Silica powder modified superfine cement crack repair material and preparation method thereof

A technology for repairing ultra-fine cement and cracks, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. There are few problems in material development to achieve the effect of reducing concrete seepage channels, excellent durability, and improving the ability of filling joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

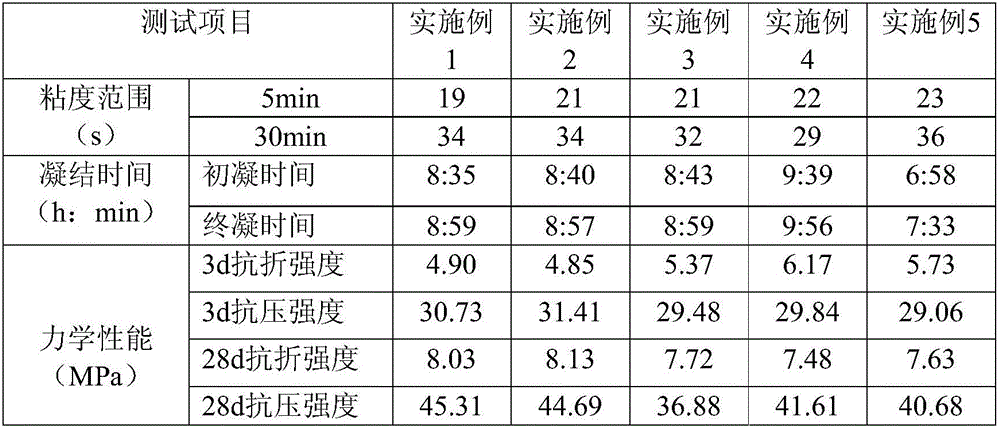

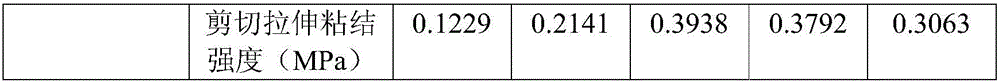

Examples

Embodiment 1

[0022] The silica fume-modified superfine cement crack repair material of the present invention is prepared from superfine cement, water, silica fume, polycarboxylate high-efficiency water reducer and polycarboxylate high-efficiency water reducer, wherein the water The mass, the mass of silica fume, the mass of polycarboxylate superplasticizer and the mass of expansion agent are respectively 55%, 5%, 0.8% and 8% of the ultrafine cement mass.

[0023] 50% of the particles in ultrafine cement have a particle size of 4-6um, the particle size of ultrafine cement is less than or equal to 20um, and the specific surface area of ultrafine cement is 850m 2 / Kg.

[0024] The preparation method of silica fume modified superfine cement crack repair material of the present invention comprises the following steps:

[0025] 1) Weigh superfine cement, water, silicon powder, polycarboxylate superplasticizer and polycarboxylate superplasticizer;

[0026] 2) Put the ultrafine cement into an ...

Embodiment 2

[0029] The silica fume-modified superfine cement crack repair material of the present invention is prepared from superfine cement, water, silica fume, polycarboxylate high-efficiency water reducer and polycarboxylate high-efficiency water reducer, wherein the water The mass, the mass of silica fume, the mass of polycarboxylate superplasticizer and the mass of expansion agent are respectively 55%, 5%, 1% and 9% of the ultrafine cement mass.

[0030] 50% of the particles in ultrafine cement have a particle size of 4-6um, the particle size of ultrafine cement is less than or equal to 20um, and the specific surface area of ultrafine cement is 850m 2 / Kg.

[0031] The preparation method of silica fume modified superfine cement crack repair material of the present invention comprises the following steps:

[0032] 1) Weigh superfine cement, water, silicon powder, polycarboxylate superplasticizer and polycarboxylate superplasticizer;

[0033] 2) Put the ultrafine cement into an ov...

Embodiment 3

[0036] The silica fume-modified superfine cement crack repair material of the present invention is prepared from superfine cement, water, silica fume, polycarboxylate high-efficiency water reducer and polycarboxylate high-efficiency water reducer, wherein the water The mass, the mass of silica fume, the mass of polycarboxylate superplasticizer and the mass of expansion agent are respectively 57%, 7%, 1% and 10% of the ultrafine cement mass.

[0037] 50% of the particles in ultrafine cement have a particle size of 4-6um, the particle size of ultrafine cement is less than or equal to 20um, and the specific surface area of ultrafine cement is 850m 2 / Kg.

[0038] The preparation method of silica fume modified superfine cement crack repair material of the present invention comprises the following steps:

[0039] 1) Weigh superfine cement, water, silicon powder, polycarboxylate superplasticizer and polycarboxylate superplasticizer;

[0040] 2) Put the ultrafine cement into an o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com