A kind of anti-seepage concrete and its preparation process

A technology of impermeable concrete and metakaolin, applied in the field of concrete, can solve the problems of poor impermeability and other problems, and achieve the effects of compact internal structure, reduction of capillaries, and improvement of structural density and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

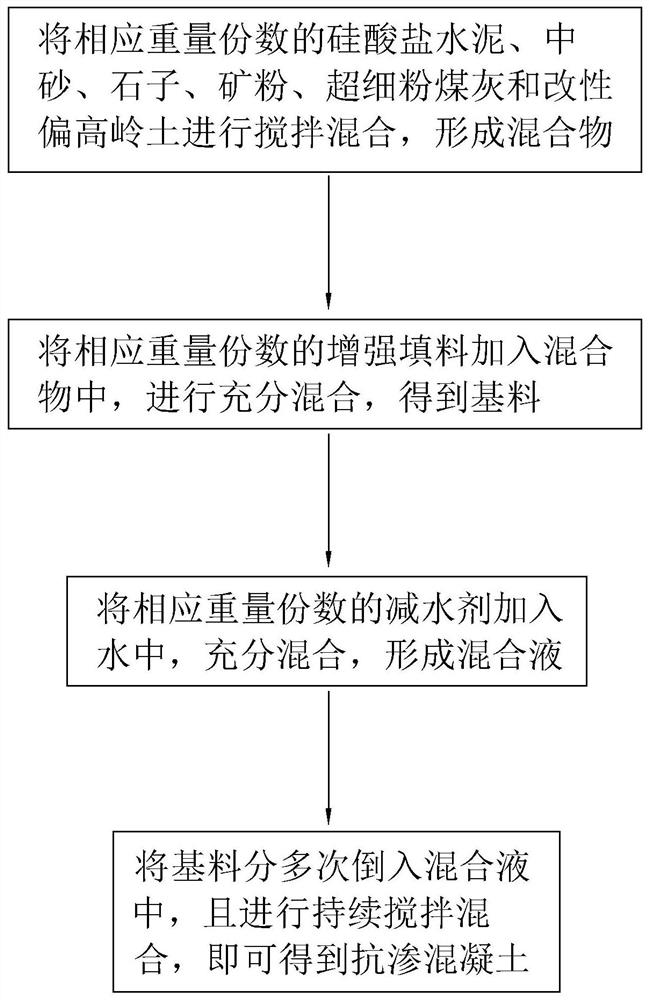

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: A kind of anti-seepage concrete, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0047] Step 1: Stir and mix Portland cement, medium sand, gravel, mineral powder, ultra-fine fly ash and modified metakaolin in a drying barrel with a rotating speed of 500 rpm, a time of 30 minutes, and a temperature of Control at 90°C to form a mixture;

[0048] Step 2, adding the quartz powder of corresponding parts by weight into the mixture, fully mixing, the time is 10min, and the stirring speed is 500rpm to obtain the base material;

[0049] Step 3, adding sodium lignosulfonate in corresponding parts by weight into water, fully mixing, the time is 10 minutes, and the stirring speed is 300 rpm to form a mixed solution;

[0050] Step 4: Pour the mass of the base material into the mixed solution in 3 times, and carry out continuous stirring and mixing at a stirring speed of 800 rpm, and the stirrin...

