Method for extracting pectin from pepper skin slag

A technology of chili peel and pectin, which is applied in the field of plant extracts, can solve the problems of environmental pollution and waste of resources, and achieve the effects of reducing environmental hazards, improving quality, and having obvious effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

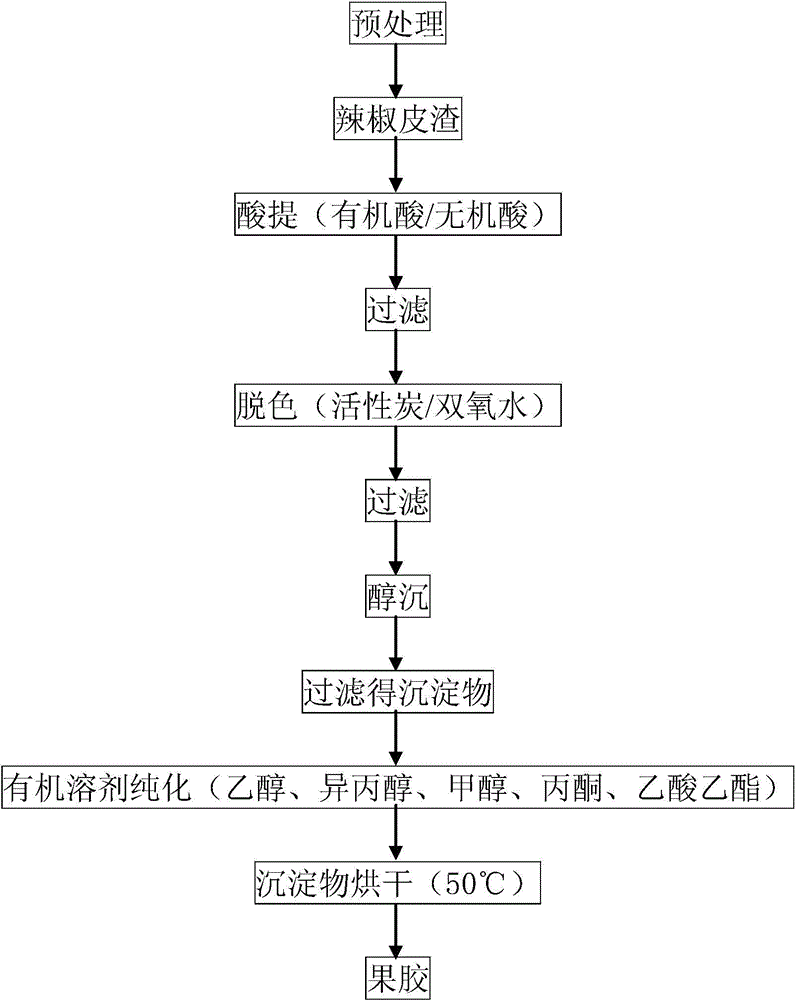

Method used

Image

Examples

Embodiment 1

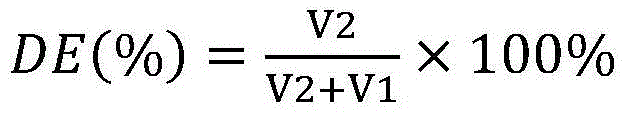

[0031]Mix the chili peel dregs with water at a mass ratio of 1:20, add hydrochloric acid to adjust the pH to 1.5, raise the temperature to 90°C, stir for 2 hours, filter with suction to obtain the pectin extract, adjust the pH to 3.0 with sodium hydroxide, and dissolve the activated carbon Fully stir and mix with the pectin extract according to the mass percentage concentration (w / v) of activated carbon in the mixed solution as 1.0%, decolorize at a temperature of 80°C for 60min, and pump it in a Buchner funnel cushioned with diatomaceous earth while it is hot Filtrate, concentrate the filtrate to 1 / 3 of the original volume under a vacuum condition of -0.90Mpa~0.95Mpa, add ethanol solution to the obtained concentrated solution to make the volume fraction 65%, and let it stand at a temperature of 15°C After 3 hours, centrifuge to get the precipitate, wash it for 40 minutes with ethanol aqueous solution with the volume fraction of 75% and 85% respectively according to the ratio o...

Embodiment 2

[0033] Mix the chili peel dregs with water at a mass ratio of 1:40, add citric acid to adjust the pH to 4.0, raise the temperature to 70°C, stir for 3 hours, and filter to obtain pectin extract. The vacuum degree is -0.90Mpa~0.95Mpa Concentrate to 1 / 4 of the original volume under the vacuum conditions, fully stir and mix the hydrogen peroxide and the concentrated pectin extract according to the volume percentage (v / v) of hydrogen peroxide as 10%, and decolorize at 60°C for 24 hours. Collect the filtrate by filtration, add isopropanol solution to the resulting filtrate to make the volume fraction 70%, let it stand at 4°C for 6 hours, centrifuge to obtain a precipitate, and use an isopropanol aqueous solution with a volume fraction of 85% according to the solid-liquid mass ratio The ratio of 1:20 was washed for 30 minutes, and the obtained precipitate was dried at 50°C for 12 hours to obtain a pectin product with a yield of 8.65%, a purity of 72%, and a degree of esterification o...

Embodiment 3

[0035] Mix the chili peel dregs with water at a mass ratio of 1:50, add sulfuric acid to adjust the pH to 0.5, raise the temperature to 60°C, stir for 1 hour, filter with suction to obtain the pectin extract, adjust the pH to 3.0 with sodium hydroxide, and dissolve the activated carbon Fully stir and mix with the pectin extract according to the ratio of 0.8% mass percentage concentration (w / v) of activated carbon in the mixed solution, decolorize at 60°C for 90min, and pump while hot in a Buchner funnel cushioned with diatomaceous earth Filtrate, concentrate the filtrate to 1 / 4 of the original volume under a vacuum condition of -0.90Mpa~0.95Mpa, add ethanol solution to the obtained concentrated solution to make the volume fraction 45%, and let it stand at a temperature of 25°C After 6 hours, centrifuge to obtain a precipitate, and then wash it for 15 minutes with methanol aqueous solution with a volume fraction of 75% according to the ratio of solid to liquid mass ratio of 1:5,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of esterification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com