Carbon Black Dispersion and Its Utilization

A technology of dispersion liquid and carbon black, which is applied in fibrous fillers, coatings, non-aqueous electrolyte battery electrodes, etc., can solve the problems of consuming a lot of energy and time, and achieve reduced usage, low surface resistance, and coating film physics. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1~ Embodiment 1-7

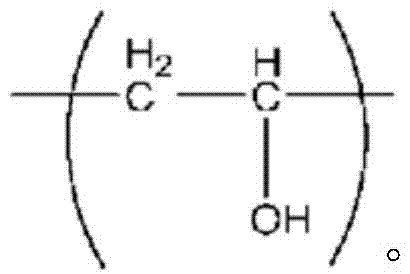

[0280] According to the composition shown in Table 1-1, put NMP and various polyvinyl alcohols into glass bottles and mix and dissolve them thoroughly, or after mixing and dispersing, add various carbon blacks and use 1.25mmφ zirconia beads as the medium. It was dispersed with a paint shaker for 2 hours to obtain each carbon black dispersion. They all have low viscosity and small D50 value, and have good storage stability. In addition, it was clarified that whether polyvinyl alcohol was modified or not had no major influence on the performance as a dispersant.

Embodiment 1-8~ Embodiment 1-24

[0285] According to the composition shown in Table 1-1, put NMP and polyvinyl alcohol into a glass bottle, mix and dissolve it thoroughly, or after mixing and dispersing, add various carbon blacks, use 1.25mmφ zirconia beads as the medium, and use paint The dispersion was performed for 2 hours with a shaker, and each carbon black dispersion liquid was obtained. They all have low viscosity and small D50 value, and have good storage stability.

[0286] [Comparative Example 1-3, Reference Example 1-1]

[0287] According to the composition shown in Table 1-1, put NMP and polyvinyl alcohol into a glass bottle, mix and dissolve it thoroughly, or after mixing and dispersing, add various carbon blacks, use 1.25mmφ zirconia beads as the medium, and use paint The dispersion was performed for 2 hours with a shaker, and each carbon black dispersion liquid was obtained. Since the obtained dispersion liquids were all in a state of remarkably high viscosity and a large D50 value, the carbon bla...

Embodiment 2-1~ Embodiment 2-16

[0290] According to the composition shown in Table 1-2, put NMP, various polyvinyl alcohols and various binders into glass bottles, mix and dissolve them thoroughly, or add various carbon blacks after mixing and dispersing, using a homogenizer After dispersion for 1 hour, each carbon black dispersion liquid was obtained. None of them has coarse particles, has low viscosity, and has good storage stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| aggregation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com