Organic complex supported activated carbon adsorbent and its preparation method and application

An organic complex and activated carbon adsorption technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problem of low removal efficiency, achieve high safety, inhibit decomposition, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Prepare the organic complex-loaded activated carbon adsorbent of the present invention according to the following steps, and carry out the operation of adsorption and purification of hydrogen peroxide solution.

[0041] (1) Get 10g of activated carbon with the macroscopic structure required by the present invention as a carrier, use 100ml concentration of dilute hydrochloric acid solution of 10% by weight to soak for 2 hours at 50°C, clean, filter out the acid solution, then use 1000ml of deionized Repeated soaking, washing, and drying in water for 5 times, and drying at 120°C;

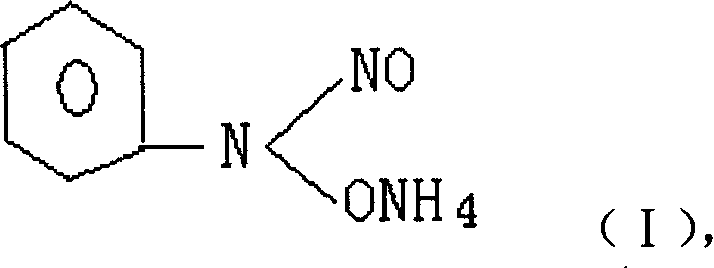

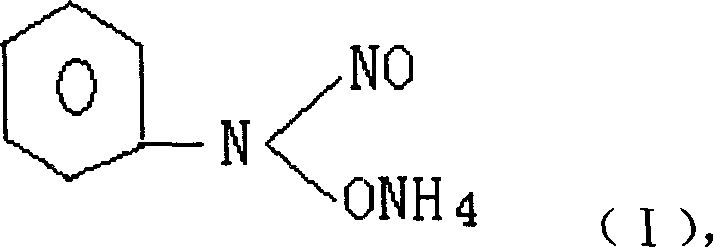

[0042] (2) 0.21 g of the ammonium salt (I) of N-nitrosophenyl hydroxylamine was weighed and dissolved in 30 ml of acetone to obtain an impregnation solution;

[0043] (3) prepare 2.0% weight acetone aqueous solution as eluent, for subsequent use;

[0044] (4) Place the activated carbon pretreated in step (1) in a closed container with stirring, vacuumize for 3 hours, and keep the vacuum at 9.5...

Embodiment 2~3

[0054] Only the step (2) in Example 1 was changed, and 0.42 g and 0.62 g of N-nitrosophenyl hydroxylamine ammonium salt (I) were weighed respectively, and the rest of the steps were carried out according to Example 1. Make the ammonium salt of N-nitrosophenyl hydroxylamine account for respectively the ammonium salt loaded active carbon adsorbent of adsorbent about 4%, the N-nitrosophenyl hydroxylamine of 6% weight, be used for hydrogen peroxide solution then purification.

Embodiment 4

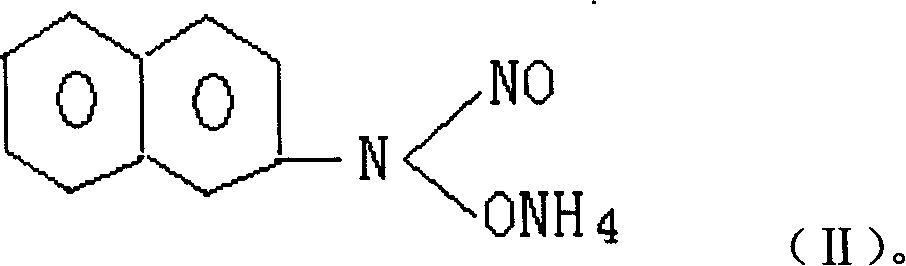

[0056] Only the step (2) in Example 1 was changed, and 0.21 g of N-nitrosonaphthyl hydroxylamine ammonium salt (II) was weighed, and the rest of the steps were carried out according to Example 1. Prepare the N-nitrosonaphthyl hydroxylamine ammonium salt loaded activated carbon adsorbent in which the N-nitroso naphthyl hydroxylamine ammonium salt accounts for about 2% by weight of the adsorbent, and then use it for the purification of the hydrogen peroxide solution. .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com