High-thermal-conductivity low-viscosity two-component organic silicon pouring sealant and preparation method thereof

A low-viscosity silicone potting compound technology, applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor application of thermally conductive fillers and achieve excellent anti-settling properties , Disperse evenly and reduce viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

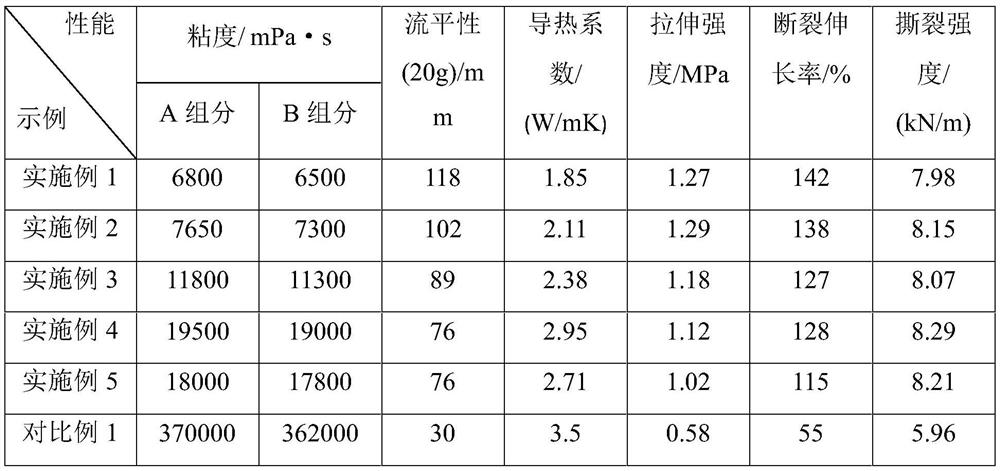

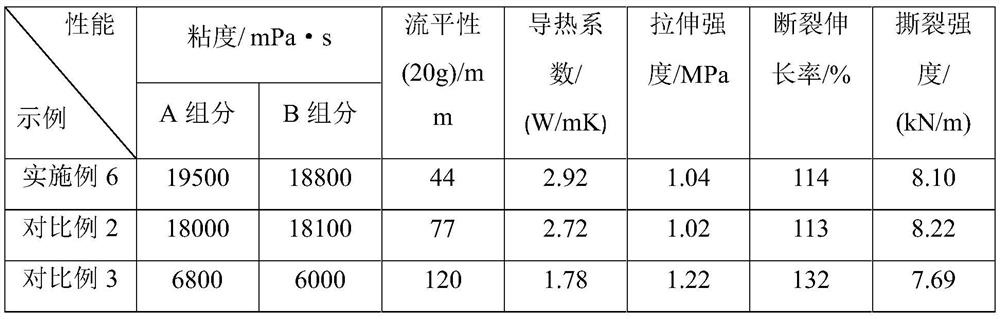

Examples

Embodiment 1

[0059] Preparation of component A: In parts by weight, add 25 parts of vinyl silicone oil and 0.3 parts of silane coupling agent into the reactor, mix and stir at 600 rpm for 10 minutes, then add 0.2 parts of anti-settling agent and 80 parts of Spherical alumina, stirred at a rotating speed of 1000rpm for 15 minutes, then added 80 parts of spherical alumina, stirred at a rotating speed of 1000rpm for 2 hours to obtain base glue A, cooled to room temperature, transferred base glue A to a homogenizer and Add 2 parts of polydimethylsiloxane and 0.2 parts of platinum catalyst, stir at 1200rpm for 20 minutes, then vacuumize and defoam for 20 minutes at a vacuum of 0.02MP to obtain component A;

[0060] Preparation of component B: Mix 21 parts of vinyl silicone oil and 0.3 parts of silane coupling agent and stir at 600 rpm for 10 minutes, then add 0.2 parts of anti-sedimentation agent, 0.1 part of carbon black and 80 parts of spherical alumina. Stir at a speed of 1000rpm for 15 minu...

Embodiment 2

[0063] Preparation of component A: In parts by weight, add 21 parts of vinyl silicone oil and 0.35 parts of silane coupling agent into the reactor, mix and stir at 650 rpm for 8 minutes, then add 0.3 parts of anti-settling agent and 85 parts of Spherical alumina, stirred at a rotating speed of 1050rpm for 12 minutes, then added 85 parts of spherical alumina, stirred at a rotating speed of 1050rpm for 1.5 hours to obtain base glue A, cooled to room temperature, transferred base glue A to a homogenizer and Add 4 parts of polydimethylsiloxane and 0.25 parts of platinum catalyst, stir at 1300rpm for 15 minutes, and then vacuumize and defoam for 15 minutes at a vacuum of 0.04MP to obtain component A;

[0064] Preparation of component B: Mix 18 parts of vinyl silicone oil and 0.35 parts of silane coupling agent and stir at 650rpm for 8 minutes, then add 0.3 parts of anti-sedimentation agent, 0.2 parts of carbon black and 85 parts of spherical alumina. Stir at 1050rpm for 12 minutes,...

Embodiment 3

[0067] Preparation of component A: In parts by weight, add 20 parts of vinyl silicone oil and 0.4 parts of silane coupling agent into the reactor, mix and stir at 700 rpm for 5 minutes, then add 0.35 parts of anti-settling agent and 87.5 parts of Spherical alumina, stirred at a rotating speed of 1100rpm for 10 minutes, then added 87.5 parts of spherical alumina, stirred at a rotating speed of 1100rpm for 1 hour to obtain base glue A, cooled to room temperature, transferred base glue A to a homogenizer and Add 3 parts of polydimethylsiloxane and 0.3 parts of platinum catalyst, stir at 1500rpm for 15 minutes, then vacuumize and defoam for 10 minutes at a vacuum of 0.06MP to obtain component A;

[0068] Preparation of component B: Mix 16 parts of vinyl silicone oil and 0.4 parts of silane coupling agent and stir at 700 rpm for 5 minutes, then add 0.35 parts of anti-sedimentation agent, 0.3 parts of carbon black and 87.5 parts of spherical alumina. Stir at a speed of 1100rpm for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com