Patents

Literature

37results about How to "Dense internal structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

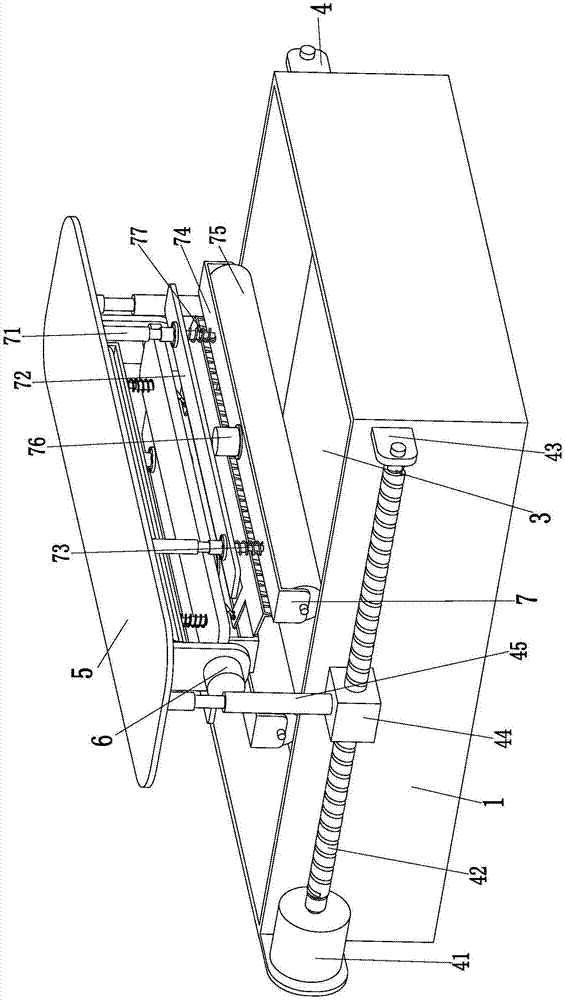

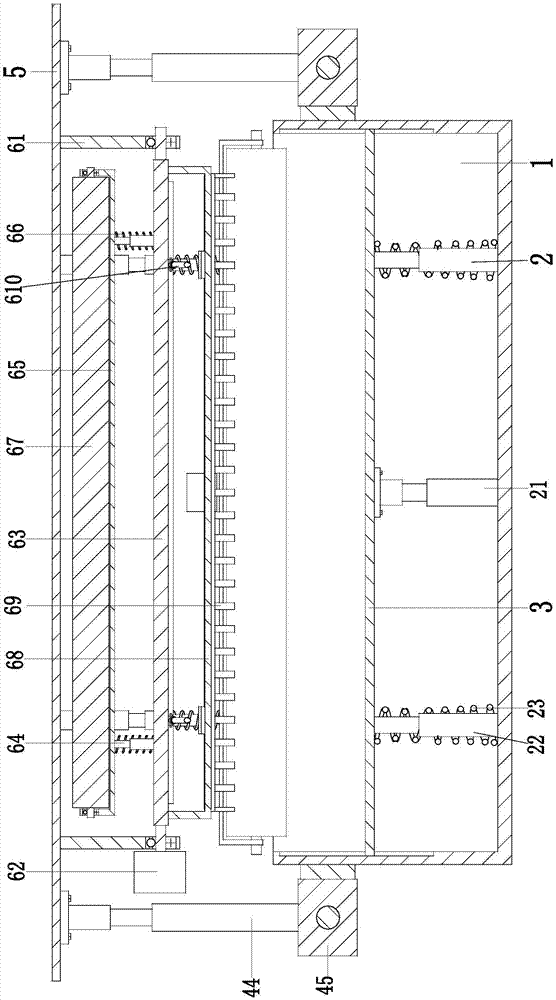

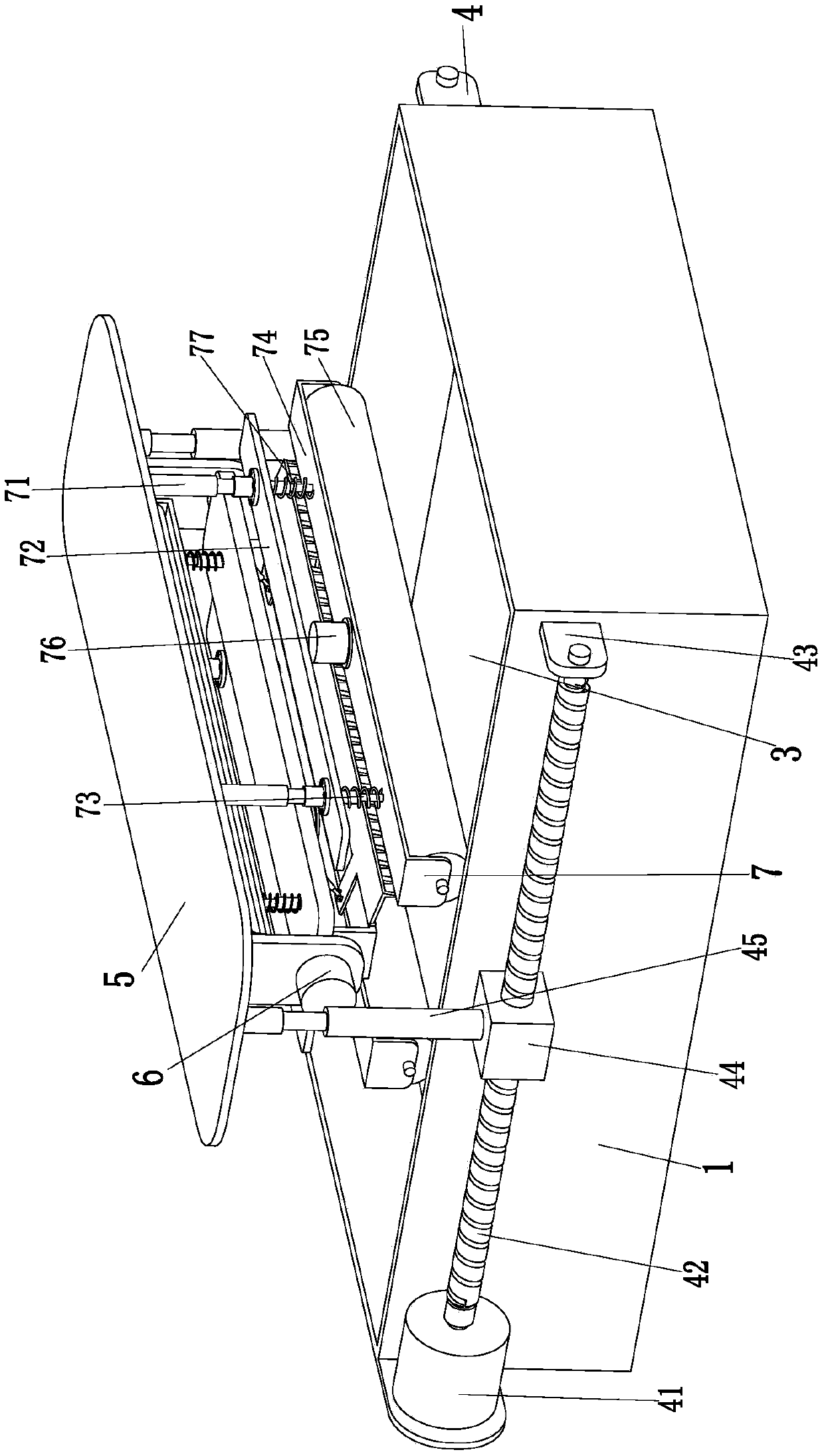

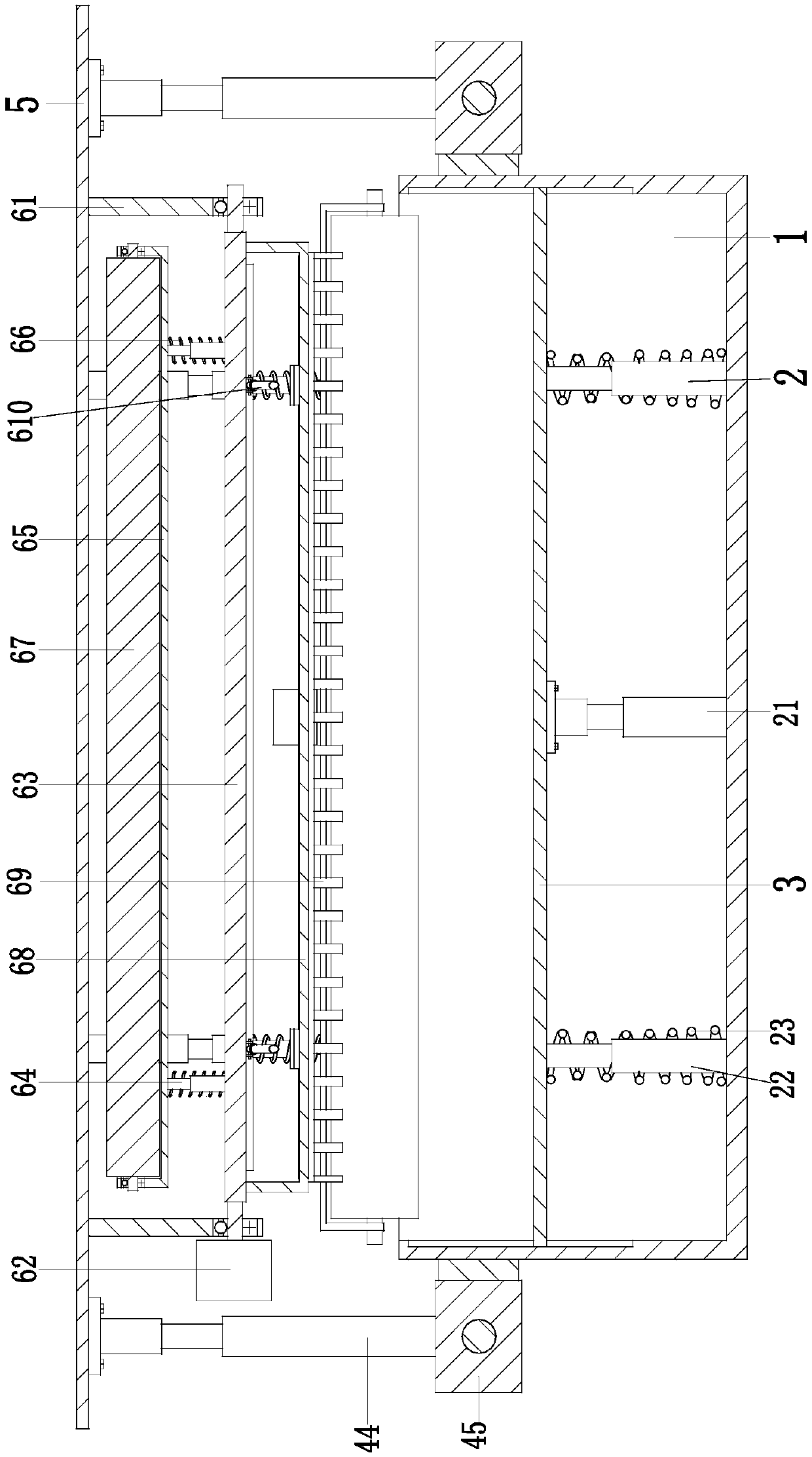

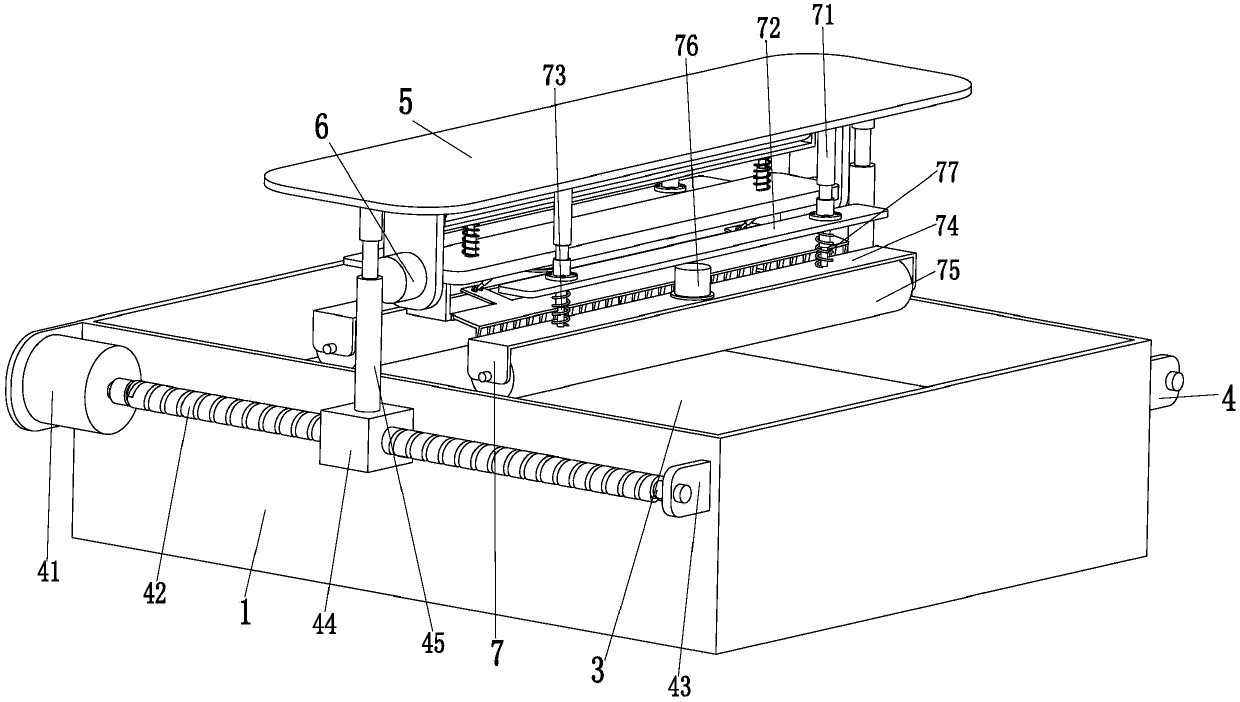

Automatic processing and manufacturing equipment for shaving boards

ActiveCN107283554AQuality will not affectSmall savings in qualityPlywood pressesVeneer pressesEngineeringMachining process

