A kind of reinforced foamed concrete and its configuration method

A foamed concrete and enhanced technology, applied in the field of building materials, can solve the problems of reduced concrete particle strength, limited practicability, complicated production process, etc., and achieve the effects of enhancing the compressive capacity, reducing the difficulty of configuration, and improving the final strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

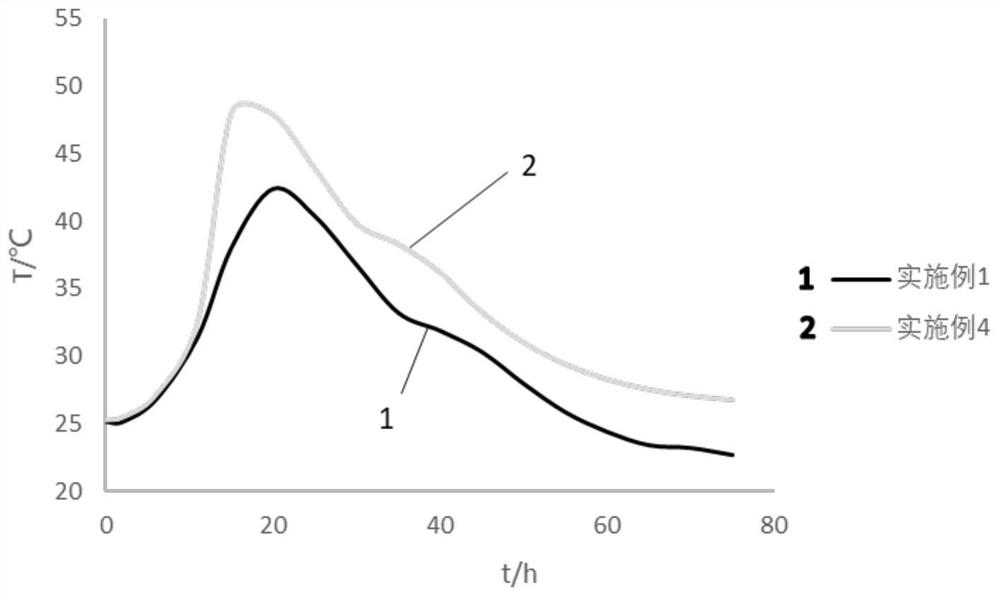

Image

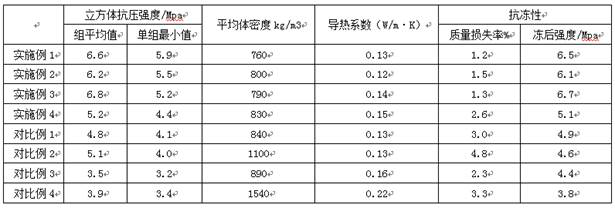

Examples

Embodiment 1

[0052] A method for configuring reinforced foamed concrete, comprising the following steps:

[0053] S1. Mix 70 parts of Portland cement, 22 parts of fly ash, 18 parts of aggregate, 4.4 parts of polyvinyl alcohol particles, 3.6 parts of aluminum powder, and 1.1 parts of polyferric phosphate, add water slowly and stir to obtain a slurry material;

[0054] S2. Add 7.2 parts of foam stabilizer, 8.8 parts of mixed emulsion, 9.5 parts of acrylamide type strengthening agent and 4.3 parts of hydrogen peroxide to the slurry material obtained in S1 in sequence and keep stirring. The interval between adding each material is 3 minutes. Stir for 10min to obtain foamed concrete;

[0055] S3. Putting the foamed concrete obtained in step S2 into a mold, curing, and obtaining reinforced foamed concrete after the foamed concrete is solidified and demoulded.

[0056] Described foam stabilizer comprises the following components in parts by mass:

[0057] Sodium dodecylbenzenesulfonate: 17.6 pa...

Embodiment 2

[0069] A method for configuring reinforced foamed concrete, comprising the following steps:

[0070] S1. Mix 60 parts of Portland cement, 30 parts of fly ash, 15 parts of aggregate, 5 parts of polyvinyl alcohol particles, 3 parts of aluminum powder, and 1.5 parts of polyferric phosphate, add water slowly and stir to obtain a slurry material;

[0071] S2. Add 6 parts of foam stabilizer, 10 parts of mixed emulsion, 7 parts of acrylamide type strengthening agent and 5 parts of hydrogen peroxide to the slurry material obtained in S1 in order and keep stirring. The interval between adding each material is 3 minutes. Stir for 10min to obtain foamed concrete;

[0072] S3. Putting the foamed concrete obtained in step S2 into a mold, curing, and obtaining reinforced foamed concrete after the foamed concrete is solidified and demoulded.

[0073] Described foam stabilizer comprises the following components in parts by mass:

[0074] Sodium dodecylbenzenesulfonate: 15 parts;

[0075] T...

Embodiment 3

[0086] A method for configuring reinforced foamed concrete, comprising the following steps:

[0087] S1. Mix 80 parts of Portland cement, 20 parts of fly ash, 20 parts of aggregate, 3 parts of polyvinyl alcohol particles, 5 parts of aluminum powder, and 0.5 part of polyferric phosphate, slowly add water and stir to obtain a slurry material;

[0088] S2. Add 8 parts of foam stabilizer, 5 parts of mixed emulsion, 11 parts of acrylamide type enhancer and 3 parts of hydrogen peroxide to the slurry material obtained in S1 in order and keep stirring. The interval between adding each material is 3 minutes. Stir for 10min to obtain foamed concrete;

[0089] S3. Putting the foamed concrete obtained in step S2 into a mold, curing, and obtaining reinforced foamed concrete after the foamed concrete is solidified and demoulded.

[0090] Described foam stabilizer comprises the following components in parts by mass:

[0091] Sodium dodecylbenzenesulfonate: 20 parts;

[0092] Tea saponin: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com