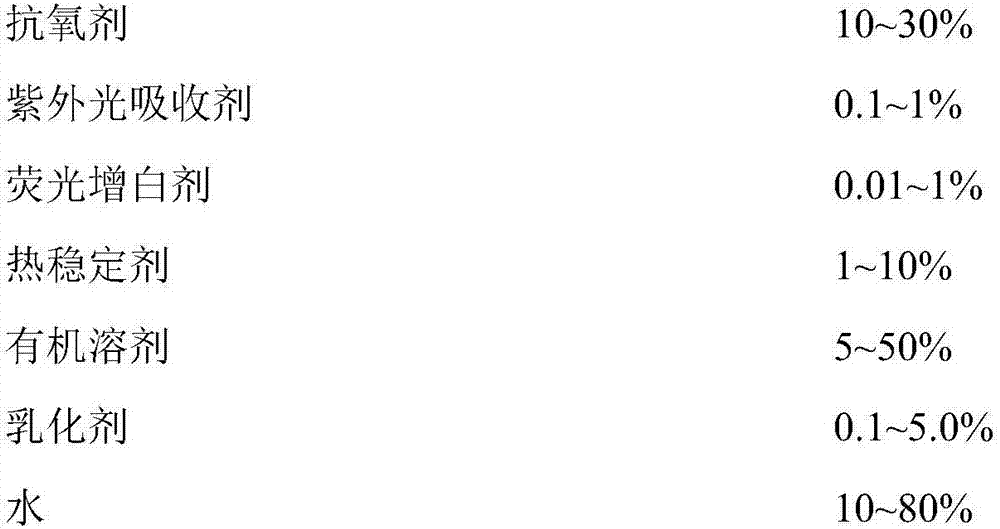

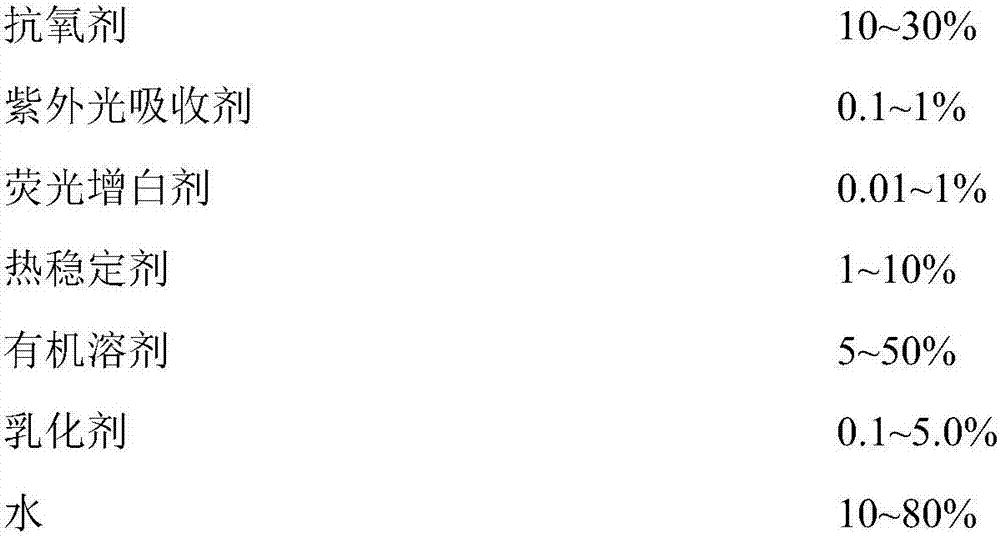

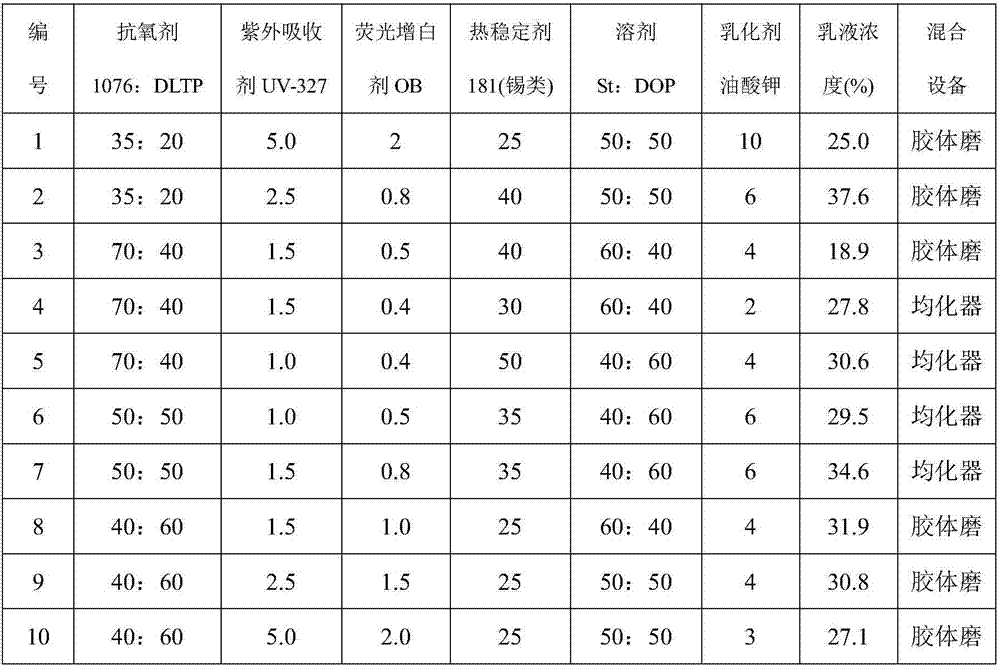

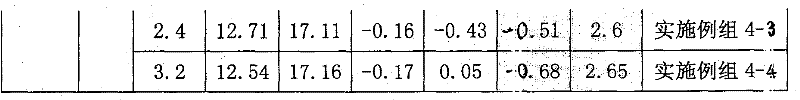

Emulsion composition for improving color of MBS resin powder, and resin prepared therefrom

The invention relates to an emulsion composition for improving the color of MBS resin powder. The emulsion composition comprises oil-phase components and water-phase components, wherein the oil-phase components comprise an antioxidant, an ultraviolet absorber, a heat stabilizer, a fluorescent brightener and an organic solvent, and the water-phase components comprise an emulsifier and water. When the emulsion composition is used, homogeneous emulsion dispersion is prepared by using a high-speed mechanical mixing manner, and the emulsion composition is added to an MBS resin emulsion in a coagulation process, so that the initial color and heat resistance of resin can be greatly improved. The emulsion composition presents complementary and synergistic effects of different aids for improving the same physical property of MBS resin, and has an excellent using effect.

Owner:山东鼎鼎化学科技股份有限公司

Method for improving rare earth permanent magnet coercive force

ActiveCN101499345BImprove coercive forceSmall residual magnetismPermanent magnetsInductances/transformers/magnets manufactureRemanenceRare earth

The invention discloses a method for improving coercive force of a rare-earth permanent-magnet, which is characterized in that in the process of manufacturing the rare-earth permanent-magnet, other rare-earth oxides except DyO and TbO are added into and fully mixed with prepared powdered alloy, and then the mixture is molded in an oriented way and sintered; and the added rare-earth oxides are NdOand / or GdO, and are treated by dehydration at the temperature of over 500 DEG C, and the doping proportion