Method for extracting stevioside from fresh stevia rebaudiana leaves

A technology of stevia leaves and steviol glycosides, which is applied in the field of stevioside extraction, can solve the problems of large water consumption for soaking and extraction, increased production costs, and large water discharge, so as to save time and procedures, save time, and reduce The effect of efflux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

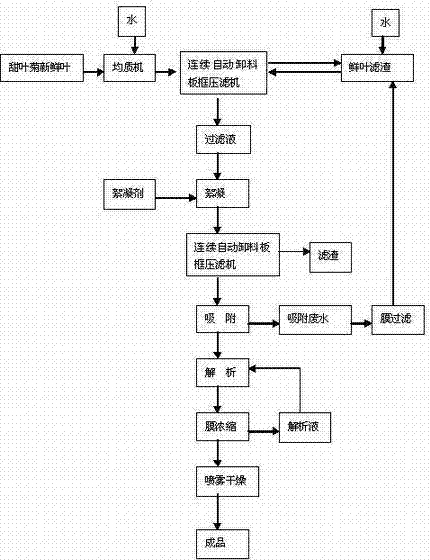

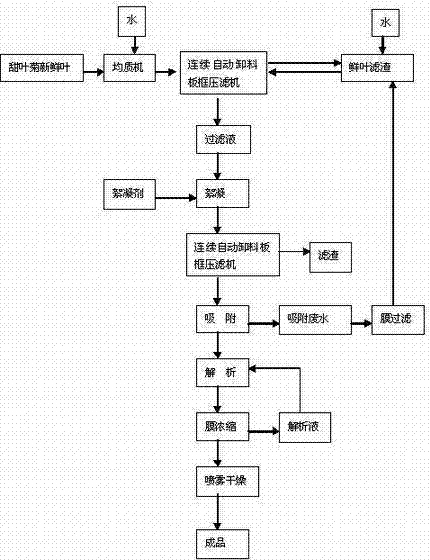

Image

Examples

Embodiment 1

[0038] Take 60kg of fresh stevia leaves, and homogeneously crush the fresh stevia leaves with 5 times the volume of water with homogeneous crushing equipment to obtain 360kg of stevia crushed slurry.

[0039] Pump the crushed fresh stevia leaf slurry into the continuous automatic unloading filter equipment for pressure filtration, add 8 times the volume of water to the filtered fresh leaf filter residue, and carry out the first extraction under ultrasonic and stirring. 30 minutes, then pour into the continuous automatic unloading filter equipment to filter, obtain the extract of 480kg. Add 8 times the volume of water to the filter residue for the second extraction under ultrasonic and stirring, and then filter with continuous automatic unloading filter equipment, and the second filtrate is used as water for homogeneous crushing.

[0040] Combine the homogeneously crushed filtrate and the filtrate extracted once, and add 0.25% of FeSO by weight of the combined filtrate under st...

Embodiment 2

[0046] Get 60kg of stevia fresh leaves, and homogeneously crush the fresh stevia leaves together with 10 times the volume of water with homogeneous crushing equipment. Obtained 660 kg of stevia crushed slurry.

[0047]Pump the crushed fresh stevia leaf slurry into the continuous automatic unloading filter equipment for press filtration, add 10 times the volume of water to the filtered fresh leaf filter residue, and carry out the first extraction under ultrasonic and stirring. 30 minutes. Squeeze into continuous automatic unloading filtration equipment then and filter, obtain the extract of 600kg. Add 10 times the volume of water to the filter residue for a second extraction under ultrasonic and stirring, and then filter with continuous automatic unloading filter equipment, and use the filtrate obtained from the second filter as water for homogeneous crushing.

[0048] Combine the homogeneously crushed filtrate and the filtrate extracted once, and add 0.25% of FeSO by weight ...

Embodiment 3

[0053] Get 60kg of stevia fresh leaves, and use homogeneous crushing equipment to carry out homogeneous crushing of the fresh stevia leaves together with 15 times the volume of water. Obtain 960kg of stevia fresh leaf slurry.

[0054] Pump the crushed fresh stevia leaf slurry into the continuous automatic unloading filter equipment for pressure filtration, add 15 times the volume of water to the filtered fresh leaf filter residue, and carry out the first extraction under ultrasonic and stirring. 30 minutes. Squeeze into continuous automatic unloading filter equipment then and filter, obtain the extract of 900kg. Add 10 times the volume of water to the filter residue for the second extraction under ultrasonic and stirring, and then filter with continuous automatic unloading filter equipment, and the filtrate after the second filter is used as water for homogeneous crushing.

[0055] Combine the homogeneously crushed filtrate and the filtrate extracted for the first time, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com