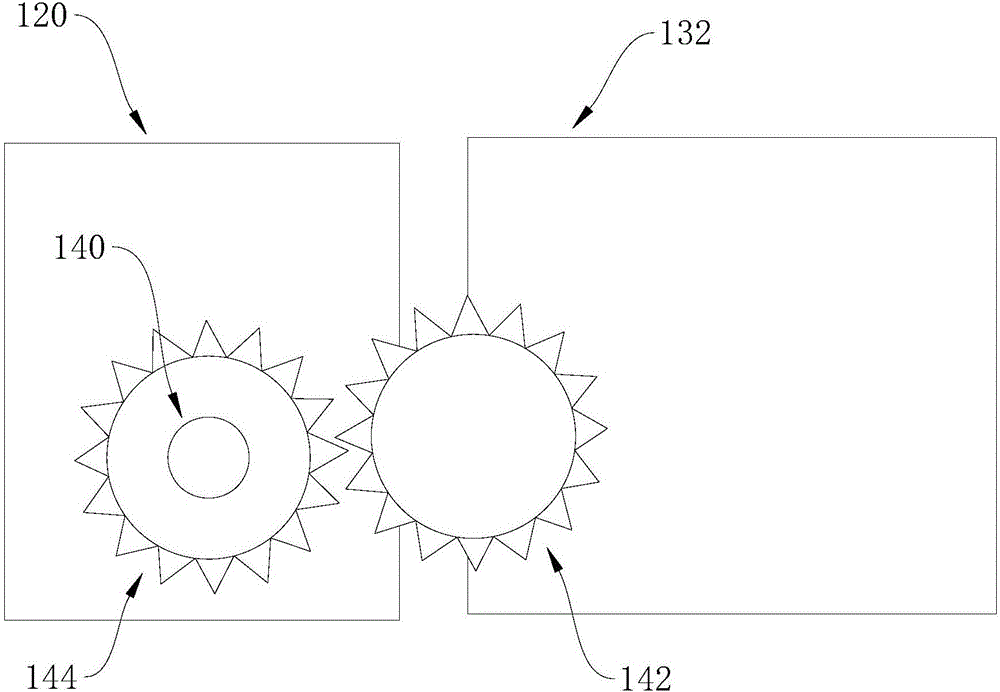

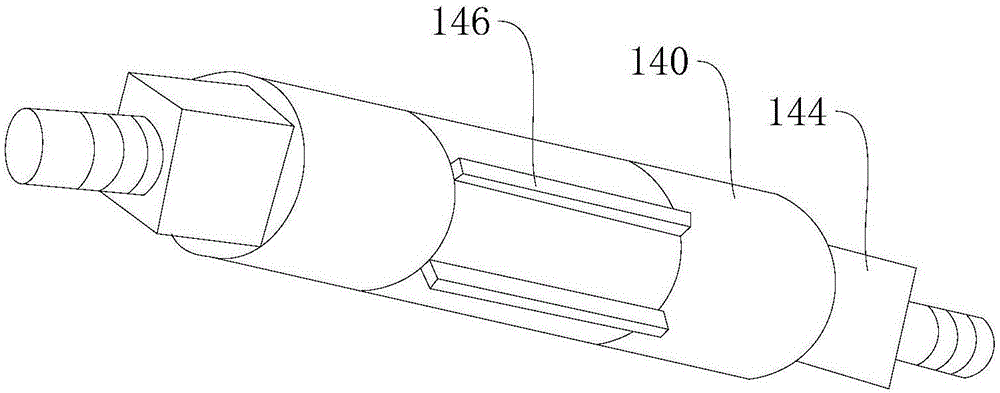

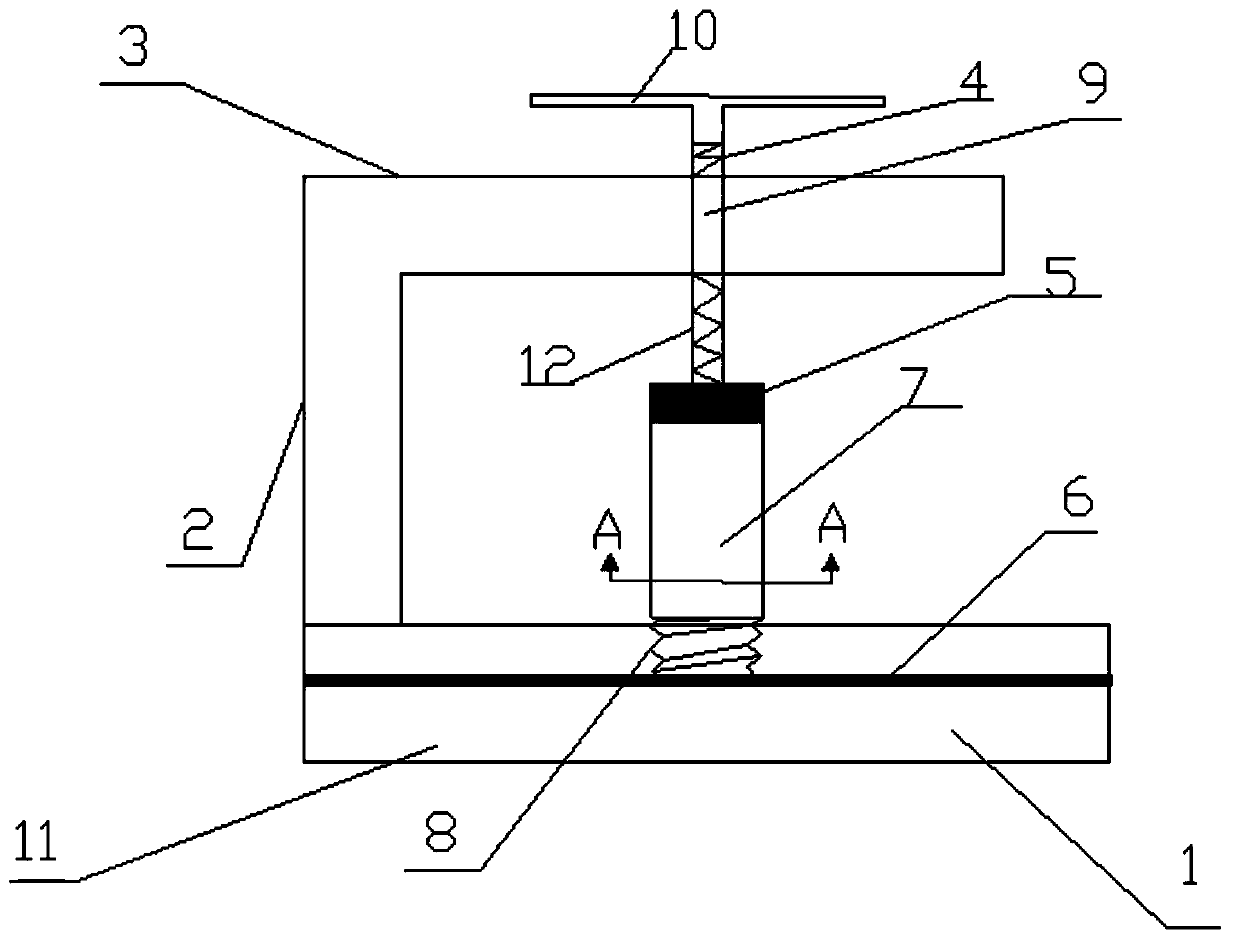

The invention relates to automatic processing and manufacturing equipment for shaving boards. The automatic processing and manufacturing equipment comprises a working box, wherein two supporting mechanisms are symmetrically mounted at the front end and the rear end of the bottom of the working box separately; a working plate is mounted at the upper ends of the two supporting mechanisms; two moving and lifting mechanisms are symmetrically mounted on the left side and the right side of the working box separately; a transverse plate is mounted at the upper ends of the two moving and lifting mechanisms; an auxiliary material rolling mechanism is mounted at the middle of the transverse plate; two vibration extrusion mechanisms are symmetrically mounted on the two sides of the transverse plate separately; and the supporting mechanisms, the moving and lifting mechanisms, the auxiliary material rolling mechanism and the vibration extrusion mechanisms well coordinate with each other to complete the automatic processing and manufacturing process of shaving boards. According to the automatic processing and manufacturing equipment for shaving boards, the problems that during the conventional processing process of shaving boards, the occupied space of the equipment is large, stirred materials are easy to cake after being fed into a die to affect the quality of shaving boards, the die needs to be manually adjusted when shaving boards with different thicknesses are processed, the labor intensity of working personnel is improved and the working efficiency is reduced are solved, and the function of automatically processing and manufacturing shaving boards is realized.

Owner:临沂兴滕人造板机械有限公司

Impact-resistant and corrosion-proof cement-based composite material and preparation method thereof

The invention relates to an impact-resistant and corrosion-proof cement-based composite material and a preparation method thereof. The impact-resistant and corrosion-proof cement-based composite material comprises a cementing material, aggregate, steel fibers, polypropylene fibers, carbon nanotubes, polyvinyl alcohol, a water reducing agent and water. The mass ratio of the cementing material: the aggregate: the water is 1: 0.8-1: 0.26-0.32. With the weight of the cementing material counted as 100 parts, the composite material comprises 0.6-1.0 part of steel fibers, 0.5-0.8 part of polypropylene fibers, 1-1.5 parts of carbon nanotubes, 0.5-1 part of water reducing agent and 0.18-0.32 part of polyvinyl alcohol. According to the technical scheme of the preparation method, firstly, polypropylene fibers, carbon nanotubes, the water reducing agent and the polyvinyl alcohol are added into water and then obtained materials are stirred. Secondly, the cementing material and the aggregate are added and then obtained materials are stirred. Thirdly, the steel fibers are added and then obtained materials are stirred. Finally, obtained materials are subjected to casting, vibrating and molding to obtain the impact-resistant and corrosion-proof cement-based composite material.

Owner:WUHAN UNIV OF TECH

High-durability damping concrete and preparation method thereof

The invention discloses a high-durability damping concrete and a preparation method thereof, and relates to several concretes and a preparation method thereof. The invention solves the problems of low damping capability and poor durability of the conventional concrete structure material per se. The high-durability damping concrete is prepared by stirring and mixing cements, rubber powder, water, medium sand, stones, and adding fibers and silicon powder. In the invention, c the loss factors of the high-durability damping concrete are improved by about 80-200 percent compared with that of pain concrete under the condition of different frequencies. After maintenance for 28 days, the concrete prepared by using the method has chloridion-resistant permeability and carbonizing-resistant capability both superior to that of blank concretes.

Owner:刘铁军

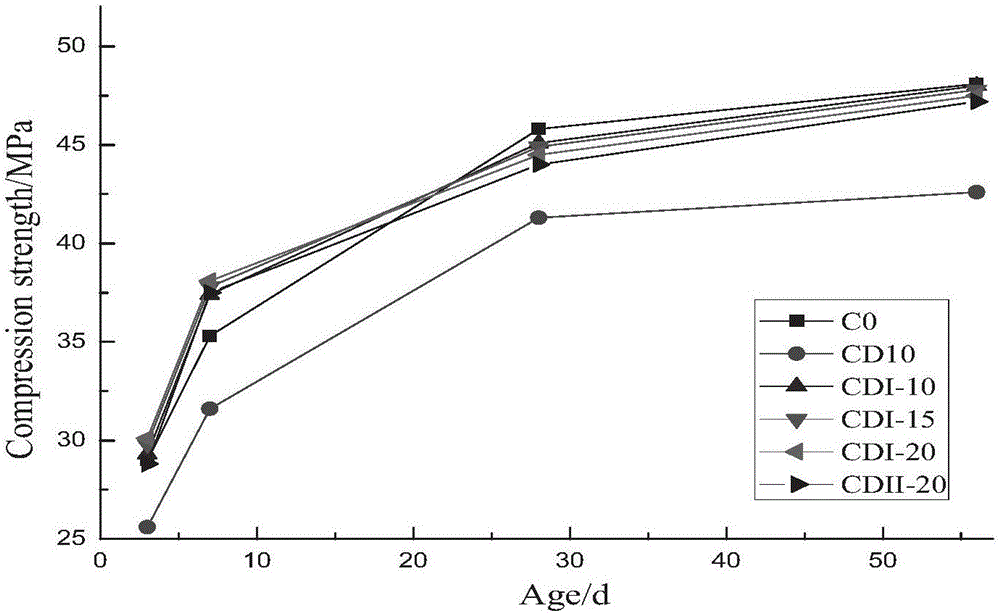

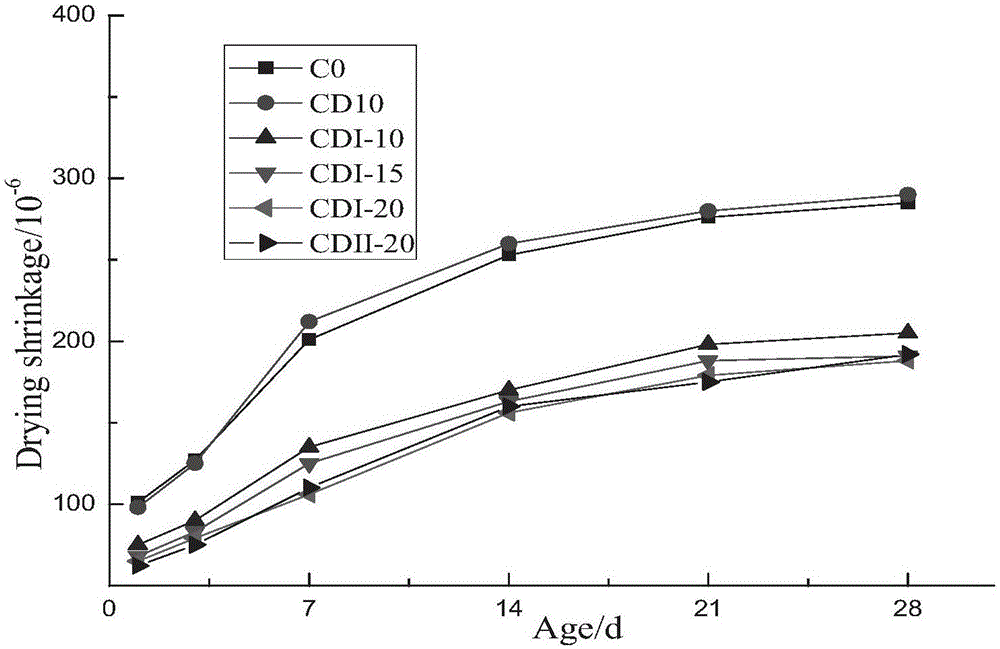

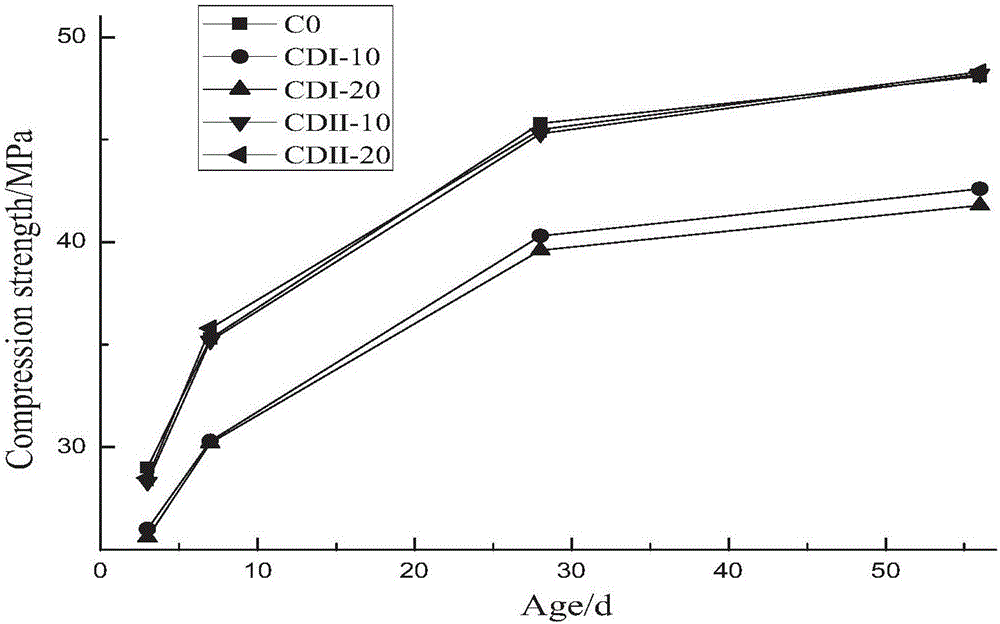

Modified dolomite powder based mineral admixture and preparation method thereof

InactiveCN106747090AHigh strengthResistance to Chloride Ion Penetration and DurabilitySolid waste managementDolomiteWork performance

The invention discloses a modified dolomite powder based mineral admixture. The modified dolomite powder based mineral admixture is prepared by uniformly mixing the following raw materials in parts by weight: 50-60 parts of dolomite powder, 15-20 parts of mineral powder, 15-20 parts of fly ash and 5-10 parts of bentonite. Besides, the invention also discloses a preparation method of the admixture. According to the invention, the dolomite powder is used as the concrete mineral admixture, thereby obviously enhancing the working performance of cement concrete, improving water bleeding, ensuring the strength and durability, lowering the cost, and achieving remarkable economic and social benefits.

Owner:CENT SOUTH UNIV

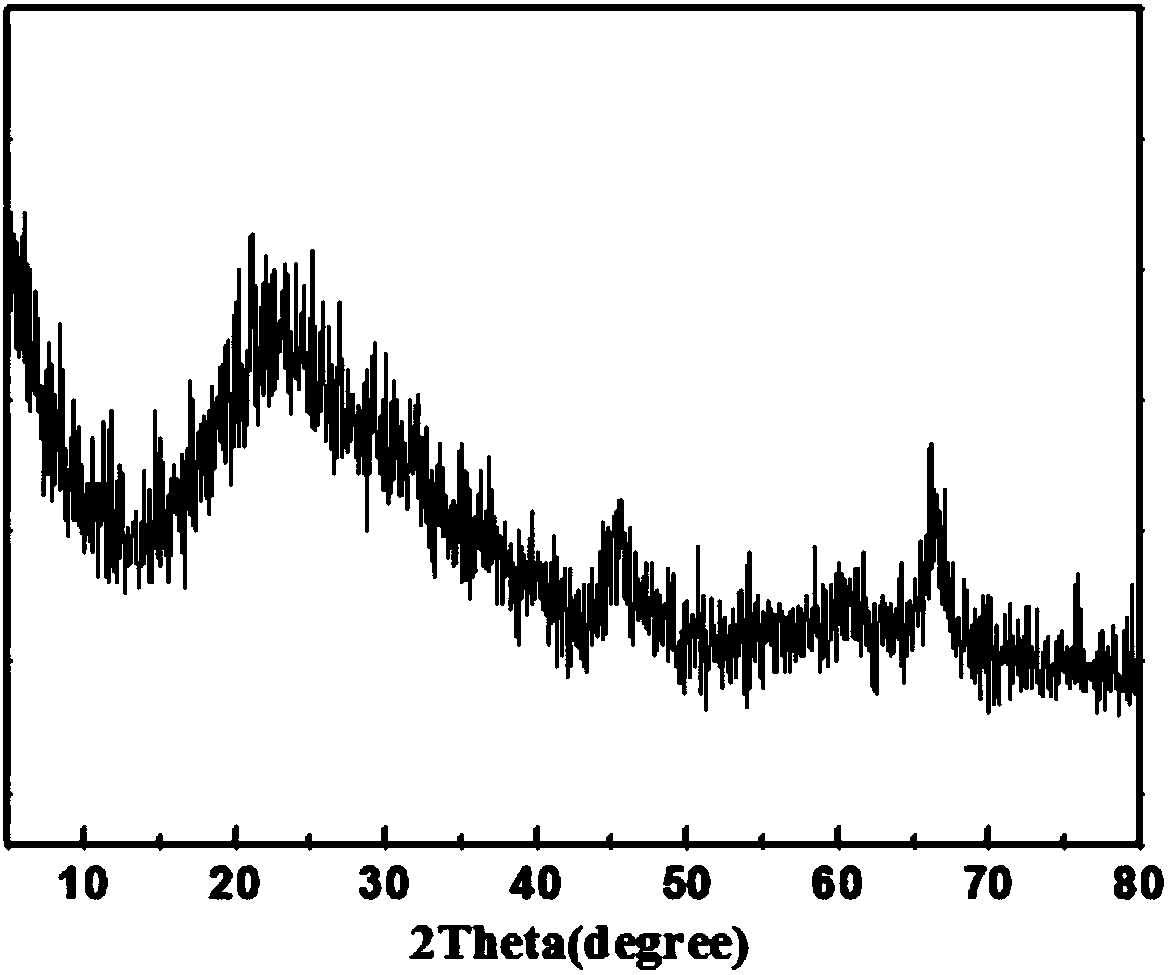

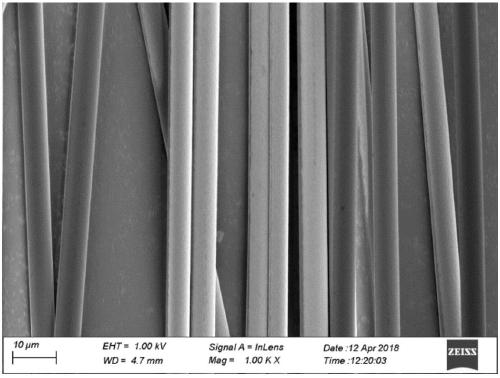

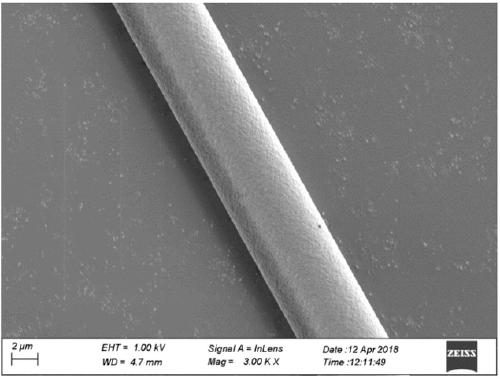

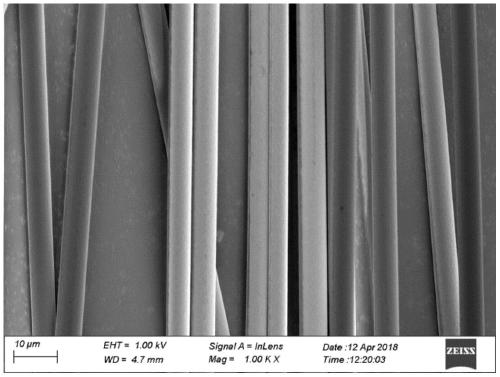

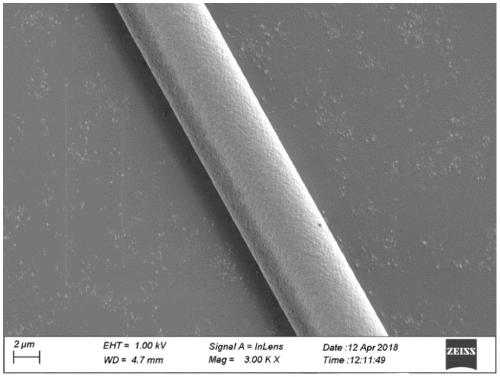

Preparation method for aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3

ActiveCN109437862AImprove stabilityImprove tensile propertiesInorganic material artificial filamentsFiberTemperature resistance

The invention provides a preparation method for an aluminum oxide-based ceramic continuous fiber containing 1-5 wt% of B2O3. The method comprises the following steps that alumina sol containing Al13 colloidal particles, a pseudo-boehmite nano-dispersion, silica sol, a boric acid aqueous solution and a high-molecular spinning auxiliary are mixed so as to obtain a mixed solution; then aging and concentrating are carried out until the viscosity of a system is 500-1000 Pa*s so as to obtain spinnable precursor sol; and dry spinning, drying and calcining are carried out so as to obtain the aluminumoxide-based ceramic continuous fiber. According to the preparation method, the electron deficiency effect of boron is utilized, and addition reaction of water is carried out on the boric acid to formB(OH)4<->, so that the boric acid can be stably combined with polyhydroxyl pseudo-boehmite nano-particles so as to prepare the spinnable precursor sol and the fiber with excellent properties. The method has the advantages that the raw materials are easy to obtain, and industrialized application is easy to realize; and the diameter of the prepared fiber is 5-8 microns, the strength of the single fiber can reach 2.0 GPa, the modulus can reach 149 GPa, and various excellent performances such as high temperature resistance, flexibility and spinnability are achieved.

