Humidity control method for mixture used in sintering production

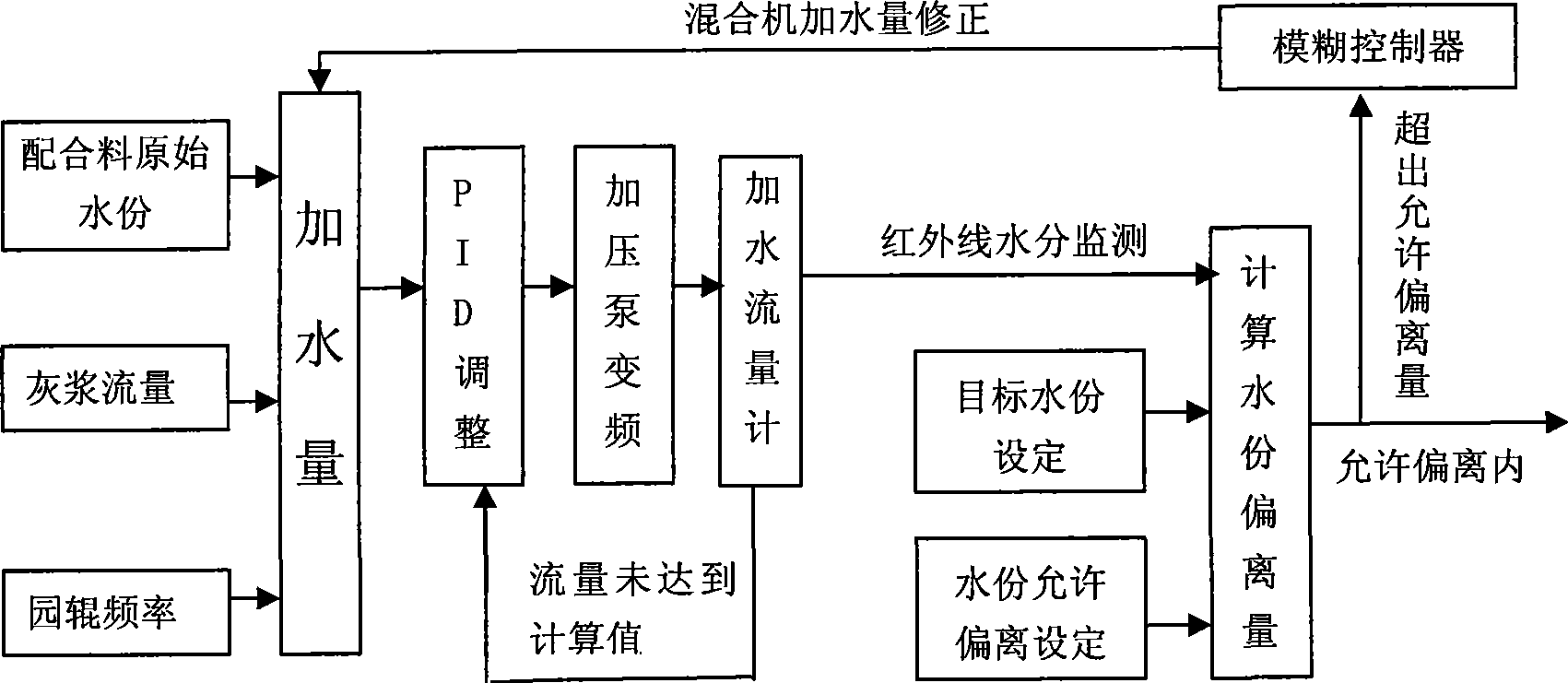

A mixed material moisture and mixed material technology, which is applied in general control system, multi-fluid ratio control, self-adaptive control, etc., can solve the problems of manual water adding, water instability, inaccurate control, etc., to improve labor efficiency and reduce labor Intensity, reducing the effect of regulatory perturbations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Install one MM710 infrared moisture meter in each of the three series of the primary mixing system (the manufacturer is responsible for the installation, and the sintering plant cooperates). After installation, the manufacturer and the sintering plant will jointly adjust the parameters. The part value is compared with the moisture value detected by the sampling drying weight loss method, and different curves are collected according to different material layers and different material ratios, and the moisture detection data and adjustment parameters after the material change are basically obtained, until the infrared moisture meter monitors The value meets the expected requirement.

[0024] 2. Lay signal cables for data transmission, transmit real-time monitoring moisture data to PLC system and sintering plant server, provide real-time data parameters for the control system, and enable production operators to understand real-time changing moisture data.

[0025] 3. Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com