Embodiment 2-8

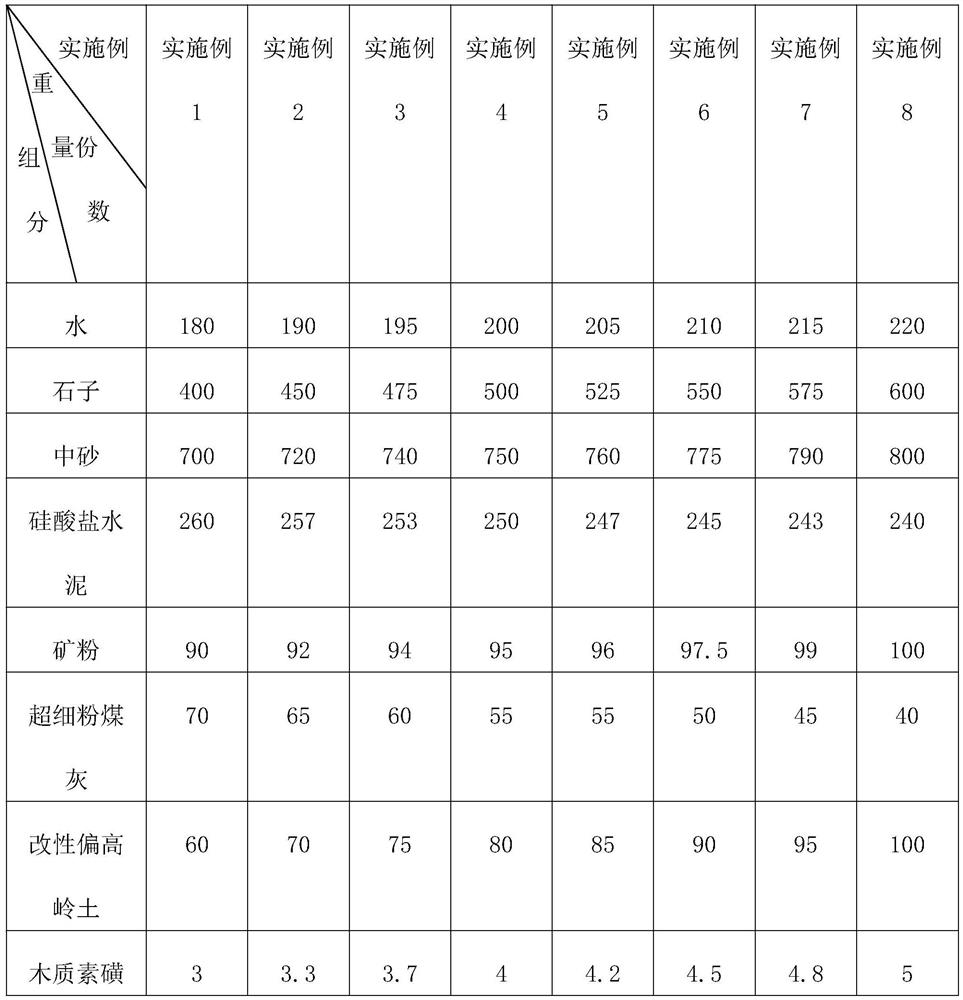

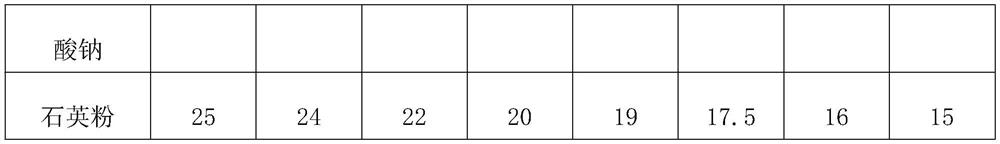

[0054] Embodiment 2-8: An anti-seepage concrete. The difference from Embodiment 1 is that each component and its corresponding parts by weight are shown in Table 1.

[0055] Each component and parts by weight thereof in table 1 embodiment 1-8

[0056]

[0057]

Embodiment 9

[0058] Embodiment 9: A kind of impermeable concrete, the difference with embodiment 1 is, in step one, modified metakaolin is made by following steps:

[0059] S1. Put metakaolin in a container, add 4 times the amount of polyacrylic acid solution, adjust the pH to 3, control the temperature at 25°C, react for 12 hours, and use a stirrer to stir during the reaction to obtain a mixed solution;

[0060] S2. Vacuum filter the mixed solution to obtain the precipitate, then place the precipitate in an oven at 60°C for drying, rinse with ethanol, put it in an oven at 60°C for drying, and grind to obtain Modified metakaolin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com