Owner:SHANDONG UNIV

Medical stone flexible floor board and preparation method thereof

InactiveCN107189268AImprove physical performanceDense internal structureFlooring insulationsResiliently-mounted floorsFiberAdditive ingredient

The invention provides a medical stone flexible floor board and a preparation method thereof, and belongs to the technical field of a building material. The medical stone flexible floor board solves the technical problems that the flexibility of the floor board is poor; harmful substances cannot be adsorbed, and the like. The medical stone flexible floor board is made from the following materials including 30 to 50 weight percent of medical stone, 15 to 25 weight percent of heavy calcium powder, 15 to 20 weight percent of PVC resin 5 type powder, 3 to 10 weight percent of EVA co-extrusion resin, 8 to 15 weight percent of DOTP plasticizers, 3 to 6 weight percent of calcium / zinc heat stabilizers and 5 to 10 weight percent of bamboo wood fiber powder; the total quantity is 100 weight percent. The ingredients and materials are mixed and stirred and are subjected to extrusion forming to prepare the medical stone flexible floor board. The medical stone flexible floor board has the advantages that harmful substances can be adsorbed; the softness is high, and the like.

Owner:湖北格丽特新材料科技股份有限公司

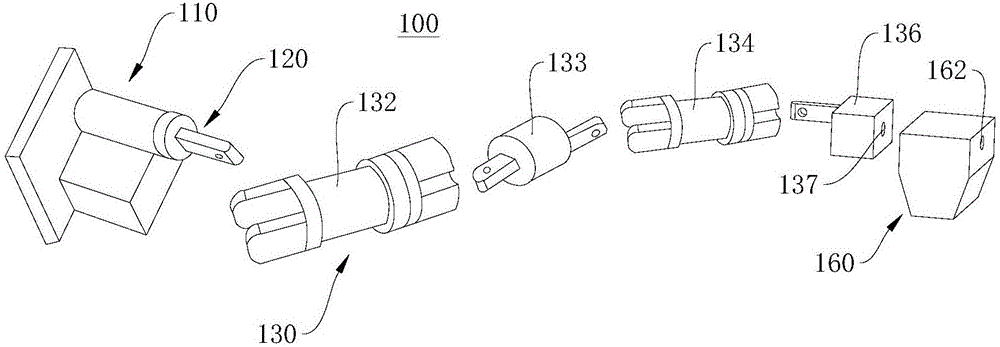

3D (Three-dimensional) printing process intelligent forging casting hammer and 3D printer

PendingCN107521095ADense internal structureSmall volume changeAdditive manufacturing apparatusPower hammersMachining processInternal stress

The invention relates to the technical field of 3D (Three-dimensional) printing, and discloses a 3D printing process intelligent forging casting hammer and a 3D printer. According to the 3D printing process intelligent forging casting hammer provided by the embodiment of the invention, a driving device is connected with a rotating arm so that a mechanical arm rotates, stretches and retracts relative to a fixed seat. A first rotating device is connected with the mechanical arm, and is used for driving the mechanical arm to rotate relative to the rotating arm, so that the mechanical arm rotates vertically relative to the fixed seat. The first rotating device drives the mechanical arm to rotate vertically relative to the fixed seat, so that the mechanical arm drives the forging casting hammer to stretch away from or retract to the fixed seat. The mechanical arm drives the forging casting hammer to perform forging casting machining on a product which is manufactured by a 3D printing machine; and the compactness of the internal structure of the product can be greatly improved by utilizing the forging casting machining process, meanwhile, the internal stress response of the product is eliminated, and the product quality is improved. The 3D printing machine provided by the embodiment of the invention also has the beneficial effects because of comprising the 3D printing process intelligent forging casting hammer.

Owner:窦鹤鸿

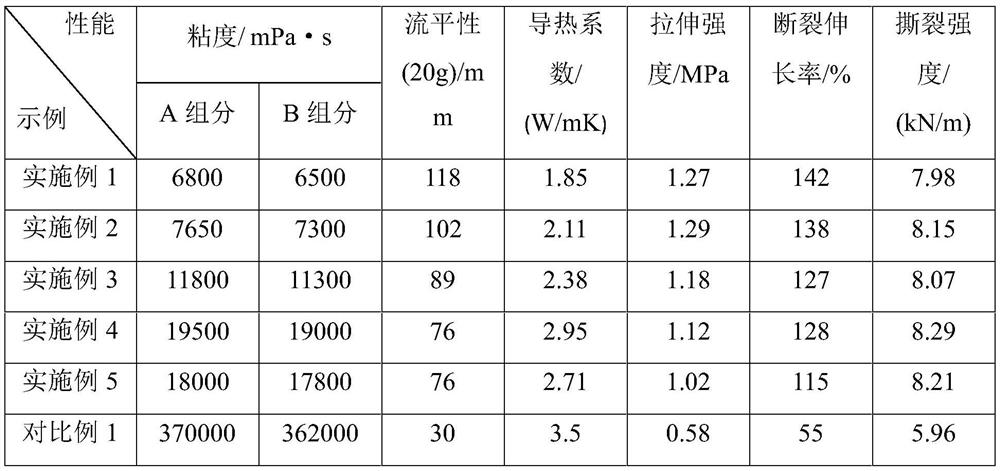

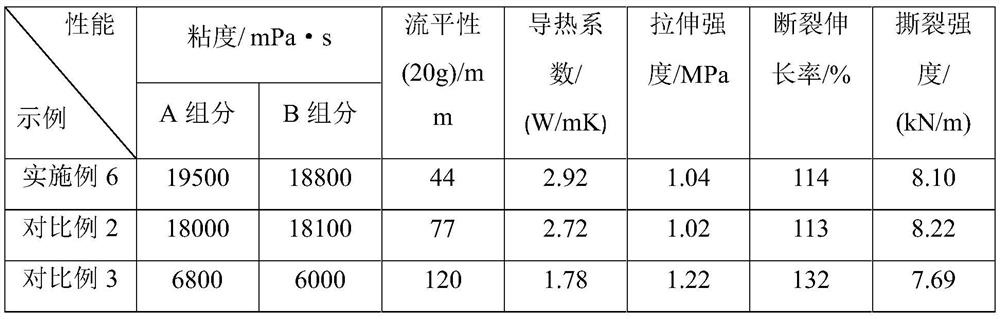

High-thermal-conductivity low-viscosity two-component organic silicon pouring sealant and preparation method thereof

PendingCN114032063AEasy to disperseNot easy to settleNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryOrganosilicon

The invention relates to the field of organic silicon pouring sealants, and particularly discloses a high-thermal-conductivity low-viscosity two-component organic silicon pouring sealant and a preparation method thereof. The organic silicon pouring sealant is composed of a component A and a component B, the component A is prepared from the following raw materials in parts by weight: 15 to 25 parts of vinyl silicone oil, 2 to 5 parts of polydimethylsiloxane, 0.3 to 0.5 part of a silane coupling agent, 0.2 to 0.4 part of a catalyst, 160 to 185 parts of spherical aluminum oxide and 0.2 to 0.5 part of an anti-settling agent; and the component B is prepared from the following raw materials in parts by weight: 13 to 21 parts of vinyl silicone oil, 2 to 5 parts of polydimethylsiloxane, 0.3 to 0.5 part of a silane coupling agent, 2 to 5 parts of hydrogen-containing silicone oil, 160 to 185 parts of spherical aluminum oxide, 0.02 to 0.1 part of an inhibitor, 0.2 to 0.5 part of an anti-settling agent and 0.1 to 0.5 part of carbon black.

Owner:深圳联腾达科技有限公司

High-alumina refractory brick and preparation method thereof

ActiveCN111099905AStable internal structureDense internal structureCeramicwarePolystyrene microsphereAluminium

The invention relates to a high-alumina refractory brick and a preparation method thereof, and belongs to the technical field of building materials. According to the technical scheme, the surfaces ofmonodisperse polystyrene microspheres are filled with a compact glass conversion layer; the glass frit and the clay form complex glazed porcelain in the melting and sintering process, so the structural performance of the material is further improved, thus improving fire strength of material; meanwhile, the high-alumina bauxite material is adopted as a main base material, pores of the brick body are filled with the high-alumina bauxite micro-powder under the high-temperature condition after high-temperature calcination, so sintering is promoted, the mechanical strength, high-temperature resistance and durability of the brick body can be effectively improved, fire resistance is effectively achieved, and the mechanical property of the material is improved.

Owner:DONGTAI HONGDA REFRACTORY MATERIAL

High-toughness, durable and anti-skid steel bridge deck pavement structure and construction method thereof

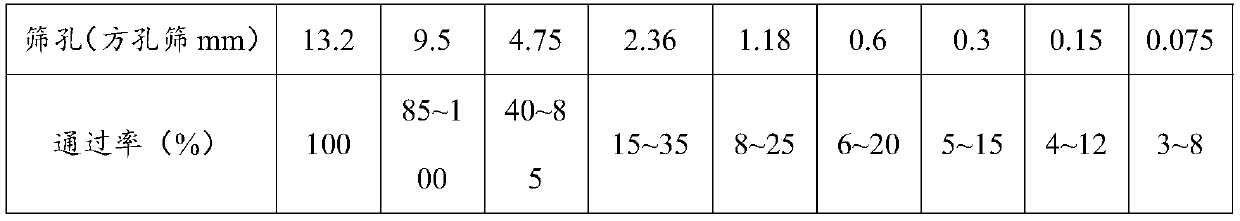

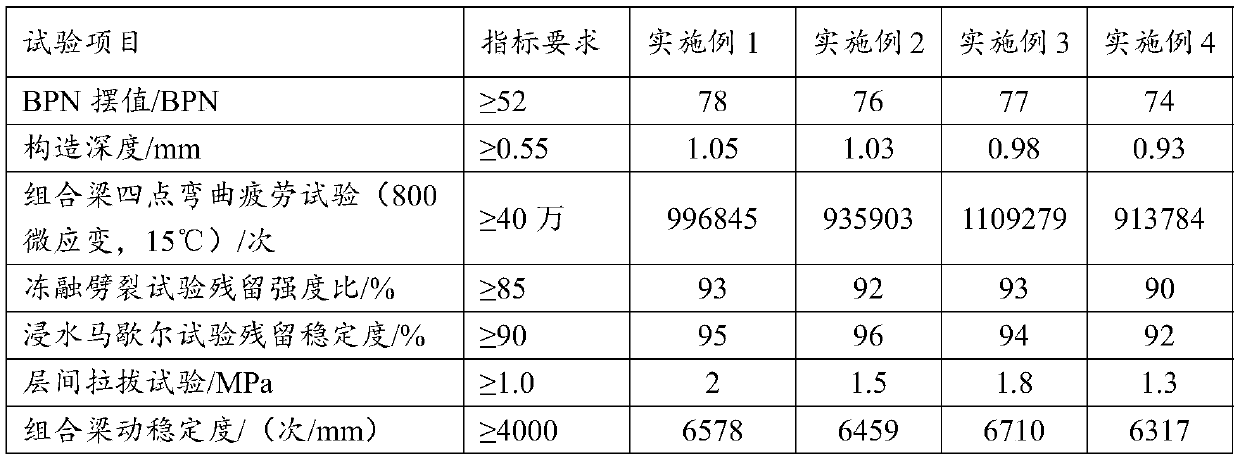

InactiveCN110952447AIncrease stiffnessImprove stabilityBridge structural detailsBridge erection/assemblyEpoxyBridge deck

The invention discloses a high-toughness, durable and antiskid steel bridge deck pavement structure and a construction method thereof. The steel bridge deck pavement structure comprises a steel bridgedeck steel plate; a bonding bottom layer, a buffer layer, an adhesion layer and a wearing layer are sequentially laid on the surface of the steel bridge deck steel plate from bottom to top; the buffer layer and the wearing layer are both made of high-toughness modified asphalt concrete composed of aggregate, filler and asphalt cement, the thickness of the buffer layer is 1-3 cm, and the thicknessof the wearing layer is 2-3 cm. The bridge deck pavement structure has good high-temperature rut resistance, fatigue durability, skid resistance, bonding strength and deformation compliance, comparedwith epoxy asphalt concrete, the engineering cost is greatly reduced, the construction process is simple, and later maintenance is convenient.

