A method for improving the strength of polyacrylonitrile-based carbon fiber

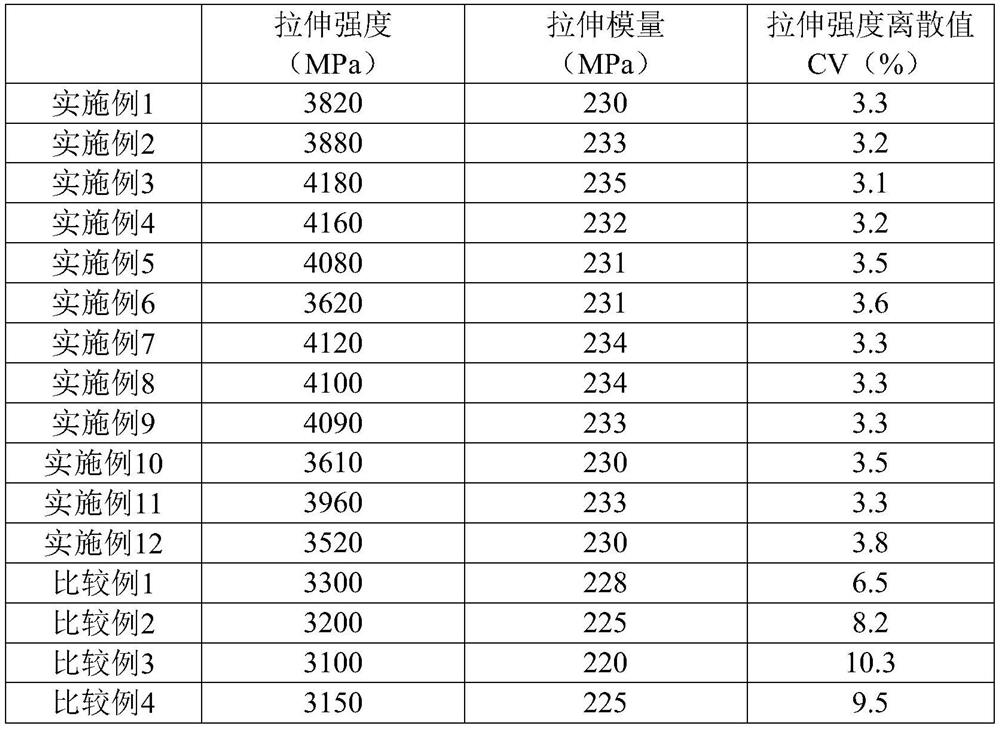

A polyacrylonitrile-based carbon fiber, strength technology, applied in the direction of chemical characteristics of fibers, textiles and papermaking, etc., can solve the problem of no technical report, and achieve the effect of obvious invention effect, stable performance and high mechanical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

