Tracking plate shearing machine for transverse plate shearing

A transverse shearing and shearing machine technology, which is applied to devices for shearing and forming blanks, shearing devices, shearing machine equipment, etc., can solve the problems of inability to meet the needs of thick plate processing, and achieves remarkable invention effects, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

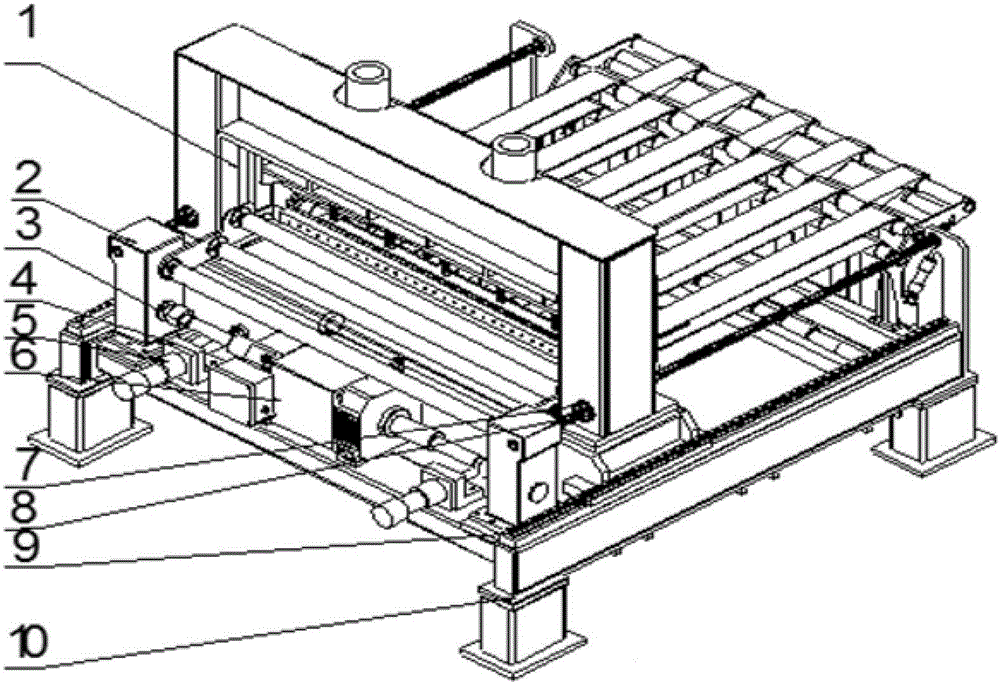

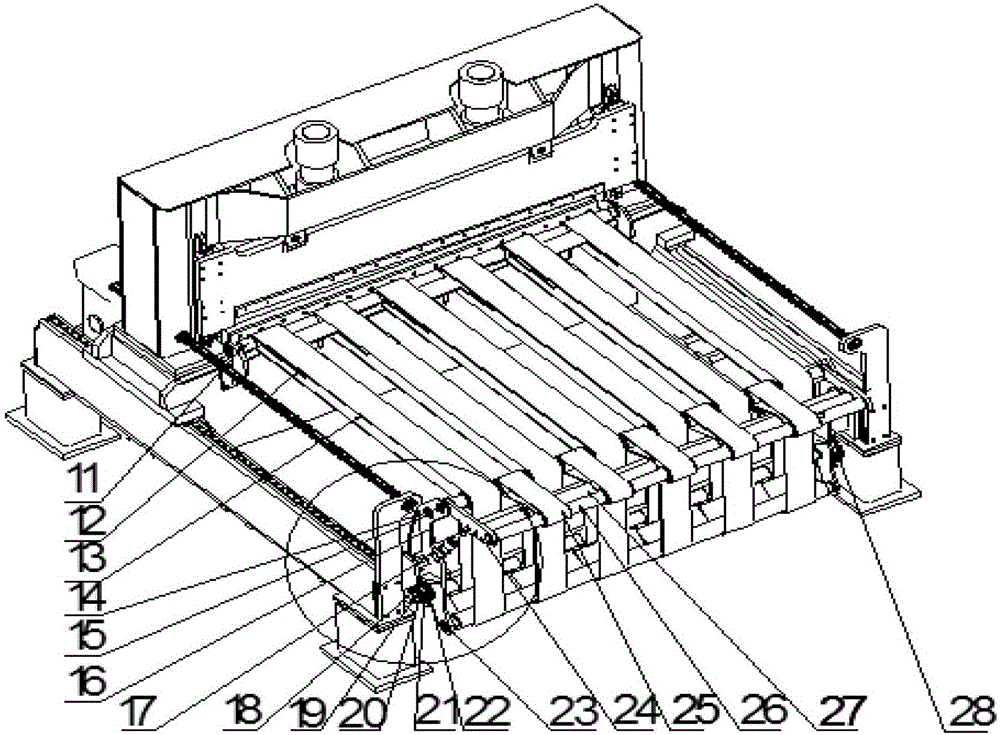

[0014] The specific design of the tracking plate shearing machine according to the embodiment of the present invention is as attached figure 1 - attached Figure 5 As shown, it mainly includes a shearing mechanism traveling device, a retractable belt device and a turning belt device.