Owner:广州市市维新材料科技有限公司

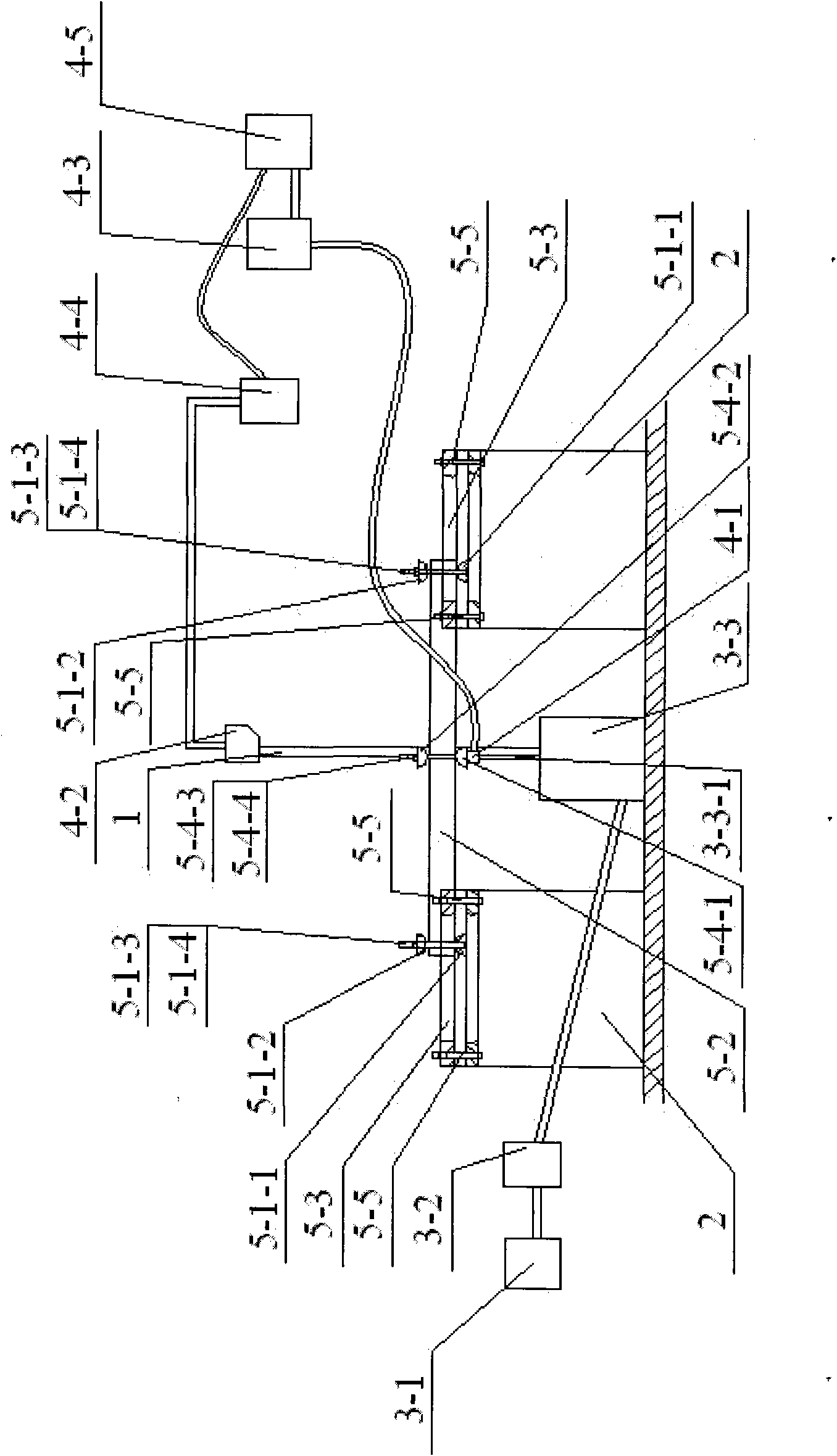

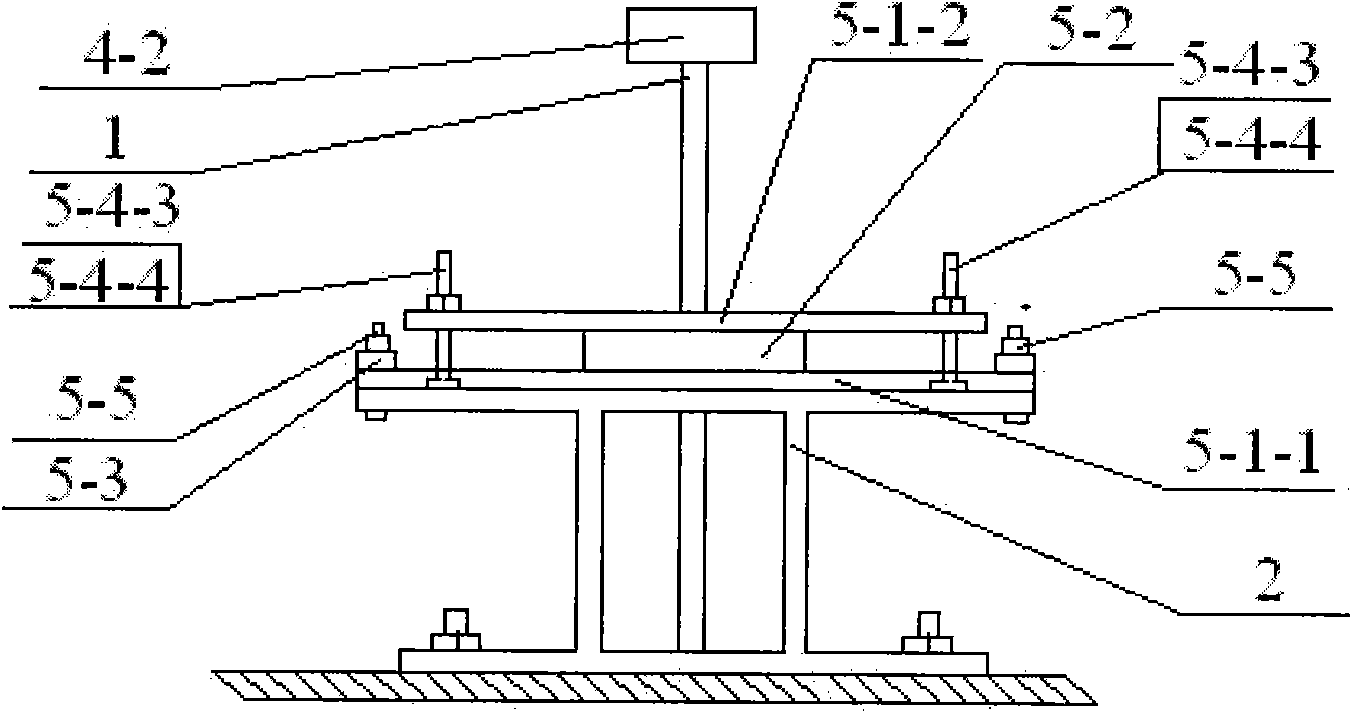

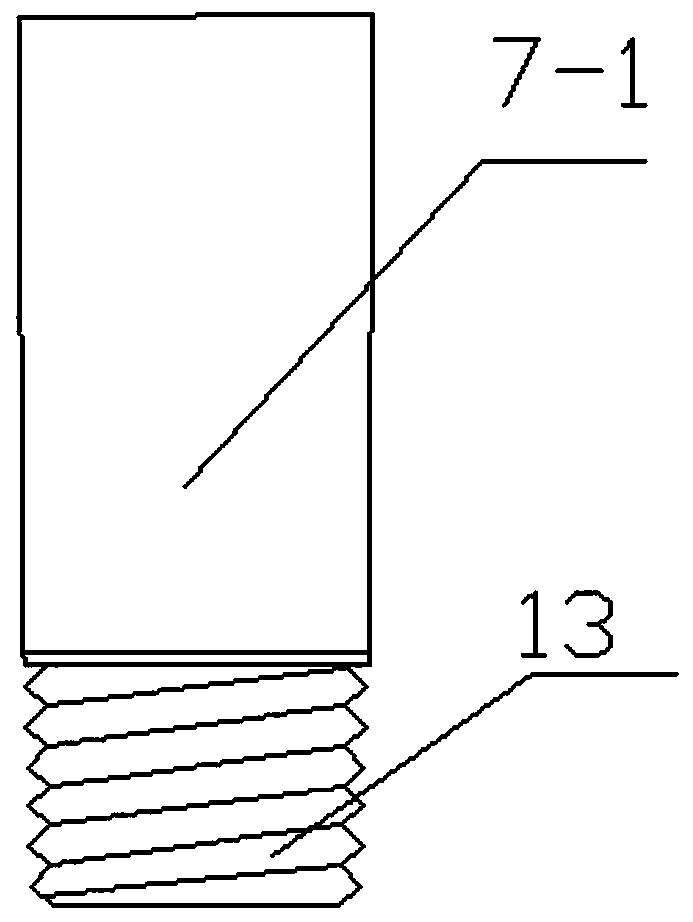

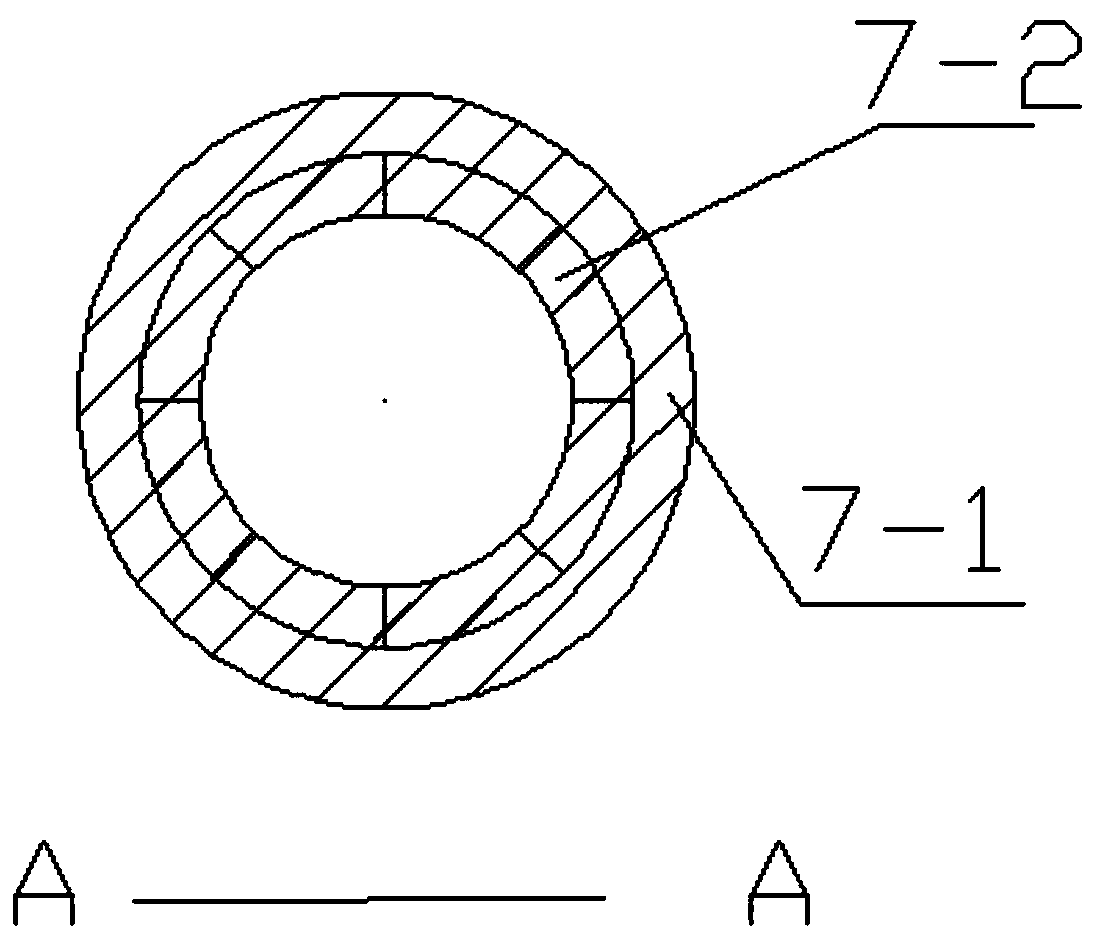

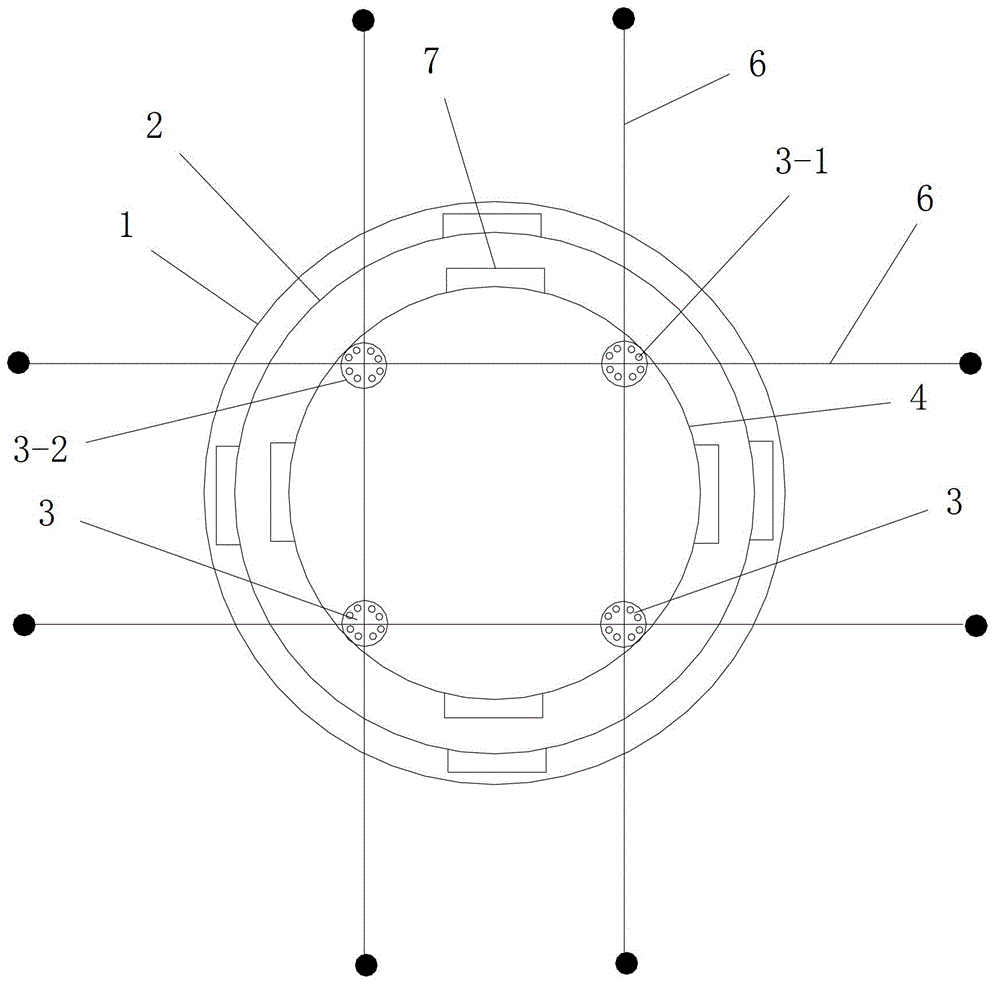

Test mould for preparation of shear thickening glue test piece and using method thereof

PendingCN109765092AGeometrically accurateDense internal structurePreparing sample for investigationMoulding devicePiston

The invention relates to a test mould for preparation of a shear thickening glue test piece and a using method thereof. The test mould comprises a base device, a test piece mould device and a test piece compaction device, wherein the base device comprises a base, a fixed slot, a buffer foam layer, a support frame, a cross beam and a threaded hole; the test piece mould device comprises an outer design finalizing cylinder and a jointable sheet-like cylinder; and the test piece compaction device comprises a screw, a piston type pressing plate and a handle. The test mould is capable of improving the compaction and moulding quality of the shear thickening glue test piece while simplifying the manufacturing process of the shear thickening glue test piece, and is suitable for the manufacturing ofthe shear thickening glue test piece for rheological test. On the basis of characteristics of shear thickening glue, the shearing speed is relatively low in the test piece preparation process, and the fluid state between shear thickening glue particles is lubricating contact and deformation is easy to occur, the jointable sheet-like cylinder overcomes the difficulty, solves the problem that the test pieces is easy to destroy when being directly taken during traditional test piece preparation, and a broad application prospect is provided in the aspect of preparing the shear thickening glue test piece in laboratories.

Owner:ANHUI UNIV OF SCI & TECH

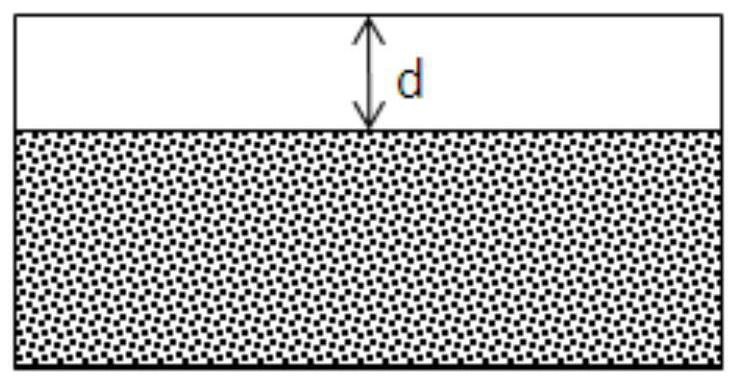

Method for measuring penetration depth of permeable liquid hardening agent in cement-based material

PendingCN114371115ADense internal structureSimple methodUsing optical meansPermeability/surface area analysisPhysical chemistryDepth of penetration

The invention relates to a method for measuring the penetration depth of a permeable liquid hardening agent in a cement-based material. The method comprises the following steps: 1) obtaining a cement-based material sample hardened by a permeable liquid hardening agent; 2) splitting the sample; (3) developing the profile by using a color developing agent; and 4) measuring the distance from a non-color-changing point on the edge of the color developing area on the section to the treatment surface of the cement-based material sample, namely the penetration depth of the permeable liquid hardening agent in the cement-based material. The technical problem to be solved is how to simply, quickly and effectively obtain data of the penetration depth of a penetration type liquid hardening agent in a cement-based material so as to guide a construction unit to select a model of a ground hardening material and serve as a reference basis for formulating a ground modification hardening process, so that the method is more practical.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

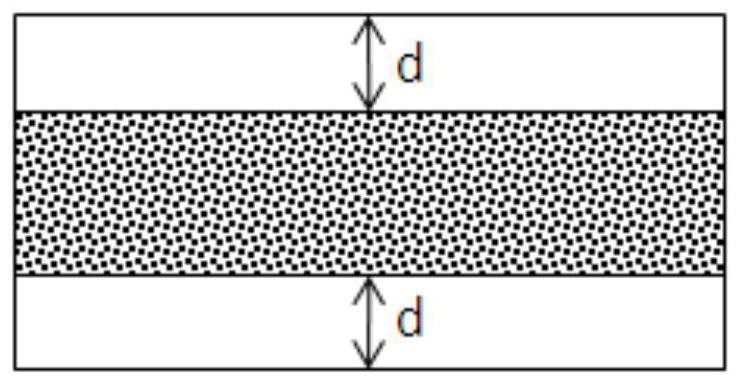

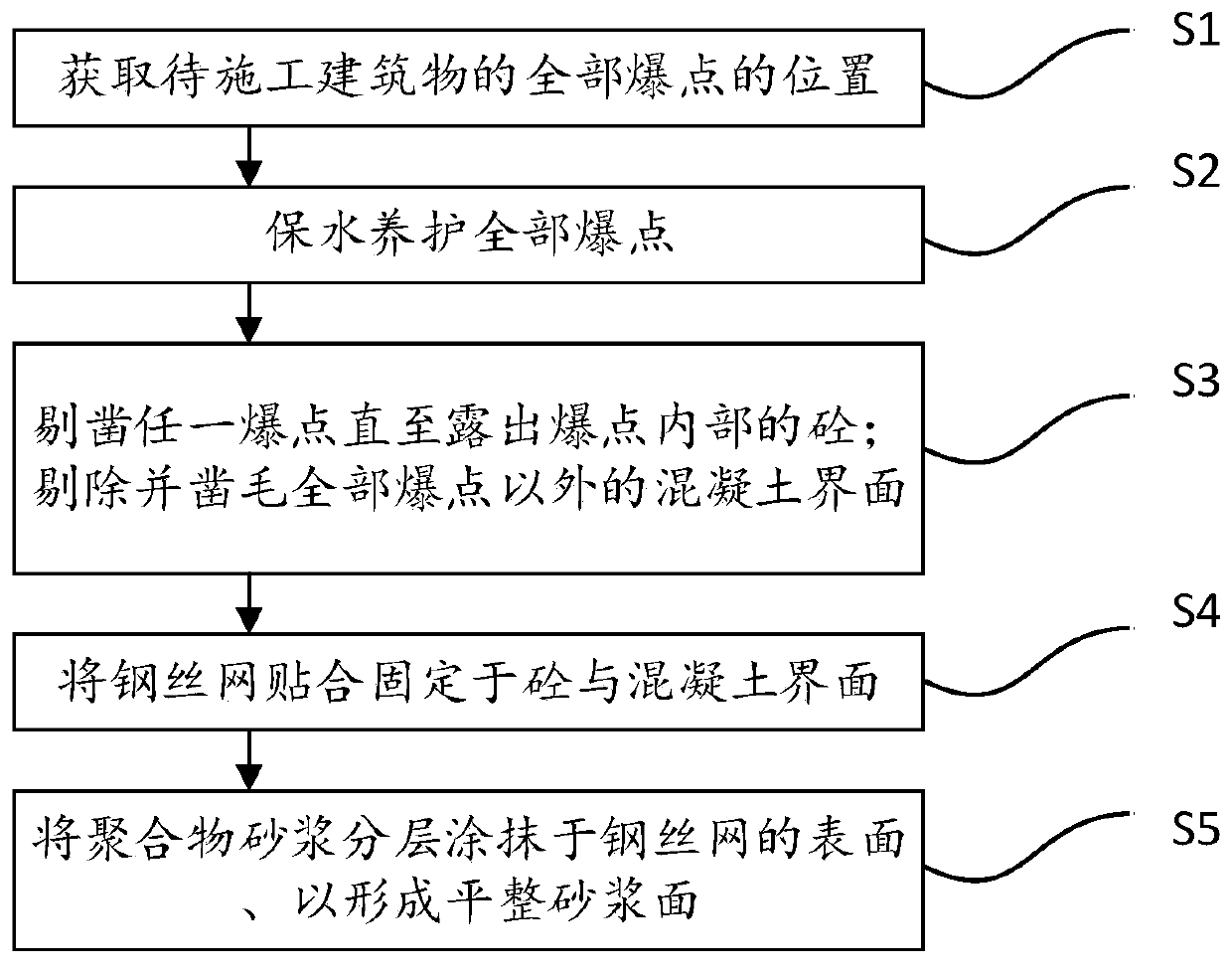

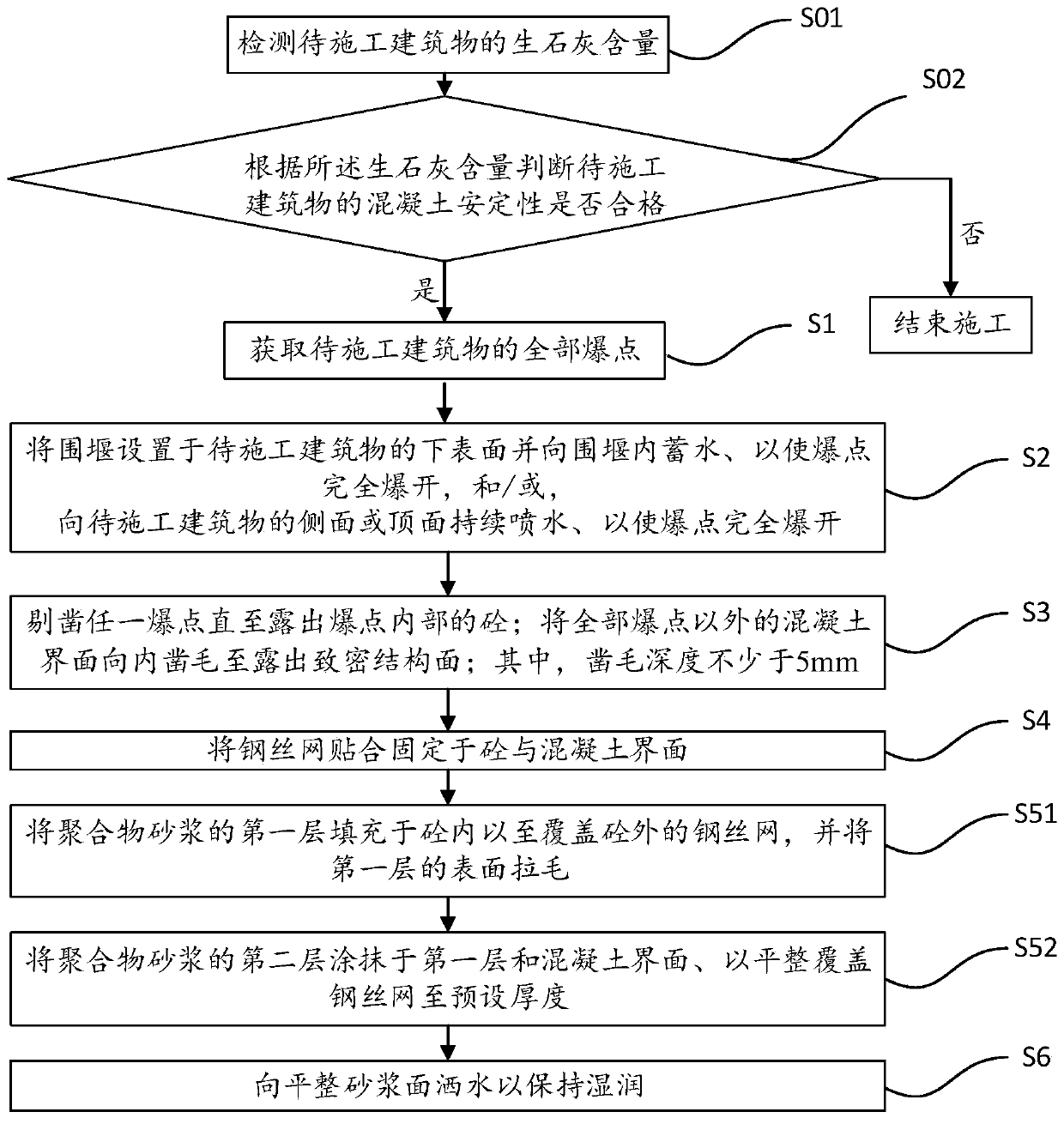

Construction method for improving quality of concrete explosion points

InactiveCN110792238ADense internal structureImprove performanceCovering/liningsArchitectural engineeringStructural engineering

The invention discloses a construction method for improving the quality of concrete explosion points. The method comprises the following steps of acquiring positions of all explosion points of a building to be constructed; keeping water and maintaining all the explosion points; removing any explosion point until concrete inside the explosion point is exposed, and removing and roughening concrete interfaces except all the explosion points; attaching and fixing a steel wire mesh to all concrete and the concrete interfaces; and coating polymer mortar on the steel wire mesh layer by layer to forma flat mortar surface. According to the construction method for improving the quality of the concrete explosion points, when the concrete building with the explosion points is repaired, the explosionpoints are eliminated, surface reinforcement and waterproof sealing are realized on concrete components with the explosion points of the concrete building, the integral structural performance of the concrete building is improved, the consumption of materials in the construction process is small, and the construction period is short.

