Preparation method of energy-saving sludge-based adsorbent

An adsorbent and energy-saving technology, which is applied in the field of adsorbent preparation, can solve the problems of poor environmental protection and high energy consumption, and achieve the effect of enhanced adsorption effect, obvious gasification atmosphere and obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

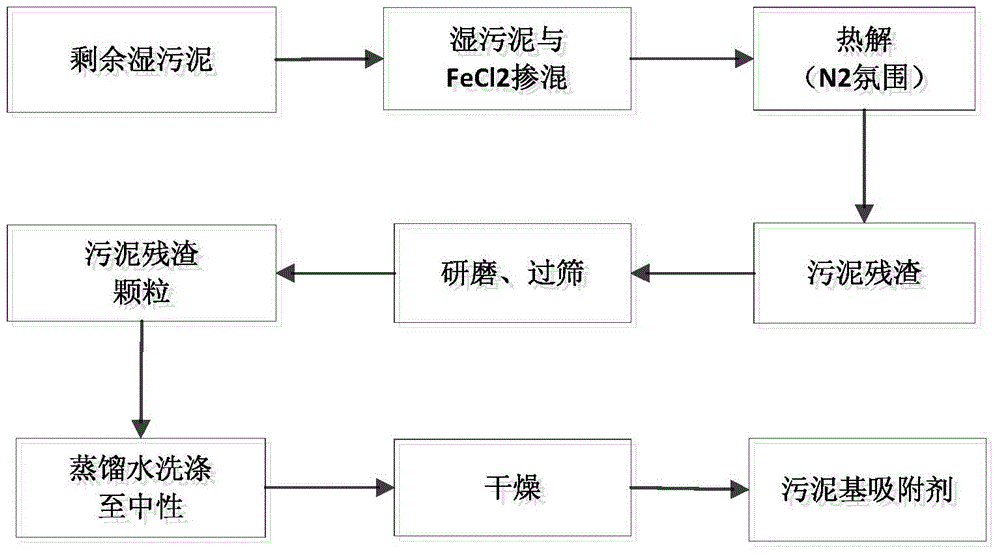

[0017] refer to figure 1 , a method for preparing an energy-saving sludge-based adsorbent, the preparation method comprising the following steps:

[0018] In the first step, the blending activator FeCl 2 The remaining wet sludge with a moisture content of 60-90% is placed in the heating zone of the pyrolysis reactor of the external heating tube furnace, in which the activator FeCl 2 The mass-number ratio of the wet sludge sample with a moisture content of 60-90% is: 1: (10-20);

[0019] Carry out pyrolysis reaction under nitrogen atmosphere: heating rate is 70-80°C / min, pyrolysis temperature is 550°C-560°C, stay for 10-15 minutes, nitrogen blowing rate is 25-30ml / min; when the reaction is finished, close the tube furnace and Nitrogen cylinder switch, after cooling, sludge pyrolysis residue is obtained;

[0020] The second step is to collect sludge pyrolysis residues for grinding, and pass through a 50-70 mesh sieve to obtain sludge residue particles;

[0021] In the third ...

example 1

[0025] Example 1: A preparation method of an energy-saving sludge-based adsorbent, the preparation method comprising the following steps:

[0026] In the first step, the blending activator FeCl 2 The remaining wet sludge with a moisture content of 60% is placed in the heating zone of the pyrolysis reactor of an external heating tube furnace, in which the activator FeCl 2 The mass-number ratio of the wet sludge sample with a moisture content of 60% is: 1:10;

[0027] Carry out pyrolysis reaction under nitrogen atmosphere: heating rate 70°C / min, pyrolysis temperature 550°C, stay for 10 minutes, nitrogen blowing rate 25ml / min; turn off the tube furnace and nitrogen bottle switch after the reaction is completed, and obtain sludge after cooling Pyrolysis residue;

[0028] The second step is to collect sludge pyrolysis residues for grinding, and pass through a 50-mesh sieve to obtain sludge residue particles;

[0029] In the third step, the sludge residue particles are washed wit...

example 2

[0031] Example 2: A preparation method of an energy-saving sludge-based adsorbent, the preparation method comprising the following steps:

[0032] In the first step, the blending activator FeCl 2 The remaining wet sludge with a moisture content of 70% is placed in the heating zone of the pyrolysis reactor of the external heating tube furnace, in which the activator FeCl 2 The mass-number ratio of the wet sludge sample with a moisture content of 70% is: 1:15;

[0033] Carry out pyrolysis reaction under nitrogen atmosphere: heating rate is 76°C / min, pyrolysis temperature is 555°C, stays for 12 minutes, nitrogen blowing rate is 28ml / min; after the reaction is finished, turn off the tube furnace and nitrogen bottle switch, and obtain sludge after cooling Pyrolysis residue;

[0034] The second step is to collect sludge pyrolysis residues for grinding, and pass through a 60-mesh sieve to obtain sludge residue particles;

[0035] In the third step, the sludge residue particles are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com