is 0.8-3.2% of the weight of the prepared powdered alloy. The rare-earth oxides with lower price are added into the prepared powdered alloy, and other processes are not changed, serial tests prove that when about 0.8% of rare-earth oxides are added, the coercive force is increased by 1900-3900KOe, and the remanence of the product is reduced by 200-300Gs. When the adding proportion is more than 1.6%, the remanence of the product is reduced, and the significance is significantly lowered. The method has simple technique, lower cost and remarkable effect.

Owner:SINO MAGNETICS TECH

A method for improving the strength of polyacrylonitrile-based carbon fiber

ActiveCN107881599BImprove mechanical propertiesPrevent water absorptionFibre chemical featuresPolymer scienceCarbon fibers

The invention discloses a method for improving the strength of polyacrylonitrile-based carbon fibers. In this method, the polyacrylonitrile-based carbon fiber enters an environment with controlled temperature and humidity immediately after the tow exits the oxidation furnace and the low-temperature carbonization furnace, so as to avoid a series of moisture absorption effects after the tow enters a humid environment, so that the tow enters The moisture absorbed after the high-temperature carbonization furnace mouth is instantly gasified and combined with the carbon atoms in the fiber, releasing CO and other gases, thereby leaving defects or holes on the surface or inside of the tow, reducing the strength and other properties of the fiber. The method of the invention can avoid fluctuations in properties such as carbon fiber strength due to changes in ambient temperature and humidity, so that the prepared carbon fibers have fewer holes, uniform quality, small dispersion, and excellent properties such as strength.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com