Method for improving rare earth permanent magnet coercive force

A rare-earth permanent magnet and coercive force technology, which is applied in the direction of magnetic objects, permanent magnets, rare-earth metal compounds, etc., can solve the problems of high price, lack of competitiveness, and high price of permanent magnet materials, and achieve low cost, simple process, and coercive force. The effect of stamina reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

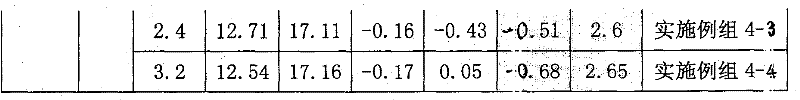

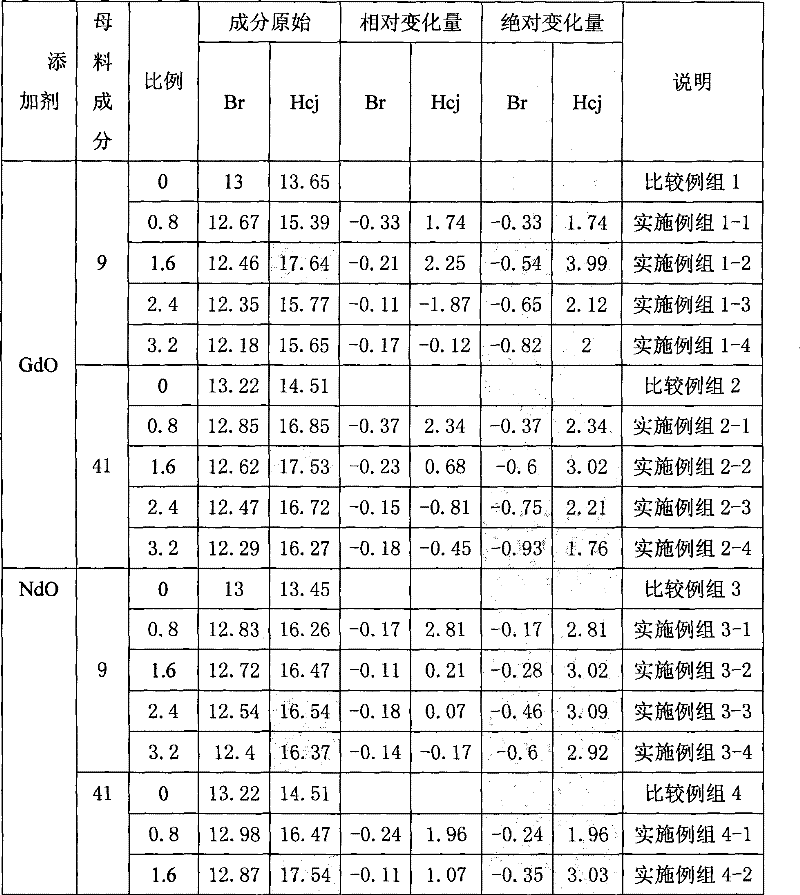

[0012] The present invention has chosen following two steel ingot alloy components:

[0013] Nd-Pr Dy Fe Al Cu B 32.40% 0.50% 65.40% 0.60% 0.10% 1.00% Alloy No. 9 Powder Composition 29.95% 1.50% 67.05% 0.40% 0.10% 1.00% Alloy 41 powder composition

[0014] Powder making: jet milling after hydrogen crushing, the particle size of the powder is 4.1 microns.

[0015] The rare earth oxide prepared (high temperature hollow treatment for vacuum removal of possible crystal water above 500° C.) is added to the prepared alloy powder according to 0.8-3.2% of its weight, and then mixed for 4 hours. The weight of the test powder is 8-15 kg per batch. In the mass production test, it was added to the medium powder before milling, and mixed for 2 hours, and then milled. The data in this test table is the test data added after jet milling.

[0016] Alloy powders without rare earth oxides and alloy powders with four different ratios of rare earth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com