Owner:上海宝冶市政工程有限公司 +1

Anorthite lightweight refractory material not prone to cracking and preparation method thereof

PendingCN112028610AAvoid crackingDense internal structureCeramic materials productionCeramicwareFiberPyrophyllite

The invention provides a anorthite light refractory material not prone to cracking and a preparation method thereof. The anorthite light refractory material is prepared from 48-55wt% of coal gangue, 3-6wt% of kyanite, 4.5-6.5wt% of pyrophyllite, 10-14.5wt% of refractory clay, 9.5-15.5wt% of calcium carbonate, 5-10wt% of high-alumina cement, 1-3wt% of zirconium-containing fibers and 3-8wt% of an additive, wherein the content of Al2O3 in the zirconium-containing fiber is 35-50wt%, and the content of zirconium in the zirconium-containing fiber is 14-20wt%; and the particle size of the refractoryclay is 300-400 meshes, and the particle size of the calcium carbonate is 550-650 meshes. By adjusting the grain composition of the raw materials used by the anorthite refractory material and cooperatively using the zirconium-containing fibers, the internal structure of the prepared anorthite cast brick is more compact after being sintered, so that the anorthite cast brick has higher compressive strength and is not easy to crack.

Owner:山东鲁阳浩特高技术纤维有限公司

Preparation method of silicon nitride ceramic granulation powder

The invention provides a preparation method of silicon nitride ceramic granulation powder, and belongs to the technical field of silicon nitride ceramics. The preparation method comprises the following steps: grinding and mixing a sintering aid, water and silicon nitride raw powder to obtain first slurry; dissolving polyvinyl alcohol and polyethylene glycol into water to obtain a glue solution, wherein the mass ratio of the polyvinyl alcohol to the polyethylene glycol is (0.16-0.20):1, and the total mass of the polyvinyl alcohol and the alcohol polyethylene glycol is 2-8% of the total mass of the sintering aid and the silicon nitride raw powder; mixing the first slurry, the glue solution and a dispersing agent to obtain second slurry; and carrying out spray granulation on the second slurry to obtain granulated powder, wherein the inlet temperature of the spray granulation is 300 to 340 DEG C. According to the method disclosed by the invention, the apparent density of the silicon nitride ceramic granulation powder can be improved to 0.92 g / cm<3> or above.

Owner:SINOMA ADVANCED NITRIDE CERAMICS CO LTD

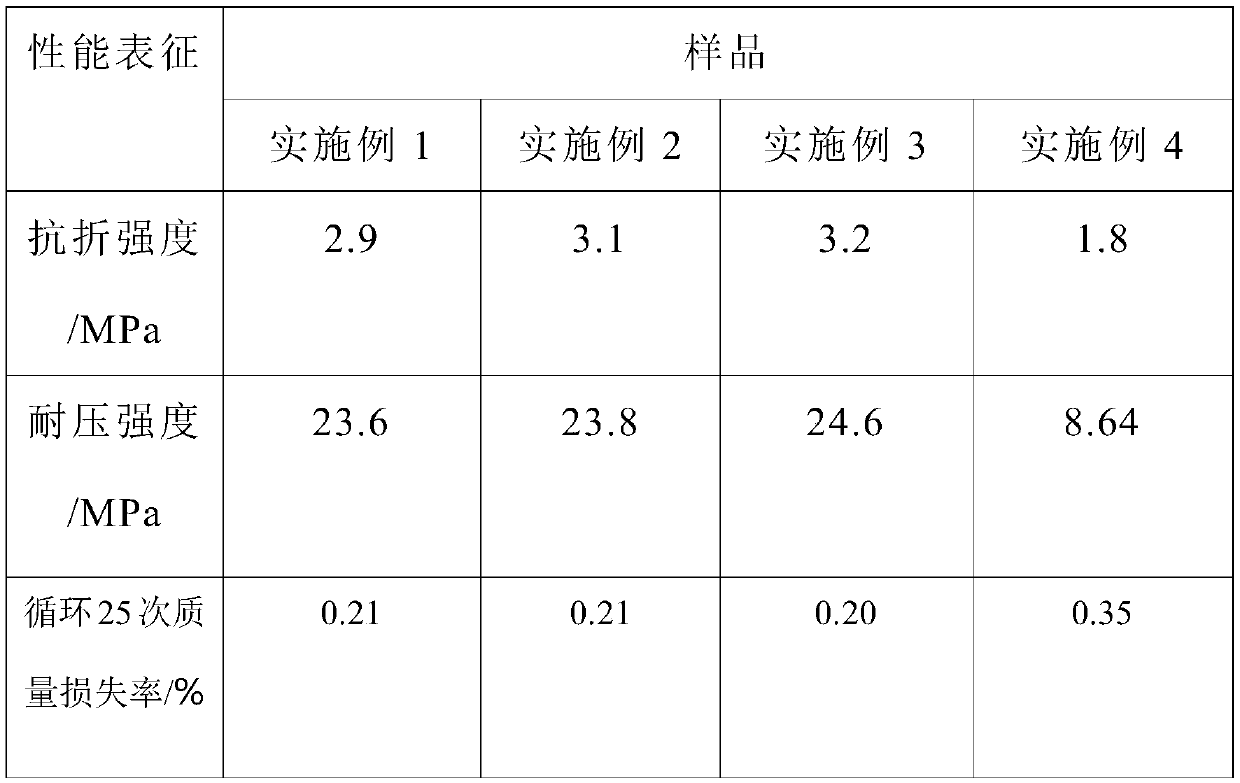

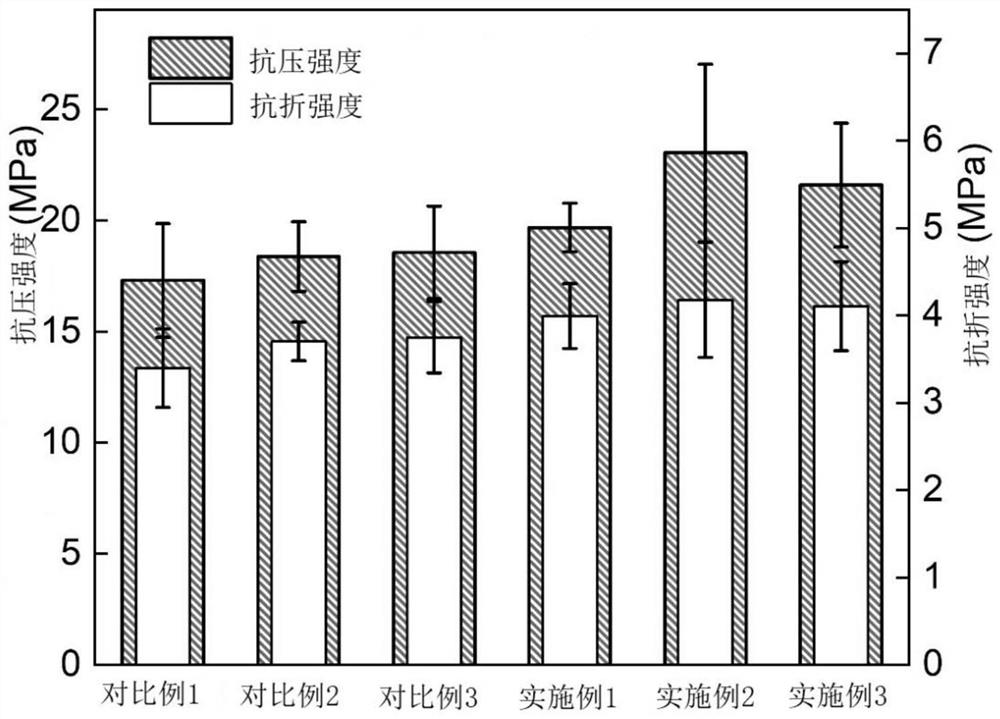

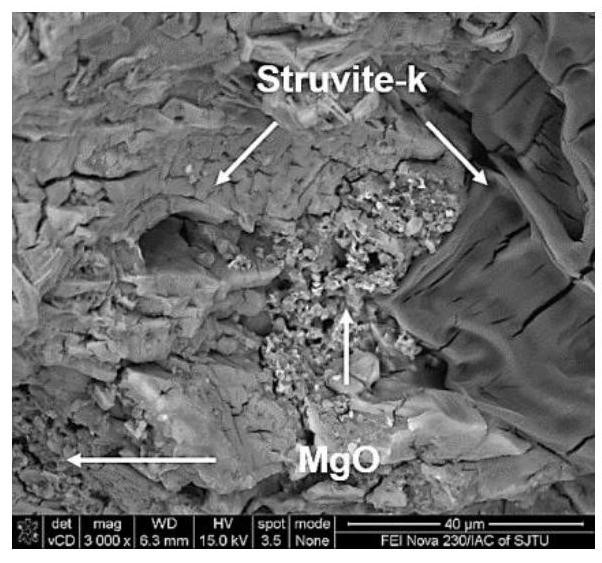

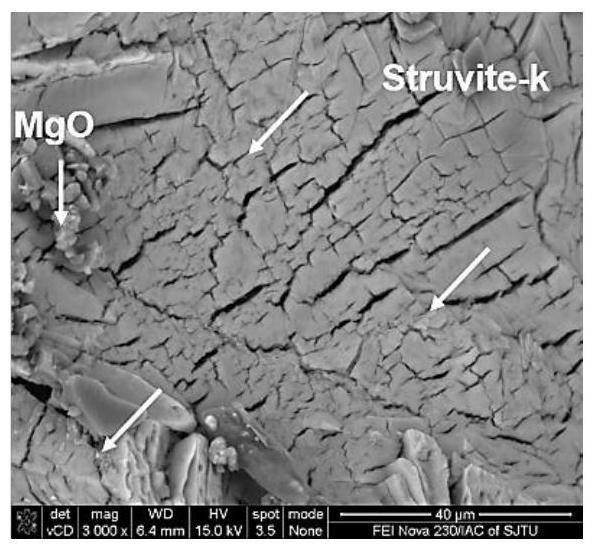

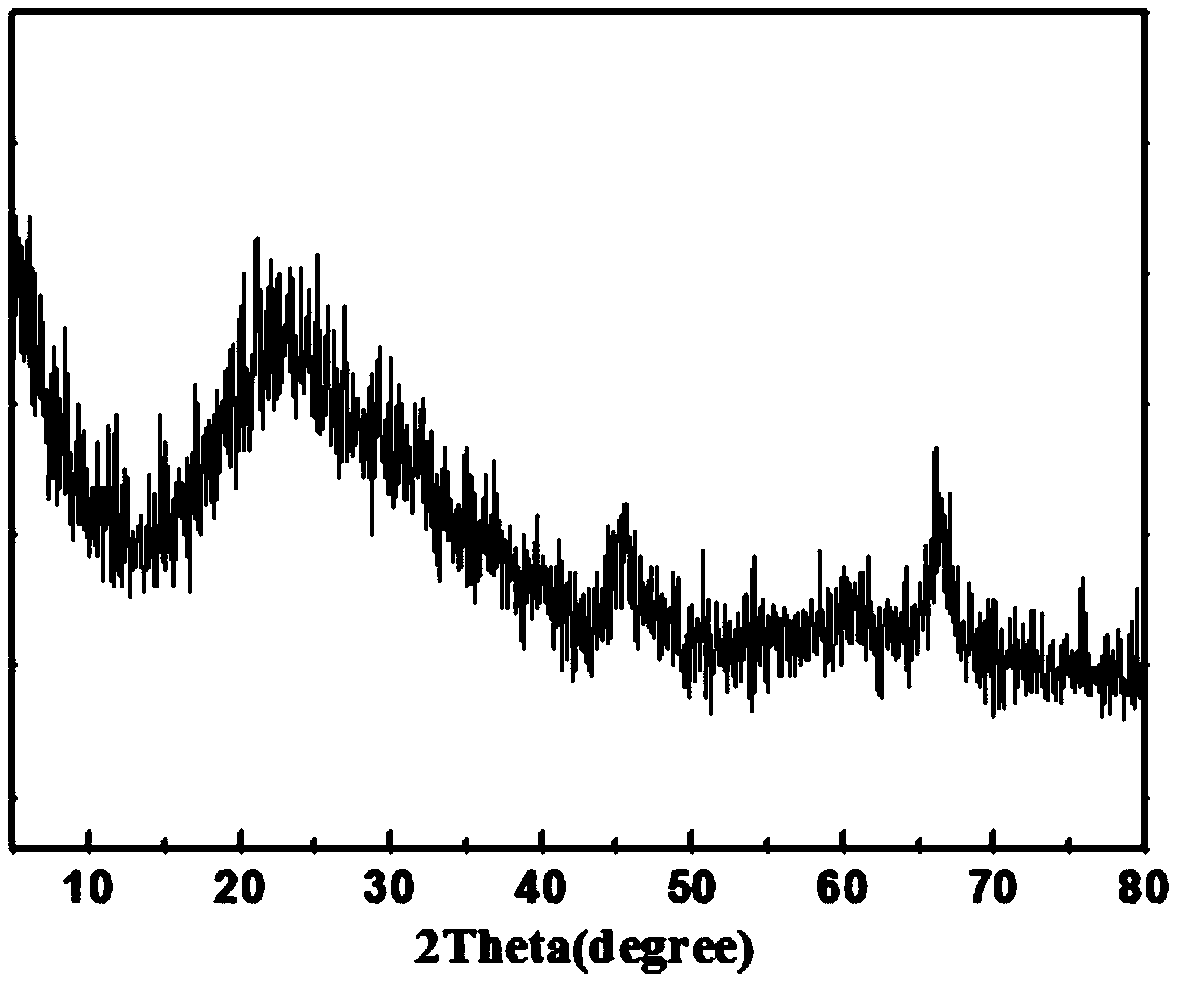

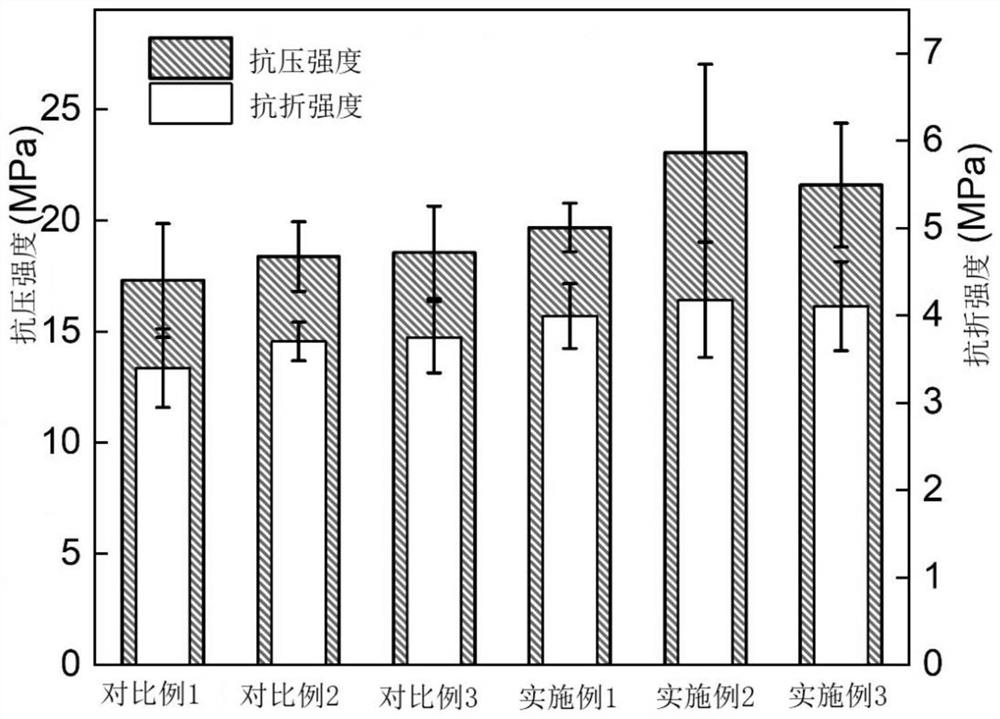

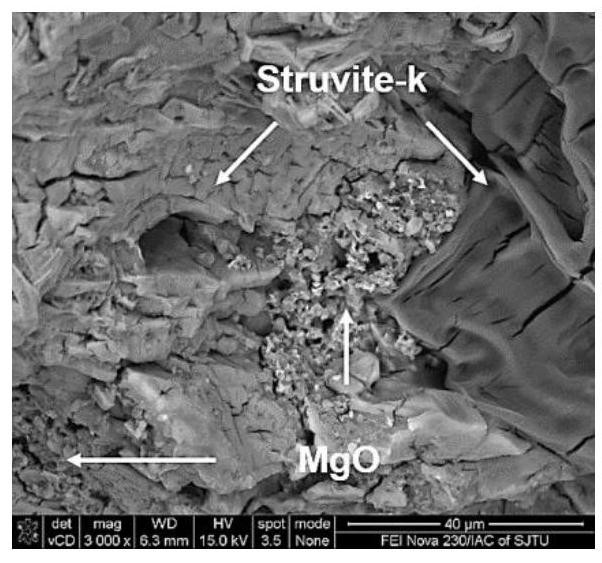

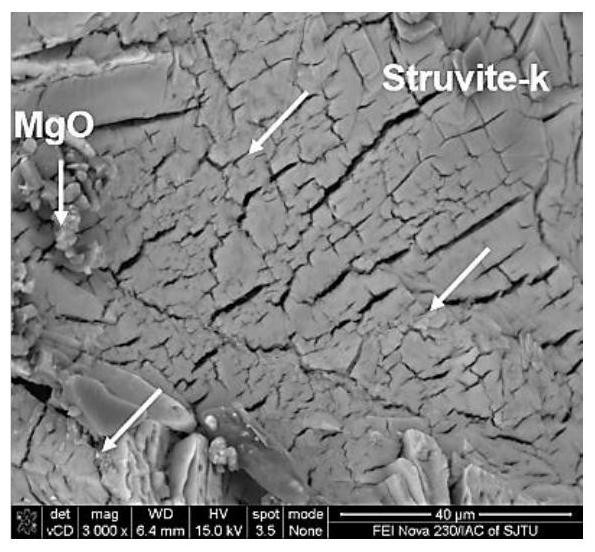

Reinforced magnesium phosphate cement composite material and preparation method thereof

The invention provides a reinforced magnesium phosphate cement composite material and a preparation method thereof, the composite material comprises a graphene oxide / carbon nanotube composite modifierand a magnesium phosphate cement dry material, the graphene oxide / carbon nanotube composite modifier is compounded by graphene oxide and carbon nanotubes, The ratio of the total dry weight of the graphene oxide and the carbon nanotubes to the dry weight of the magnesium phosphate cement dry material is 0.01-0.5: 100. The method comprises the following steps: preparing the graphene oxide / carbon nanotube composite modifier; mixing the prepared graphene oxide / carbon nanotube composite modifier with the magnesium phosphate cement dry material, and uniformly stirring to obtain cement paste; pouring the cement paste into a mold for shaping, removing bubbles through oscillation, covering the surface of the mold with a film, demolding after curing, and finally curing to the use age. The preparedmagnesium phosphate cement is high in strength and good in mechanical property, the internal structure is neat and compact, the pore structure is optimized, and the durability is good.