[0015] The running device of the shearing mechanism includes: shearing mechanism 1, reducer 2, coupling 3, cylinder bracket 4, cylinder 5, servo motor 6, ball screw nut 7, ball screw 8, linear guide 9, base 10 ;

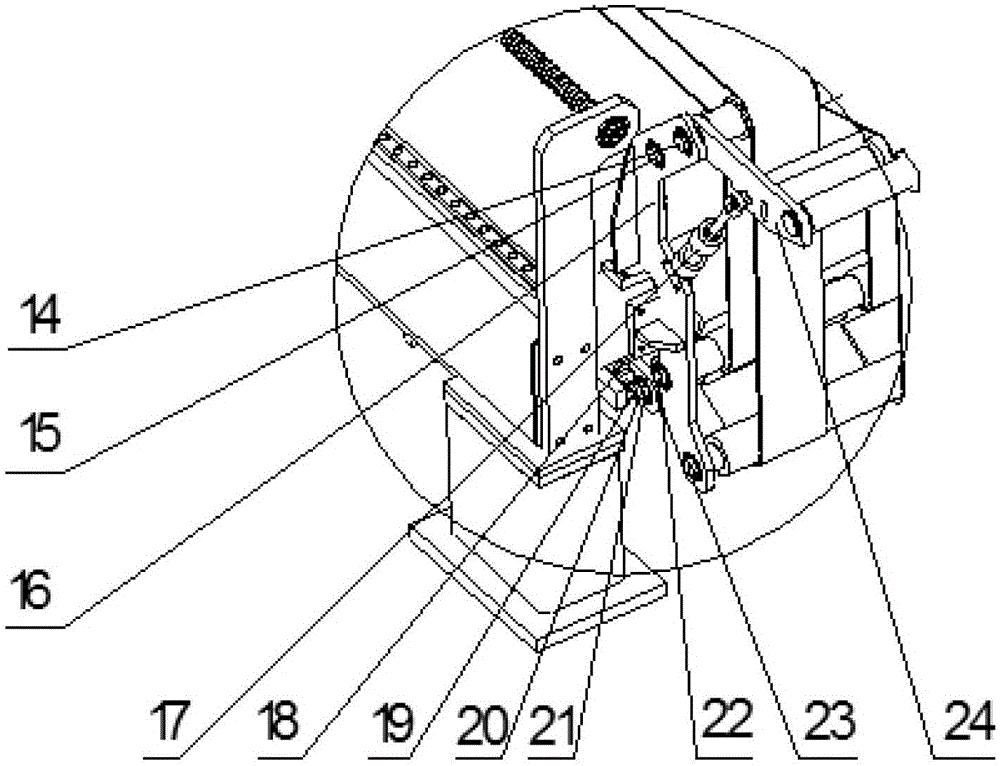

[0016] The telescopic belt device includes: fixed roller one 11, pallet 12, telescopic belt 13, fixed roller two 14, fixed roller five 15, fixed roller bracket 16, telescopic belt guide rail slider 18, telescopic belt guide rail 19, drive roller bracket 20, Drive roller 21, fixed roller four 22, fixed roller three 23, belt travel motor 28, eccentric sleeve 29, fixed ring 30, screw 31, key 32, set screw 33, short roller 34;

[0017] The overturning belt device comprises: overturning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com