Marble desulfurizing agent desulfurization method and byproduct cyclic utilization method thereof

A technology for desulfurization by-products and marble, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of occupying a large amount of land, secondary environmental pollution hazards, and returning to the land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

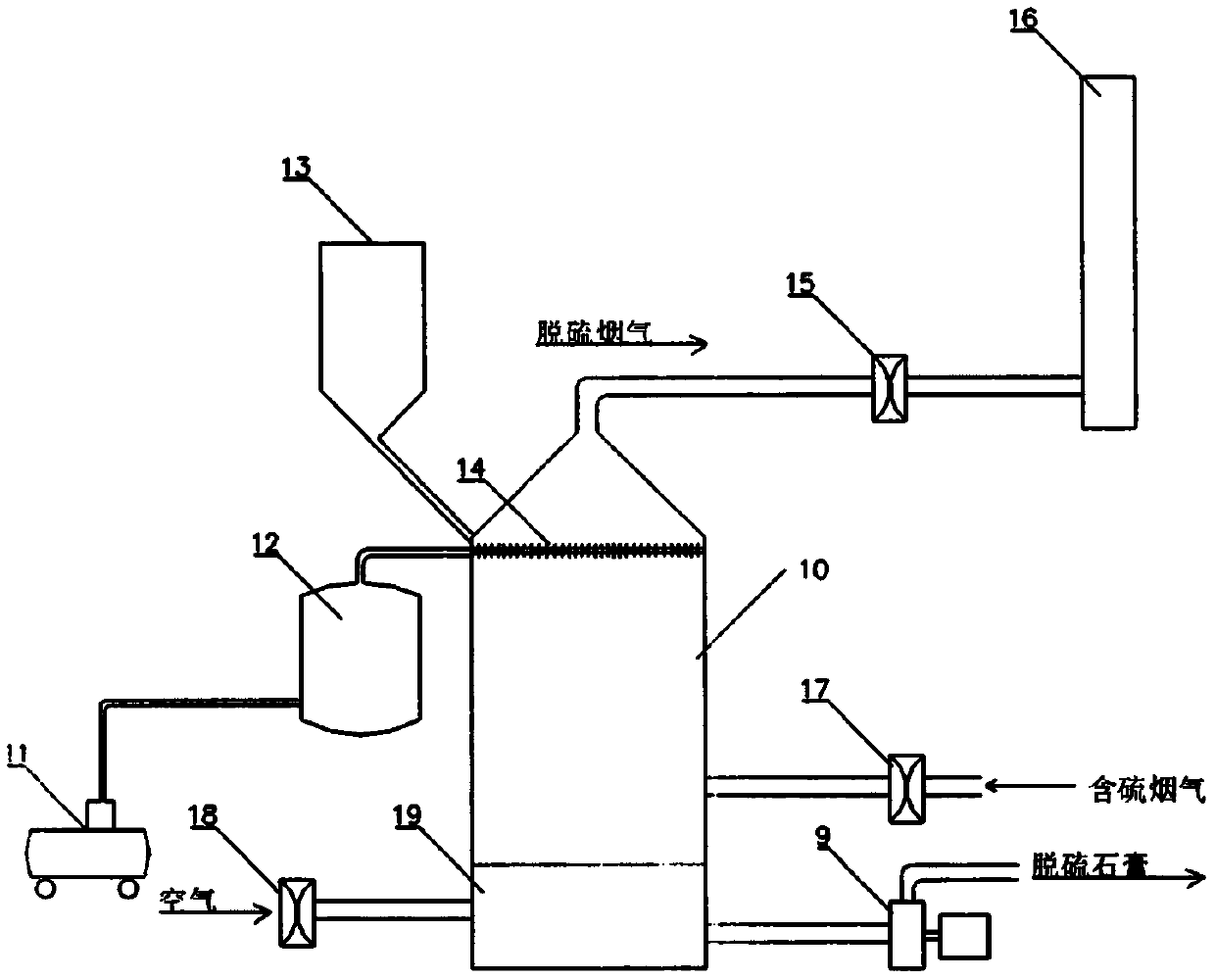

[0026] The invention provides a method for recycling marble waste slag desulfurizer and desulfurization by-products thereof. In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0027] Implementation example one

[0028] In this example, a marble desulfurizer is obtained by recovering cutting and polishing waste generated during marble processing, sedimentation in a sedimentation tank, pressing by a filter press, and crushing by a roller compactor.

[0029] In this example, the desulfurizer is mixed with water to prepare an absorption slurry with a solid content of 30%.

[0030] In this example, the sulfur-containing flue gas enters the desulfurization absorption tower, and is sprayed from the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com