Owner:SHANGHAI JIAO TONG UNIV

A containing 1 ~ 5wt% b 2 o 3 Preparation method of alumina-based ceramic continuous fiber

ActiveCN109437862BReduce defectsThin diameterInorganic material artificial filamentsSpinningSingle fiber

Owner:SHANDONG UNIV

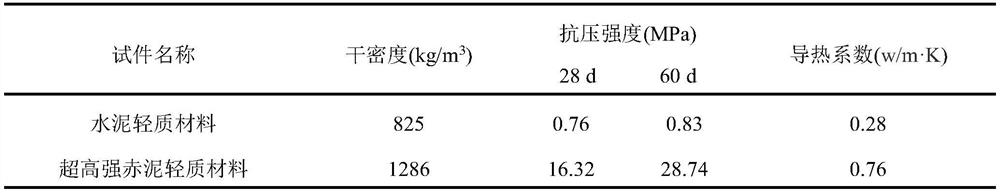

Ultrahigh-strength red mud light material and preparation method thereof

The invention relates to an ultrahigh-strength red mud light material and a preparation method thereof, and the method comprises the following steps: crushing and ball-milling red mud, uniformly mixing red mud micro powder, slag micro powder, fly ash and slaked lime powder, and adding sodium hydroxide and liquid sodium silicate. The purpose of light weight by using ultrahigh-strength water absorption of red mud particles and adopting an ultrahigh liquid-solid ratio mode is achieved, meanwhile, through the interaction among the red mud micro powder, the slag micro powder, the fly ash and the slaked lime powder, the polymerization reaction activity among the materials is fully exerted, so that preparation of the ultrahigh-strength red mud light material is realized. The red mud light material is prepared by taking red mud as a main raw material, resource recycling of wastes is realized, and meanwhile, the red mud light material has the characteristics of low preparation cost and ultrahigh mechanical properties.

Owner:ANHUI UNIV OF SCI & TECH

Environment-friendly ceramsite brick and production method thereof

The invention provides an environment-friendly ceramsite brick and a production method thereof, and relates to the technical field of building material manufacturing. The environment-friendly ceramsite brick comprises the following raw materials in parts by weight: 50-80 parts of ceramsite, 20-25 parts of straw, 10-15 parts of fly ash, 3-5 parts of glass beads, 3-5 parts of methyl bentonite, 1-3 parts of a flame retardant, 1-3 parts of a polystyrene resin solution, 3-5 parts of a water-retaining agent, 1-3 parts of nano-zinc oxide, 1.5-2.5 parts of a chelating agent and 2-3 parts of an adhesive. The straw and the fly ash are added into the raw materials, the fly ash is an active hydraulic material and can continue to generate a hydration reaction in a humid environment, so that the internal structure of the ceramsite brick is denser and the strength is improved, the straw and the fly ash are cheap raw materials so that the production cost investment of the ceramsite brick can be reduced, the viscosity among various raw materials can be increased through the methyl bentonite and the chelating agent, so that the strength of the ceramsite brick is improved.

Owner:广东前景建筑科技有限公司

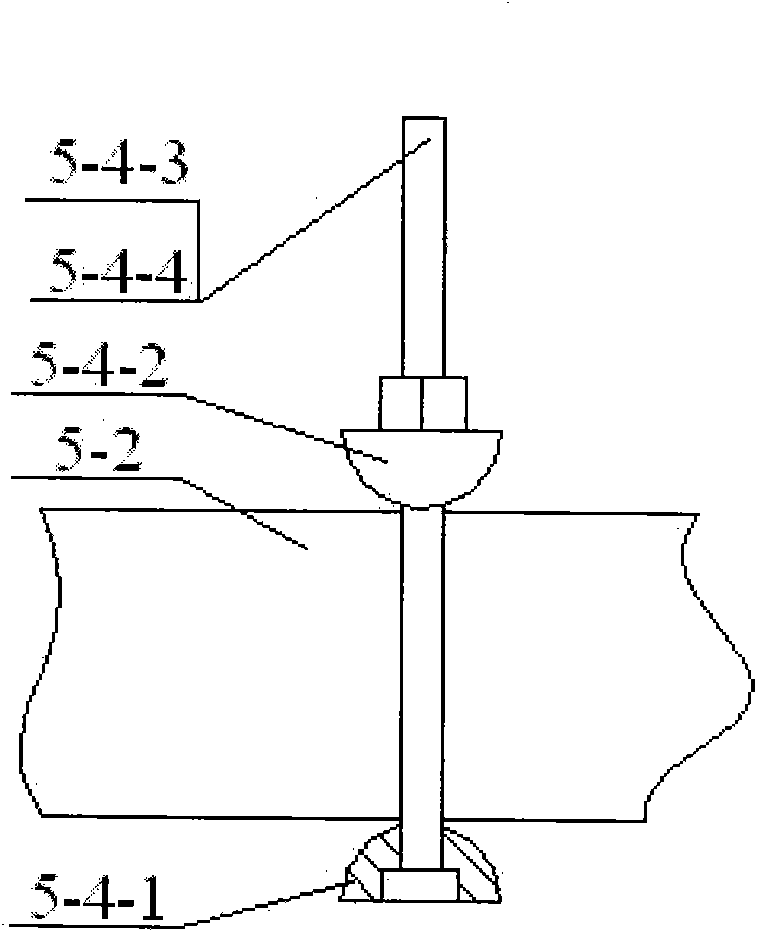

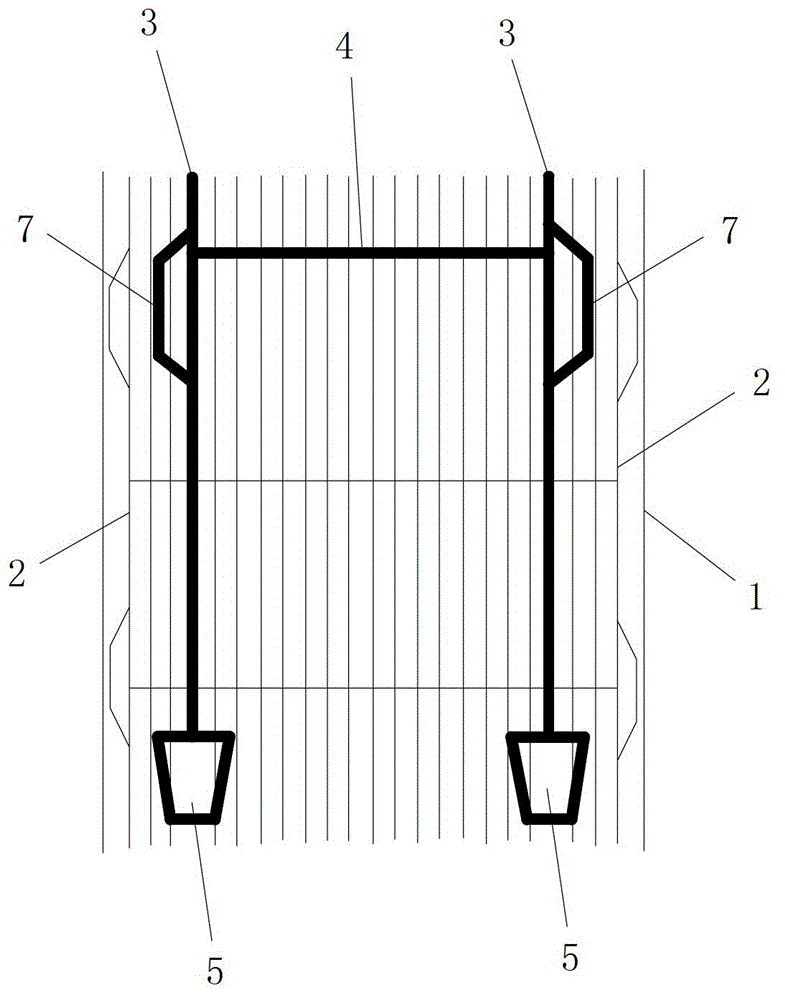

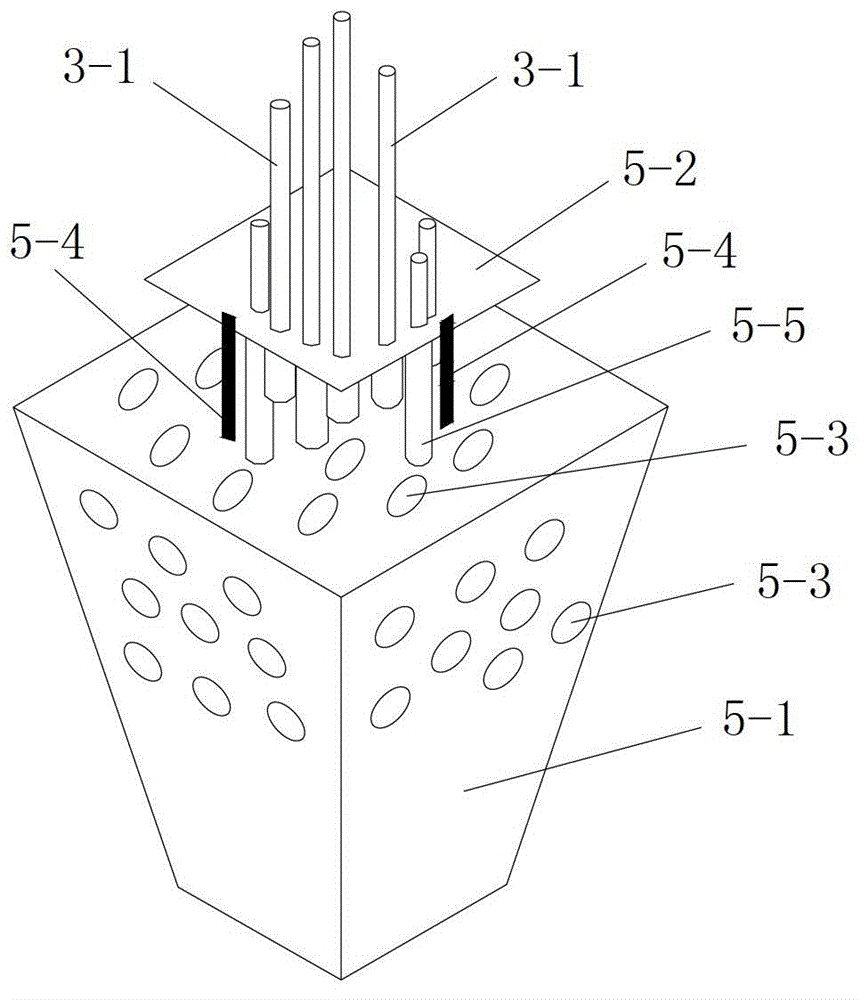

Construction structure and construction method of anchor pile for large-tonnage test pile

ActiveCN103276725BSimple construction structureGuarantee molding qualityBulkheads/pilesPre stressRebar

Owner:CHINA RAILWAY FIRST GRP CO LTD

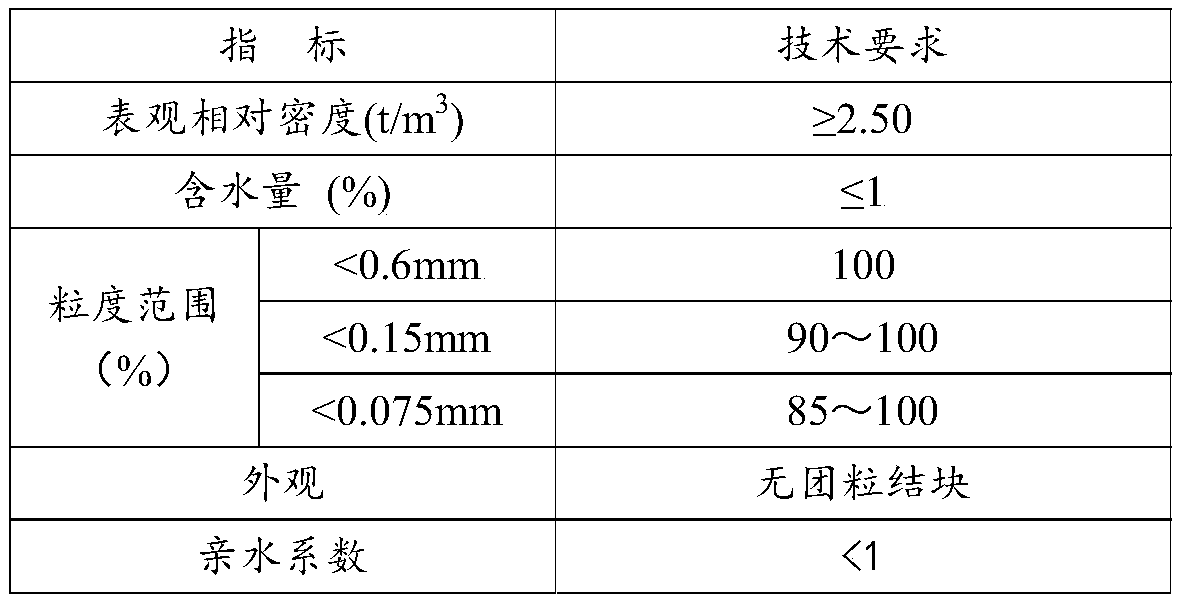

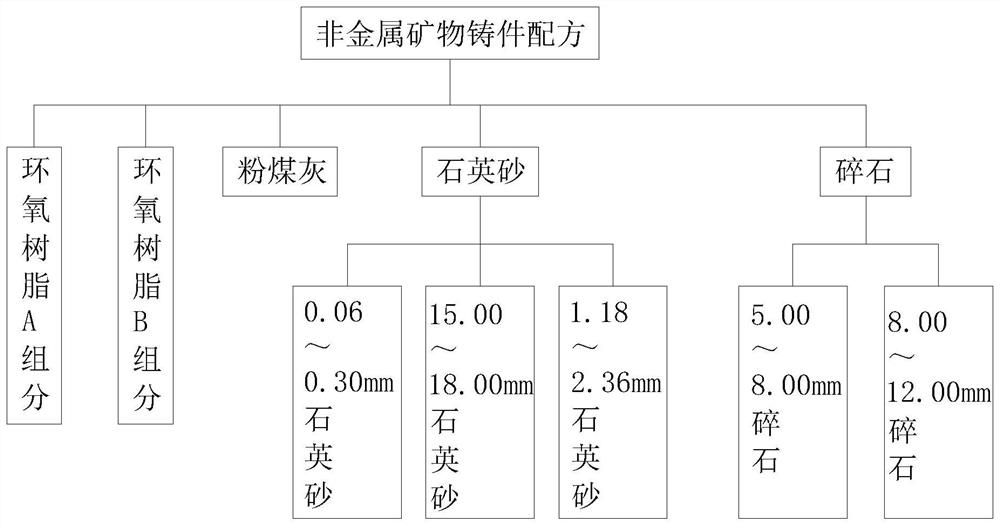

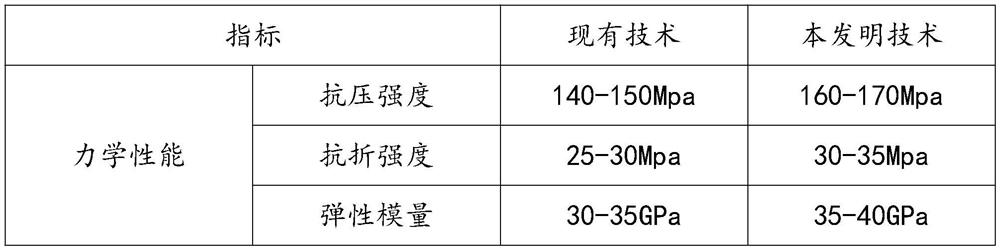

Preparation formula of non-metallic mineral casting

The invention discloses a preparation formula of a non-metallic mineral casting, and relates to the technical field of application of non-metallic mineral castings. The design is reasonable, the formula for preparing the non-metallic mineral casting comprises 7.0-8.0% of an epoxy resin component A, 1.68-1.92% of an epoxy resin component B, 7.0-8.0% of fly ash, 35.0-45.0% of quartz sand and 37.0-47.0% of gravel, adopted aggregate grading is continuous grading, a mixture is not prone to segregation, workability and fluidity are improved, the mixing amount of the fly ash is increased to 7-8% from 3-3.5%, and the mixing amount of the fly ash is increased to 7-8% from 3-3.5%. The ratio of the epoxy resin component A to the epoxy resin component B is 25: 6, so that the internal structure is denser, the compressive strength, the breaking strength and the elastic modulus are increased, the compressive strength is increased to 170 MPa, the breaking strength is increased to 35 MPa, and the elastic modulus is increased to 40 GPa.

Owner:常州高鼎新材料科技有限公司

An automatic processing and manufacturing equipment for shaving wood boards

ActiveCN107283554BQuality will not affectSmall savings in qualityPlywood pressesVeneer pressesAutomatic test equipmentEngineering

The invention relates to automatic processing and manufacturing equipment for shaving boards. The automatic processing and manufacturing equipment comprises a working box, wherein two supporting mechanisms are symmetrically mounted at the front end and the rear end of the bottom of the working box separately; a working plate is mounted at the upper ends of the two supporting mechanisms; two moving and lifting mechanisms are symmetrically mounted on the left side and the right side of the working box separately; a transverse plate is mounted at the upper ends of the two moving and lifting mechanisms; an auxiliary material rolling mechanism is mounted at the middle of the transverse plate; two vibration extrusion mechanisms are symmetrically mounted on the two sides of the transverse plate separately; and the supporting mechanisms, the moving and lifting mechanisms, the auxiliary material rolling mechanism and the vibration extrusion mechanisms well coordinate with each other to complete the automatic processing and manufacturing process of shaving boards. According to the automatic processing and manufacturing equipment for shaving boards, the problems that during the conventional processing process of shaving boards, the occupied space of the equipment is large, stirred materials are easy to cake after being fed into a die to affect the quality of shaving boards, the die needs to be manually adjusted when shaving boards with different thicknesses are processed, the labor intensity of working personnel is improved and the working efficiency is reduced are solved, and the function of automatically processing and manufacturing shaving boards is realized.

