Low-cost drying technology for grains and agricultural and sideline products

A low-cost technology for agricultural and sideline products, applied in the direction of static material dryers, drying gas arrangement, local agitation dryers, etc., can solve the problems of high equipment investment, achieve low operating costs, low cost, and reduce grain deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

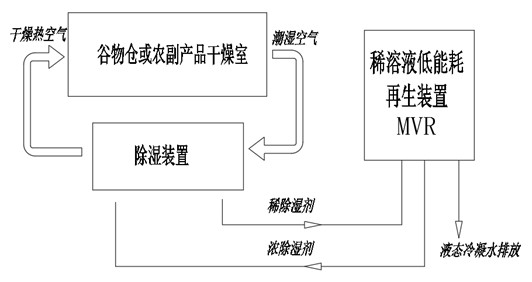

[0037] Example 1 is suitable for drying of high moisture grains:

Warehouses are divided into storage warehouses, reserve warehouses, transit warehouses, port warehouses, raw material and finished product warehouses, supply warehouses, futures delivery warehouses, and comprehensive warehouses. Requirements are slightly lower. The storage warehouse is located in the grain production area. It is a temporary warehouse that directly purchases grain and oil crops from farmers and transfers them to other transit warehouses or storage warehouses. At this stage, because the grain and oil crops have just been harvested, the moisture content is high, the microorganisms are active, and the grain is prone to heat and mildew. Therefore, it is necessary to control moisture when harvesting grains, and farmers often have bad weather and no drying conditions during the harvesting stage, so they need to be sold in time, which forms a contradiction. If the storage warehouse has good drying condi...

Embodiment 2

[0040] Example 2: Drying of large-scale storage granaries:

The moisture content of the grain transferred from the storage warehouse to the storage warehouse is basically up to the standard, and the required water removal amount is relatively small. However, due to the phenomenon of moisture and heat diffusion, the problem of different moisture content will occur locally. In the early stage of storage, dry air can be regularly introduced according to certain procedures. , for long-term safe storage. Due to the small size of the dehumidifier, it can be moved to the designated location by vehicle, and then connected to the inlet and outlet to dehumidify the air to keep the air humidity inside the grain pile and the air humidity in the upper space of the granary less than 65%, or select the set humidity according to requirements. The storage warehouse can share one dehumidification device with multiple warehouses. For large-scale storage warehouses with multiple warehouses, multi...

Embodiment 3

Embodiment 3 is suitable for drying of agricultural and sideline products:

The characteristics of agricultural and sideline products are that the material has a large water content, a large dehydration load, a fixed production location, and strong seasonality. In order to maintain the flavor and cannot be dried at high temperature, some products need to maintain rehydration and other requirements. They should not be dried under too low humidity conditions, similar to drying in the shade. These drying characteristics are just more suitable for the advantages of the present invention to be used.

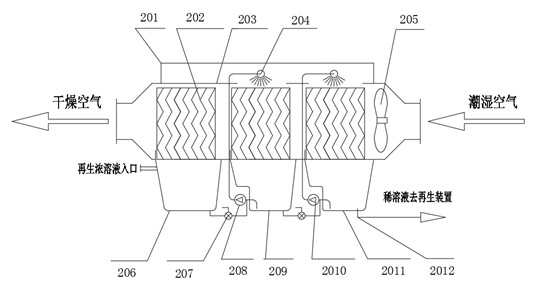

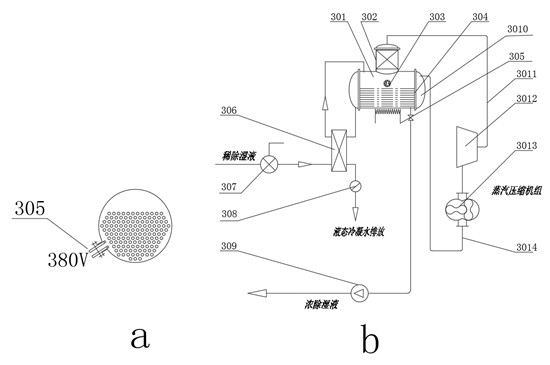

[0041] like Figure 5 As shown, the whole process consists of material drying chamber, tray and tray rack, heating heat source, dehumidification device and dilute desiccant regeneration device. Both dehumidification device and MVR are built in the drying boundary area. Because the heat energy required for material preheating and MVR start-up is very small, and the heat source grade r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com