Ventilating method capable of effectively inhibiting pipeline valve cavitation erosion

A technology for pipeline valves and valves, which is applied in the direction of pipe components, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve the problems of cavitation and cavitation of water delivery valves that cannot be effectively solved, gas incorporation, and cannot play a role in corrosion reduction, etc. problem, to achieve the effect of improving engineering safety, simple structure and remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

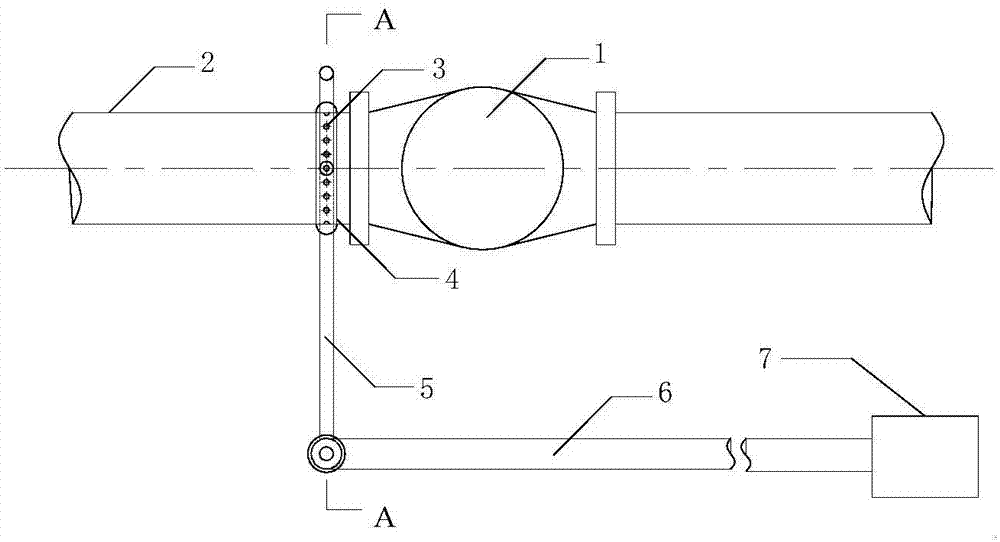

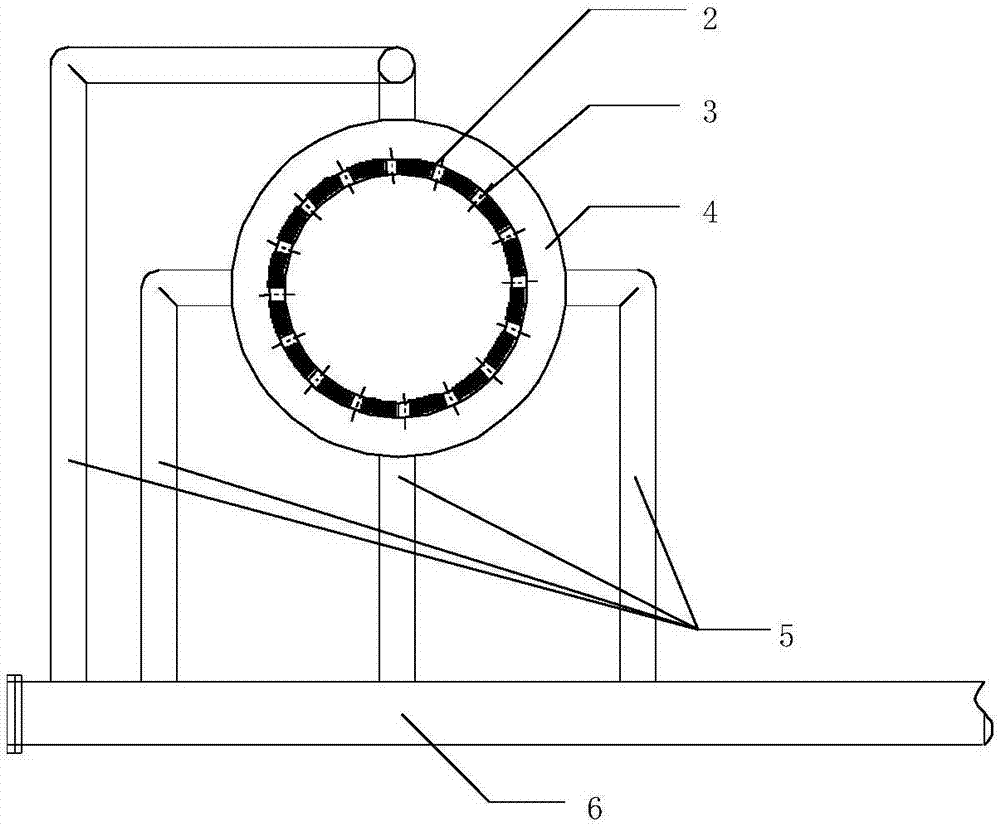

[0052] See the specific layout Figure 1~2 . Due to the high water head and high pressure in front of the valve 1, natural aspiration cannot be realized. Therefore, it is necessary to use the air compressor 7 to pressurize the air into the ventilation device, and evenly mix the water flow in front of the valve. The air bubbles distributed in the aerated water flow act as an air cushion. function, absorb the huge energy generated by cavitation collapse, and inhibit cavitation damage.

[0053] The arrangement of the implementation case of the present invention is the same as figure 1 , has been applied to a hydraulic ship lift discharge valve.

[0054] 1) Basic ventilation type design;

[0055] 2) Obtain the ventilation required for corrosion reduction through the decompression model test;

[0056] 3) According to the test results, set vent holes in the water pipe section upstream of the valve.

[0057] The 1) basic body shape design includes:

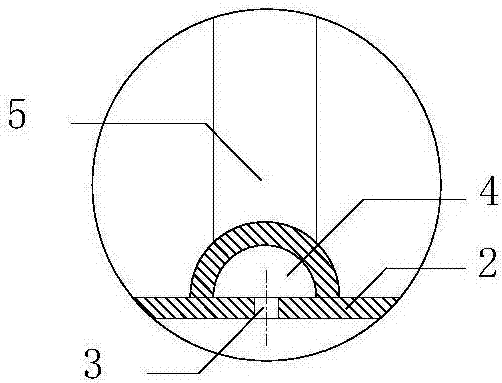

[0058] 1a) Ventilation hole 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com