Owner:临沂兴滕人造板机械有限公司

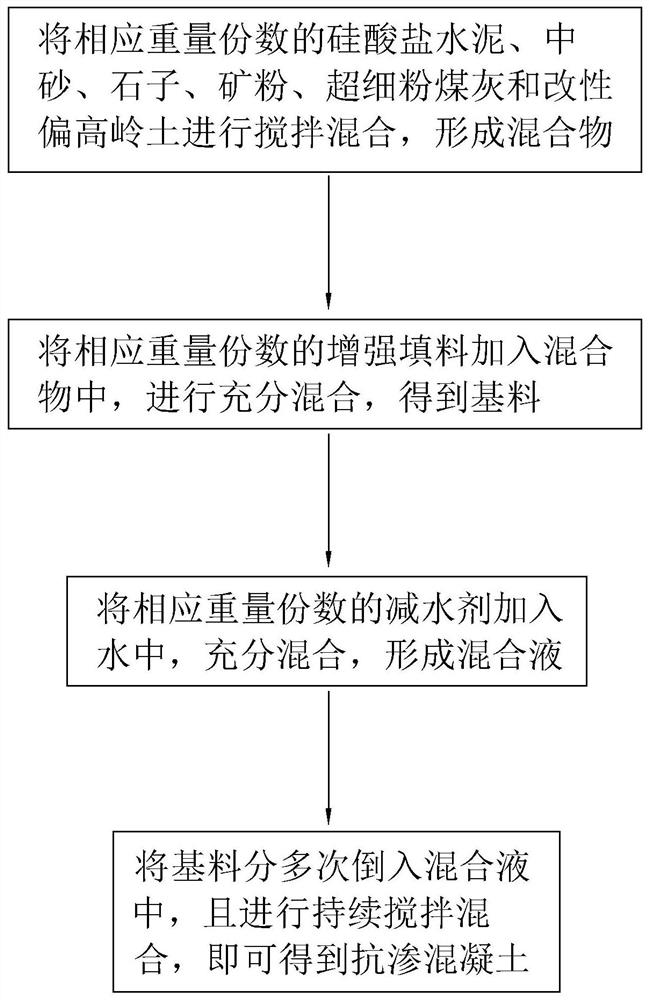

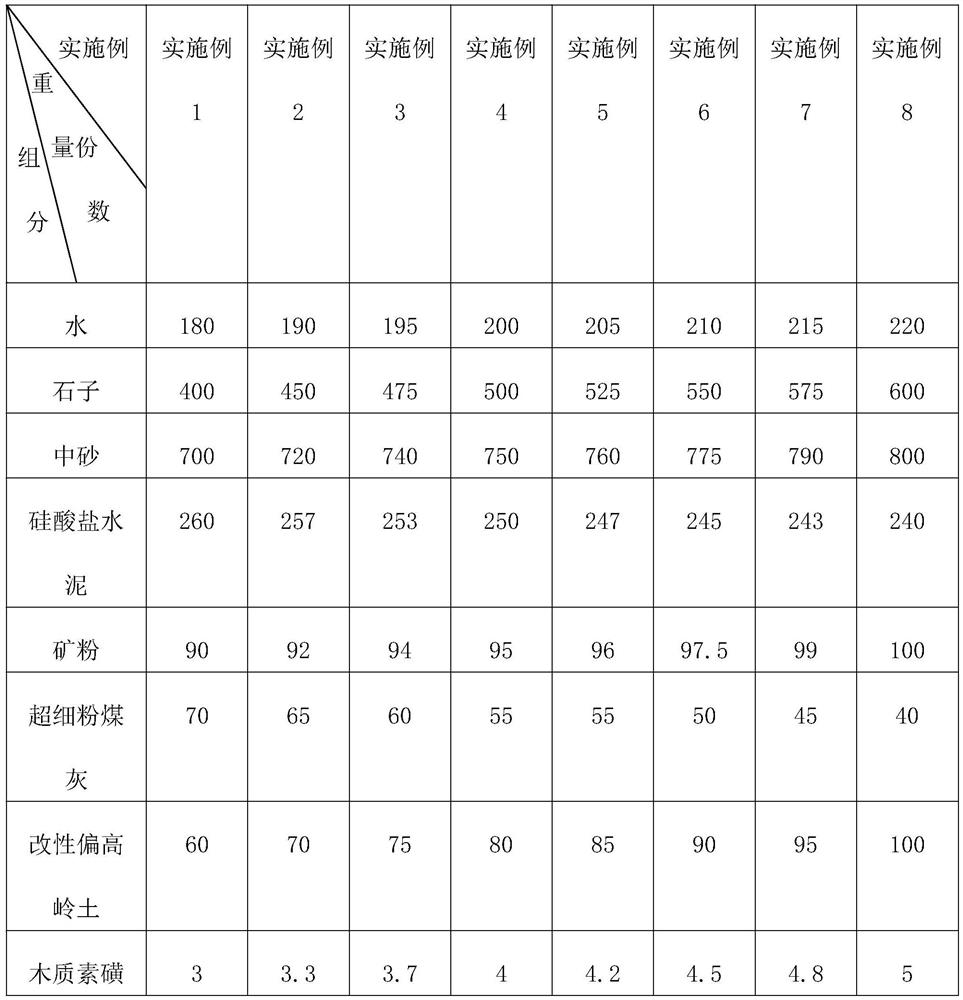

A kind of anti-seepage concrete and its preparation process

The invention discloses an anti-seepage concrete and a preparation process thereof, relates to the technical field of concrete, and solves the problem that a large number of voids and connected capillaries are easily formed inside the concrete, resulting in poor overall anti-seepage performance. An anti-seepage concrete, which includes the following components in parts by weight: 180-220 parts of water; 400-600 parts of stones; 700-800 parts of medium sand; 240-260 parts of Portland cement; 90-100 parts of mineral powder ; 40-70 parts of superfine fly ash; 60-100 parts of modified metakaolin; 3-5 parts of water reducing agent; 15-25 parts of reinforcing filler. The anti-seepage concrete in the present invention has a dense internal structure, fewer internal voids and connected capillaries, and has good anti-seepage performance as a whole.

Owner:上海浦盈混凝土有限公司

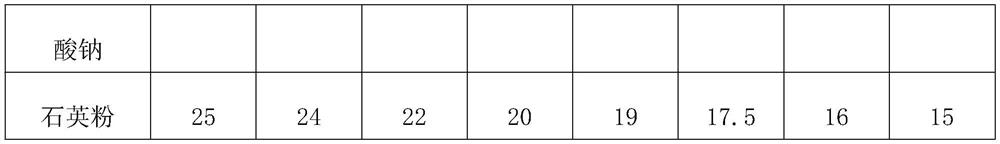

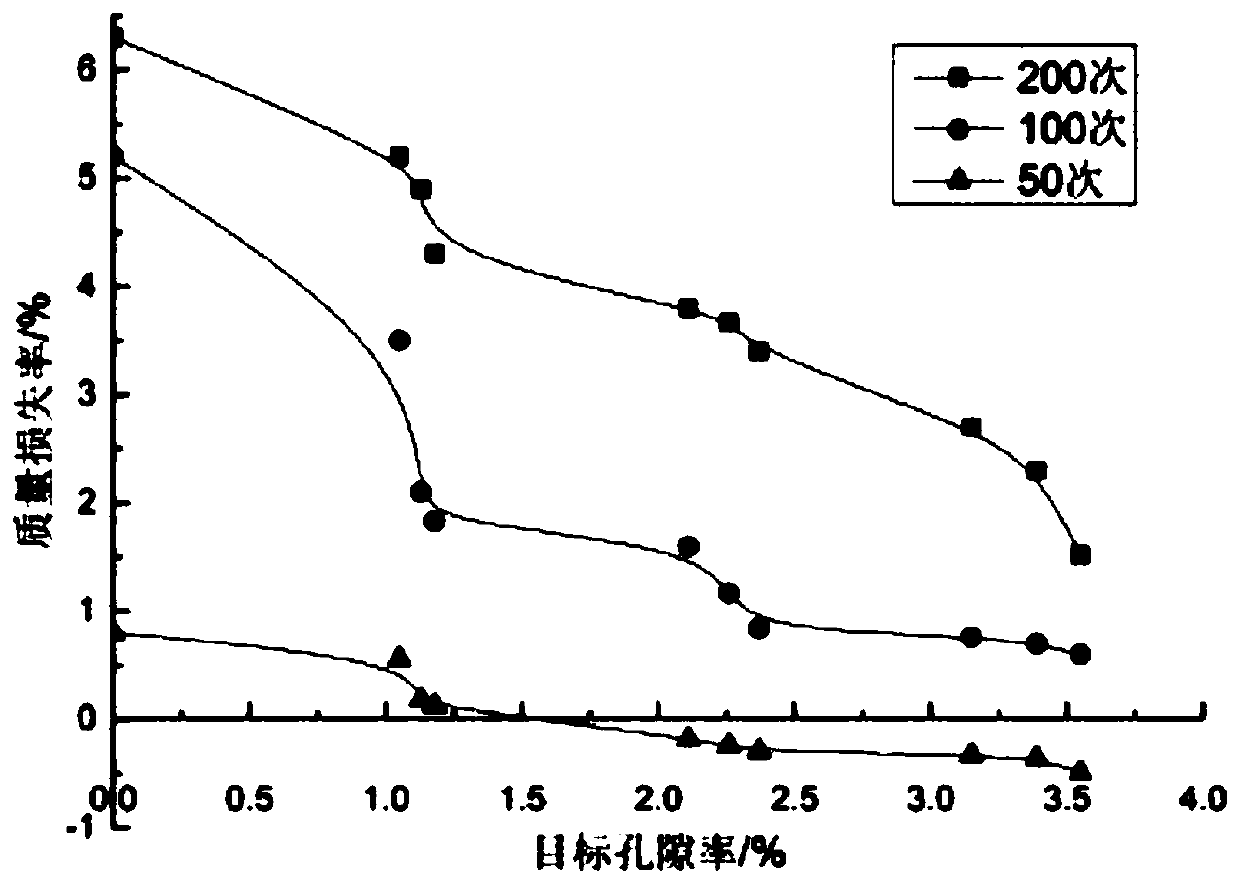

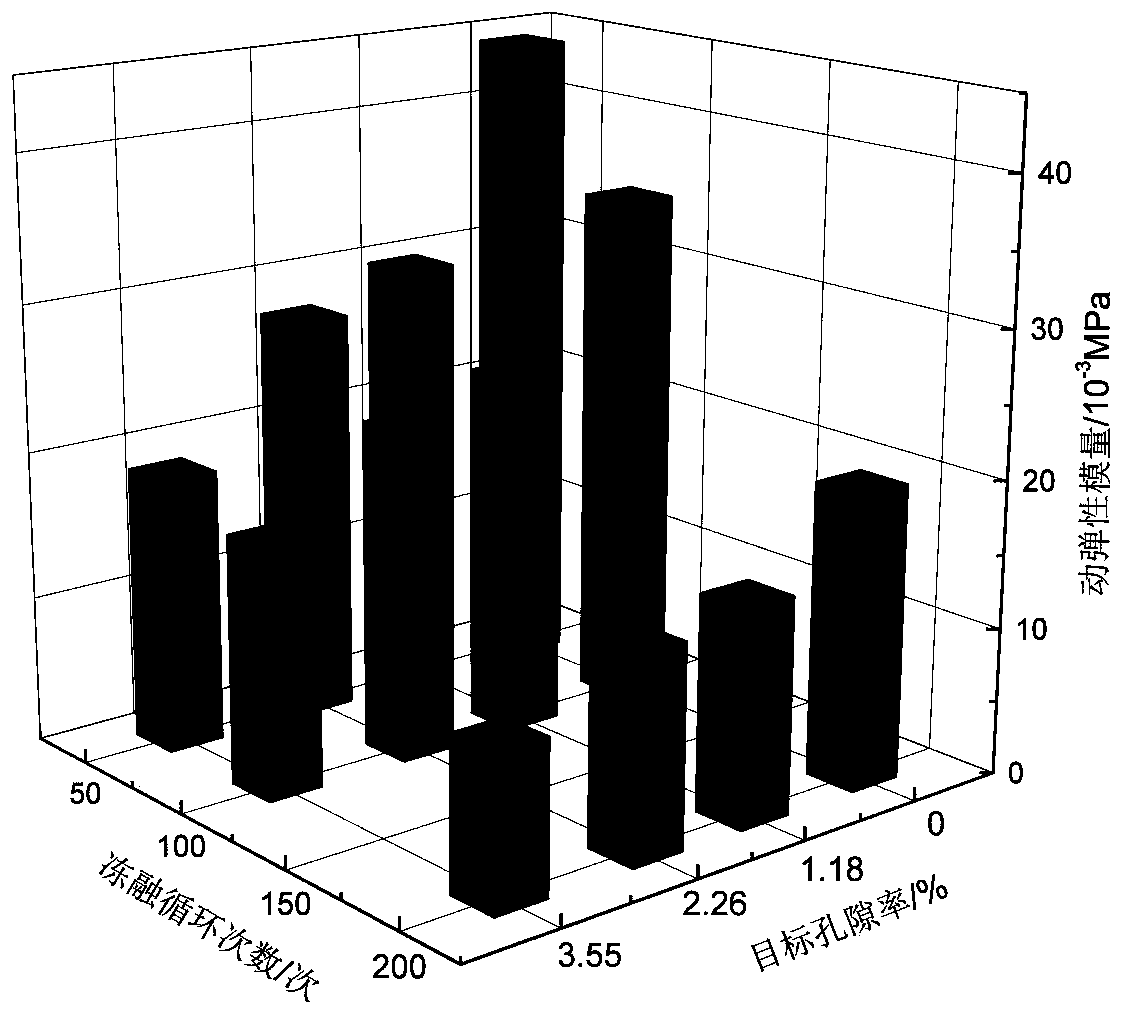

Method for accurately controlling porosity of concrete and application thereof

PendingCN111454077APrecise volume controlPorosity facilitates quantitative controlCeramicwareFreeze thawingPorosity

The invention belongs to the technical field of building materials. The invention relates to the technical field of concrete preparation, in particular to a method for accurately controlling concreteporosity and an application of the method in pumice concrete preparation in cold regions. The method specifically comprises the steps that rubber particles approximately serve as pores in concrete, anatural pumice concrete strength empirical formula based on target porosity is established, the target porosity can be equivalent to the total porosity in concrete, the volume of the rubber particlesrequired to be doped is calculated according to the required target porosity, the mass loss rate and the dynamic elastic modulus of the concrete are analyzed to obtain that the rubber particles slow down the freeze-thaw damage of the natural pumice concrete. CT image scanning analysis of the concrete shows that the pumice concrete prepared by the method is more compact in an internal structure, and the durability of the concrete is also improved on the premise of ensuring the strength. The method is suitable for northeast, northwest and other severe cold areas.

Owner:CHANGCHUN ARCHITECTURE & CIVILENGEERING CO LLEGE

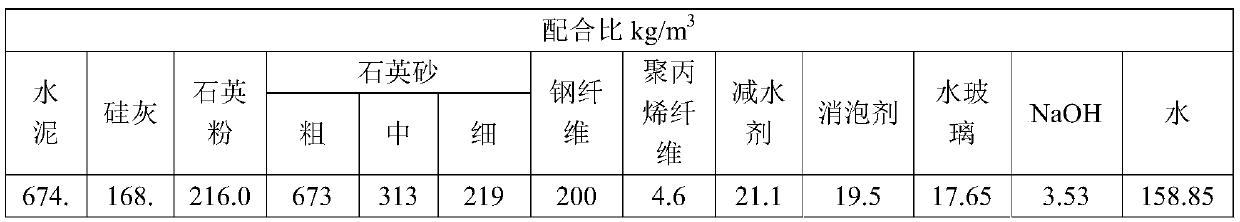

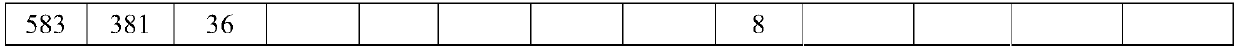

A kind of early-strength ultra-high performance concrete mixed with alkali activator and preparation method thereof

The invention discloses alkali-activating-agent-doped early strength super-high performance concrete and a preparation method thereof. The concrete comprises, by mass, 1019-1059 parts of a cementing material, 1120-1271 parts of quartz sand, 165-205 parts of fibers, 20.38-21.18 parts of a water reducing agent, 12.2-25.6 parts of a de-foaming agent, 20.38-21.18 parts of an alkali activating agent and 152.85-180.03 parts of water. Under the effect of the alkali activating agent, the cementing material contains lots of Si-O and Al-O bond rupture, SiO4 and AlO4 tetrahedrons are made to be fast dissolved out, lots of inorganic high-molecular polymers are fast formed through a polycondensation reaction, the early strength of the concrete is improved fast, and the super early strength effect is achieved. The alkali activating agent is doped in, the initial setting time of the super-high performance concrete is greatly shortened, the super-high performance concrete is made to have very high early strength, the stripping time is shortened, and the circulation efficiency of preparation of the concrete is accelerated.

Owner:西安华清科教产业(集团)有限公司

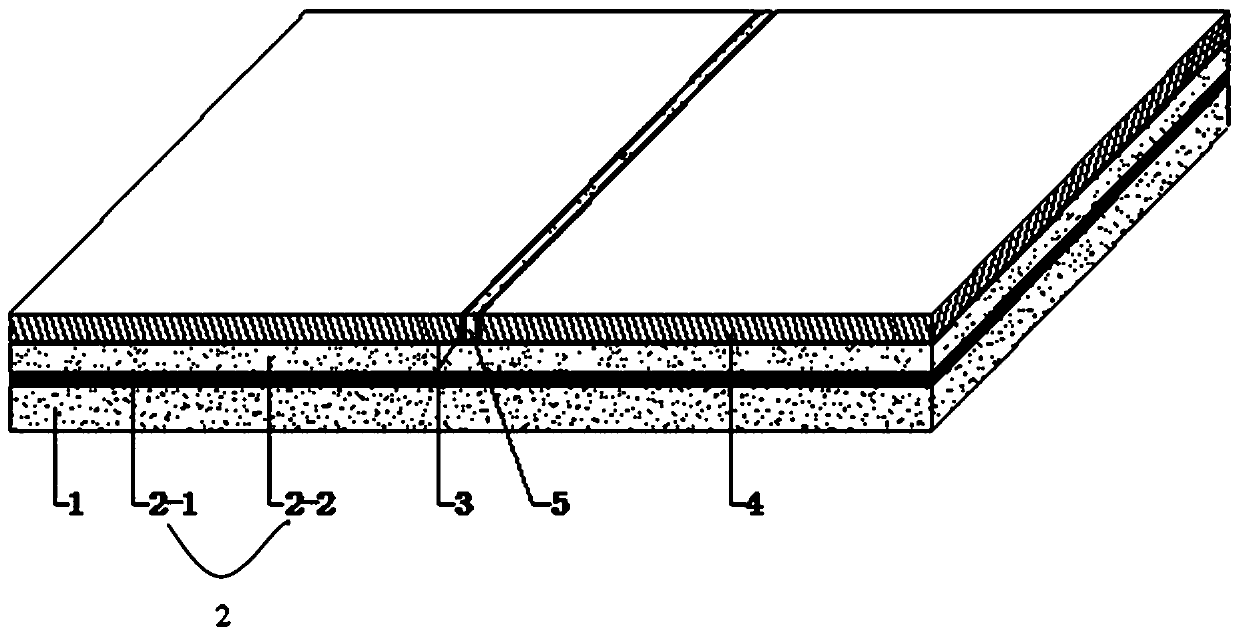

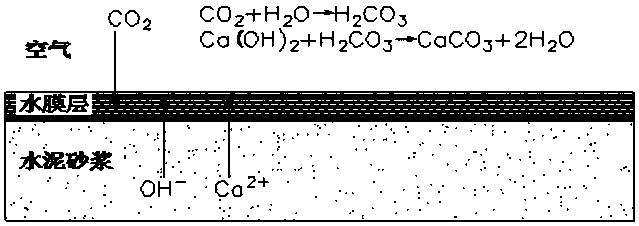

A ground decoration structure using non-alkali sand anti-separation white material

The invention discloses a ground decoration structure using an alkali-free sand white-color-seepage-prevention material. The structure sequentially comprises a bottom surface base layer 1, a white-color-seepage-prevention material layer 2, a protection layer 3, a face layer 4 and a jointing filling material 5 from bottom to top, wherein the white-frost-prevention material layer 2 comprises an alkaline substance consumption layer 2-1 and a white-color-seepage-prevention cement mortar layer 2-2; and the white-color-seepage-prevention cement mortar comprises low-alkali cement, processed good-grading alkali-free sand, fly ash and additives. After the alkali-free sand white-color-seepage-prevention material provided by the invention is used, a caulking material and the white-color-seepage-prevention material layer at the middle layer per se cannot separate out alkaline substances; the white-color-seepage-prevention material layer can prevent moisture from bringing out the alkaline substances through seeping into the bottom surface base layer; the alkaline substances produced during the hydration reaction of the bottom surface base layer can also be effectively reduced; the protection layer forms a sealed layer on the inner surface of the face layer, so that the alkaline substances are prevented from flowing out from pores of the face layer; the occurrence of a white-color-seepage phenomenon is avoided; and a good decoration effect is achieved.