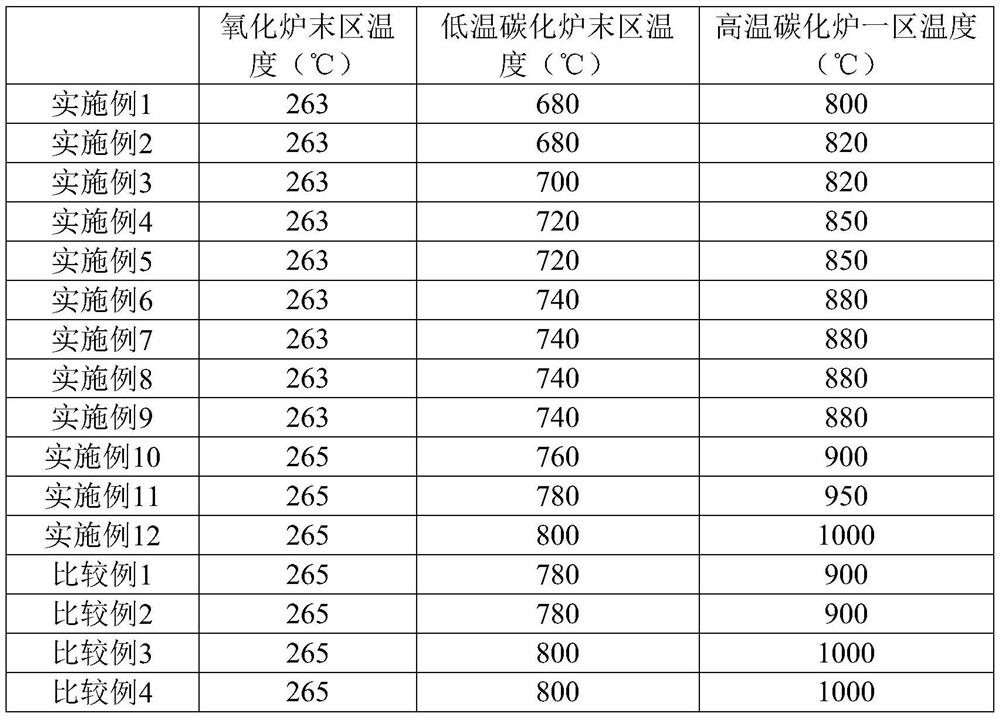

[0031] Carry out the preparation of carbon fiber according to the following steps:

[0032] 1) After warping, the polyacrylonitrile raw silk enters the 1# oxidation furnace with a temperature of 225 and 232°C at 5.5m / min and a certain tension in sequence (225 and 232°C are the control temperatures of the two temperature zones of the 1# furnace respectively, The same below), then enter the 2# oxidation furnace that the temperature is 238,245°C, and finally enter the 3# oxidation furnace that the temperature is 253,263°C, the residence time in the furnace is 95min; wherein the oxidation furnace end zone temperature of each embodiment See Table 2.

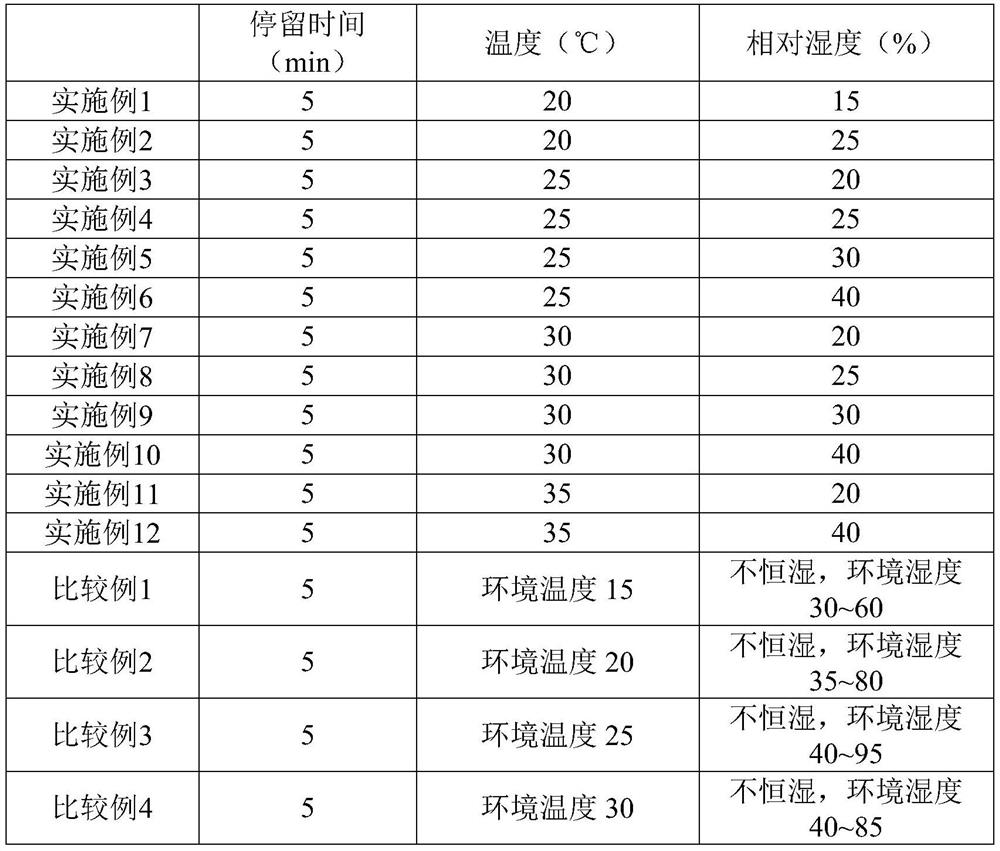

[0033] 2) The pre-oxidized wire coming out of the 3# oxidation furnace is pulled by the exit pulling roller into the first constant temperature and humidity chamber. Compressed air with a pressure of 0.6 MPa and a dew point of -40°C is introduced into the room, and the pressure in the constant temperature and humidity room is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com