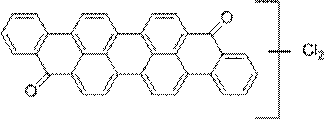

Preparation method of vat violet 1

A technology of isoviolanthrone dichloride and isovinanthrone, which is applied in the field of dye preparation, can solve the problems of toxic substances and difficult recycling, and achieve the effects of high raw powder strength, obvious chlorination effect, and saving drying process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Put 41.45g of isoviolanthrone wet filter cake (water content 45wt.%), and put 22.8 g of 100% isviolanthrone dry product into a container, add 30 g of water, 50 g of 98 wt.% sulfuric acid, grind and pulverize Fineness reaches 20 μm, then add 45 g of 1,1,2-trichloroethane. The temperature of the material is 30~35°C, then add 100 mL of sodium hypochlorite solution evenly under the liquid surface within 6 hours (the content of available chlorine is 13 wt.%), and then add 80 mL of sodium hypochlorite evenly within 6 hours at 35~45°C Solution (the content of available chlorine is 13wt.%), keep warm for another 2 h, and reach the reaction end point when the chlorine content of the sample is determined to be 13~14 wt.%. After the end point is reached, add 3wt.% sodium hydroxide solution to adjust the pH= 7~7.5, heat up to reflux, steam trichloroethane, filter after trichloroethane is completely evaporated, wash the filtered filter cake with hot water until the filtrate is color...

Embodiment 2

[0030] Put 38 g of isoviolanthrone wet cake (containing 40 wt.% moisture) and 22.8 g of 100% isoviolanthrone dry product into a container, add 30 g of water, 45.0 g of 98 wt.% sulfuric acid, grind and pulverize The fineness reached 30 μm, then 40 g of 1,2-dichloroethane was added, the temperature of the material was raised to 55 °C, and 180 mL of sodium hypochlorite solution (the content of available chlorine was 13 wt.%) was uniformly added within 16 h below the liquid surface, and then Continue to keep warm for 2 h, add 20 wt.% dilute soda ash solution to adjust pH = 7, raise the temperature to reflux, distill dichloroethane, dichloroethane is distilled and filtered, and the filtered filter cake is washed with hot water until the filtrate colorless. Then the filter cake is taken out and dried to obtain a bright red light product.

Embodiment 3

[0032] Put 45.6g of isoviolanthrone wet cake (containing 50 wt.% moisture) and 22.8 g of 100% isoviolanthrone dry product into a container, add 70 g of water, grind and pulverize to a fineness of 10 μm, and then add Tetrachloroethane 50 g, the material is heated up to 45 ~ 50 ℃. Then, within 20 hours, slowly inject 35 g of chlorine gas at the bottom of the liquid surface, keep it warm for 2 hours, add 20wt.% dilute soda ash solution to adjust the pH=7, raise the temperature to reflux, distill tetrachloroethane, and wait until the tetrachloroethane is completely evaporated After filtering, wash the filtered filter cake with hot water until the filtrate is colorless, then take out the filter cake and dry it to obtain a bright red product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com