Owner:浙江羽泽科技有限公司

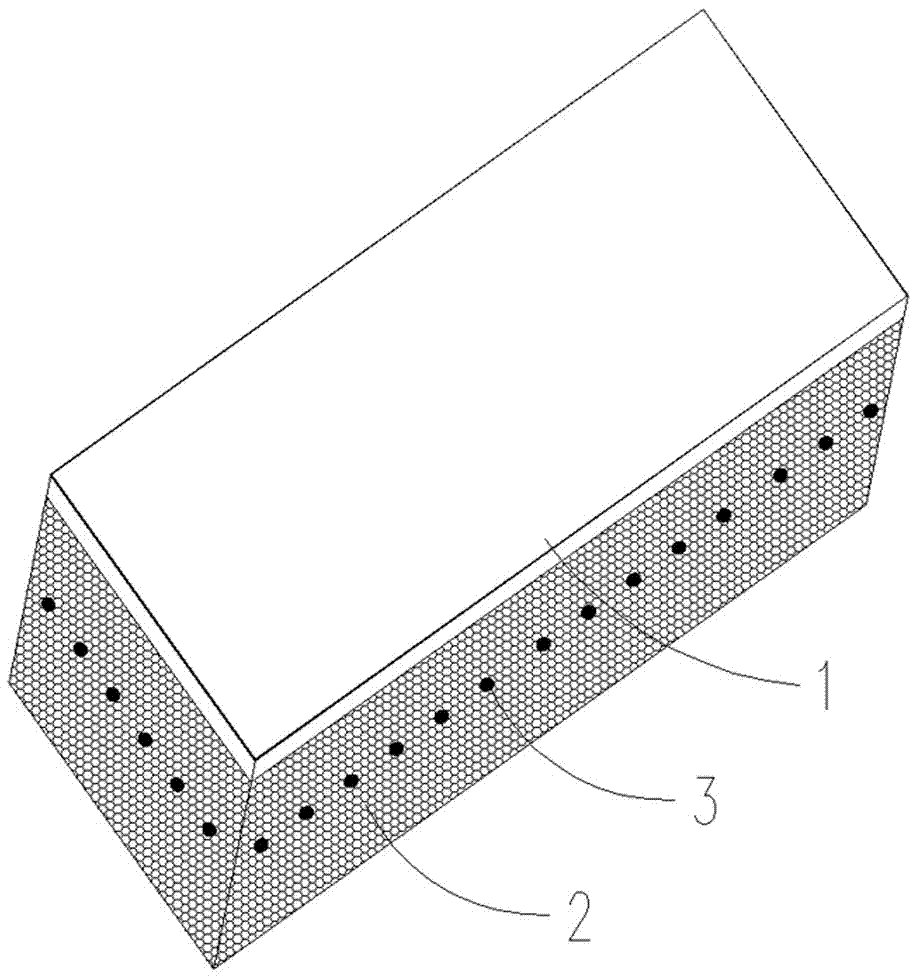

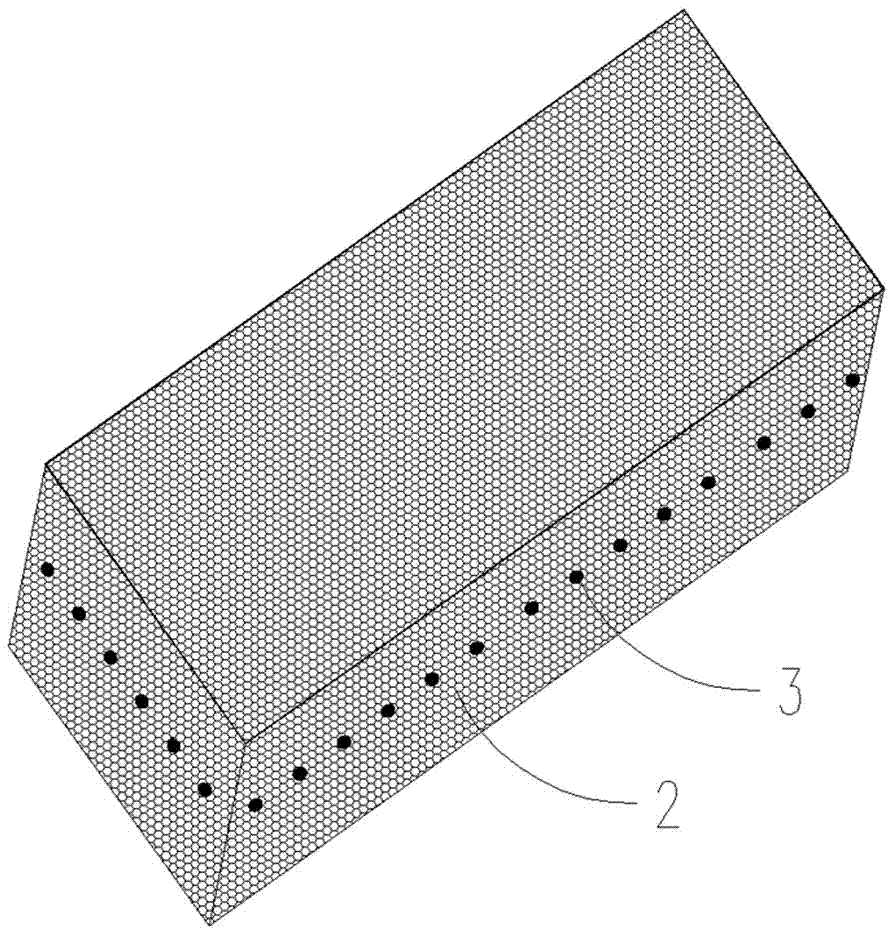

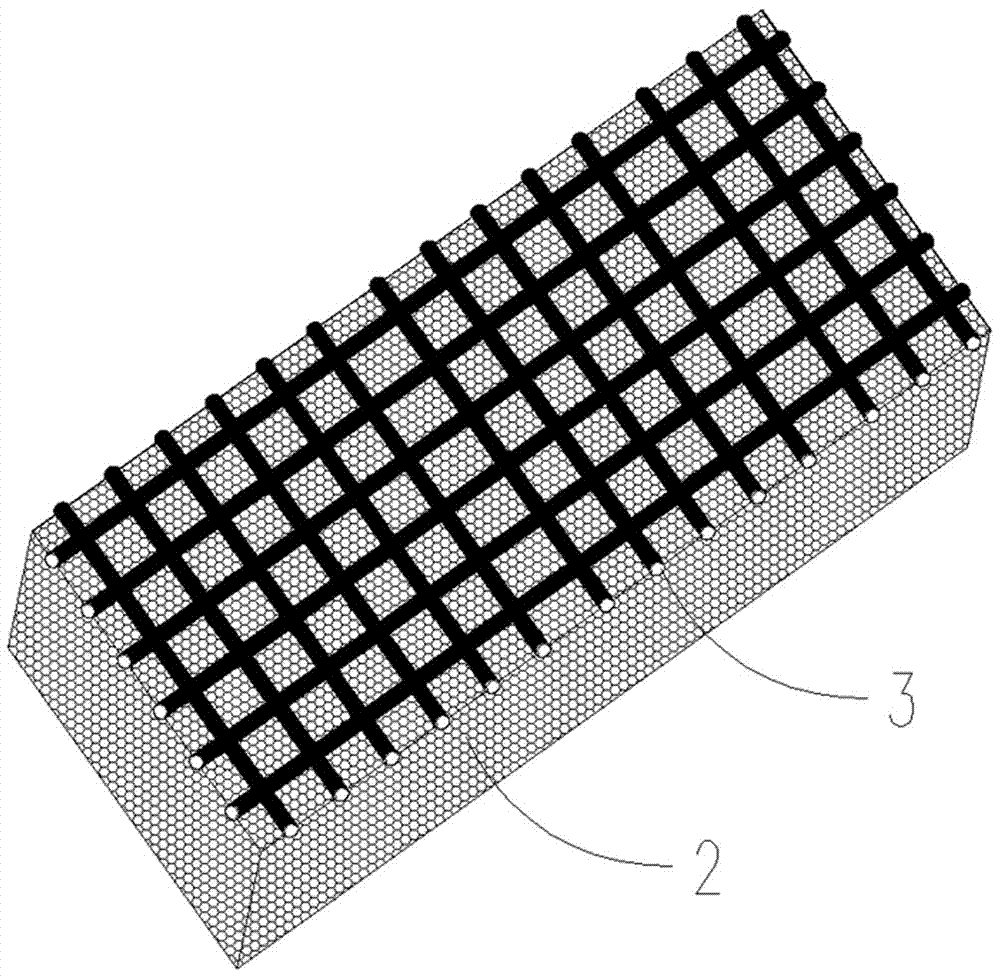

High-strength microcrystalline foamed fireproof and thermal insulation board produced by attapulgite and Guanyin soil and its production process

ActiveCN104847025BDense internal structureHigh strengthFeeding arrangmentsHeat proofingThermal insulationProcess engineering

The invention relates to a high-strength inorganic foaming fireproof heat insulation wall body material produced by attapulgites and white clay and a production process of the high-strength inorganic foaming fireproof heat insulation wall body material. The production process has the technical scheme that the attapulgites, the white clay, red clay and limestone are prepared into tiny fine powder and are proportionally and uniformly mixed; then, the fine powder mixture is uniformly spread in a firing mold; a high-strength fire-proof steel net is fixedly arranged in the mold and is arranged in the middle of the fine powder mixture; and the mixture and the fire-proof steel net are integrally fired, cooled and formed through a high-temperature firing kiln. The high-strength inorganic foaming fireproof heat insulation wall body material and the production process have the beneficial effects that the integral support structure strength of a plate can be regulated and enhanced through the strength of the steel net arranged in the middle of the plate, so that the plate realizes a greater application space in the engineering; meanwhile, the safety of the building plate in the use process is enhanced; and the service life of the building plate in the use process is prolonged.

Owner:NINGXIA BLACK GOLD TECH CO LTD

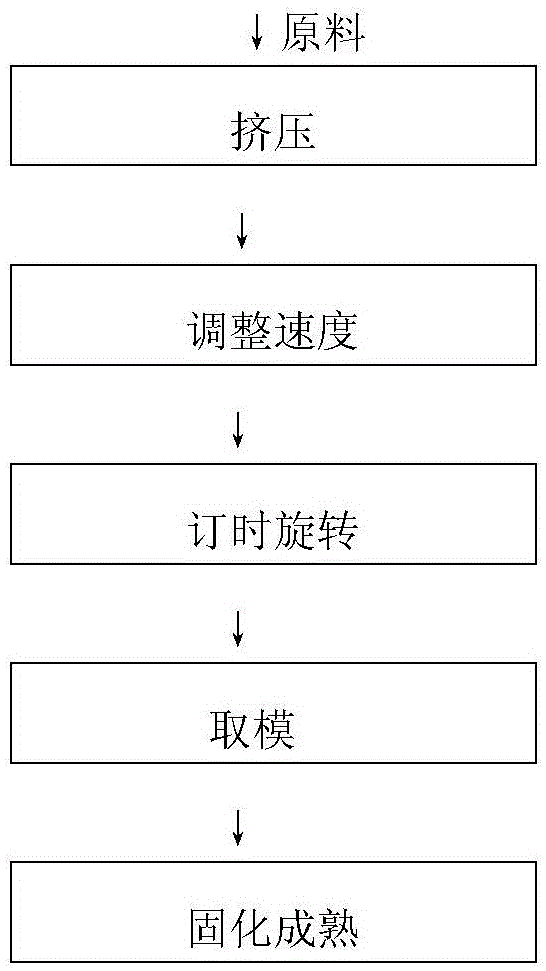

Technology for forming high-viscous material in mould

The invention discloses a technology for forming high-viscous materials in a mould, which mainly relates to the forming manufacture technology for food, resin, chemicals, ceramics, printing ink, argil and other high-viscous materials, and belongs to the technical field of forming of the high-viscous materials. The technology comprises the following steps: (1) a high-viscous material is extruded and pressed into the mould; (2) the mould containing the raw material is arranged in a centrifuge which is adjusted to rotate at 200 to 3000 rpm, and proper speed is adjusted; (3) the centrifuge is subjected to timing rotation until the raw material is uniformly distributed in the mould; (4) the mould is taken out of the centrifuge, and curing is performed according to properties of the raw material. The technology process disclosed by the invention is simple in operation and good in forming effect; shapes can be changed according to various kinds of moulds, and formed products are compact in inner structure and smooth in surface, so that the requirement of life quality is met; and furthermore, the manufacture cost is low, so that the technology is easy to promote.

Owner:李国峰

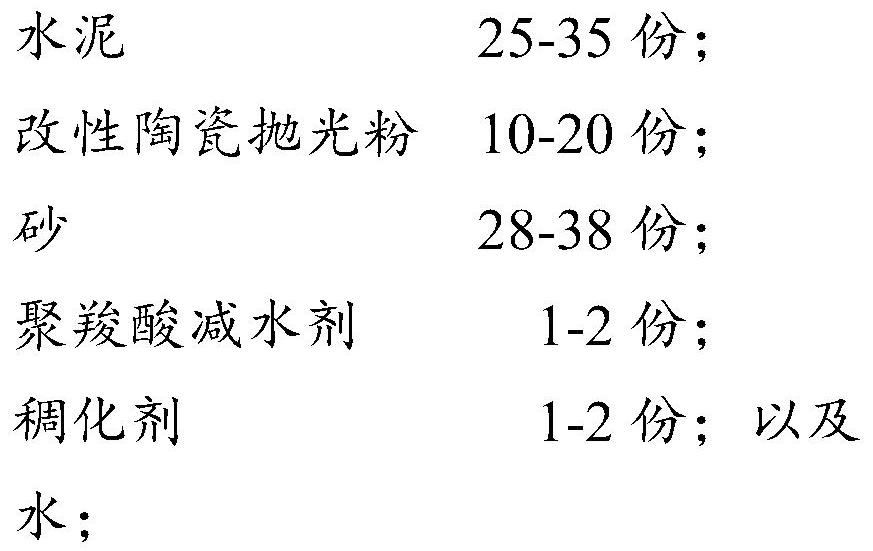

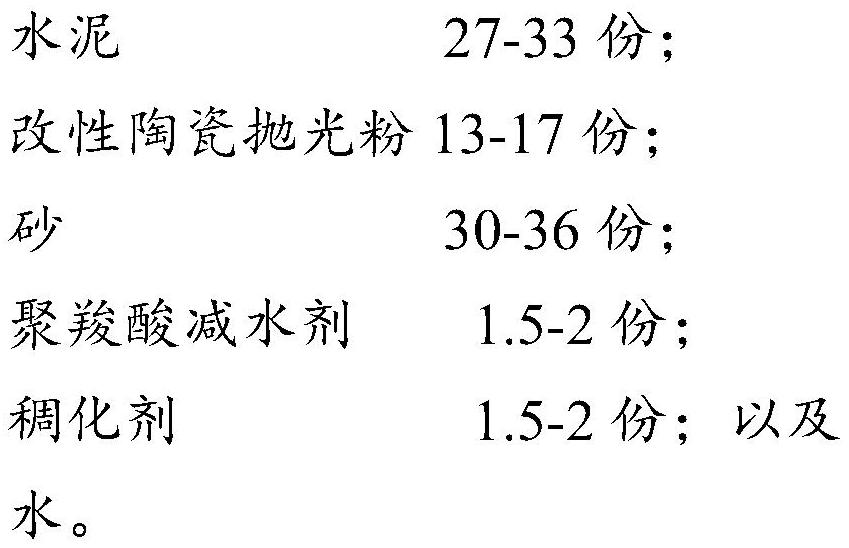

Masonry mortar and preparation method thereof

PendingCN114230271AImprove water retentionDense internal structureSolid waste managementPowderSuperplasticizer

The invention relates to masonry mortar and a preparation method thereof, and the masonry mortar is prepared from the following raw materials in parts by weight: 25-35 parts of cement; 10-20 parts of modified ceramic polishing powder; 28 to 38 parts of sand; 1-2 parts of a polycarboxylate superplasticizer; 1-2 parts of a thickening agent; water; modifying the activity gt of the ceramic polishing powder; 65%. According to the masonry mortar and the preparation method thereof provided by the invention, the modified ceramic polishing powder is used for replacing fly ash and mineral powder in the masonry mortar, so that the stability of the performance of the masonry mortar is improved.

Owner:GUANGDONG KEZHIJIE NEW MATERIALS +1

A kind of reinforced magnesium phosphate cement composite material and preparation method thereof

The invention provides a reinforced magnesium phosphate cement composite material and a preparation method thereof. The composite material includes a graphene oxide / carbon nanotube composite modifier and magnesium phosphate cement dry material, and the graphene oxide / carbon nanotube composite modifier is formed by oxidation Graphene and carbon nanotubes are compounded, and the ratio of the total dry weight of graphene oxide and carbon nanotubes to the dry weight of magnesium phosphate cement is 0.01-0.5:100. The method includes: preparing a graphene oxide / carbon nanotube composite modifier; mixing the prepared graphene oxide / carbon nanotube composite modifier with magnesium phosphate cement dry material, stirring evenly to obtain cement slurry; pouring the cement slurry to the mold Type, the air bubbles are removed by shaking, the surface of the mold is covered with a film, and the mold is demoulded after curing, and finally cured to the age of use. The magnesium phosphate cement prepared by the invention has high strength and good mechanical properties, and the internal structure is orderly and dense, the pore structure is optimized, and the durability is good.

Owner:SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com