Amisulpride tablet and preparation method thereof

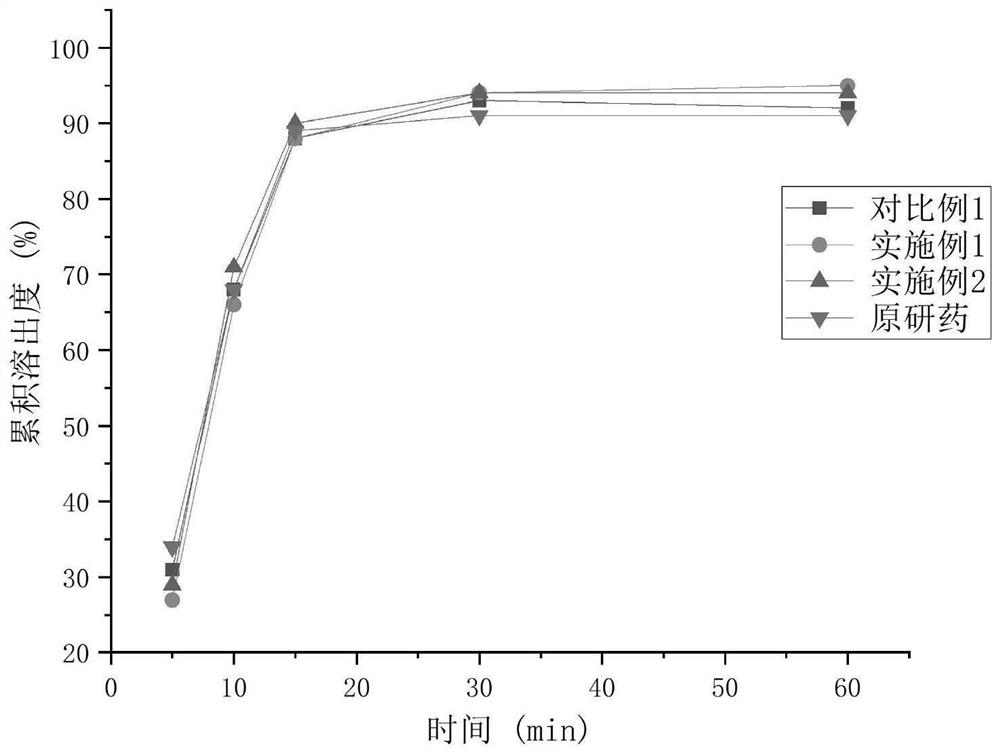

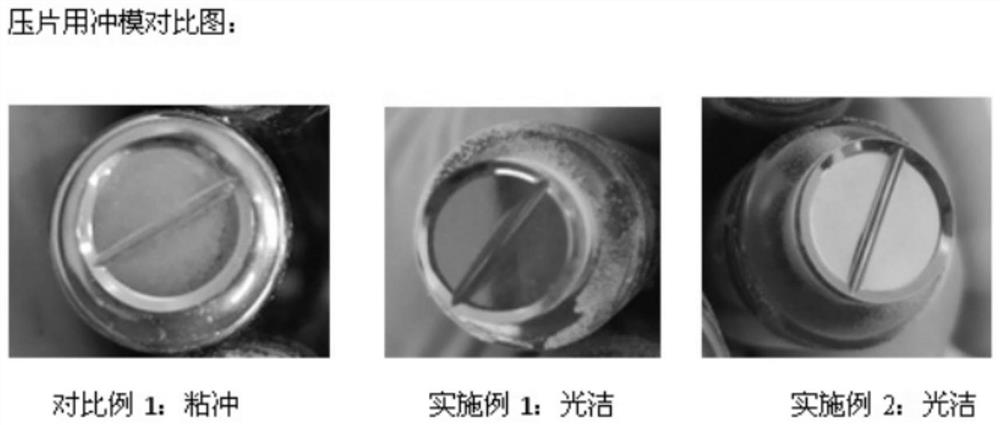

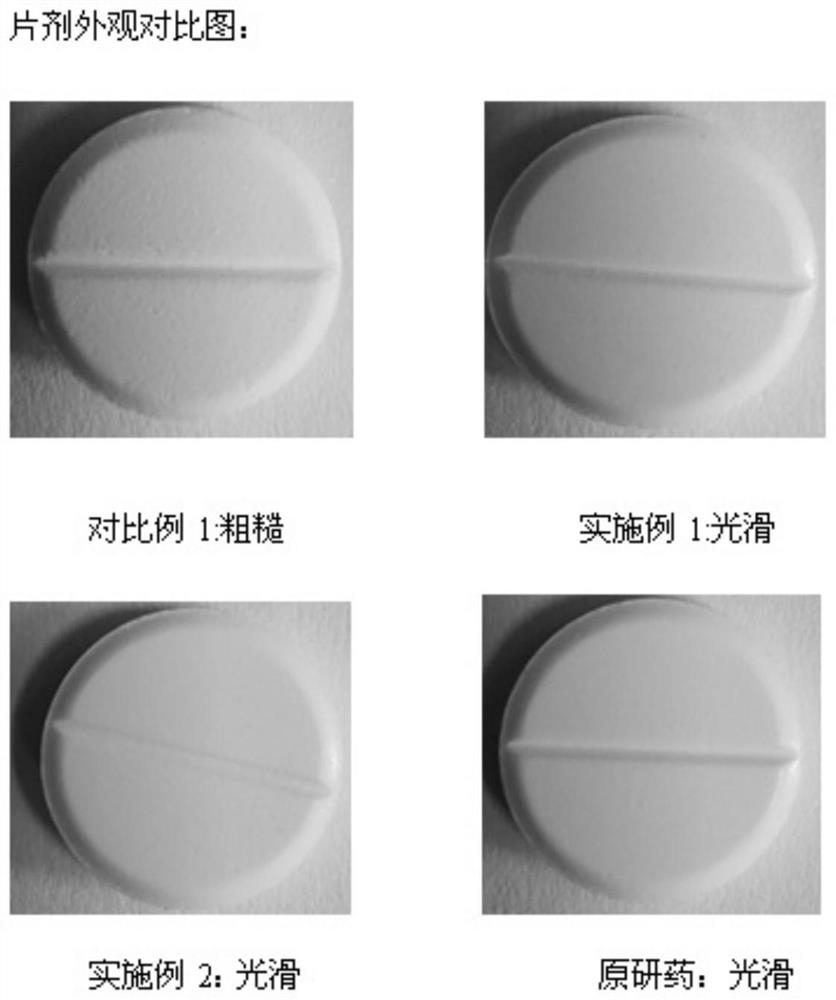

A technology of amisulpride tablets and amisulpride, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, pill delivery, etc., can solve problems such as sticking and punching, and achieve solving the problem of sticking and punching, reducing drying process, Avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of amisulpride tablet:

[0028] 1. Prescription

[0029] prescription Dosagekg Amisulpride 20 lactose 13.92 microcrystalline cellulose 5.76 Carboxymethyl Starch Sodium 5.28 hypromellose 0.88 Magnesium stearate 0.72 stearic acid 1.44

[0030] 2. Process (preparation of 100,000 pieces)

[0031] 1. Granulation

[0032] Pour lactose, amisulpride, microcrystalline cellulose, carboxymethyl starch sodium, hypromellose and stearic acid into the wet mixing granulator in turn, set the stirring speed at 150rpm, the cutter speed at 2000rpm, pre- Mix for 6 minutes. After the premixing is completed, open the pot cover and clean the powder on the pot body into the pot body. After the interlayer of the wet mixing granulator is heated to 90 degrees, continue to run for 15 minutes, cool the interlayer to room temperature, continue to run for 10 minutes, and discharge Get granules.

[0033] 2. Whole grain mixing

[0034...

Embodiment 2

[0039] A kind of amisulpride tablet:

[0040] 1. Prescription

[0041]

[0042]

[0043] 2. Process (preparation of 100,000 pieces)

[0044] Pour lactose, amisulpride, microcrystalline cellulose, carboxymethyl starch sodium, hypromellose and polyethylene glycol 6000 into the wet mixing granulator in turn, set the stirring speed to 300rpm, and the cutter speed to 1500rpm , pre-mixed for 6 minutes, after the pre-mixing is completed, open the lid to clean the powder on the pot body into the pot, after the interlayer of the wet mixing granulator is heated to 90 degrees, continue to run for 15 minutes; the interlayer is cooled to room temperature, continue to run for 10 minutes, and then Feed particles.

[0045] 2. Whole grain mixing

[0046] The granules are dry sized using a mobile granulator, installed with a mesh plate with a pore size of 2.0mm, and set the speed at 750rpm. The granulated granules are mixed with the magnesium stearate in a mixer.

[0047] 3. Tablet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com