Continuous rapid drying device for grains

A rapid drying and grain technology, applied in the direction of drying and preserving seeds, can solve the problems of being stored at the bottom of the box that cannot be in contact with hot air, cannot meet the needs of large-scale grain production, and affect the rapid drying of grain particles, etc., to achieve ingenious design , high degree of automation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

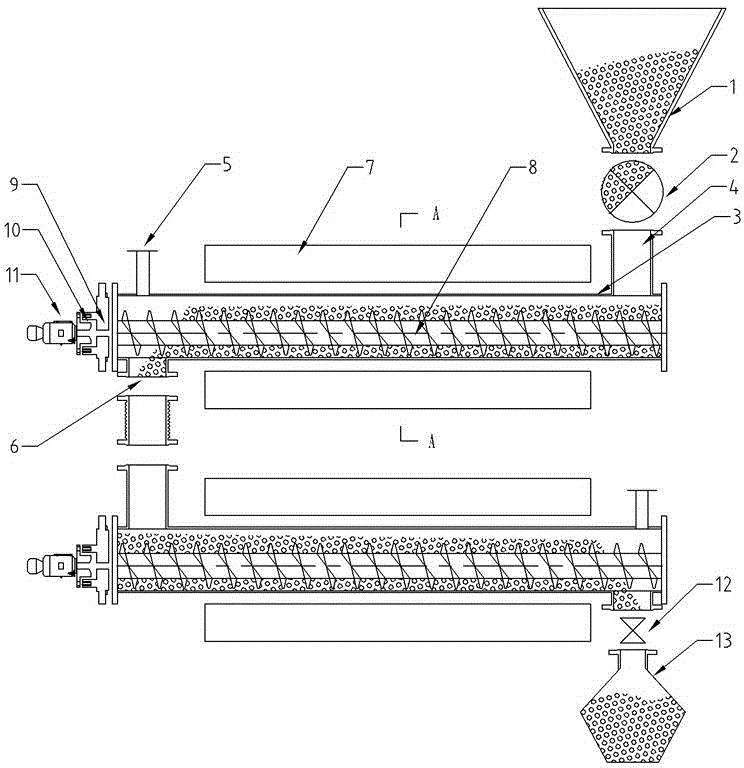

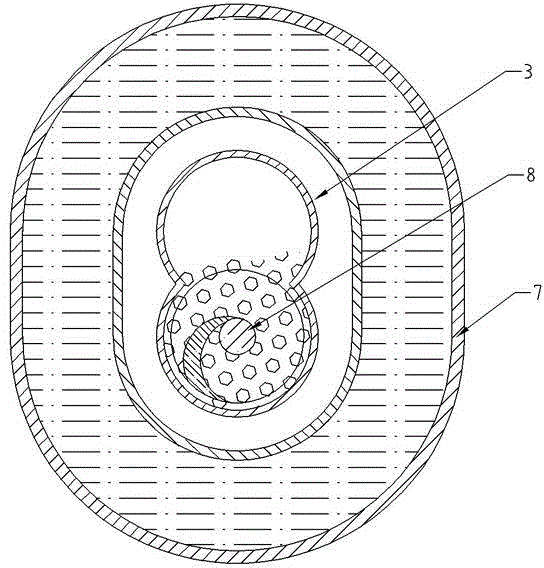

[0017] attached figure 1 And attached figure 2 , a continuous rapid drying device for grain, comprising a feeding system, a heating section and a discharging system connected in sequence; the feeding system is a conical bin 1 with a funnel opening at the bottom and a feeder 2; the feeding system, The heating section and the discharge system are connected through the measurement and control system; the heating section is two or more sections of horizontal pipes arranged from high to low, and the sections are connected in series; the first section of two or more sections of horizontal pipes is In the preheating part, the second or more horizontal tubes are the main heating and drying part; each of the above-mentioned horizontal tubes has basically the same structure, all of which are elongated cylinders 3 with caps on both ends, elongated cylinders 3 It is integrally composed of heat-conducting materials. There is a feed port 4 above one end, a water discharge port 5 connected...

Embodiment 2

[0023] The utility model relates to a continuous and rapid drying device for grain, which comprises a feeding system, a heating section and a discharging system connected in sequence. Structurally, the elongated interlayer heat source box 7 is a boiler steam box; the elongated cylinder body 3 is made of aluminum as a heat-conducting material. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com